You see battery innovations driving the evolution of electronic devices in industrial and commercial settings. These batteries deliver greater efficiency and reliability. Advanced battery technologies boost the performance of battery-powered devices. Lithium-ion batteries continue to evolve, and new batteries offer innovative solutions for battery innovation. Battery-powered devices now set new standards in the field.

Key Takeaways

Battery innovations enhance efficiency and reliability in electronic weighing devices, leading to longer run times and faster charging.

Upgrading to advanced battery technologies can reduce maintenance costs and improve productivity in various industrial applications.

Emerging battery chemistries, like solid-state and lithium-sulfur, promise higher energy density and sustainability for future weighing solutions.

Part 1: Battery Innovations Impact

1.1 Efficiency Gains

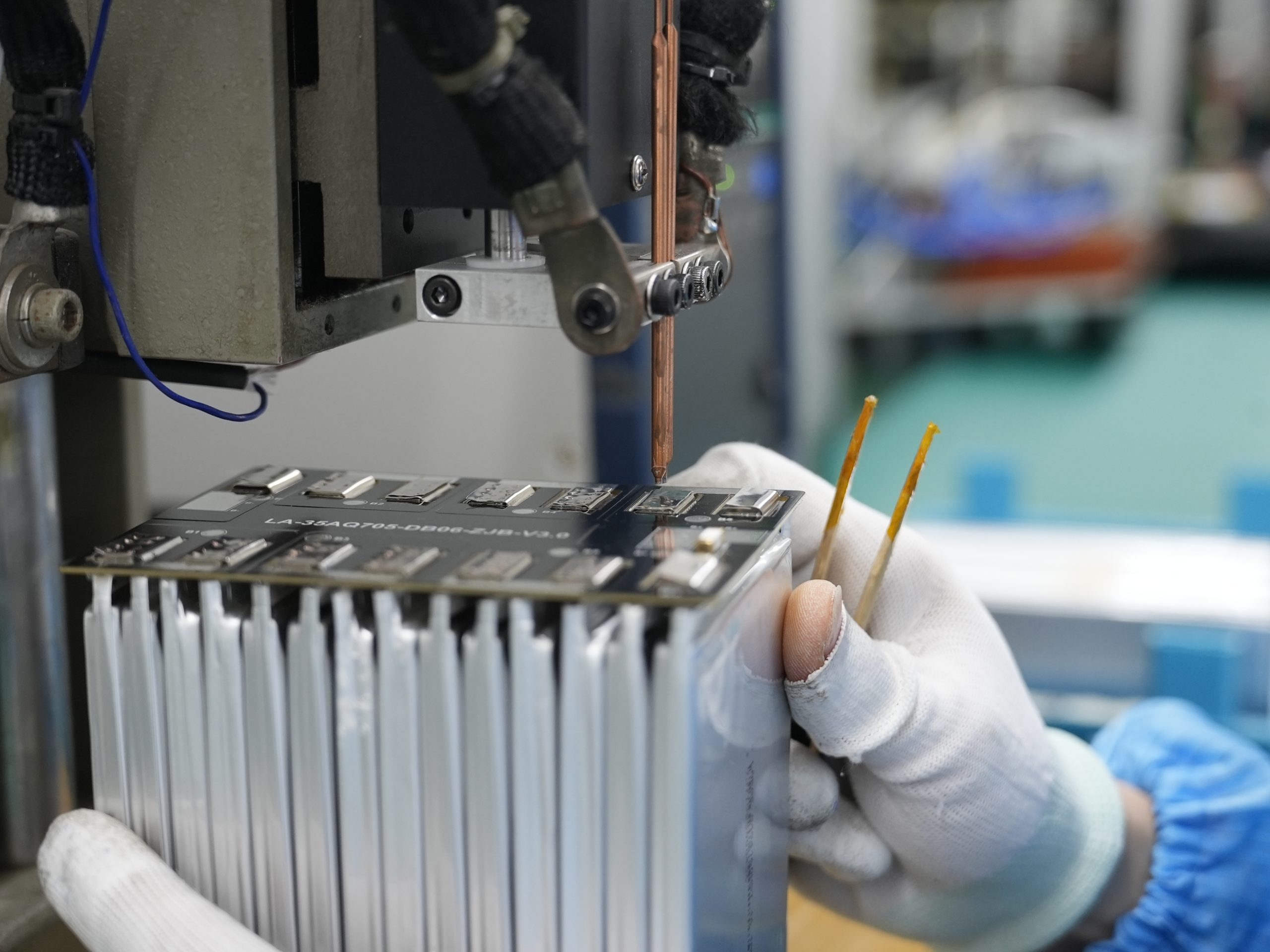

You see battery innovation trends changing how you use electronic weighing devices in your business. Modern battery technology delivers longer run times and faster charging, which means less downtime for your operations. Lithium-ion batteries now offer higher energy storage and improved reliability. These advancements help you keep your weighing equipment running smoothly, even in demanding environments like warehouses or production lines.

Many companies now choose battery-powered digital weight indicators for bench and floor scales. You benefit from lightweight, portable devices that do not rely on constant power sources. This flexibility allows you to move equipment where you need it most, such as receiving departments or inventory management areas. With better energy storage and smarter battery management, you reduce maintenance and replacement costs.

Tip: Upgrading to advanced battery technology can help you streamline your workflow and boost productivity.

1.2 Expanding Applications

Battery innovation trends open new possibilities for real-world applications of battery innovation across industries. In commercial foodservice, compact battery-powered scales make bag filling and material handling easier and more efficient.

You also see these devices in industrial sectors where power access is limited. Companies switch to battery-powered solutions for cost-effective digital weighing in remote or temporary locations. Improved energy storage and advanced chemistries, such as lithium-ion and emerging alternatives, support these expanding applications. As battery technology evolves, you gain access to more reliable, versatile, and sustainable weighing solutions for your business.

Part 2: Key Battery Technology

You see battery technology evolving rapidly in the weighing device industry. You rely on batteries to power digital scales, portable weight indicators, and industrial weighing systems. The most relevant battery technologies for these applications include lithium-ion batteries, solid-state batteries, lithium-sulfur batteries, sodium-ion batteries, and graphene-based batteries. Each chemistry offers unique advantages for energy storage, safety, and performance.

2.1 Lithium-Ion Advances

Lithium-ion batteries dominate the market for electronic weighing devices. You benefit from their high energy density, long cycle life, and reliable performance. These batteries deliver consistent power for lithium battery packs used in bench scales, floor scales, and mobile weighing systems. You see lithium-ion battery research focusing on improving energy storage and safety.

You can choose from several lithium-ion chemistries, each with distinct properties. The table below compares key lithium battery chemistries using standardized nomenclature and technical data:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-350 | 2000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

You see NMC and LiFePO4 batteries used widely in industrial weighing devices. NMC offers higher energy density, while LiFePO4 provides longer cycle life and improved safety. LTO batteries excel in fast charging and extreme temperature performance. Solid-state batteries and lithium metal batteries represent next-generation batteries with higher energy storage and safety.

Note: Choosing the right lithium-ion battery chemistry depends on your application needs, such as cycle life, energy density, and safety requirements.

2.2 Solid-State Batteries

Solid-state batteries mark a major step forward in battery technology for weighing devices. You gain several advantages when you use solid-state batteries:

Higher energy density allows you to store more energy in a smaller battery.

Improved safety reduces the risk of fire hazards and thermal runaway.

Faster charging and discharging boost device performance.

You see solid-state batteries using a solid electrolyte instead of a liquid separator. This design reduces battery size and increases thermal stability. The lithium metal anode makes the battery lighter and more efficient. You benefit from longer battery life and enhanced security, which is critical for industrial weighing applications.

Tip: Solid-state batteries offer a safer and more compact solution for portable weighing devices, especially in environments where reliability matters most.

2.3 Emerging Chemistries

You see battery research driving the development of new chemistries for future weighing devices. Lithium-sulfur batteries attract attention for their high energy storage and lightweight design. These batteries promise longer run times and lower costs. Sodium-ion batteries offer a cost-effective alternative, using abundant materials but with lower energy density. Graphene-based batteries provide rapid charging and high conductivity, which can improve device efficiency.

The table below highlights key features of emerging battery chemistries and their potential for electronic weighing devices:

Battery Chemistry | Key Features | Potential for Electronic Weighing Devices |

|---|---|---|

Silicon Anode | High theoretical capacity, energy density boost, abundant, lower carbon footprint | High due to energy density improvements |

High-Nickel Cathodes | Enhanced energy density, reduced cost, controversial cobalt mining | Moderate, mainly used in automotive |

Solid-State Batteries | High energy density, reduced fire risk, ongoing development challenges | High, due to safety and performance |

Sodium-Ion Batteries | Abundant, lower cost, but lower energy density | Moderate, cost-effective alternative |

You see lithium-sulfur batteries leading the way for next-generation batteries in weighing devices. These batteries offer high energy storage and sustainability. You also see solid-state batteries and silicon anode batteries providing new options for energy storage and safety.

Callout: You should monitor advances in lithium-sulfur batteries and solid-state batteries. These technologies may soon transform battery-powered weighing devices with longer life and improved safety.

Part 3: Benefits of Battery Innovations

3.1 Longer Life

You gain significant advantages when you choose advanced battery technology for your electronic weighing devices. Modern lithium-ion batteries deliver up to 2000 to 3000 full charge cycles, far surpassing the 300 to 500 cycles of lead-acid batteries and the 500 to 1000 cycles of NiMH batteries. You can expect a lithium battery to last up to 10 years with regular use, while lead-acid batteries often require replacement every 1 to 2 years. This longer operational life means:

Reduced downtime for your business operations

Lower operating costs over time

Fewer interruptions due to battery maintenance

Lithium-ion batteries also offer 3 to 5 times longer lifespan compared to older chemistries. You benefit from up to 70 percent higher energy efficiency, which is essential for applications in industrial packaging and food processing. These batteries require zero maintenance and include features like overcharge protection and real-time monitoring, which further improve reliability and battery performance.

3.2 Faster Charging

You experience faster charging with new battery chemistries and improved energy storage. High-energy density lithium-ion batteries and solid-state batteries allow you to recharge your weighing devices quickly, minimizing downtime. This rapid charging supports continuous operations in environments where every minute counts. You also see increased battery capacity, which means your devices run longer between charges. This improvement is especially valuable in sectors like logistics and manufacturing, where efficiency drives success.

3.3 Safety and Sustainability

You must meet strict safety and sustainability standards when you use batteries in your business. Regulatory frameworks, such as the European Battery Regulation 2023/1542, set clear requirements for battery safety, hazardous substance limits, and labeling. The table below summarizes key regulations:

Regulation | Key Provisions |

|---|---|

European Battery Regulation 2023/1542 | Mandatory safety requirements, limits on hazardous substances, strict labeling and marking |

Safety Tests | Batteries must pass specific safety tests for reliability |

Heavy Metals Limits | Mercury: max 0.0005%, Cadmium: max 0.002%, Lead: max 0.01% (from August 2024) |

Digital Battery Passport | Required for industrial rechargeable batteries and electric vehicles from February 2027 |

You benefit from these standards because they ensure your batteries are safe, reliable, and environmentally responsible. High-energy density batteries and advanced chemistries support sustainability by reducing waste and improving energy storage efficiency. As battery technology evolves, you see a positive impact on both safety and the environment.

Part 4: Battery Technology Challenges

4.1 Material Sourcing

You face several challenges when sourcing materials for advanced batteries used in electronic weighing devices. The supply of lithium, cobalt, and other minerals often depends on regions with geopolitical instability. This can disrupt your supply chain and create price volatility. Mining activities may harm local ecosystems and communities, leading to water scarcity, contamination, and deforestation. Ethical concerns such as child labor and unsafe working conditions remain widespread in some mining areas. You must also consider conflict minerals, which can enter your supply chain and raise compliance risks. For more information, review the conflict minerals statement.

Challenge Type | Description |

|---|---|

Geopolitical Instability | Political tensions in producing regions affect mineral sourcing. |

Environmental Impacts | Mining can damage ecosystems and local communities. |

Ethical Sourcing Concerns | Child labor and unsafe conditions are prevalent in some mining regions. |

Need for Sustainable Practices | Sourcing policies must prioritize sustainability and ethics. |

Tip: You can reduce risks by choosing suppliers who follow sustainable and ethical sourcing practices.

4.2 Recycling

You must address recycling challenges as batteries reach end-of-life. Many lithium battery packs contain valuable materials that you can recover and reuse. However, recycling processes remain complex and costly. You need specialized facilities to handle hazardous substances and extract usable components. Improved recycling methods can help you lower environmental impact and support circular energy storage systems. You should look for partners who invest in advanced recycling technologies and comply with safety regulations.

Recycling helps you recover lithium, cobalt, and nickel.

Proper disposal prevents pollution and protects local communities.

Circular energy storage supports sustainability goals.

4.3 Cost Barriers

You encounter cost barriers when adopting new battery technology for weighing devices. Solid-state batteries cost between $400 and $800 per kWh, much higher than lithium-ion batteries at $100 to $150 per kWh. Complex manufacturing and expensive materials drive these costs. As production scales up, you may see prices fall, making advanced batteries more accessible. Innovations in materials science and battery design continue to lower costs and improve energy storage efficiency.

Note: Lower battery costs can help you expand the use of lithium battery packs in industrial weighing systems.

Part 5: Future and Sustainable Battery Technology

5.1 Smart Management

You see smart management systems shaping the future of batteries in electronic weighing devices. Battery management systems (BMS) monitor and control lithium battery packs, improving safety and performance. You can track battery health, optimize charging, and extend battery life. Smart management helps you reduce downtime and maintenance costs. You can learn more about battery management systems at this resource. As you look ahead, smart management will play a key role in creating reliable energy storage solutions for industrial applications.

5.2 IoT Integration

You benefit from IoT integration in future battery-powered weighing devices. IoT technology connects batteries to cloud platforms, allowing you to monitor energy usage and device status in real time. You can receive alerts for maintenance and optimize battery performance remotely. IoT integration supports predictive maintenance, which helps you avoid unexpected failures. You see this trend driving the adoption of clean energy and renewable energy in industrial weighing systems. IoT will help you manage sustainable batteries more efficiently and support future business growth.

5.3 Modular Packs

You gain flexibility with modular battery packs in future weighing devices. Modular packs allow you to scale energy storage capacity and power requirements easily. You can adapt your system to different usage profiles without replacing the entire battery. Maintenance becomes simpler because you can replace individual modules, reducing downtime and repair costs. Modular designs support sustainable battery technology by making recycling and upgrades easier.

Scalability lets you adjust energy storage for future needs.

Simplified maintenance lowers costs and improves reliability.

Industry experts highlight the importance of responsible sourcing, recycling, and innovative manufacturing for future batteries. You can read more about sustainability practices here. Ethical sourcing strengthens your supply chain and benefits local communities. As you plan for the future, you see sustainable batteries and energy storage solutions becoming essential for meeting environmental goals.

You see battery innovations transforming electronic weighing devices. Batteries now deliver longer life, faster charging, and improved safety. B2B users gain cost savings and operational efficiency with advanced battery management. You should consider project scope, battery options, system size, and site needs. Future batteries, including solid-state and lithium-sulfur, promise higher energy density and sustainability.

Batteries support cleaner logistics and help you meet sustainability goals.

Battery advancements will continue to shape your industry.

Define your battery-powered weighing project needs.

Evaluate batteries for cost, efficiency, and reliability.

Plan for future battery upgrades and recycling.

FAQ

What is the main advantage of using lithium battery packs in industrial weighing devices?

You get longer run times and higher energy density. Lithium battery packs also reduce maintenance and support portable weighing solutions for your business.

How do batteries impact the safety of electronic weighing devices?

You benefit from advanced safety features. Modern batteries include overcharge protection and thermal management, which help prevent accidents and ensure reliable operation.

Can you recycle a battery from a digital weighing device?

Yes, you can recycle a battery. Many recycling centers accept used batteries and recover valuable materials, supporting your company’s sustainability goals.