Battery redundancy systems keep your critical care equipment running without interruption. In healthcare, even a brief loss of power can threaten patient safety and disrupt vital procedures. Lithium battery packs deliver high reliability and efficiency for emergency devices and portable medical systems. Modular UPS systems now see wide use, ensuring uninterrupted operations in mission-critical environments.

Reliable power supply is critical for healthcare services, as failures in uninterruptible power systems can cause severe disruptions.

You must consider practical solutions and challenges to maintain uninterrupted power and protect patients.

Key Takeaways

Battery redundancy systems ensure continuous power for critical care equipment, protecting patient safety during power outages.

Regular testing of battery backup systems is essential to confirm they deliver instant emergency power when needed.

Modular battery solutions offer flexibility and quick replacement, minimizing downtime and maintaining backup power.

Automated switchover mechanisms keep power supply stable, ensuring uninterrupted operation of life-saving devices.

Stay compliant with safety standards to enhance reliability and protect patients in healthcare settings.

Part 1: Battery Redundancy Systems Overview

1.1 Critical Care Equipment Needs

You rely on battery redundancy systems to maintain a stable power supply for critical care equipment. These systems deliver instant, automatic backup power when the main source fails. In hospitals, protecting critical equipment is essential for patient safety and uninterrupted care. You see battery backup emergency power supporting life-saving equipment such as:

Anesthesia machines

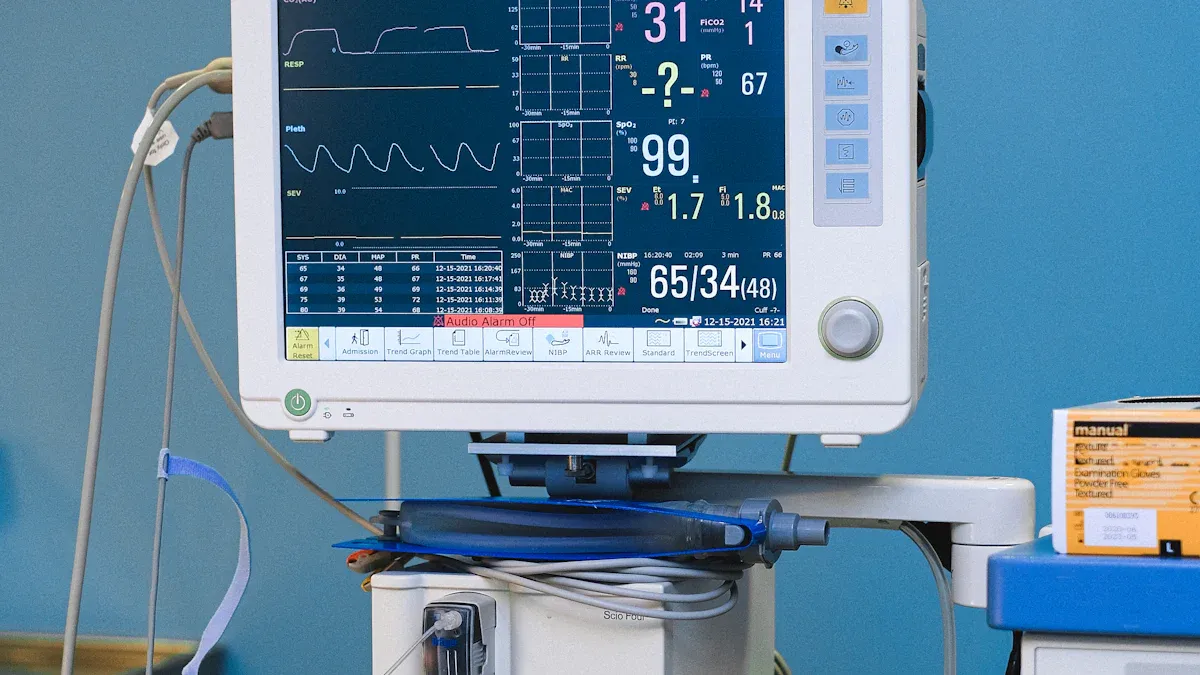

Heart monitors

Ventilators

Facilities must meet minimum power requirements, especially during emergencies. The table below shows risk categories and examples of equipment that need constant power:

Risk Category | Description | Examples |

|---|---|---|

Category 1 | Electrical failures could result in serious injury or death. Power supplies must be constantly available. | Operating rooms, life support systems, intensive care units |

Category 2 | Electrical failures are likely to cause minor injury. | Emergency call systems, lighting in patient rooms |

Category 3 | Electrical failures are unlikely to result in injury. | Hospital plumbing systems, power in general care rooms |

Category 4 | Electrical failures have no impact on patient health. | Televisions in waiting rooms, lawn sprinklers, public-address systems |

You must prioritize backup power solutions for Category 1 and Category 2 areas to minimize downtime and ensure reliable power supply.

1.2 Redundancy Design Types

Battery redundancy systems use several design types to provide backup power protection for critical equipment. You often see dual AC input systems, which connect to two independent power circuits. These systems allow rapid failover (under 10 ms), preventing interruptions in battery backup power. External UPS systems offer battery backup emergency power and surge protection, but you need to replace batteries periodically to maintain safety.

Common design types include:

Emergency services and ICUs: Protecting critical equipment like ventilators and monitors.

Operating rooms: Ensuring constant power for surgical lights and anesthesia machines.

Medical imaging: Supporting sensitive diagnostic equipment such as CT scanners and MRI machines.

Laboratory equipment: Powering centrifuges and incubators.

Data centers: Protecting electronic health records and vital IT systems.

You can incorporate parallel UPS units or use an N+1 configuration to guarantee backup power systems remain available.

1.3 Modular Battery Solutions

Modular battery redundancy systems offer advanced safety and flexibility for critical care equipment. You benefit from features such as overcharge protection, deep discharge protection, and temperature monitoring. Each module includes real-time monitoring for voltage, temperature, and current. If a module fails, you can isolate it and replace it quickly, minimizing downtime and maintaining backup power.

Advantage | Description |

|---|---|

Advanced Safety Measures | Overcharge, deep discharge, and temperature monitoring. |

Real-time Monitoring | Cell monitoring for voltage, temperature, and current. |

Isolation of Faulty Modules | Faulty modules can be isolated, preventing system-wide hazards. |

Efficient Heat Dissipation | Individual cooling reduces risk of thermal runaway. |

Quick Replacement | Degraded modules can be replaced without dismantling the system. |

Redundant Modules | Continued operation if one module fails, ensuring system reliability. |

You can expand or reduce modular battery systems to meet changing energy demands. This adaptability supports medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Lithium battery packs, including LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal chemistries, provide high energy density, long cycle life, and robust platform voltage for backup power protection. You should review sustainability and conflict minerals statements when selecting battery backup systems for your facility.

Part 2: Protecting Critical Equipment

2.1 Life-Saving Equipment Backup

You depend on battery backup emergency power to keep life-saving devices running at all times. In critical care settings, even a short power outage can put patient safety at risk and cause downtime for essential procedures. Lithium battery packs, such as LiFePO4 and NMC, deliver reliable backup for ventilators, heart monitors, and anesthesia machines. These chemistries offer high energy density and long cycle life, making them ideal for continuous operation.

Battery redundancy systems provide immediate backup when the main power source fails. You see these systems supporting critical equipment in intensive care units and emergency rooms. Advanced UPS units ensure seamless transitions to battery backup emergency power, preventing disruptions during surgeries or emergencies. You protect sensitive medical materials from temperature changes and maintain the integrity of life-critical equipment.

Tip: Regularly test your battery backup systems to confirm they deliver instant emergency power when needed.

2.2 Operating Room & Emergency Devices

Operating rooms rely on uninterrupted power for critical procedures. You must protect devices that are most vulnerable to power loss, including:

Loss of lighting in the OR

Failure of electrosurgical units

Inoperability of video display monitors

Loss of suction

Battery backup emergency power keeps these devices running, allowing you to continue surgeries without interruption. Lithium battery packs, including LCO and LMO chemistries, support high-drain equipment and provide stable platform voltage. You minimize downtime and maintain safety for both patients and staff.

Protocols for uninterrupted power in surgical and emergency environments include:

Battery backup systems ensure continuous operation of critical equipment in operating rooms.

Immediate power delivery during outages allows you to complete surgical procedures safely.

Backup systems protect sensitive medical materials from being compromised by power failures.

Protocol/System | Description |

|---|---|

Emergency Safety Protocol (ESP) | A structured approach to minimize errors and improve safety through clear communication and role clarity. |

Simulation Training (ST) | Training that enhances team coordination and situational awareness during high-pressure situations. |

A system that provides backup power to critical equipment, ensuring operations continue during power failures. |

You must comply with strict codes and regulations when designing and installing these systems. Advanced lithium battery packs, such as LTO and solid-state, offer robust performance and fast recharge times, supporting critical equipment in high-pressure environments.

2.3 Data & Environmental Protection

You rely on battery redundancy systems to safeguard sensitive data and maintain environmental controls in healthcare facilities. Continuous power supply is essential for diagnostic tools, pharmacy refrigeration units, and biomedical storage. Power interruptions can lead to equipment failure, risking patient lives and compromising facility integrity.

Sensitive biomedical materials require precise temperature control. Power outages can spoil these materials, causing financial loss and threatening patient safety. Properly sized UPS systems ensure seamless transitions to backup power, maintaining continuity of patient care.

Power failures can result in significant data loss. If a power interruption occurs while data is being processed, unsaved information may be lost permanently. Sudden outages can damage hardware and operating systems, leading to further data loss and operational disruptions. In critical care environments, the absence of a UPS during a power outage can cause data corruption or loss. For example, if imaging equipment or patient data servers lose power unexpectedly, the integrity of patient information may be compromised, directly affecting patient safety.

Note: Protecting digital systems and environmental controls with reliable backup power reduces downtime and supports uninterrupted patient care.

Lithium battery packs, including lithium metal and solid-state chemistries, provide high energy density and long cycle life for backup systems in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. You ensure that critical equipment and sensitive data remain protected, even during unexpected power events.

Part 3: Reliability & Maintenance

3.1 N+1 and 2(N+1) Redundancy

You need to understand redundancy strategies to ensure continuous operation of critical systems. N+1 redundancy means you add one spare component to your system. This setup reduces hardware costs and is easy to implement. However, if the spare fails, your system faces risk. For high-availability environments, 2N redundancy duplicates the entire system. This approach eliminates single points of failure and supports seamless power transition, but it increases costs and complexity.

Redundancy Type | Description | Advantages | Disadvantages |

|---|---|---|---|

N+1 | One additional spare component to handle failures. | Reduces hardware costs. Easy to implement. Provides backup for a single failure. | Risk of system failure if the spare fails. Less efficient for larger systems. |

2N | Complete duplication of the system. | No single point of failure. Can handle multiple component failures. Ideal for high availability. | Higher costs for hardware and maintenance. More complex to manage. |

You should select the redundancy type that matches your facility’s critical needs and budget. In medical, robotics, and industrial sectors, minimizing downtime is essential for safety and reliability.

3.2 Testing & Lifecycle Management

You must test battery backup emergency power systems regularly to maintain reliability. Routine checks help you detect issues early and prevent emergency failures. Recommended testing intervals include monthly, quarterly, and yearly assessments of voltage, current, and temperature. You should also perform acceptance tests at installation and periodic discharge tests based on service life.

Test Type | Frequency |

|---|---|

Overall float voltage measured at the battery terminals | Monthly, Quarterly, Yearly |

Charger output current and voltage | Monthly, Quarterly, Yearly |

DC float current (per string) | Monthly, Quarterly, Yearly |

Ambient Temperature | Monthly, Quarterly, Yearly |

Temperature of the negative terminal of each cell | Quarterly, Yearly |

Cell/unit internal ohmic values | Quarterly, Yearly |

Cell-to-cell and terminal connection detail resistance | Yearly |

AC ripple current and/or voltage | Yearly |

Tip: Regular testing and monitoring of lithium battery packs, such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal, help you achieve continuous operation and minimize downtime.

You can optimize battery management by using advanced battery management systems (learn more about BMS). These systems monitor cell health, temperature, and charge cycles, supporting backup and emergency power needs in critical equipment.

3.3 Regulatory Compliance

You must comply with international standards to ensure safety and reliability in battery redundancy systems. Standards such as ANSI/AAMI ES 60601-1 and IEC 60086-4 set requirements for medical device safety and lithium battery performance. IEC 62133 and IEC 62485-X address safety for secondary cells and battery installations. Following these standards helps you protect patients and maintain regulatory approval.

Standard | Description |

|---|---|

ANSI/AAMI ES 60601-1 | General requirements for basic safety and essential performance of medical devices that require an electrical outlet or a battery. |

IEC 60086-4 | Safety of Lithium Batteries, outlining tests and requirements for primary lithium batteries. |

IEC 62133 | Safety requirements for secondary cells and batteries containing alkaline or other non-acid electrolytes. |

IEC 60086-5 | Safety of Batteries with Aqueous Electrolyte. |

IEC 62485-X | Safety Requirements for Secondary Batteries and Battery Installations. |

You should stay updated on regulatory changes and maintain documentation for all lithium battery packs used in critical care equipment. This approach supports emergency power reliability and ensures seamless power transition in medical, robotics, security, infrastructure, consumer electronics, and industrial applications.

Part 4: Innovations in Battery Redundancy

4.1 Intelligent Monitoring

You can improve reliability in critical care by using intelligent monitoring for lithium battery packs. These systems collect real-time data to help you detect issues before they affect patient safety. You monitor battery state of charge (SOC), state of health (SOH), charging records, temperature variations, voltage measurements, and data quality metrics. Field data gives you a clear picture of battery performance in real-world conditions, which helps you predict battery lifetime and spot faults early.

Benefit | Description |

|---|---|

Continuous Monitoring | Provides ongoing data to detect issues before they lead to failures. |

Proactive Maintenance | Enables timely interventions to maintain battery health and performance. |

Early Failure Detection | Identifies potential problems early, reducing downtime and ensuring reliability. |

Extended Battery Life | Helps achieve the rated service life of batteries, crucial for healthcare operations. |

Improved Site Availability | Ensures that power systems are reliable, supporting mission-critical services in hospitals. |

You can use advanced battery management systems (BMS) to support intelligent monitoring. These tools help you maintain lithium battery packs such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. Learn more about BMS.

4.2 Automated Switchover

Automated switchover mechanisms keep your power supply stable during interruptions. When the main power fails, an Automatic Transfer Switch (ATS) moves the load to the emergency source within set voltage preferences. Once power returns, the ATS switches back to the primary source. This process reduces downtime and protects critical care equipment.

The main power fails

An ATS switches the load to the emergency power source within its prescribed voltage preferences

Once power is restored, the transfer switch returns the load back to the primary power source

You see automated switchover in medical facilities, large-scale data centers, industrial complexes, and telecommunication hubs. These systems ensure continuous operation for robotics, security, infrastructure, and consumer electronics sectors.

Tip: Automated switchover helps you maintain uninterrupted power for life-saving equipment.

4.3 Future Trends

You will see new technologies shaping battery redundancy in healthcare. Companies like LG Energy Solution and Samsung SDI are improving battery management for medical devices. Startups use AI-driven BMS solutions to optimize battery performance. Energy harvesting technology, such as Mindray’s BMS, captures ambient energy to extend battery life in portable devices.

Technology Type | Description |

|---|---|

Enhancing battery performance in medical devices. | |

AI-driven BMS Solutions | Optimizing battery management with artificial intelligence. |

Energy Harvesting Technology | Extending battery life in portable devices by capturing ambient energy. |

You may also see hydrogen fuel cells for long-lasting backup power, AI-driven cyber defense for threat detection, and blockchain for securing pharmaceutical supply chains. Advancements in lithium-ion and sodium-ion technologies will boost energy density, safety, and cost-effectiveness. Solid-state batteries and silicon anodes will improve stability and sustainability, making redundancy systems more reliable and efficient.

You need robust battery redundancy systems to protect critical care equipment and ensure patient safety. Lithium battery packs like LiFePO4 offer long lifespan and low maintenance, while modular UPS solutions provide scalability and reliability. You can lower operational costs and improve dependability by combining modern power systems with ongoing inspection and maintenance.

Consider these steps for your facility:

Evaluate your current backup systems.

Invest in scalable lithium battery packs and modular UPS solutions.

Train staff and follow electrical codes.

Schedule regular testing and maintenance.

FAQ

What is the main benefit of battery redundancy systems in critical care equipment?

You gain a stable power supply for critical equipment. Battery redundancy systems provide instant backup power protection, minimizing downtime and supporting uninterrupted operations. This ensures patient safety and reliable power supply for life-saving equipment in medical, robotics, and industrial sectors.

How do lithium battery packs improve emergency power reliability?

You use lithium battery packs like LiFePO4, NMC, and solid-state for high energy density, long cycle life, and robust platform voltage. These chemistries deliver battery backup emergency power for life support systems, protecting critical equipment and enabling seamless power transition during emergencies.

What maintenance practices help minimize downtime in backup power systems?

You should test battery backup systems regularly. Monitor voltage, temperature, and current. Replace degraded modules quickly. Use advanced battery management systems for continuous operation and minimizing downtime. This keeps backup power solutions ready for emergency and life-saving interventions.

Why is automated switchover important for protecting critical equipment?

You rely on automated switchover to maintain uninterrupted power. When the main power fails, systems instantly switch to battery backup power. This process supports continuous operation, protects critical equipment, and ensures safety in medical, security, and infrastructure applications.

Can modular battery backup systems scale for different sectors?

You can expand or reduce modular battery backup systems to meet changing energy demands. These systems support medical, robotics, consumer electronics, and industrial sectors. Modular designs offer backup power solutions, efficient heat dissipation, and quick replacement for uninterrupted operations.