You depend on battery safety to protect lives when using handheld medical equipment. Medical-grade lithium-ion batteries deliver reliable power, keeping your devices ready for critical care situations. Battery safety prevents downtime that can jeopardize patient outcomes and ensures that devices perform at their best.

Reliable battery contacts support optimal device performance and patient safety.

Poor-quality contacts risk device failure and threaten care during emergencies.

Efficient battery safety features guarantee timely device functionality.

Strict safety standards and advanced features make battery safety essential for every medical application.

Key Takeaways

Battery safety is crucial for reliable performance in handheld medical devices, ensuring they function during emergencies.

Choose high-quality lithium-ion batteries with advanced safety features to prevent overheating and chemical leaks.

Follow strict maintenance protocols, including regular inspections and timely battery replacements, to enhance patient safety.

Stay informed about regulatory standards to ensure compliance and improve the safety of medical devices.

Adopt new battery technologies and safety practices to protect patients and enhance the reliability of medical equipment.

Part 1: Battery Safety in Medical Devices

1.1 Patient Care Impact

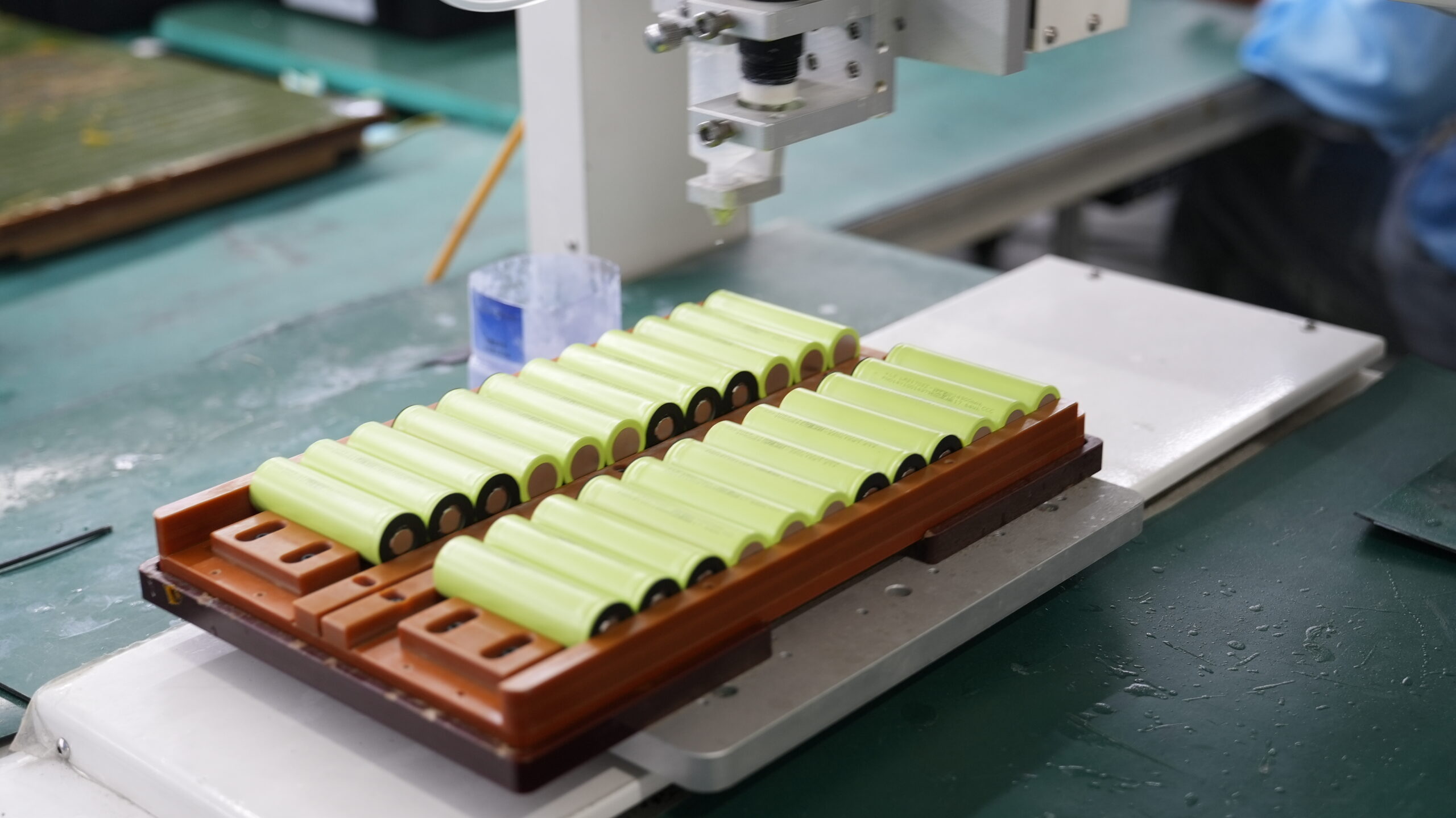

You rely on medical device battery safety to deliver consistent care in clinical environments. When you choose a high-quality lithium battery pack, such as those using LiFePO4 or NMC chemistries, you improve the reliability of your handheld medical devices. Reliable power ensures that devices like infusion pumps, defibrillators, and portable monitors work when you need them most.

Battery safety is essential for the reliability of handheld medical devices as it influences device performance and risk management. Ensuring battery reliability helps reduce the risks of device failures, which is critical for maintaining patient safety.

A dependable medical device battery reduces the risk of sudden power loss. This reliability supports your ability to respond quickly during emergencies. You can trust that your medical devices will function as intended, even in demanding situations.

Mitigating the risk of battery and product failure due to manufacturing defects and environmental factors is vital for medical device manufacturers, as it directly relates to patient safety.

1.2 Incident Examples

You may have seen reports of medical device battery failures causing serious incidents. In 2022, the FDA received over 1,000 reports of adverse events linked to battery-powered medical devices. Many of these incidents involved lithium-ion battery packs overheating or losing charge unexpectedly. These failures led to device shutdowns during patient care, which put patients at risk.

Medical device battery reliability remains a top concern for manufacturers and healthcare providers. Even a single battery failure can disrupt patient monitoring or delay treatment. You must select medical-grade batteries that meet strict standards for safety and reliability.

Exponent’s multidisciplinary teams offer medical device manufacturers extensive support for battery selection and evaluation, which is crucial for ensuring the safety and reliability of medical devices in clinical settings.

You can see how the right medical device battery choice protects both your patients and your reputation. Reliable batteries help you avoid costly recalls and maintain trust in your medical devices. With over 20 years of expertise, Large Power provides reliable custom medical battery solutions. Consult Large Power today for your tailored project.

Part 2: Lithium-Ion Batteries and Key Risks

Lithium-ion batteries power a wide range of medical devices, from portable monitors to infusion pumps. You depend on these batteries for reliable performance in critical healthcare settings. Understanding the risks and safety features of lithium-ion batteries helps you make informed decisions for your equipment and your patients.

2.1 Overheating and Fire

Lithium-ion batteries offer high energy density and long cycle life, making them a popular choice for medical devices, robotics, security systems, and industrial applications. However, you must recognize the risk of overheating and fire. When lithium-ion batteries overheat, they can enter a dangerous state called thermal runaway. This process can lead to fires or even explosions, especially if the battery pack design does not include proper safety features.

You can reduce the risk of overheating and fire by choosing lithium-ion batteries with advanced safety features. These features include:

Pressure-relief devices that release excess pressure safely

Positive temperature coefficient (PTC) resistors that act as fuses to prevent overheating

Battery Management Systems (BMS) that monitor voltage, current, and temperature

Improved battery pack design to minimize heat buildup and thermal propagation

Use of safer chemistries like Lithium Iron Phosphate (LiFePO4), which have higher thermal stability

Over 25,000 incidents of overheating or fire hazards were reported involving more than 400 types of consumer products from 2012 to 2017. Waste facilities also experienced 245 fires likely caused by lithium-ion batteries between 2013 and 2020.

You can see how these incidents highlight the importance of robust safety features in lithium-ion battery packs for medical devices. By selecting batteries with these protections, you help prevent catastrophic failures and protect both patients and equipment.

2.2 Leakage and Chemical Exposure

Lithium-ion batteries contain chemicals that can pose serious health risks if they leak. In medical devices, a leaking battery can expose patients and healthcare workers to harmful substances. You need to understand the potential health effects of chemical exposure from lithium-ion batteries.

Health Risks | Description |

|---|---|

Chronic respiratory illnesses | May develop or be exacerbated, such as asthma or bronchitis. |

Heavy metal accumulation | Can cause neurological problems. |

Increased cancer risk | Potential long-term consequence of exposure. |

Cardiovascular strain | Resulting from repeated inhalation of fine particulate matter. |

Skin and eye damage | Possible recurring rashes or corneal damage. |

You may notice symptoms such as:

Difficulty breathing

Chest pain or tightness

Persistent coughing

Nausea or vomiting

Dizziness or confusion

Burning in the eyes or throat

Worsening of pre-existing chronic respiratory conditions

You must handle lithium-ion batteries with care and follow strict protocols for storage and disposal. Proper battery management reduces the risk of leaks and protects everyone in the clinical environment.

2.3 Power Loss and Device Failure

Power loss in lithium-ion batteries can lead to sudden device failure. In medical devices, this risk can interrupt patient monitoring, delay treatment, or cause life-threatening situations. You need to select lithium-ion batteries with reliable safety features to minimize the risk of unexpected shutdowns.

Battery Management Systems (BMS) play a key role in preventing power loss. A BMS monitors the battery’s voltage, current, and temperature, ensuring safe operation and extending battery life.

You should also consider the battery chemistry when choosing lithium-ion batteries for medical devices. For example, LiFePO4 batteries offer higher thermal stability and longer cycle life compared to NMC or LCO chemistries. This makes them a safer choice for critical applications in healthcare, robotics, and security systems.

Here is a comparison of common lithium-ion battery chemistries used in medical devices:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Thermal Stability | Typical Applications |

|---|---|---|---|---|---|

LiFePO4 | 3.2 | 90-120 | 2000+ | High | Medical, robotics, security |

NMC | 3.7 | 150-220 | 1000-2000 | Moderate | Medical, industrial, infrastructure |

LCO | 3.7 | 150-200 | 500-1000 | Low | Consumer electronics |

LMO | 3.7 | 100-150 | 300-700 | Moderate | Power tools, industrial |

LTO | 2.4 | 70-80 | 5000+ | Very High | Industrial, infrastructure |

You can see that selecting the right lithium-ion battery chemistry and safety features helps you reduce the risk of power loss and device failure. This ensures your medical devices remain reliable and safe for patient care.

Part 3: Medical Device Battery Standards

3.1 Regulatory Overview

You must understand the regulatory standards that govern medical device battery safety. These standards protect patients and ensure reliable performance in medical equipment. The FDA and IEC set strict requirements for medical devices, including lithium battery packs. You need to follow IEC 62133 for rechargeable batteries, UL 2054 for general safety, and ISO 13485 for quality management. IEC 60601-1 covers electrical safety for medical equipment. The EU Medical Device Regulation (MDR) also sets essential safety and performance requirements.

You should pay attention to conflict minerals regulations when sourcing batteries. Learn more about responsible sourcing in our conflict minerals statement.

You see these standards applied to battery selection for devices in medical, robotics, and security systems. Regulatory compliance helps you avoid device failures and supports effective failure analysis.

3.2 Compliance for Manufacturers

You must meet several compliance steps to ensure your medical device battery meets regulatory standards. Manufacturers need to design batteries with overcharge protection, thermal shutdown, battery management systems, and battery health monitoring systems. You must also ensure biocompatibility and serialization for traceability. Quality management systems like ISO 13485 guide the design and manufacturing process.

Here is a summary of compliance requirements for medical device battery manufacturers:

Requirement | Description |

|---|---|

FDA General Safety and Performance Requirements | Batteries must meet safety requirements of IEC 62133, UL 2054, ISO 13485, and IEC 60601-1. |

Biocompatibility | Batteries must be biocompatible and have safety features for use near patients. |

Serialization | Batteries must be serialized and traceable to prevent counterfeiting. |

EU Medical Device Regulation | Batteries must comply with essential safety and performance requirements of the MDR (Annex I). |

Quality Management System | Batteries must be designed and manufactured according to ISO 13485. |

Additional Testing | Batteries used in implantable devices may have extra safety and performance requirements. |

You need to perform thorough failure analysis to identify risks and improve battery technology. You should select battery chemistries like LiFePO4 or NMC for better safety and reliability. Battery selection impacts device performance and regulatory compliance. You must monitor battery health and maintain records for traceability. These steps help you deliver safe and effective medical devices for clinical use.

Overcharge protection

Thermal shutdown

Battery management systems

Battery health monitoring systems

You see how regulatory compliance and robust battery technology support safe medical equipment. You improve patient safety and reduce the risk of device failure through careful battery selection and ongoing failure analysis.

Part 4: Best Practices and Innovations

4.1 Battery Selection and Sourcing

You need to select the right medical grade battery for your devices to ensure safety and performance. When you choose batteries for portable medical equipment, focus on these criteria:

Reliability and durability under various conditions

High energy density and long lifespan, especially for devices that require years of service

Safety from leaks, explosions, and compliance with biocompatibility standards

Full regulatory compliance, including ISO 13485

Sourcing practices play a major role in the quality of battery-powered medical devices. You should work with suppliers who prioritize design, manufacturing, and testing. Reliable power sources depend on strict quality control and traceable supply chains. Early battery depletion or device failure can put patient safety at risk.

Never underestimate the energy stored in a medical grade battery. Always follow safety practices during design and sourcing.

4.2 Charging and Handling

Proper charging and handling of medical grade battery packs protect your devices and patients. You should:

Purchase devices and chargers from reputable sources with UL or ETL marks

Use only manufacturer-approved chargers and follow all instructions

Charge devices in safe, ventilated locations—never under bedding or near flammable materials

Store batteries at room temperature, away from direct sunlight

The table below summarizes key fire safety measures for handling lithium battery packs in healthcare environments:

Fire Safety Measure | Description |

|---|---|

Lithium-ion-specific fire extinguishers | Address unique hazards of lithium battery fires |

Routine inspection and maintenance | Check for wear, damage, or swelling |

Safe charging and storage practices | Train staff to avoid overheating and fires |

Compliance with fire safety regulations | Meet all legal and safety requirements |

Collaboration with fire safety experts | Maintain robust protocols with professional input |

Education and preparedness | Train staff on dangers and emergency response |

4.3 Maintenance Protocols

You must establish strict maintenance protocols for all medical grade battery packs in your devices. Regular testing helps you detect early signs of wear, swelling, or damage. Schedule inspections and replace batteries before they reach end-of-life. Keep detailed records of all maintenance and testing activities for traceability and compliance. Training your staff on safe handling and emergency procedures reduces risks in clinical settings.

4.4 Technology Advances

Recent advances in battery technology have improved the safety and performance of portable medical equipment. You now have access to alternatives like nickel-metal hydride and silver-zinc batteries, which offer unique benefits for specific applications. Solid-state batteries provide higher energy density and longer cycle life, making them ideal for compact devices. Modern lithium-ion chemistries such as LiFePO4 and NMC deliver advanced safety features, including protective circuitry and improved electrolytes.

Smart safety features in today’s medical grade battery packs include:

Safety Feature | Description | Importance in Medical Devices |

|---|---|---|

Protection Circuits | Prevent overcharging, over-discharging, and short circuits | Ensure safe operation of critical devices |

Overheating Prevention | Minimize dangers of overheating and explosion | Maintain stable performance over long periods |

Reduced Risk of Failure | Continuous improvements lower the risk of device failure | Essential for life-supporting and monitoring devices |

You can learn more about battery management systems and their role in device safety here.

As battery technology evolves, you gain safer, more reliable power sources for your battery-powered medical devices.

You play a vital role in ensuring battery safety and biocompatibility in handheld medical devices. You can strengthen risk management by maintaining batteries at optimal capacity, performing spot checks, and using battery analyzers. You support risk assessment through ongoing education, such as community outreach led by medical associations. You benefit from research on lithium-based batteries, including LiFePO4 and NMC, which improves safety in medical, robotics, and security systems.

Stay vigilant and adopt new safety technologies to protect patients and advance device reliability.

Replace batteries at the right capacity level.

Monitor battery health regularly.

Promote safety awareness among healthcare teams.

FAQ

What are the main safety features in lithium battery packs for medical devices?

You find key safety features such as overcharge protection, thermal shutdown, and battery management systems. These features help prevent overheating, fire, and device failure in medical, robotics, and security systems.

How do lithium battery chemistries compare for medical applications?

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Thermal Stability | Typical Applications |

|---|---|---|---|---|---|

LiFePO4 | 3.2 | 90-120 | 2000+ | High | |

NMC | 150-220 | 1000-2000 | Moderate | ||

LCO | 3.7 | 150-200 | 500-1000 | Low |

Why should you choose medical-grade lithium battery packs over consumer-grade options?

You gain higher reliability, longer lifespan, and better safety with medical-grade lithium battery packs. These packs meet strict standards for medical, robotics, and security systems, reducing risks of device failure and chemical exposure.

What maintenance protocols help extend battery life in handheld medical equipment?

You should schedule regular inspections, replace batteries before end-of-life, and train staff on safe handling. These steps help maintain optimal performance in medical, industrial, and infrastructure devices.

How do smart safety features improve lithium battery pack reliability?

You benefit from protection circuits, temperature monitoring, and advanced battery management systems. These smart features reduce risks of overheating, fire, and sudden power loss in medical, robotics, and security applications.