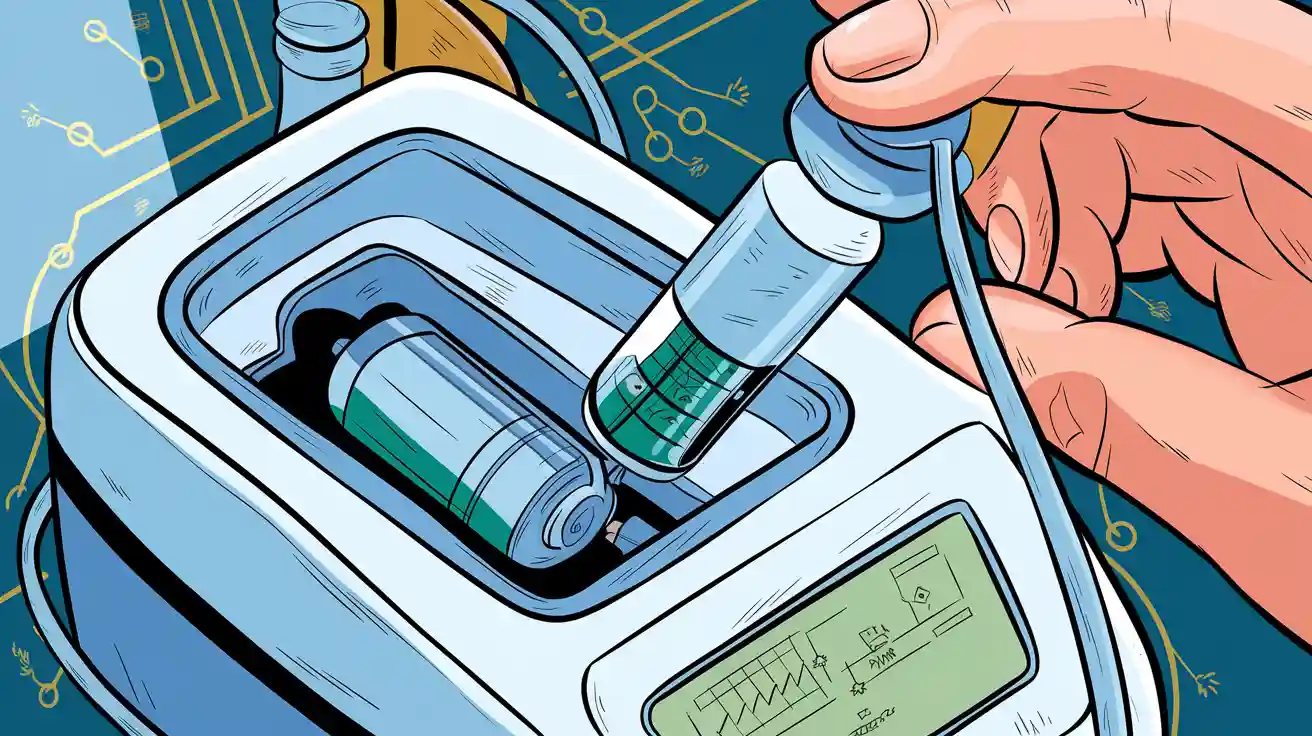

You rely on battery design to achieve consistent precision and reliability in every infusion pump. Hospitals report that up to 50% of service calls involve battery issues, highlighting the critical need for robust solutions. When you choose a medical lithium battery pack, you gain advantages such as:

Enhanced safety, including protection from overcharge, short circuits, and thermal runaway.

Extended runtime, supporting both portable and stationary operations.

Feature | Description |

|---|---|

Enhanced Safety | Protection against over-charge, over-discharge, over-current, short circuits, and thermal runaway. |

Optimized Performance | Precise voltage and current control, cell balancing for maximum capacity and cycle life. |

Data Monitoring & Communication | Real-time monitoring and system integration capabilities. |

Redundant Detection | Real-time monitoring and independent cross-verification. |

Redundant Execution | Physical disconnection mechanisms for added reliability. |

You improve patient safety and device performance when you prioritize these advanced battery features.

Key Takeaways

Prioritize advanced battery features like safety protections and real-time monitoring to enhance patient safety and device performance.

Select lithium batteries with high energy density and long cycle life to ensure reliable operation and minimize therapy interruptions.

Incorporate redundancy in battery design to prevent power failures and maintain continuous operation in critical medical environments.

Part 1: Infusion Pump Battery Design

1.1 Precision Power Delivery

You demand precise power delivery in every infusion pump to ensure accurate medication dosing. Battery design must support stable voltage and current output, which directly impacts the performance of the modular infusion platform. You rely on advanced hardware and software integration to maintain this stability.

Key requirements for precision power delivery include:

Switch-mode voltage regulators maximize battery life and reduce size and weight.

Low-dropout linear regulators (LDOs) serve low-power circuits where efficiency is less critical.

Power supplies require voltage identification digital (VID) control, fast load-step response, and precision low-voltage/high-current outputs.

Digital-to-analog converters (DACs) and digital potentiometers provide programmability for power supplies.

Compliance with UL® and IEC safety standards protects patient care and device operation.

Rechargeable battery packs are mandatory for safe operation during patient transport.

Accurate battery fuel gauges prevent unexpected power loss and ensure uninterrupted treatment.

You must select components that deliver consistent power to all critical hardware. If you overlook these details, you risk data loss and inaccurate dosing. You also benefit from real-time data monitoring and feedback, which improve usability and allow for proactive maintenance.

Tip: Always verify that your infusion pump includes an accurate battery fuel gauge and programmable power supply components. This step reduces the risk of therapy interruption and enhances reliability.

1.2 Reliability and Redundancy

You cannot compromise on reliability in infusion pump battery systems. Redundant design features prevent power interruptions and support continuous operation, even in demanding hospital or home care environments.

Common redundancy features include:

Backup power systems that maintain operation during primary power failures.

Additional batteries kept fully charged and ready for immediate use.

Robust battery design supports continuous operation by:

Providing long battery life for ambulatory infusion pumps, ensuring uninterrupted treatment.

Preventing complications from depleted batteries, which would otherwise require patient or staff intervention.

Enhancing reliability in both hospital and home care settings by selecting pumps with extended battery life.

You must address the most common causes of battery failure to protect patient safety and device performance.

Description | |

|---|---|

Power Failure | Can cause the device to stop functioning unexpectedly, leading to loss of therapy and data. |

Excessive Battery Discharge | Damages batteries and interrupts therapy, potentially causing serious patient harm. |

Component Failures | Directly linked to infusion pump failures, leading to critical interruptions in therapy. |

You improve usability and reduce risk by choosing battery design strategies that include redundant hardware and software safeguards. You also ensure that your modular infusion platform delivers consistent performance, even in challenging conditions.

Part 2: Key Features and Safety

2.1 Lithium Battery Types

You must evaluate the main lithium battery types for your infusion pump to optimize clinical application and reliability. Each technology offers distinct advantages for hardware integration and modular infusion platform design. The table below compares lithium-ion, lithium-polymer, and solid-state batteries, focusing on safety features, performance, and usability:

Battery Type | Key Advantages | Description |

|---|---|---|

Lithium-ion | High energy density, long cycle life | Delivers over 500 charge cycles, supports compact components, and ensures efficient treatment. |

Lithium-polymer | Flexible design, improved safety | Allows easy stacking, reduces leakage risk, and enhances electrode adhesion for better performance. |

Solid-state | Superior safety, higher energy density | Eliminates flammable electrolytes, enables longer runtime, and supports rapid charging. |

You gain improved safety and enhanced electrode-electrolyte adhesion with lithium-polymer and solid-state batteries. Solid-state technology offers better cycle life and faster charging, which supports continuous patient care and clinical workflows.

2.2 Capacity and Runtime

You need batteries with high energy density and long cycle life to maximize operational time in both portable and emergency settings. Lithium batteries provide higher energy density than older technologies, allowing you to use smaller, lighter hardware without sacrificing performance. Most lithium-ion batteries last 2 to 3 years or 300 to 500 charge cycles, which supports extended treatment and reduces maintenance intervals. Rechargeable battery packs offer cost-effectiveness and lower environmental impact compared to disposable options. Devices with efficient components and optimized software deliver reliable data and feedback, improving usability for clinical staff.

Note: Select batteries with cycle life exceeding 500 charge cycles and energy density above 150 Wh/kg for best results in modular infusion platforms.

2.3 Safety Protections

You must prioritize integrated safety mechanisms to protect your infusion pump and ensure reliable patient care. Medical-grade lithium battery packs include smart battery management systems (BMS), overcharge and overdischarge protection, short-circuit safeguards, and temperature monitoring. These components prevent overheating, leakage, and electrical faults. Safety devices such as thermal fuses and protection vents further reduce risk. Regulatory standards like ANSI/AAMI ES 60601-1 and IEC 60601-2-24 set strict requirements for hardware and software safety features. Real-time data monitoring and communication interfaces support proactive feedback and maintenance, enhancing overall reliability.

Part 3: Impact on Performance

3.1 Infusion Accuracy

You depend on battery design to maintain consistent infusion accuracy in every clinical application. When battery performance fluctuates, you risk unstable medication delivery. Syringe pumps often experience delivery instability due to external g-force stresses, which can compromise treatment. You must select components that deliver stable voltage and current to critical hardware. As battery life decreases, the accuracy ratio of your infusion pump drops, affecting patient care and clinical outcomes.

Battery Life Percentile | Accuracy Ratio | Difference |

|---|---|---|

10th Centile (14 months) | 0.983 | -0.026 |

90th Centile (69 months) | 1.009 |

You see that pumps with longer battery life maintain higher accuracy ratios. Real-time data monitoring and feedback from hardware and software help you detect performance changes early. You improve usability and reliability by integrating advanced components and modular infusion platform technology.

Note: Always monitor battery health and replace packs before accuracy drops below clinical standards.

3.2 Risk Reduction

You minimize risk by choosing robust battery design and reliable components. Integrated safety features and real-time data monitoring protect patient care and device performance. You benefit from hardware redundancy and software safeguards, which reduce the chance of therapy interruption. You support continuous treatment in medical, robotics, and industrial sectors by using lithium battery packs with proven reliability.

You prevent data loss and inaccurate dosing.

You enhance usability for clinical staff.

You ensure uninterrupted operation in critical scenarios.

You achieve better outcomes by prioritizing advanced technology and custom battery solutions. You can consult with battery experts to optimize your modular infusion platform for specific application needs.

You drive precision and reliability in infusion pumps by choosing advanced lithium battery packs. Recent improvements in lithium technology give you:

Reliable rechargeable batteries for long operation times

Quick recharging and extended life capacity

Fewer interruptions in medication delivery

Projected Trend in Battery Technology |

|---|

Improved lithium-ion chemistry for higher energy density |

Wireless charging for greater efficiency |

Eco-friendly, recyclable solutions |

Miniaturization for portable pumps |

Affordable, high-quality options for emerging markets |

You reduce risks from battery-related recalls and pump failures by focusing on proper battery management. Your commitment to battery innovation shapes safer patient care and the future of medical devices.

FAQ

What advantages do lithium battery packs offer for infusion pumps in medical and industrial settings?

Lithium battery packs provide high energy density, long cycle life, and reliable performance. You ensure uninterrupted operation for critical devices in medical, robotics, and industrial applications.

How can you customize a battery solution for your specific device requirements?

You can consult with Large Power for custom battery design. Their team tailors lithium battery packs to your voltage, capacity, and safety needs.

Which lithium battery type best suits portable medical devices?

Battery Type | Key Benefit | Application Scenario |

|---|---|---|

Lithium-ion | High energy density | Portable infusion pumps |

Lithium-polymer | Flexible form factor | Wearable medical devices |

Solid-state | Enhanced safety | Critical care equipment |

Tip: Choose the battery type that matches your device’s size, runtime, and safety requirements.