You want to get the most from every battery in your operation. Recent advancements in battery chemistry, such as silicon–graphene composite anodes and high-nickel cathodes, deliver longer cycle life and greater stability. Modern batteries now offer over 5,000 cycles and more than 10 years of life, especially with a proactive battery endurance plan. Energy density has improved by up to 30% in some designs, while innovations in battery management and thermal systems help maintain performance. Batteries power critical applications across Medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Key Takeaways

Keep battery charge between 20% and 80% daily to greatly extend battery life and reduce harmful wear.

Use a strong battery endurance plan with regular monitoring, maintenance, and clear emergency roles to ensure safety and reliability.

Store batteries in cool, dry places at 40–60% charge and avoid extreme temperatures to prevent fast degradation.

Part 1: Battery Degradation

1.1 Causes of Battery Degradation

You face several challenges when managing lithium-ion batteries in EV, medical, robotics, security, infrastructure, consumer electronics, and industrial applications. Battery degradation results from a combination of chemical, physical, and environmental factors.

Solid Electrolyte Interphase (SEI) growth

Electrolyte dry-out

Lithium plating

Loss of Active Material (LAM)

Particle cracking from mechanical stress

These mechanisms interact, causing capacity fade and increased resistance. For example, particle cracking exposes new surfaces, which accelerates SEI growth. Lithium plating can react with the electrolyte, forming inactive SEI and further reducing battery capacity. High charging rates and deep discharges speed up these processes.

Temperature plays a critical role. As shown below, higher temperatures dramatically increase degradation rates:

Temperature (°C) | Degradation Rate Multiplier (vs. 25°C) |

|---|---|

25 | 1 (baseline) |

45 | 2.01 |

65 | 3.45 |

1.2 Science Behind Battery Aging

Lithium-ion batteries age through both linear and non-linear stages. Early in life, SEI growth dominates, causing steady resistance increases. Later, mechanical stress leads to electrode cracking and cathode collapse, which accelerates degradation.

You can observe these changes as increased internal resistance, swelling, and reduced battery health. Advanced techniques like electrochemical impedance spectroscopy and post-mortem analysis reveal that aging depends on temperature, state of charge, and charging rate. Maintaining moderate conditions helps preserve over 80% capacity after 1,500 cycles, which is vital for EV battery life and electric cars.

1.3 Predicting Battery Endurance

Modern B2B operations rely on predictive models to estimate battery endurance. Large Quantitative Models (LQMs), trained on millions of hours of battery data, now deliver accurate forecasts for shelf-life and end-of-life. These models use AI to detect subtle electrochemical changes, reducing prediction time by up to 95% and improving accuracy by 35 times compared to traditional methods.

Battery health diagnostics combine model-based, data-driven, and hybrid approaches. Advanced models, such as HI-C dual Gaussian process regression, achieve mean absolute percentage errors below 0.02 in controlled tests. However, real-world variability still presents challenges.

Part 2: Extending Battery Longevity

2.1 Battery Endurance Plan Essentials

A robust battery endurance plan forms the backbone of any successful operation using lithium battery packs. You need to focus on three pillars: proper charging, maintenance, and storage. Industry experts recommend that you avoid excessive discharge, monitor battery age, and implement optimal storage conditions to slow battery aging and extend battery lifetime. Assign clear roles for emergency procedures and communication, and ensure your team receives regular training on battery safety and response protocols.

Tip: Collaborate with technology providers and local responders to keep your battery endurance plan current and effective.

Organizations maximize battery longevity by integrating advanced Battery Management Systems (BMS) that control charging, thermal management, and estimate state-of-charge (SOC) and state-of-health (SOH). Active cell balancing redistributes charge among cells, maintaining uniform SOC and voltage. Machine learning models predict remaining useful life, enabling proactive maintenance and optimized charging strategies.

You should also invest in real-time monitoring systems to track voltage, temperature, and capacity. Regular inspections, comprehensive testing, and robust maintenance plans—such as cleaning terminals and controlling temperature—help prevent premature failure and reduce downtime.

Key Components of a Battery Endurance Plan:

Assign roles and communication plans for emergencies.

Establish and review emergency response protocols.

Train first responders and staff annually.

Collaborate with technology providers and responders.

Integrate BMS for real-time monitoring and predictive maintenance.

Schedule regular inspections and maintenance.

Use active cell balancing to maintain uniform charge.

2.2 Optimal Charging and Storage

Charging protocols play a critical role in extending battery longevity. Scientific studies show that model-based optimal charging, especially with smart charging technology, can reduce capacity loss by nearly 50% compared to traditional methods. You should avoid full charge cycles when possible. Partial charging—charging to about 80% instead of 100%—minimizes harmful reactions and doubles battery life.

Tip: Avoid deep discharges. Cycling between 20% and 80% state-of-charge can more than double the cycle life compared to full 0–100% cycles.

Charging Practice | Impact on Battery Longevity | Notes |

|---|---|---|

Full charge/discharge | Shortens battery life | Causes more wear per cycle, increases risk of lithium plating |

Partial charge (20–80%) | Extends battery life | Reduces stress, doubles or triples cycle life |

Fast charging (DCFC) | Accelerates degradation | Up to 22% less capacity over 10 years vs. slow charging |

Smart charging technology | Optimizes longevity | Uses predictive models to minimize aging and damage |

For storage, maintain batteries at 40–60% charge and store them in a cool, dry place. Avoid direct sunlight and humidity above 60%. Facilities often use climate-controlled environments to keep temperatures between 10°C and 25°C (50°F–77°F).

Note: Batteries stored at 15°C (59°F) retain about 95% capacity after one year, while those at 55°C or -20°C lose up to 15%.

Aspect | Short-Term Storage (Days to a Month) | Long-Term Storage (Over a Month) |

|---|---|---|

Charge Level | Maintain 40-60% capacity; minimal intervention | Maintain 40-60% capacity; inspect every 3 months and recharge as needed |

Temperature Control | Store in cool, dry place (50°F–77°F / 10°C–25°C) | Consistent ambient temperature (10°C–30°C / 50°F–86°F) to prevent degradation |

Monitoring Frequency | Minimal monitoring; periodic visual checks | Regular inspections and periodic cycling to maintain cell health |

Storage Container | Simple storage; avoid direct sunlight and extreme conditions | Use non-conductive or fireproof containers for safety |

2.3 Temperature and Usage Patterns

Temperature management is essential for extending battery longevity. High temperatures accelerate chemical reactions, causing faster aging and increasing the risk of thermal runaway. Low temperatures slow chemical reactions, increase internal resistance, and can cause lithium plating, which leads to permanent damage.

Tip: Operate batteries within the recommended temperature range and use thermal management systems to maintain stability.

Temperature Condition | Effects on Cycle Life and Capacity | Mechanisms and Observations |

|---|---|---|

Accelerates capacity degradation | Lithium plating, cathode cracking, dead lithium formation | |

High Temperature | Shortens lifespan | Increased resistance, risk of thermal runaway, faster degradation |

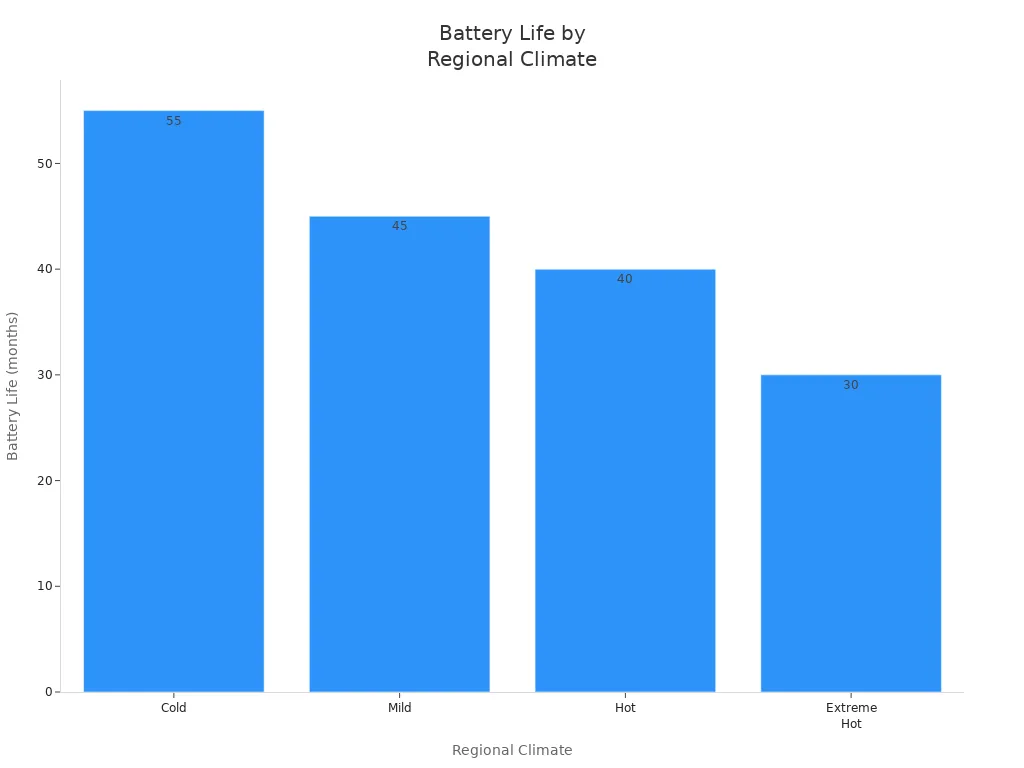

Seasonal temperature variations impact battery performance and longevity. In cold climates, you see reduced efficiency and capacity. Charging below freezing increases the risk of lithium plating. In hot climates, batteries degrade faster, shortening battery lifetime.

Regional Climate | Estimated Battery Life Expectancy |

|---|---|

Cold | Approximately 55 months |

Mild | Approximately 45 months |

Hot | Approximately 40 months |

Extreme Hot | Approximately 30 months |

Usage patterns also affect battery endurance plan outcomes. Frequent fast charging, high charging power, and deep discharges accelerate degradation. For example, daily fast charging can reduce capacity by up to 22% over 10 years compared to slow charging.

Tip: Balance usage and rest periods. Use BMS to monitor and equalize charge across cells, and perform periodic rebalancing every six months.

2.4 Myths vs. Facts

Many common battery myths persist in the industry. You may hear that lithium-ion batteries must be fully discharged before charging, or that overcharging is dangerous. Modern lithium-ion batteries, including NMC, LiFePO4, and LCO chemistries, do not suffer from memory effect. Partial charging is not only safe but preferred. Overcharging is prevented by built-in protections, and optimal storage is at 40–60% charge in a cool, dry place.

Common Battery Myths vs. Facts:

Myth: Lithium batteries are unsafe and prone to explosions.

Fact: Modern batteries, especially LiFePO4, include BMS and are among the safest options.Myth: Lithium batteries don’t work in cold weather.

Fact: High-quality batteries have low-temperature cut-offs and heating elements for reliable operation.Myth: Lithium batteries are too expensive.

Fact: While initial costs are higher, batteries last over a decade and offer lower total cost of ownership.Myth: Lithium batteries are bad for the environment.

Fact: Longer lifespans and recycling technologies make them more sustainable. Learn more about our sustainability approach.Myth: Lithium batteries aren’t compatible with solar power.

Fact: Modern solar systems are designed for lithium battery integration.

Other misconceptions include the belief that deep discharges are necessary or that batteries should be stored fully charged. In reality, deep discharges cause irreversible damage, and optimal storage is at partial charge.

Tip: Always follow manufacturer guidelines and industry standards for battery care. For custom solutions, consult our experts.

You can maximize battery performance and lifespan by following these key actions:

Maintain battery charge between 20% and 80% for daily use.

Use ongoing battery monitoring to detect issues early and reduce costs.

Update battery maintenance practices annually as new research emerges.

Implement a comprehensive battery endurance plan for operational reliability.

KPI Category | Example/Impact |

|---|---|

Cost Savings | ROI improvements up to 200% within 2 years |

Operational Reliability | Downtime reduction saves up to 10% production |

Stay proactive—adopt best battery practices, leverage advanced monitoring, and review your battery strategy regularly.

FAQ

1. How often should you update your battery endurance plan for industrial applications?

You should review and update your battery endurance plan annually. This ensures you align with the latest research and operational requirements for your business.

2. What is the best way to monitor battery health in Medical or robotics systems?

Use a real-time battery management system (BMS) for accurate monitoring. This approach helps you detect issues early and optimize performance in critical applications.

3. Why choose Large Power for custom battery solutions?

Large Power provides tailored battery solutions for B2B clients. You receive expert support and advanced technology. Request a custom consultation here.