You manage battery needs differently based on your business size. Retail stores often rely on lithium-ion battery packs to power devices for daily operations. Battery technology changes quickly, and you must stay updated to keep your systems efficient. When you plan battery purchases, you need to consider supply chain speed and cost management. Battery choices affect your bottom line, so you must decide whether wholesale or retail battery options fit your needs best.

Key Takeaways

Understand your battery needs based on your retail store size. Small stores benefit from flexibility, while large chains require bulk purchasing for efficiency.

Stay updated on lithium-ion battery trends. These batteries offer high energy density, quick recharging, and low maintenance, making them ideal for retail operations.

Evaluate wholesale versus retail battery purchasing. Wholesale can lower costs significantly, while retail offers immediate access to a variety of battery types.

Implement effective inventory management. Use the FIFO method to keep stock fresh and regularly inspect batteries to ensure safety and reliability.

Consider environmental impacts when choosing batteries. Opt for chemistries that support sustainability and have better recycling rates to minimize waste.

Part 1: Battery Needs in Retail Stores

1.1 Scale Differences

You face different challenges in battery supply depending on the size of your retail stores. Small businesses often need fewer battery packs and can manage with limited storage space. Large chains require a steady supply of batteries to support many devices across multiple locations. Your energy needs grow as your operations expand, making efficient supply and storage solutions critical.

For small retail stores, you might prioritize flexibility and quick access to backup power. You can store a modest number of battery packs on-site, which helps you respond to outages or equipment failures. Large businesses, such as big-box retailers, must coordinate battery supply across many sites. You need robust inventory management to avoid shortages and ensure every location has enough storage capacity.

Tip: Assess your current and future battery supply needs by tracking device usage and outage history. This helps you plan for both daily operations and emergencies.

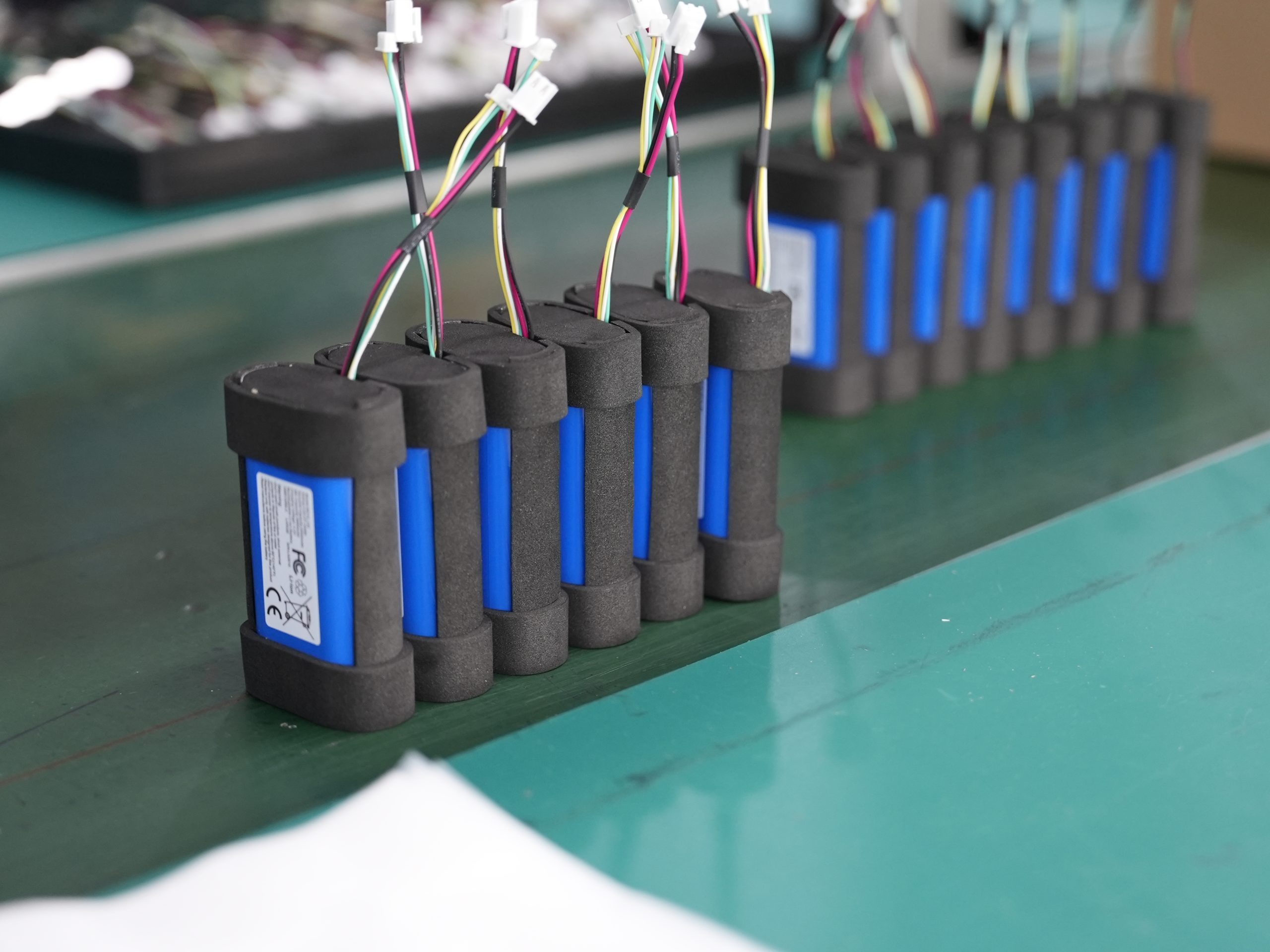

1.2 Lithium-Ion Trends

Lithium-ion battery packs have become the standard in retail stores. You benefit from their high energy density, which means you get more power in a smaller package. These batteries recharge quickly, often in just one to two hours, so you can keep your operations running with minimal downtime. You do not need to perform regular maintenance, such as adding distilled water, which saves you time and labor.

You also gain reliable performance in challenging environments, such as cold storage areas. Lithium-ion batteries can discharge to as low as two percent, allowing you to use more of the stored energy before recharging. This efficiency supports your decarbonization goals and helps you integrate renewable energy sources into your operations.

Here are the main drivers behind the shift toward lithium-ion battery packs in retail stores:

Higher energy density, providing more power in the same size

Faster recharging times, taking only one to two hours

Maintenance-free operation, eliminating the need for distilled water refills

Better performance in various operational conditions, such as cold storage

Ability to discharge to two percent, allowing for longer usage before charging

You can choose from several lithium battery chemistries, each with unique properties. The table below compares the most common types used in retail and industrial applications:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Use Cases |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 | Storage, backup power, industrial |

NMC | 3.6-3.7 | 150-220 | 1000-2000 | EVs, retail storage, robotics |

LCO | 3.6 | 150-200 | 500-1000 | Consumer electronics, POS devices |

LMO | 3.7 | 100-150 | 300-700 | Power tools, medical devices |

LTO | 2.4 | 70-80 | 7000-20000 | Infrastructure, backup, security systems |

Solid-state | 3.7-4.2 | 250-500 | 2000-10000 | Next-gen storage, medical, robotics |

Lithium metal | 3.4-3.7 | 300-500 | 500-1000 | Advanced storage, aerospace |

You should consider the availability of critical minerals, such as lithium, cobalt, and nickel, when planning your battery supply. These minerals impact battery manufacturing costs and supply chain stability.

1.3 Application Types

You rely on battery storage for several critical functions in your retail stores. During power outages, battery storage keeps your locations operational, protecting sales and customer satisfaction. You use energy storage for peak shaving, which helps you reduce monthly energy costs by storing energy during low-demand periods and using it during peak times. Essential services, such as lighting and refrigeration, depend on reliable battery supply to maintain operations during outages.

Your point-of-sale systems need a dependable power supply to function, especially when the grid fails. An uninterruptible power supply (UPS) ensures that registers and scanners keep working, so you do not lose sales or disrupt customer service. Security devices, on the other hand, often require long-term standby power. You must select battery packs that match the specific needs of each application.

Common battery-powered applications in retail stores include:

Backup power for lighting and refrigeration

Energy storage for peak shaving and cost reduction

Uninterruptible power supply for point-of-sale systems

Long-term standby power for security systems

You can also find battery storage solutions in medical equipment, robotics, and infrastructure systems within large retail environments. These applications require careful selection of battery chemistry and supply management to ensure safety and reliability.

Note: As you expand your use of renewable energy, such as solar panels, you will need advanced battery storage to balance supply and demand. This supports your decarbonization efforts and helps create a more resilient environment for your business.

Part 2: Procurement Strategies

2.1 Wholesale vs. Retail

You face a key decision when sourcing battery packs for your retail stores: should you buy wholesale or retail? Wholesale procurement allows you to purchase large quantities directly from suppliers, often at discounted rates. Retail purchasing gives you immediate access to a wide variety of battery types, but you pay higher prices due to markups and added services.

The table below compares wholesale and retail battery procurement for retail stores:

Aspect | Wholesale Pricing | Retail Pricing |

|---|---|---|

Cost | Generally lower, with discounts of 10% to 50% off retail prices | Higher due to operational costs and markups |

Availability | May require time for delivery; bulk orders | Immediate availability in stock |

Variety | Limited to bulk orders | Wide range of brands and types available |

Convenience | Less convenient, requires storage | Convenient for immediate needs |

Additional Services | Minimal, focused on bulk sales | Includes warranties, returns, and customer service |

Wholesale purchasing helps you maximize profit margins. You benefit from cost efficiency, consistent supply, and convenience. You avoid frequent reordering and ensure you always have battery packs available for your energy needs. Retail purchasing suits businesses with unpredictable demand or those needing a wide selection of battery chemistries for specialized applications.

Tip: Leverage bulk purchasing agreements to secure better margins and reliable supply for your retail stores.

You should also understand how pricing models work in the ev battery supply chain. Suppliers often use tiered or volume pricing, which rewards you for larger orders. The table below shows how these models function:

Pricing Model | Description |

|---|---|

Tiered Pricing | Different price points for different quantities; lower price applies to all units once a new tier is reached. |

Volume Pricing | Fixed discount on total order based on quantity; the more you buy, the more you save. |

Building strong relationships with suppliers in the ev battery supply chain can help you negotiate better deals and secure priority access to critical minerals needed for battery manufacturing.

2.2 Cost Factors

You must consider several cost factors when procuring battery packs for your retail stores. Global events, such as the pandemic and the war in Ukraine, have disrupted the ev battery supply chain. These disruptions increase the cost of raw materials like lithium, which drives battery prices up by 20% to 30%. Transportation costs have surged, especially for shipments from China to the U.S.

Competition for supply between the EV industry and battery energy storage systems buyers affects your procurement decisions. EV manufacturers often secure better terms due to higher demand, which can limit your access to critical battery chemistries.

Here are the main cost factors you should evaluate:

Supply chain disruptions increase raw material costs, especially for lithium and other critical minerals.

Transportation costs for batteries have risen sharply.

Competition for supply with the EV industry can affect availability and pricing.

Total Cost of Ownership (TCO) includes purchase price, maintenance, replacement, and disposal costs.

Li-Ion batteries may cost more upfront, but their longer lifespan and lower maintenance make them more cost-effective over time.

Bulk purchasing and long-term contracts provide cost savings, but you must avoid stockpiling batteries that may degrade.

Choosing a reliable supplier in the ev battery supply chain is critical. A reputable supplier provides quality products and offers support services such as technical advice, warranty options, and after-sales service. You should evaluate the supplier’s track record and ability to meet future energy needs, including newer battery technologies for decarbonization and renewable energy integration.

Note: Always consider delivery times and payment terms, not just price. Build relationships with suppliers for better deals and be ready to explore other options if negotiations stall.

2.3 Inventory Management

Effective inventory management ensures you have the right battery packs available to meet your energy needs and backup power requirements. You must organize your storage to prevent confusion and maintain battery quality. Categorize batteries by type and size. Use bulk battery storage solutions, such as bins with dividers, to keep your inventory organized.

Rotate your stock using the FIFO (first in, first out) method. This practice helps you use older batteries first and maintain freshness. Label batteries with purchasing or manufacturing dates for effective tracking. Regularly inspect your battery stock for signs of damage or degradation.

The table below outlines best practices for battery storage in retail stores:

Strategy | Details |

|---|---|

Charge Level | Rechargeable batteries should ideally be stored at 40-60% charge to preserve shelf life. |

Fire Safety | Store batteries in fire-resistant containers or rooms due to their energy density. |

Insulation | Batteries should be stored separately from metal objects to avoid short-circuiting. |

Climate Control | Maintain a stable room temperature around 68-77°F to preserve battery quality. |

Segregation and Organization | Different types of batteries should be stored separately to prevent cross-contamination. |

Fire Safety and Suppression | Equip warehouses with advanced fire suppression systems for lithium-ion batteries. |

Regular Inspection | Implement routine checks for corrosion, leakage, and terminal damage to ensure safety. |

You should use the FIFO rule to ensure older batteries are used first. Label batteries clearly and inspect them regularly. These steps help you maintain a safe environment and reliable supply for your retail stores.

Alert: Proper battery storage and inventory management reduce risks and support your decarbonization goals by minimizing waste and ensuring efficient use of resources.

Part 3: Choosing the Right Battery

3.1 Quantity Needs

You must determine the right quantity of battery packs for your retail stores. The ev battery supply chain affects how you plan your purchases. You need to balance financial capacity with available storage space. Overstocking batteries can tie up capital and increase the risk of obsolescence. Sales forecasts and inventory turnover rates help you predict demand and avoid shortages. You should negotiate with suppliers to secure favorable terms and maintain a steady supply of energy storage for your businesses.

Factor | Description |

|---|---|

Financial Capacity | Assess your financial ability to purchase batteries. |

Storage Space | Ensure you have adequate space to store the batteries safely. |

Risk of Overstocking | Understand the potential downsides of having too many batteries in stock. |

Sales Forecast | Use sales predictions to guide your purchasing decisions. |

Inventory Turnover Rate | Aim for a high turnover rate to minimize the risk of obsolescence. |

Supplier Negotiation Strategies | Negotiate with suppliers to find favorable terms and conditions. |

3.2 Quality Standards

You need to follow industry standards when selecting battery packs for your businesses. Compliance with safety standards protects your staff and customers. Design considerations ensure new products meet best practices. You should use battery packs with thermal protection and charge/discharge safeguards. Quality control during battery manufacturing is critical for safety and performance. Battery management systems and charger compliance help prevent failures. Testing end-product systems together confirms safe operation under real conditions.

Recommendation | Description |

|---|---|

Compliance with standards | Components and battery-powered products should adhere to applicable voluntary standards to ensure safety. |

Design considerations | New products not yet under standards should follow best practices from existing standards. |

System approach | Battery-powered products should be designed with thermal protection and charge/discharge safeguards. |

Quality control | Cells must be manufactured with good quality control to ensure safety under intended loads. |

Battery Management Systems | Battery packs should include systems for charge control and short-circuit protection. |

Charger compliance | Chargers must meet applicable standards and be suitable for the product. |

Testing | End-product systems should be tested together to ensure safe function under appropriate conditions. |

3.3 Environmental Impact

You must consider the environmental impact of different battery types in your supply chain. Alkaline batteries create waste and have low recycling rates. Lithium-ion batteries require critical minerals, which can disrupt habitats and increase pollution. Nickel metal hydride batteries offer better recyclability and longer lifespan, reducing waste. Lead-acid batteries contain toxic materials and pose disposal challenges. You should choose energy storage solutions that support renewable goals and minimize environmental harm.

Alkaline batteries contribute to waste due to their single-use nature and have a low recycling rate. Their production is energy-intensive and involves mining of harmful materials.

Lithium-ion batteries require rare minerals, leading to habitat disruption and pollution. Their production has a high carbon footprint, and improper disposal can result in hazardous waste.

Nickel metal hydride batteries are more environmentally friendly as they are recyclable and do not contain harmful heavy metals. They have a longer lifespan and reduce waste compared to single-use batteries.

Lead-acid batteries contain toxic materials, posing significant disposal challenges and environmental hazards if not managed properly.

3.4 Supplier Support

You should work with suppliers who offer strong support for your businesses. Battery suppliers provide technical assistance and prompt after-sales service, helping you maintain reliable supply for backup power and energy storage. Reputable distributors perform quality inspections and testing to ensure battery performance. They share in-depth knowledge of battery technology, guiding you in selecting the right solutions and troubleshooting issues. Supplier support is critical for maintaining efficiency in the ev battery supply chain and meeting your operational needs.

Battery suppliers provide best-in-class dealer support and technical assistance, ensuring that after-sales battery orders are shipped promptly to help EV customers.

Reputable lithium-ion battery distributors ensure the quality and performance of batteries through quality inspections and testing.

Distributors offer in-depth knowledge of battery technology, assisting customers in selecting the right battery and troubleshooting issues.

Part 4: Case Studies

4.1 Small Retail Example

You run a small retail store that needs reliable battery supply for point-of-sale systems, lighting, and backup power. You often face unpredictable demand, so you choose to purchase batteries in smaller quantities. This approach gives you flexibility and reduces the risk of overstocking. You store batteries in a cool, dry place and rotate your stock to keep inventory fresh. You select lithium battery packs with longer shelf lives to support your energy needs and minimize waste. You also maintain clear labeling and documentation for each battery type.

Tip: Build a strong relationship with your supplier to ensure you always have access to the latest battery technologies and avoid shortages in critical situations.

4.2 Large Chain Example

You manage a large retail chain with multiple locations. Your battery needs are much greater, and you must ensure a steady supply for all stores. You implement bulk purchasing strategies to lower costs and streamline inventory. The table below shows how these strategies benefit your businesses:

Benefit | Description |

|---|---|

Cost-Effectiveness | Reduces the per-unit cost considerably when ordering in large quantities. |

Streamlined Inventory | Maintains a larger supply, reducing the risk of stockouts and ensuring product availability. |

Simplified Reordering | Minimizes the frequency of deliveries, reducing logistical challenges associated with smaller orders. |

Commitment to Safety | Ensures batteries are sourced from reliable suppliers, enhancing store reputation for quality. |

You partner with reputable manufacturers who conduct rigorous quality control testing. You demand certifications such as ISO Standards and perform regular checks on each battery shipment. You also select battery technologies with longer shelf lives, store batteries properly, and rotate stock to keep your supply fresh. These steps help you manage the ev battery supply chain and support your energy storage needs across all locations.

4.3 Best Practices

Best Practice | Description |

|---|---|

Minimize non-recyclable waste and optimize packaging materials. | |

Third-Party Logistics | Use specialized logistics providers for tailored battery storage solutions. |

Temperature Control | |

Humidity Management | Keep humidity levels between 30% to 50% to prevent corrosion and degradation. |

Adequate Ventilation | |

Compliance with Regulations | Adhere to safety regulations and conduct regular inspections. |

Battery Segregation | Classify batteries by chemistry and state of charge to avoid hazards. |

Clear Labeling | Use durable labels for important battery information and maintain documentation. |

Appropriate Racking | Utilize non-conductive racking systems for safe storage. |

Designated Charging Stations | Establish safe charging areas with proper safety measures. |

Routine Inspections | Conduct regular checks for damage and maintenance needs. |

You should always monitor your supply of critical minerals and stay updated on battery manufacturing trends. These actions help you maintain a reliable energy supply, support renewable goals, and ensure your businesses remain competitive in the evolving ev battery supply chain.

You see battery needs change as your retail business grows. Small stores need flexibility, while large chains benefit from bulk buying and strong supplier relationships. When you choose between wholesale and retail battery options, consider cost, inventory turnover, and supplier support.

Local battery supply chains receive major investments.

Circular economy strategies extend battery lifespan and reduce material demand.

Recycling programs and financial incentives promote sustainability.

You should adapt quickly to lithium-ion market trends. The battery sector will keep innovating, with safer, higher-capacity solutions driving growth in retail. The global battery market may reach $423.9 billion by 2030, fueled by electric mobility and renewable energy storage.

FAQ

What lithium battery chemistries suit retail stores best?

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Common Use |

|---|---|---|---|

LiFePO4 | 90-160 | 2000-7000 | Backup, storage |

NMC | 150-220 | 1000-2000 | EVs, robotics |

LCO | 150-200 | 500-1000 | POS devices |

You should select LiFePO4 for backup and storage. NMC works well for robotics and EVs.

How do you maximize battery pack lifespan in retail operations?

You should store lithium battery packs at 40-60% charge. Maintain temperatures between 68-77°F. Rotate stock using FIFO. Inspect batteries regularly for damage. These steps help you extend battery life and reduce replacement costs.

What is the main advantage of bulk battery purchasing?

Bulk purchasing lowers your per-unit cost by 10% to 50%. You secure a steady supply and improve profit margins. You also reduce the risk of running out during peak demand.

How do you ensure battery safety in your supply chain?

You must use battery packs with thermal protection and charge/discharge safeguards. Choose suppliers who follow ISO standards. Test batteries before use. Store batteries in fire-resistant containers and maintain climate control.

What environmental factors should you consider when choosing lithium battery packs?

Factor | Impact on Environment |

|---|---|

Mineral sourcing | Habitat disruption, pollution |

Recycling rate | Reduces waste |

Carbon footprint | Affects sustainability goals |

You should select chemistries with higher recyclability and lower carbon footprint to support sustainability.