You need reliable Battery Solutions to keep your security patrol robots running efficiently. Lithium-ion battery packs, such as the 36V 20Ah NMC Battery, deliver high energy density and long lifespan for demanding environments. Custom battery packs offer flexibility for unique electrical needs. Automatic charging stations help maintain continuous operation. When you select batteries, focus on durability, future-proofing, and operational reliability to support autonomous patrols in harsh conditions.

Key Takeaways

Choose lithium-ion batteries for high energy density and long lifespan. Models like the Panasonic 18650 36V 20Ah NMC Battery are ideal for extended patrols.

Consider custom battery packs to meet specific operational needs. These packs enhance safety and efficiency in various environments.

Utilize automatic charging stations to maintain continuous operation. This reduces downtime and supports ongoing surveillance for security robots.

Prioritize safety features in battery packs, such as Battery Management Systems (BMS) and thermal sensors, to prevent overheating and ensure reliable performance.

Implement smart charging practices to extend battery life. Recharge when the battery reaches 20%-30% power and calibrate regularly for optimal performance.

Part 1: Battery Solutions

Security patrol robots rely on advanced Battery Solutions to deliver reliable, long-lasting power in demanding environments. You need to understand the strengths and limitations of each battery type to select the best option for your application.

1.1 Lithium-ion Batteries

Lithium-ion batteries dominate the market for security patrol robots. You benefit from their high energy density, lightweight design, and fast charging capabilities. These batteries support continuous monitoring and extended patrol times, making them ideal for autonomous robots in security, medical, and industrial sectors.

Tip: Choose lithium-ion battery packs like the 36V 20Ah NMC Battery, 25.2V 60Ah, or 96V 300Ah models for high-capacity, long-duration patrols.

Characteristic | Description |

|---|---|

Lightweight Design | Enhances robot mobility and energy efficiency, crucial for frequent movement. |

Fast Charging | Achieves 80% charge in just 15 minutes, reducing downtime. |

Low Maintenance | Endures over 3,000 charge/discharge cycles with minimal upkeep. |

High Energy Density | Provides long runtime and supports compact robot designs. |

You can see the technical comparison of lithium battery chemistries below:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

NMC | 3.6-3.7V | 150-220 | 1000-2000 | Security robots, medical devices, industrial automation |

LiFePO4 | 3.2V | 90-160 | 2000-4000 | Infrastructure, grid storage, robotics |

LCO | 3.6-3.7V | 150-200 | 500-1000 | Consumer electronics |

LMO | 3.7V | 100-150 | 300-700 | Power tools, some medical equipment |

LTO | 2.4V | 70-110 | 7000-20000 | Industrial, infrastructure, specialty robotics |

Solid-state | 3.7V+ | 250-500 | 2000-5000 | Next-gen medical, security, consumer electronics |

Lithium metal | 3.7V+ | 400+ | 1000-2000 | Advanced robotics, aerospace, medical |

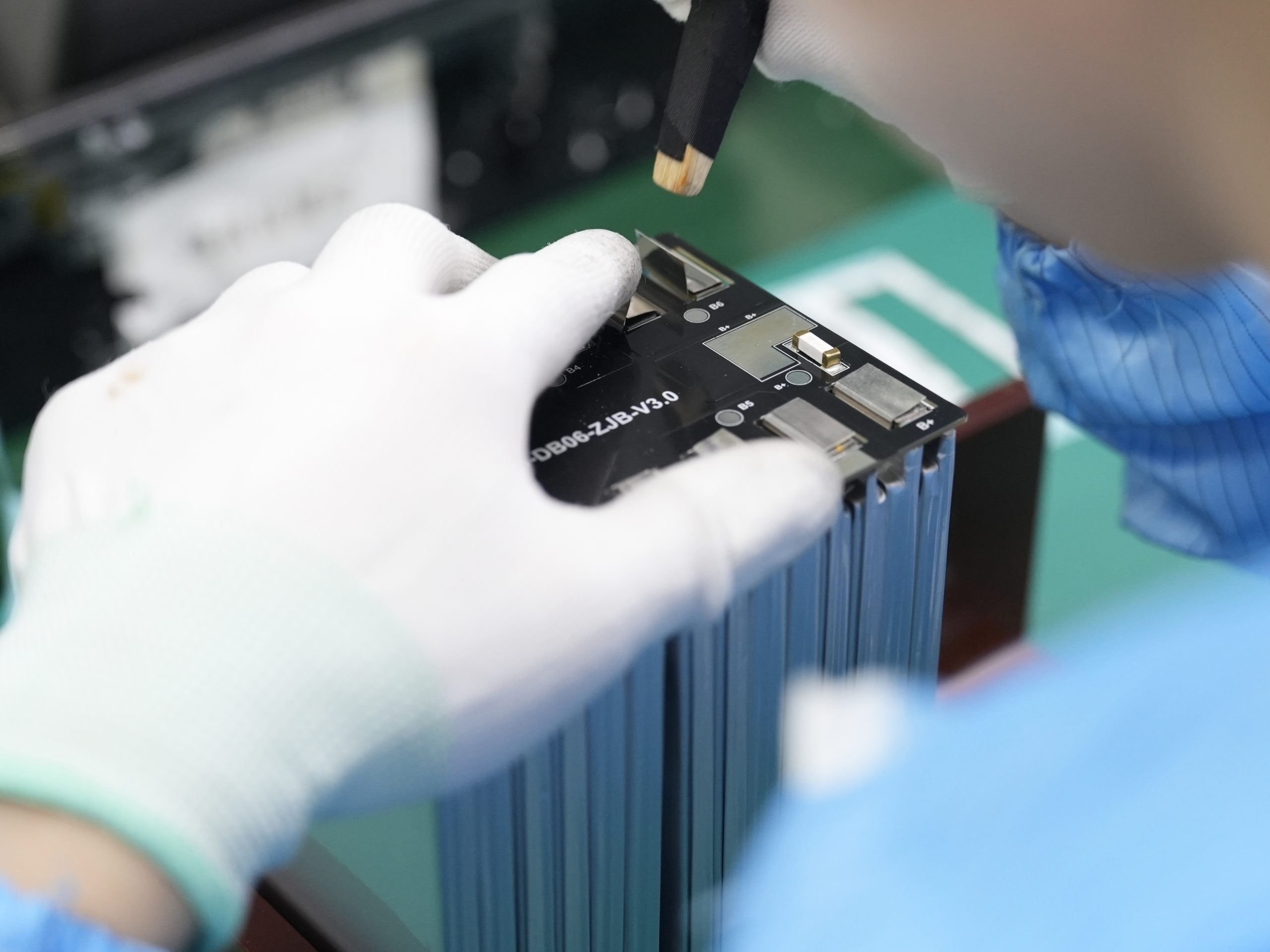

You gain flexibility with custom battery packs. These packs meet specific electrical and operational requirements, such as extreme temperature performance or high power density. Custom Battery Solutions improve safety and efficiency in various environments, including refrigerated warehouses and outdoor patrols.

1.2 Nickel-Metal Hydride

Nickel-metal hydride (NiMH) batteries offer a balance of cost and performance. You may choose NiMH for applications where environmental friendliness and moderate capacity are priorities. These batteries are heavier and have lower energy density than lithium-ion, but they remain popular in service robots and infrastructure systems.

Battery Type | Advantages | Disadvantages |

|---|---|---|

Nickel-Metal Hydride | More environmentally friendly than NiCd batteries. | Higher self-discharge rate compared to Li-ion. |

Good balance of cost and performance. | Heavier and lower energy density than Li-ion. | |

Higher capacity than alkaline batteries. | Performance can decrease in cold temperatures. | |

Lithium-Ion | High energy density ideal for portable electronics and robotics. | More expensive to manufacture. |

Can be recharged hundreds to thousands of times. | Requires protection circuits for safe operation. | |

Supports fast charging. | Performance can degrade faster if exposed to high temperatures. |

You can recharge lower capacity NiMH batteries up to 1,000 times in slow charge mode. Higher capacity batteries support fewer cycles, especially with quick charging. NiMH batteries require more maintenance and may not perform well in cold environments.

1.3 Lead-Acid

Lead-acid batteries remain a reliable and cost-effective choice for industrial and service robots. You may select lead-acid for applications where robustness and high power output matter more than energy density. Enhanced flooded batteries (EFB) and absorbed glass mat (AGM) models improve performance and longevity.

Lead-acid batteries provide high power output and durability.

They are less cost-effective in the long run due to higher maintenance and replacement costs compared to lithium batteries.

Innovations like EFB and AGM increase their competitiveness in the robot battery market.

You should consider lead-acid batteries for stationary robots or backup power systems in infrastructure and security settings.

1.4 Emerging Technologies

Emerging Battery Solutions focus on sustainability, efficiency, and future-proofing. You can explore alternatives like solar-powered and hybrid robots for operational flexibility. New technologies such as Nyobolt batteries and ultracapacitors promise significant improvements in energy capacity, weight, and cycle life.

Feature | Current Technology (Ultracapacitors) | New Technology (Nyobolt) |

|---|---|---|

Energy Capacity | N/A | 6 times more |

Weight | N/A | 40% lighter |

Cycle Life | Traditional Lithium-ion | At least 10 times longer |

DCM DC-DC converters reduce footprint and weight by 70%.

System efficiency improves by 30%, reducing power losses.

Compatibility with future battery technologies ensures long-term value.

High-energy batteries allow security robots to patrol for up to eight hours without rest. Robots can operate autonomously, enhancing effectiveness in continuous monitoring. Automatic charging stations reduce idle time and support ongoing surveillance.

Note: Battery-powered robots are preferred for their reliability and ease of use, especially in environments lacking external power sources. Innovations in battery management systems and energy-efficient components further improve performance and longevity.

Part 2: Selection Factors

Choosing the right Battery Solutions for your security patrol robots requires a careful look at several key factors. You must balance runtime, size, weight, charging methods, and safety to ensure your robots perform reliably in demanding environments. Custom-designed battery packs can support wireless surveillance, smart access control, and alarm systems, giving you flexibility for specialized applications.

2.1 Runtime Needs

You need to match battery capacity and discharge rates to your robot’s operational demands. Higher battery capacity extends patrol time, but also increases weight, which can reduce mobility and efficiency. Discharge rates determine how quickly your robot uses energy, directly affecting performance during tasks like continuous monitoring or rapid response.

Tip: For extended patrols in large facilities, select lithium-ion battery packs with high energy density, such as NMC or LiFePO4 chemistries. These options support longer runtimes without excessive weight.

Battery Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

NMC | 3.6-3.7V | 150-220 | 1000-2000 | Security robots, medical devices, industrial automation |

LiFePO4 | 3.2V | 90-160 | 2000-4000 | Infrastructure, grid storage, robotics |

LCO | 3.6-3.7V | 150-200 | 500-1000 | Consumer electronics |

LMO | 3.7V | 100-150 | 300-700 | Power tools, medical equipment |

LTO | 2.4V | 70-110 | 7000-20000 | Industrial, infrastructure, specialty robotics |

Solid-state | 3.7V+ | 250-500 | 2000-5000 | Next-gen medical, security, consumer electronics |

Lithium metal | 3.7V+ | 400+ | 1000-2000 | Advanced robotics, aerospace, medical |

You can tailor custom battery packs to meet the specific runtime needs of wireless surveillance systems and smart access control. This approach helps you maximize uptime for critical security tasks.

2.2 Size and Weight

You must consider size and weight constraints when selecting batteries for your robots. These factors affect robot design, mobility, and the ability to add future sensors or technologies.

Energy density impacts the size and weight of your battery pack.

NMC and LiFePO4 chemistries offer high energy density, which helps you minimize battery size and weight.

Smaller robots need compact, lightweight batteries to maintain agility, while larger robots may prioritize cycle life and robustness.

Note: Compact power supplies allow you to integrate advanced sensors and communication modules as your security needs evolve.

Robot Size | Battery Chemistry | Energy Density | Design Priority | Application Scenario |

|---|---|---|---|---|

Small | NMC, LiFePO4 | High | Minimize weight/size | Indoor patrol, surveillance |

Medium/Large | LiFePO4, LTO | Moderate | Maximize cycle life | Outdoor patrol, infrastructure |

2.3 Charging Methods

You need efficient charging methods to keep your robots operational around the clock. Automatic charging stations play a vital role in supporting continuous operation and reducing downtime.

Feature/Benefit | Description |

|---|---|

High-wattage AC-DC charging | Enables rapid charge cycles for security robots. |

Continuous patrolling | Keeps robots active without downtime. |

Reduced staffing | Autonomous charging minimizes human intervention. |

You can choose from several charging methods:

Contact-Based Charging:

Guided plate-to-plate

Automated connections

Battery swapping

Wireless Charging:

Magnetic resonance charging

Wireless charging solutions offer increased uptime and improved efficiency. You eliminate the need for physical connections, which reduces maintenance and simplifies operations. Wireless systems optimize energy consumption, though traditional charging docks may be more efficient in some scenarios.

Tip: Automatic charging stations help you maintain continuous surveillance and reduce labor costs. For more on sustainability in charging infrastructure, visit Our Approach to Sustainability.

2.4 Safety

You must prioritize safety features in your battery packs to prevent overheating and fire hazards. Battery management systems (BMS) monitor battery conditions and protect against dangerous events.

Safety Feature | Description |

|---|---|

Monitors battery conditions to prevent overheating and fire hazards. | |

Thermal Management | Controls battery temperature through heating, cooling, and air conditioning systems. |

Fire Protection | Alerts and takes immediate measures to prevent fire if overheating occurs. |

Short Circuit Prevention | Prevents short circuits and ground faults to enhance safety. |

Use of Flame Retardants | Incorporates materials that prevent thermal runaway and short circuits. |

Temperature Sensors | Monitors battery temperature to ensure compliance with preset limits. |

Battery management systems provide overcharge and over-discharge protection, short-circuit prevention, real-time monitoring, and thermal sensors. These features extend battery life and maintain safe operation.

Safety Feature | Function |

|---|---|

Overcharge Protection | Prevents the battery from exceeding voltage limits, avoiding overheating and thermal runaway. |

Over-discharge Protection | Stops the battery from dropping below safe voltage levels, preserving cycle life and performance. |

Short-circuit Protection | Prevents dangerous short-circuit events that could lead to battery failure or safety hazards. |

Real-time Monitoring | Continuously checks battery status to adapt to safety standards and prevent hazardous conditions. |

Thermal Sensors | Monitors battery temperature to prevent overheating or excessive cooling. |

Voltage Protection Mechanisms | Ensures the battery does not exceed voltage limits during charging. |

Current Protection Systems | Monitors and controls current flow to prevent overcurrent situations. |

⚠️ Always verify that your battery packs comply with safety standards and use certified components. For information on conflict minerals in battery manufacturing, visit Conflict Minerals Statement.

Part 3: Battery Management

3.1 Monitoring

You need to monitor battery health to keep your security patrol robots running efficiently. Battery management systems (BMS) play a key role in this process. BMS tracks voltage, temperature, and charge cycles for each cell in your lithium battery pack. This technology prevents deep discharge and over-voltage, which protects your robots from unexpected shutdowns.

Tip: Regular calibration helps maintain accurate power readings. You should fully charge the battery, run it until nearly empty, and then recharge it. This resets the internal monitoring system and ensures your robot uses its full battery capacity.

Monitoring Feature | Benefit | Application Scenario |

|---|---|---|

Voltage Tracking | Prevents overcharge and deep discharge | Security, medical, industrial robots |

Temperature Sensors | Avoids overheating and fire hazards | Infrastructure, robotics |

Cycle Count | Schedules timely maintenance | Security patrol, consumer electronics |

3.2 Charging Practices

You can extend battery lifespan and minimize downtime by following best charging practices. Smart charging systems and BMS optimize charging cycles and keep your lithium battery packs healthy.

Recharge when battery reaches 20%-30% power to reduce wear.

Unplug the charger after full charge to prevent overcharging.

Use smart charging systems for efficient energy management.

Store batteries at 50% charge during long breaks.

Calibrate batteries regularly for accurate performance.

Smart chargers regulate voltage and current, which ensures uniform charging across all cells. This process reduces the risk of cell imbalance and extends battery life.

⚡ Efficient charging practices help you maintain continuous operation in security, medical, and industrial robots.

3.3 Replacement & Recycling

You should replace batteries during scheduled preventative maintenance. Most experts recommend replacing lithium battery packs at least once a year. This practice prevents unexpected power failures and supports reliable robot operation. For backup batteries in mechanical units, check and replace them every 1.5 years or after about 5,760 hours of use.

Battery Type | Recommended Replacement Interval | Application Scenario |

|---|---|---|

Lithium-ion | 1 year | Security, medical, robotics |

Backup Battery | 1.5 years / 5,760 hours | Infrastructure, industrial |

You can support sustainability by recycling used batteries. Many manufacturers offer recycling programs for lithium battery packs. Recycling reduces environmental impact and supports responsible resource management. Learn more about sustainable battery practices at Our Approach to Sustainability.

♻️ Recycling batteries helps you meet environmental standards and maintain a responsible business image.

Part 4: Real-World Use

4.1 Case Studies

You can see the impact of advanced battery solutions in real-world security patrol robots through measurable results. Organizations that deploy robots powered by lithium battery packs, such as NMC or LiFePO4 chemistries, report significant improvements in operational efficiency and security outcomes. These robots perform continuous patrols in large facilities, infrastructure sites, and industrial environments.

The following table highlights key performance metrics from recent deployments:

Metric | Value |

|---|---|

Year-over-Year mission count increase | 385% |

Security alarms cleared | 819 |

Crime index reduction | 13% (from 19.0 to 16.6) |

Total flight hours | 1,130.5 |

Autonomous landing success rate | >90% |

Downtime for battery swap | <5 minutes |

Downtime for inductive charging | ~40 minutes |

You benefit from high-capacity lithium battery packs that support long patrol times and rapid charging. Robots equipped with these batteries clear more alarms and reduce crime rates. Fast battery swaps and inductive charging minimize downtime, keeping your security systems active.

Note: Reliable battery performance enables robots to operate in demanding sectors, including medical facilities, industrial plants, and critical infrastructure.

4.2 Expert Tips

The table below summarizes proven approaches:

Recommendation Type | Description |

|---|---|

Intelligent Charging Strategies | Effective health monitoring prevents unexpected power loss and keeps robots ready for continuous operation. |

Predictive Maintenance Techniques | Data analytics and machine learning optimize battery charging and maintenance schedules, reducing unexpected breakdowns. |

Hybrid Machine Learning Framework | High accuracy in anomaly detection allows for proactive maintenance and longer battery life. |

You should implement intelligent charging systems that monitor battery health in real time. Predictive maintenance uses data to schedule charging and replacement before failures occur. Hybrid machine learning frameworks detect anomalies early, so you can address issues before they disrupt operations.

🛡️ Proactive battery management ensures your security robots deliver reliable performance in every patrol mission.

You gain the most value from lithium-ion and custom battery packs when you select Battery Solutions for security patrol robots. Focus on factors that drive uptime, safety, and operational efficiency. The table below highlights essential considerations for future-proofing your systems:

Description | |

|---|---|

Customization | Tailor battery packs for voltage, capacity, and form factor needs. |

Support growth from prototype to mass production. | |

Compliance | Ensure certifications for safety and market access. |

Energy Density | Choose solid-state for higher energy and rapid charging. |

Safety | Use advanced BMS to monitor cell health and prevent overcharging. |

Thermal Management | Maintain optimal performance and battery longevity. |

Advanced Technologies | AI-optimized BMS adapts to usage patterns for longer life. |

Consider integrating automatic charging stations and planning for advanced technologies to keep your security robots ready for evolving operational demands.

FAQ

What lithium battery chemistry works best for security patrol robots?

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenario |

|---|---|---|---|

NMC | 150-220 | 1000-2000 | Security, medical, robotics |

90-160 | 2000-4000 | Infrastructure, robotics |

You should choose NMC for high energy density or LiFePO4 for long cycle life.

How do automatic charging stations improve robot uptime?

Automatic charging stations keep your robots ready for patrol. You reduce downtime and avoid manual battery swaps. Robots dock themselves and recharge quickly, supporting continuous operation in security, medical, and industrial environments.

What safety features should you look for in lithium battery packs?

Thermal sensors

Overcharge protection

Short-circuit prevention

You protect your robots and facilities by choosing packs with these features.

How often should you replace lithium battery packs in security robots?

Battery Type | Replacement Interval | Application Scenario |

|---|---|---|

Lithium-ion | 1 year | Security, medical, robotics |

Backup Battery | 1.5 years | Infrastructure, industrial |

You maintain reliability by following these intervals.

Can you customize lithium battery packs for specific robot applications?

🛠️ Yes, you can request custom packs for voltage, capacity, and form factor. Customization supports wireless surveillance, smart access control, and alarm systems for robotics.