You face critical choices when selecting a battery for drone patrols or ground robots in power inspection tasks. The right battery boosts operational efficiency, reliability, and safety. Lithium battery packs, known for high energy density, allow longer missions and better coverage by storing more power per unit mass. Custom battery solutions help you match unique mission profiles, supporting demanding power inspection environments. Your selection of battery technology shapes mission success, equipment uptime, and overall safety in the power sector.

Key Takeaways

Choose high energy density batteries to extend flight time and mission duration for drones. This choice enhances operational efficiency in power inspections.

Prioritize safety with smart battery management systems. These systems monitor battery health and prevent overheating, ensuring reliable operation in demanding environments.

Select the right battery chemistry based on your robot’s needs. Lithium-ion batteries offer high energy density and long cycle life, making them ideal for various applications.

Implement fast charging solutions to minimize downtime. Technologies like wireless charging can significantly boost productivity for UAVs and ground robots.

Regularly maintain batteries to extend their lifecycle. Follow best practices like storing at optimal charge levels and using smart monitoring systems.

Part 1: Battery Needs for Drone Patrols

1.1 Energy Density and Endurance

You need to select batteries with high energy density for drone patrols in power inspection. Energy density determines how much power a battery can store relative to its weight. This factor directly impacts the flight range and mission duration of your UAVs. Most conventional batteries for UAVs offer less than 300 Wh/kg in gravimetric energy density. Advanced lithium battery packs can reach over 285 Wh/kg, which allows your drone to cover more ground during bridge inspections and automated surface damage detection.

Typical energy density values for drone batteries:

Conventional batteries: less than 300 Wh/kg

High-performance lithium battery packs: over 285 Wh/kg

Endurance is another critical factor. Your UAVs often face limited patrol times, usually between 10 and 30 minutes. This short endurance means you must frequently change batteries, which disrupts inspection schedules and reduces operational efficiency. You can improve energy efficiency and reduce downtime by choosing batteries with higher energy density and optimizing battery capacity for each mission.

Key points about endurance:

Limited UAV range restricts widespread use in power inspection.

Small and medium UAVs need battery changes every 10–30 minutes.

Frequent battery replacement lowers inspection efficiency.

1.2 C-Rating and Discharge Rate

You must consider the C-rating and discharge rate when selecting batteries for drone patrols. The C-rating shows how quickly a battery can deliver power without overheating or losing efficiency. High C-ratings are essential for UAVs that carry heavy payloads or perform demanding tasks in structural health monitoring and bridge inspections.

Battery Capacity | C-rating | Recommended Use Case |

|---|---|---|

1500 mAh | 75C | High-performance (acro) |

2200 mAh | 50C | Steady camera platform |

100A | N/A | Racing quads |

Discharge rate affects both performance and safety. You need batteries that can handle continuous discharge up to 100A and rates from 25C to 100C. These specifications support UAVs in power inspection applications, where reliable energy delivery is crucial.

Specification | Details |

|---|---|

Battery Type | LiPo/Li-ion (3.7V/cell) |

Configuration | 6S–24S (22.2V–50V+) |

Capacity Range | 450mAh–30,000mAh |

Continuous Discharge | Up to 100A |

Discharge Rate | 25C–100C |

Voltage Monitoring | ±10mV accuracy |

Temperature Range | -20°C to +60°C |

Cycle Life | ≥500 cycles |

Certifications | CE, RoHS, UL |

High discharge rates allow your drone to carry heavier payloads and perform longer missions. You must use robust battery management systems to prevent overheating and ensure safe operation during demanding power inspection tasks. Advanced lithium battery packs combine high energy and lightweight design, supporting reliable performance for various payloads and mission requirements.

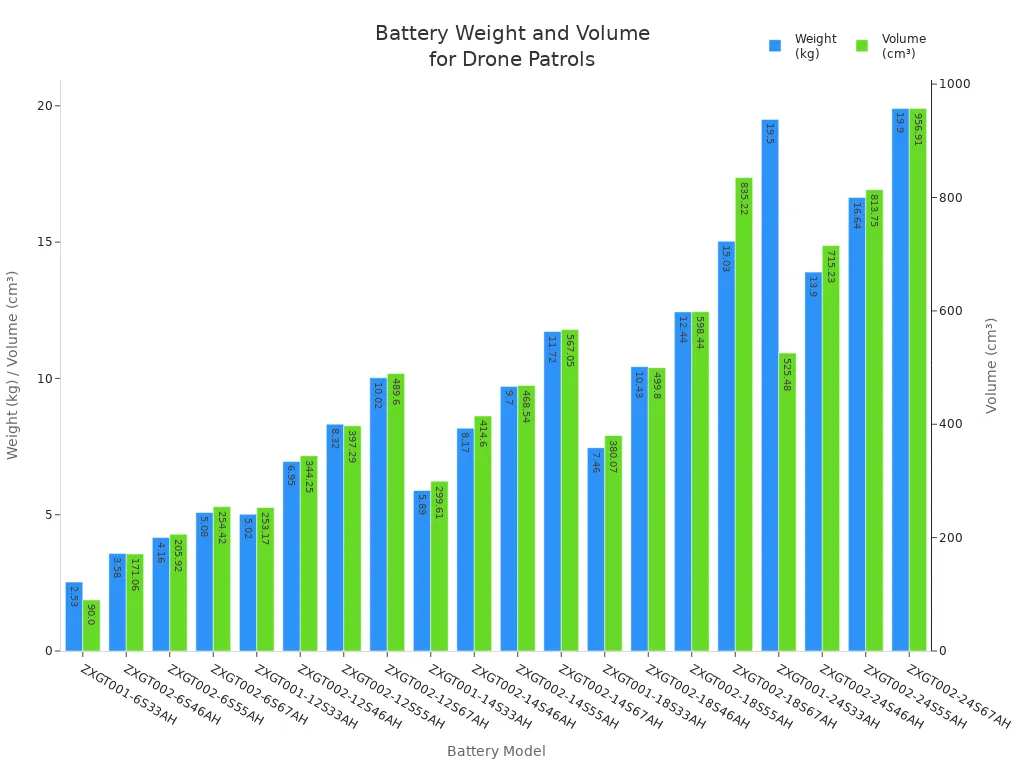

1.3 Weight and Size Impact

You need to balance battery weight and size with the energy requirements of your drone patrols. Heavier batteries can extend flight time but reduce available payload capacity. Any extra weight, including battery weight, increases the power needed to keep your UAV airborne. This higher power consumption shortens flight time and limits the effectiveness of drone-assisted inspections.

Model | Size (LWT in mm) | Weight (kg) |

|---|---|---|

ZXGT001-6S33AH | 9065217 | 2.53 |

ZXGT002-6S46AH | 46146255 | 3.58 |

ZXGT002-6S55AH | 56144255 | 4.16 |

ZXGT002-6S67AH | 67146260 | 5.08 |

ZXGT001-12S33AH | 13090217 | 5.02 |

ZXGT002-12S46AH | 90150255 | 6.95 |

ZXGT002-12S55AH | 147106255 | 8.32 |

ZXGT002-12S67AH | 128150255 | 10.02 |

ZXGT001-14S33AH | 15390217 | 5.89 |

ZXGT002-14S46AH | 105148255 | 8.17 |

ZXGT002-14S55AH | 126146255 | 9.70 |

ZXGT002-14S67AH | 151149255 | 11.72 |

ZXGT001-18S33AH | 19590217 | 7.46 |

ZXGT002-18S46AH | 130148255 | 10.43 |

ZXGT002-18S55AH | 160147255 | 12.44 |

ZXGT002-18S67AH | 195147255 | 15.03 |

ZXGT001-24S33AH | 130182222 | 19.50 |

ZXGT002-24S46AH | 194145255 | 13.90 |

ZXGT002-24S55AH | 220145255 | 16.64 |

ZXGT002-24S67AH | 257146255 | 19.90 |

Increasing payload from 0 to 1 kg can significantly decrease flight time. You must consider the relationship between battery capacity, weight, and thrust requirements. Optimizing battery selection for your UAVs helps you maximize energy efficiency and mission duration in power inspection applications.

1.4 Safety and Battery Management Systems

You must prioritize safety when deploying batteries in drone patrols. Smart battery management systems (BMS) play a vital role in maintaining the safety of lithium-ion batteries. These systems continuously monitor charge levels, temperature, and power output. Real-time diagnostics help you detect faults before they escalate. Automated safety cutoffs prevent overheating and overcharging, reducing the risk of thermal runaway.

Tip: For more details on battery management systems, visit BMS and PCM Solutions.

Function | Description |

|---|---|

Cell Monitoring and Balancing | Ensures uniform charging and discharging of cells to prevent aging or overstrain. |

Thermal Regulation | Monitors temperatures to activate cooling mechanisms or adjust performance. |

Overcurrent and Overvoltage Protection | Prevents conditions that could lead to fires or damage. |

State of Charge (SOC) Estimation | Provides real-time battery status for energy-aware navigation. |

Data Communication | Interfaces with the drone’s control unit for diagnostics and performance analytics. |

Remote Monitoring | Allows offsite assessment of battery health via Bluetooth or Cloud Gateway. |

You benefit from adaptive power management, which optimizes battery performance and longevity. Continuous monitoring and automated safety features ensure reliable operation in demanding power inspection environments. Custom battery solutions allow you to match battery capacity, energy density, and safety features to your specific mission profile, whether you work in medical, robotics, security systems, infrastructure, consumer electronics, or industrial applications.

Part 2: Battery Options for Ground Robots

2.1 Li-Ion, Li-Po, and NiMH Comparison

You need to choose the right battery chemistry for ground robots in power inspection applications. Each battery type offers unique advantages and challenges. You must consider energy density, cycle life, and safety when selecting a battery for your robot. The table below compares the most common battery chemistries used in ground robots for power monitoring and inspection:

Battery Type | Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Characteristics | Typical Platform Voltage (V) |

|---|---|---|---|---|---|

NiMH | Nickel Metal Hydride | 60-120 | 500–1,000 | Stable with low fire risk | 1.2 |

Lithium-Ion | LiFePO4, NMC, LCO, LMO | 150-250 | 500–2,000+ (LiFePO4 can exceed 6,000) | Higher energy density but overheating risks if damaged | 3.2–3.7 |

Li-Polymer | Lithium Polymer | 150-220 | 300–800 | Lightweight, flexible, but sensitive to puncture | 3.7 |

You see that lithium-ion batteries, including LiFePO4 and NMC, deliver higher energy density and longer cycle life than NiMH. Li-Polymer batteries offer flexibility in shape and weight, which helps you design compact robots for power inspection and monitoring. NiMH batteries provide stable performance and low fire risk, but they lack the energy density needed for extended missions. You must match battery chemistry to your robot’s operational profile and safety requirements.

Tip: For advanced battery management systems that support lithium battery packs in ground robots, visit BMS and PCM Solutions.

2.2 Capacity and Power Output

You must select a battery with enough capacity and power output to support your robot’s mission. Capacity, measured in ampere-hours (Ah), determines how long your robot can operate before charging. Power output, measured in watts (W), affects your robot’s ability to perform tasks such as climbing, lifting, or continuous monitoring in industrial applications.

High-capacity lithium battery packs (e.g., 10Ah–100Ah) enable longer inspection and monitoring cycles.

Robots in infrastructure and security systems often require batteries with high discharge rates to power motors and sensors.

You must balance battery size and weight with the energy needs of your robot. Too large a battery increases weight and reduces mobility. Too small a battery shortens mission duration and increases downtime.

You should use lithium-ion batteries for applications that demand high energy density and reliable power output. LiFePO4 batteries offer stable voltage and long cycle life, making them ideal for continuous monitoring in industrial and medical robots. NiMH batteries suit low-power applications where safety and cost matter more than energy density.

2.3 Durability and Cycle Life

You need a battery that withstands frequent charging and discharging cycles. Durability and cycle life determine how often you replace batteries and how much maintenance your robot requires. Lithium-ion batteries, especially LiFePO4, provide the longest cycle life, often exceeding 2,000 cycles. Some LiFePO4 batteries reach over 6,000 cycles, which reduces replacement costs and increases uptime in power inspection applications.

NiMH batteries last 500–1,000 cycles. You may need to replace them more often in demanding monitoring scenarios.

Li-Polymer batteries offer moderate cycle life but may degrade faster if exposed to high temperatures or deep discharges.

Lithium-ion batteries maintain performance over thousands of cycles, supporting long-term deployment in industrial and infrastructure monitoring.

You must consider cycle life when planning maintenance schedules and budgeting for battery replacements. Longer cycle life means fewer interruptions and lower total cost of ownership for your ground robots.

2.4 Safety Features

You must prioritize safety when selecting batteries for ground robots in power inspection and monitoring applications. Regulatory standards require you to implement safety features that protect against overheating, overcharging, and physical damage. The table below summarizes key regulatory requirements for battery safety:

Regulatory Standard | Description |

|---|---|

UN 38.3 | Required for battery transport (air, sea, land). |

IEC 62133 | Essential for consumer and industrial applications. |

UL 1642 / UL 2054 | U.S. safety standards for lithium batteries. |

CE Marking | Required for products sold in the EU. |

Battery ID (2024 Regulation) | Tracks battery lifecycle and ensures proper recycling. |

You must use batteries with built-in protection circuits, temperature sensors, and robust enclosures. Smart battery management systems monitor voltage, current, and temperature in real time. These systems help you prevent thermal runaway and ensure safe operation in harsh environments. You must comply with international standards to guarantee safe transport, deployment, and recycling of lithium battery packs.

Note: You improve safety and reliability by choosing batteries certified to UN 38.3, IEC 62133, UL 1642, and CE standards. You also support sustainability by tracking battery lifecycle and recycling according to the latest regulations.

You must select batteries that meet both performance and safety requirements for your ground robots. This approach ensures reliable power delivery, minimizes downtime, and protects your assets in power inspection and monitoring applications.

Part 3: Power and Charging Solutions

3.1 Fast Charging and Autonomous Systems

You need reliable charging solutions to maximize uptime for your UAVs and ground robots in power inspection applications. Fast charging technologies, such as wireless systems with inductive and resonant capabilities, support adaptive matching for efficient energy transfer. These systems offer charging modes from 300W fast charging to 100mW trickle charging, suitable for various robotic platforms and battery chemistries like LiFePO4, NMC, LCO, and LMO.

Feature | Description |

|---|---|

Technology | Wireless charging (inductive, resonant) |

Efficiency | Adaptive matching for maximum energy transfer |

Charging Modes | Fast (300W) to trickle (100mW) |

Application | Supports multiple battery chemistries and robotic platforms |

StoreDot’s drone battery charges in just five minutes, eliminating manual battery replacement and enabling continuous operation. Autonomous charging systems allow UAVs and robots to recharge without human intervention, minimizing downtime and boosting productivity. Your equipment can quickly return to power inspection and monitoring tasks, improving operational efficiency.

The drone locates and lands on powerlines to recharge.

It uses a gripping mechanism for stability during charging.

Charging power ranges from 15W to 181W, reducing downtime.

3.2 Battery Swapping and Replacement

You face logistical challenges when swapping batteries in remote power inspection sites. Autonomous battery-changing systems reduce the need for manual intervention, supporting continuous energy monitoring and inspection. These systems are essential for industrial, infrastructure, and security applications.

Challenge | Description |

|---|---|

Remote Locations | Maintenance teams incur higher costs and time due to difficult access |

Extreme Weather | Reliability suffers in harsh conditions, affecting battery longevity |

Software Updates | Regular updates add to logistical complexity |

You must plan for battery replacement schedules and ensure that your UAVs and robots have access to spare batteries. Automated swapping stations can help maintain energy supply and reduce operational delays.

3.3 Remote Deployment Challenges

You encounter several obstacles when deploying power and charging solutions in remote inspection environments.

High installation costs for charging stations.

Poor charging infrastructure in rural areas.

Vehicle-grid interoperability issues between the grid and charging manufacturers.

Reliability problems with charging stations, leading to downtime.

Environmental factors like temperature and humidity affect battery performance. Nickel-cadmium batteries perform well in extreme temperatures but are expensive. VRLA batteries prevent spillage and suit remote locations. Extreme temperatures can damage batteries and reduce their lifespan. The optimal temperature range for solar batteries is 59–77°F. Proper placement in temperature-controlled environments is crucial for maintaining battery efficiency.

3.4 Maintenance and Lifecycle

You must follow best practices to maintain battery health and extend lifecycle in power inspection robots and UAVs.

Keep batteries fully charged when not in use with maintenance chargers.

Store batteries in climate-controlled areas, avoiding extreme temperatures.

Wait for batteries to cool before recharging.

Use properly rated tools and quality control for battery connections.

Regularly inspect battery performance with analyzers.

Use chargers with auto-cutoff to prevent overcharging.

Store batteries at 40–60% state of charge in a cool, dry place.

Avoid deep discharges to protect battery cells.

Monitor battery health using BMS apps for real-time data.

According to IEEE standards, you should inspect battery systems monthly and test capacity annually once capacity drops below 80%. Regular maintenance prolongs battery life, prevents failures, and reduces premature replacement.

Part 4: Impact on Inspection Efficiency

4.1 Downtime Reduction

You can reduce downtime in power inspection by choosing advanced lithium battery packs for your drone patrols and ground robots. When you use high-performance batteries, you increase equipment uptime and decrease power outages. The table below shows how battery improvements affect key metrics in power monitoring applications:

Metric | Improvement |

|---|---|

Equipment uptime | |

Power outages | 15% decrease |

Maintenance response times | 40% acceleration |

Energy consumption | 15% reduction |

You see faster maintenance response and lower energy consumption. These gains help you keep your uav fleets and monitoring robots active in industrial, infrastructure, and security systems applications.

4.2 Mission Duration

You extend mission duration by selecting batteries with high energy density and stable platform voltage. Lithium battery packs such as LiFePO4, NMC, LCO, and LMO support longer uav patrols and ground robot monitoring. You achieve longer inspection cycles in medical, robotics, and consumer electronics applications. When you optimize battery capacity, you allow your drone patrols to cover more ground and collect more data before charging.

Longer battery life means fewer interruptions.

Stable voltage supports continuous power delivery.

High energy density enables extended monitoring in industrial applications.

4.3 Data Collection Quality

You improve data collection quality by using batteries that deliver consistent power output. Reliable energy supply ensures your uav sensors and monitoring equipment operate at peak performance. You avoid data gaps and maintain high accuracy in power inspection. When you use lithium battery packs with advanced battery management systems, you support real-time diagnostics and adaptive charging.

Tip: Consistent energy flow helps you capture detailed inspection data in infrastructure and security systems applications.

4.4 Reliability and Risk Management

You increase reliability and manage risk by choosing batteries with robust safety features and long cycle life. Lithium battery packs certified to UN 38.3, IEC 62133, and UL 1642 standards protect your assets in power monitoring applications. You reduce the risk of power failures and extend the lifecycle of your uav and ground robot fleets. Smart battery management systems monitor charging, temperature, and energy output, helping you prevent downtime and maintain operational safety.

Certified batteries support safe deployment in industrial and medical applications.

Long cycle life reduces replacement costs and improves reliability.

Real-time monitoring helps you manage risk in power inspection environments.

Part 5: Best Practices and Trends

5.1 Choosing the Right Battery

You need to select the right battery for your power inspection robots and drones by considering chemistry, cycle life, and safety. Lithium battery packs such as LiFePO4, NMC, LCO, and LMO offer high energy density and long cycle life, making them ideal for industrial, infrastructure, and security systems. The table below compares key features:

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Platform Voltage (V) | Typical Use Cases |

|---|---|---|---|---|

LiFePO4 | 150–160 | 2,000–6,000 | 3.2 | Industrial, robotics |

NMC | 200–250 | 1,000–2,000 | 3.7 | Security, infrastructure |

LCO | 150–200 | 500–1,000 | 3.7 | Consumer electronics |

LMO | 100–150 | 300–700 | 3.7 | Medical, monitoring |

Tip: Always verify that your battery meets international safety standards and supports your mission profile.

5.2 Optimizing Usage

You can extend battery life and improve reliability by following best practices. Store batteries at 40–60% charge in cool, dry places. Use smart battery management systems (BMS) to monitor voltage, temperature, and current. Schedule regular maintenance and avoid deep discharges.

Use chargers with auto-cutoff to prevent overcharging.

Inspect battery health monthly and test capacity annually.

Rotate battery stock to ensure even usage across your fleet.

5.3 Future Battery Technologies

You will see rapid changes in battery technology for power inspection. Solid-state batteries promise over 1,500 cycles and lower costs. Fast charging allows you to reach 80% charge in 30 minutes, which is vital for urgent industrial or security operations. Intelligent BMS and smart management systems now monitor voltage, temperature, and current to prevent overcharging and overheating.

Trend | Description |

|---|---|

Intelligent BMS Systems | Enhance performance, safety, and battery life for robots and drones. |

Solid-State Batteries | Offer long life and cost savings for frequent use. |

Fast Charging | Enable 80% charge in 30 minutes for rapid deployment. |

Smart Management Systems | Monitor critical parameters for safe and reliable operation. |

Smart management systems help you avoid downtime and maintain safe operations in all environments.

5.4 Integration with Power Inspection Workflows

You can boost efficiency by integrating advanced battery technologies with your inspection workflows. Automation and AI-driven diagnostics streamline processes and reduce human error. Real-time analytics and predictive tools help you anticipate failures and schedule maintenance. Miniaturized batteries enable compact robots for medical and infrastructure inspections.

Key Advancement | Impact on Power Inspection Workflows |

|---|---|

Automation and AI Diagnostics | Increase productivity and reduce manual errors |

Real-time Analytics | Speed up inspections and improve data accuracy |

Predictive Analytics | Anticipate failures and optimize maintenance cycles |

Miniaturization | Enable next-generation, compact inspection tools |

You support sustainability and compliance by tracking battery lifecycle and recycling according to new regulations.

You improve inspection efficiency by choosing lithium battery packs with the right chemistry, energy density, and cycle life for each mission.

You boost reliability and safety by matching battery technology to your operational needs in industries such as robotics, infrastructure, and medical.

You stay ahead by adopting best practices and monitoring new trends in battery innovation.

Smart battery management helps you reduce downtime and maximize performance in power inspection applications.

FAQ

What lithium battery chemistry should you choose for industrial ground robots?

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Platform Voltage (V) |

|---|---|---|---|

LiFePO4 | 150–160 | 2,000–6,000 | 3.2 |

NMC | 200–250 | 1,000–2,000 | 3.7 |

You should select LiFePO4 for long cycle life or NMC for higher energy density in industrial robots.

How does battery management impact safety in power inspection applications?

You improve safety by using smart battery management systems. These systems monitor voltage, temperature, and current. You prevent overheating and overcharging. You reduce risks in medical, robotics, and infrastructure industries.

What factors affect battery selection for drone patrols in security systems?

Energy density

Weight and size

C-rating

Cycle life

You must balance these factors to maximize flight time and reliability for security inspections.

How do you optimize battery lifecycle for infrastructure monitoring robots?

Tip: Store batteries at 40–60% charge in cool, dry places.

You should schedule regular maintenance and use smart battery management systems. You extend battery life and reduce replacement costs.

Which certifications should you require for lithium battery packs in B2B deployments?

Certification | Purpose |

|---|---|

UN 38.3 | Safe transport |

IEC 62133 | Consumer/industrial safety |

UL 1642/2054 | U.S. safety standards |

CE Marking | EU compliance |

You must verify these certifications for safe and compliant deployment in all industries.