Battery manufacturers in the USA currently employ 34,891 workers across 292 companies, generating combined sales of $52 billion. The domestic battery manufacturing sector demonstrates concentrated regional production, with 32% of operations located in the South.

Battery manufacturers in the USA currently employ 34,891 workers across 292 companies, generating combined sales of $52 billion. The domestic battery manufacturing sector demonstrates concentrated regional production, with 32% of operations located in the South.

Electric vehicle market projections indicate sales increases exceeding 35% in 2023, creating expanded demand for domestic battery production capabilities. The U.S. represents approximately 6% of global battery manufacturing capacity, indicating significant potential for domestic production expansion.

Battery manufacturing in America spans from established operations like East Penn Manufacturing, founded in 1946 with initial production of five battery types, to newer facilities such as Stryten Energy’s current 15 GWh annual production capacity. Environmental considerations factor prominently in domestic operations – East Penn’s 2022 lead recycling operations processed 188 million pounds of material.

The selection criteria for these manufacturers focuses on production capacity, technology portfolio, manufacturing scale, and contribution to domestic battery supply chain development. Each company represents specific capabilities within the American battery manufacturing ecosystem, from traditional lead-acid production to advanced lithium-ion cell technologies.

East Penn Manufacturing

Image Source: East Penn Manufacturing

East Penn Manufacturing began operations in 1946 from a single-room creamery facility in Bowers, Pennsylvania, initially producing five automotive battery configurations. The family-owned enterprise has developed into a major battery manufacturing operation with 10,500 employees and 515 distinct product designs.

East Penn Manufacturing company overview

East Penn operates the globally. Manufacturing operations extend across 34 U.S. states and five international markets, with 7,995 employees based in Pennsylvania facilities. The company has received recognition from Forbes as one of America’s Best Large Employers on three occasions and earned designation as one of Pennsylvania’s Best-In-State Employers for 2024.largest single-site lead battery manufacturing facility

The manufacturing process achieves a 99% material recycling rate. East Penn’s automotive battery production line has received Underwriters Laboratories validation for 98% recycled material content allocation – representing the highest UL Recycled Content Validation achieved for battery products worldwide.

East Penn Manufacturing hot products

Production centers on the Deka brand, combining the founders’ names “DeLight” and “Karl”. Battery configurations include:

- Transportation batteries – representing the second-largest Starting, Lighting and Ignition (SLI) battery supplier in North America

- Industrial batteries for material handling applications

- Reserve power systems for telecommunications and uninterruptible power supply requirements

- Specialty applications including wheelchair mobility and renewable energy storage

Manufacturing capabilities encompass flooded, AGM (Absorbed Glass Mat), and Gel battery technologies. Product innovations include UltraBattery and Synergy technologies designed for partial state-of-charge transportation applications.

East Penn Manufacturing news updates

The company introduced the Deka Ready Power product family at ProMat 2025 in Chicago. East Penn achieved certification as the first U.S. lead battery manufacturer to receive UL1973 validation for Reserve Power battery offerings. The Power2Recycle environmental initiative focuses on proper battery recycling procedures.

The Material Handling Equipment Distributors Association (MHEDA) presented East Penn with the MVS (Most Valuable Supplier) Award for 2024 performance.

Tesla

“”Been waiting to acknowledge this great achievement by Tesla’s 4680 Cell Manufacturing team since the end of last year … but as Elon announced last night, our Cell Manufacturing team in Texas reached a huge milestone at the end of 2024 with becoming the lowest cost per kWh battery cell producer for Tesla!”” — Michael Guilfoy, Director of Cell Manufacturing Operations, Tesla

“”Been waiting to acknowledge this great achievement by Tesla’s 4680 Cell Manufacturing team since the end of last year … but as Elon announced last night, our Cell Manufacturing team in Texas reached a huge milestone at the end of 2024 with becoming the lowest cost per kWh battery cell producer for Tesla!”” — Michael Guilfoy, Director of Cell Manufacturing Operations, Tesla

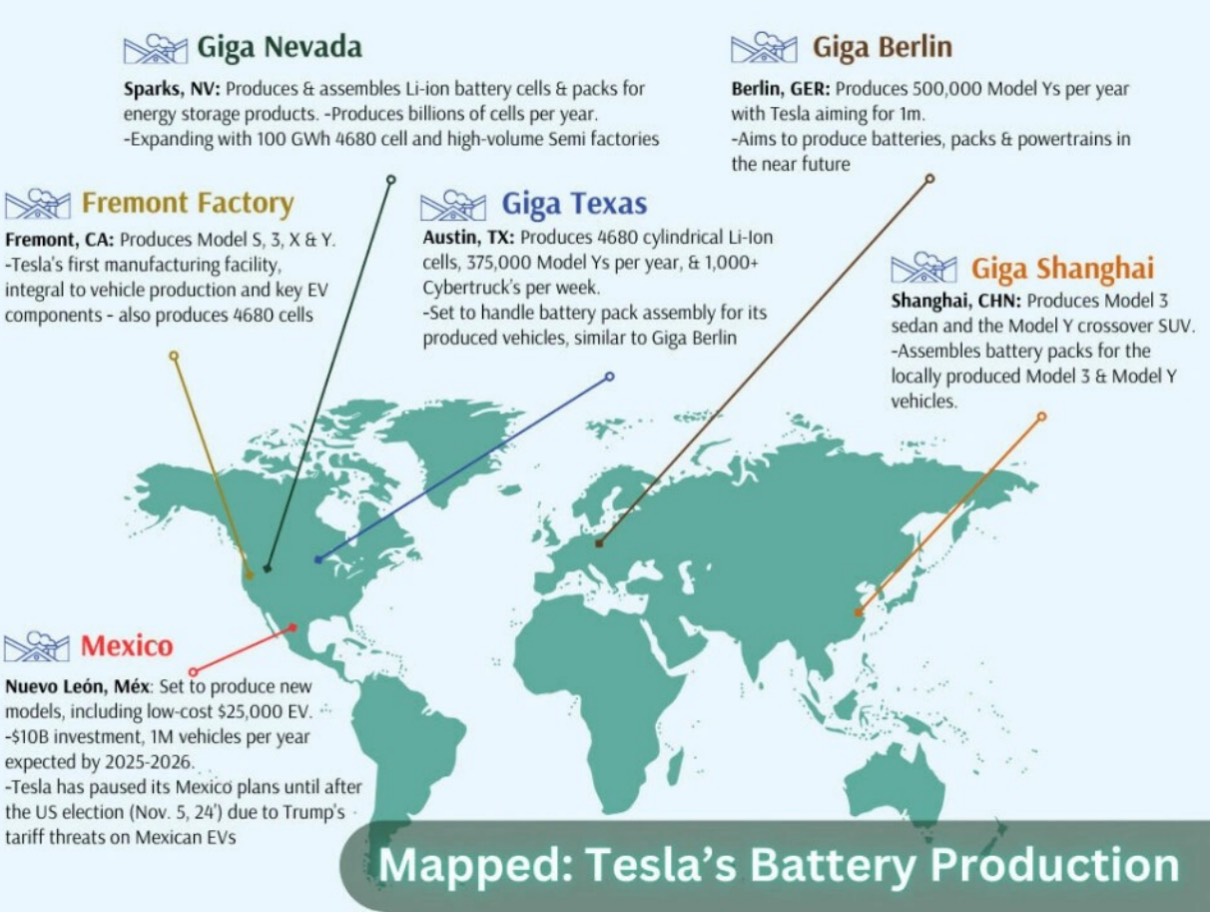

Tesla operates as both a battery manufacturer and consumer, implementing a vertically integrated approach to battery production and deployment. The company’s battery operations function as an integrated power system encompassing cell production, pack assembly, and end-application deployment across transportation and stationary energy storage sectors.

Tesla company overview

Tesla’s domestic battery production centers on , which produces billions of cells annually and ranks among the world’s highest volume plants for electric motors, energy storage products, and vehicle powertrains. The facility is undergoing a $3.6 billion expansion that includes a new 100 GWh 4680 cell factory and Tesla’s first high-volume Semi truck manufacturing line.Gigafactory Nevada

Tesla’s lithium supply chain strategy involves multiple suppliers including Ganfeng Lithium, Arcadium Lithium, and Sichuan Yahua Industrial Group. The company is developing lithium refining capabilities with a new facility in Texas designed to produce 50 GWh of battery-grade lithium annually. This vertical integration approach addresses supply chain vulnerabilities while maintaining control over critical raw material specifications.

Tesla hot products

Tesla’s battery system architecture utilizes chemistry-specific applications optimized for different performance requirements:

Vehicle Battery Systems: Tesla implements Nickel-Cobalt-Aluminum (NCA) chemistry for premium models like the Model S and Model X, developed with Panasonic. Standard-range vehicles utilize , which eliminate cobalt and nickel requirements. The chemistry selection balances energy density, cost, and safety parameters specific to each application.Lithium-Iron-Phosphate (LFP) batteries

Megapack Energy Storage: This utility-scale solution forms the backbone of Tesla Energy’s commercial offerings. Tesla established a dedicated LFP battery facility near Gigafactory Nevada specifically for Megapack production. The system architecture enables utility-scale deployment with integrated power conditioning and thermal management.

Powerwall Residential Storage: Tesla’s home energy storage device has been in production at Gigafactory Nevada since January 2016. Recent Powerwall deployments include Tesla’s first Virtual Power Plant program in the United Kingdom, demonstrating grid-interactive capabilities.

Tesla news updates

Tesla secured a $4.3 billion contract with LG Energy Solution for U.S.-built LFP batteries in July 2024. This three-year agreement commences in August 2027 and addresses Tesla’s energy storage business challenges following tariff increases on battery imports.

Tesla is developing four new versions of its 4680 battery cells for introduction in 2026, including a specialized variant code-named NC05 for robotaxi applications. Manufacturing challenges persist with the dry-coating process, where Tesla reportedly loses 70-80% of cathodes in test production compared to conventional battery makers’ 2% loss rate. Despite manufacturing hurdles, Tesla achieved “lowest cost per kWh battery cell producer” status by the end of 2024.

American Battery Factory

Image Source: americanbatteryfactory.com

American Battery Factory (ABF) addresses a critical gap in domestic battery manufacturing through its focus on Lithium Iron Phosphate (LFP) cell production. The company operates with a strategic mandate to establish entirely U.S.-owned vertical manufacturing facilities for LFP battery cells, positioning itself to reduce dependence on foreign battery supply chains.

American Battery Factory company overview

ABF was established in 2021 with headquarters in American Fork, Utah. The company’s primary manufacturing development centers on the planned for Tucson, Arizona. This 267-acre facility requires a capital investment of $1.20 billion and projects employment for 1,000 workers. Leadership includes Chairman and CEO Zhenfang “Jim” Ge, President John Kem (former Army Major General), and CFO Tyler Hortin.largest U.S. LFP battery cell gigafactory

The strategic importance of ABF’s mission becomes clear when considering that China currently controls approximately 77% of global lithium cell production capacity. This concentration presents both supply chain vulnerabilities and market opportunities for domestic manufacturers focusing on strategic applications.

American Battery Factory hot products

ABF specializes exclusively in , a chemistry that offers specific performance characteristics:prismatic Lithium Iron Phosphate batteries

- Cell longevity exceeds 8,000 life cycles with projected lifespan of 20-30 years • LFP chemistry eliminates cobalt and nickel components, reducing toxic material concerns • Prismatic cell configuration provides enhanced power density and reduced weight compared to cylindrical alternatives

Production targets include applications across utilities, data centers, telecommunications infrastructure, agricultural equipment, and defense systems. The company has established an 18 GWh lithium iron phosphate battery cell offtake agreement with Lion Energy.

American Battery Factory news updates

ABF signed a seven-year Memorandum of Understanding with Tinci Materials Texas LLC in October 2024 to secure supply. This partnership expands ABF’s strategic alliances with companies including Honeywell, LEAD Intelligent Equipment, First Phosphate, Anovion, and Celgard.battery chemical materials

The Arizona gigafactory development progressed through partnership with LEAD Intelligent Equipment in March 2024. Construction began in October 2023, with initial production phases scheduled for 2025 completion.

ABF recently announced partnership with KAN Battery for pilot line development, establishing subsidiary ABF China to utilize a 1GWh factory line for high-capacity prismatic cells. This collaboration aims to accelerate technology transfer and expertise development for U.S. operations.

EnerSys

EnerSys operates as an industrial technology company specializing in with manufacturing operations spanning over a century. The Reading, Pennsylvania-headquartered company serves more than 10,000 customers across 100 countries.stored energy solutions

EnerSys company overview

EnerSys maintains its market position through strategic manufacturing and assembly facilities distributed globally. The company’s 2025 restructuring includes closure of its Monterrey, Mexico plant with production transfer to Richmond, Kentucky, while proceeds at the Bielsko-Biala, Poland facility. This operational realignment addresses market shifts toward higher-performance maintenance-free battery technologies.$4.50 million expansion

The company’s competitive approach centers on total employee involvement, teamwork, and strategic supplier partnerships. EnerSys has developed into a multibillion-dollar enterprise serving diverse industrial sectors requiring reliable stored energy solutions.

EnerSys hot products

The company’s manufacturing capabilities encompass three primary categories:

- Reserve power batteries for telecommunications, utility industries, and uninterruptible power supply systems

- Motive power batteries designed for electric forklift trucks and commercial electric vehicles

- DC power and energy storage systems supporting broadband, telecom, and energy storage applications

Reserve power products are marketed under Alpha, PowerSafe, DataSafe, Hawker, Genesis, ODYSSEY, and CYCLON brands. Motive power offerings carry the Hawker, NexSys, IRONCLAD, and Express designations.

EnerSys news updates

EnerSys received selection for $199.00 million award negotiation to develop a lithium-ion cell gigafactory. The company completed acquisition of Bren-Tronics to expand defense application capabilities.

Recent workforce adjustments affected approximately 575 employees, representing 11% of non-production global staff, primarily targeting corporate and management positions. This strategic realignment positions the company for growth under new leadership.

The company received recognition including the German ESG Transparency Award and placement in TIME World’s Best Companies 2024. These acknowledgments reflect EnerSys’s position within the domestic battery manufacturing sector.

Stryten Energy

Stryten Energy operates from Alpharetta, Georgia, maintaining 11 U.S. manufacturing plants and battery component facilities with 2,500 employees nationwide. The company’s current production capacity reaches 14 gigawatt-hours annually, with expansion plans targeting increases to 24 gigawatts.domestic manufacturing capacity

Stryten Energy Company Overview

The company’s manufacturing strategy emphasizes technology diversification rather than single-chemistry focus. This approach reflects market demands across automotive, industrial, and energy storage applications requiring different performance characteristics. Manufacturing operations span Kansas, Georgia, Iowa, Virginia, Arkansas, Pennsylvania, New York, Indiana, Missouri, and Wisconsin.

Stryten’s vertically integrated supply chain provides battery components to both internal production lines and external U.S. battery manufacturers. This dual-purpose manufacturing model supports broader domestic battery industry development while maintaining internal production capabilities.

Stryten Energy Product Portfolio

The company manufactures three distinct battery technologies:

Advanced Lead Battery Systems: Enhanced Flooded Batteries (EFB) designed for automotive start-stop applications and tubular batteries optimized for material handling equipment.

Lithium-Ion Battery Solutions: Recent Georgia assembly plant expansion supports military and industrial applications requiring high energy density and reliability.

Vanadium Redox Flow Batteries: Technology designed for 4-12 hour energy storage duration, suitable for microgrid applications, utility-scale storage systems, and data center backup power.

Additional offerings include intelligent charging systems and proprietary inCOMMAND energy performance management software for fleet optimization decisions.

Stryten Energy Recent Developments

Stryten announced 10 gigawatts of additional U.S. energy storage manufacturing capacity for 2025, creating manufacturing jobs across existing facilities.

The company established Storion Energy LLC through affiliate Stryten Critical E-Storage LLC, partnering with Largo Inc. to address domestic sourcing of price-competitive electrolytes for vanadium redox flow battery production.

Partnership agreements with Dragonfly Energy expand lithium battery availability to automotive aftermarket and distributor networks. These collaborations maintain focus on domestic production while extending market reach.

Large Power

Large Power is a global leader in , serving as a vital technology partner to U.S.-based OEMs in demanding sectors like industrial automation, medical devices, aerospace, and marine applications. The company distinguishes itself with an engineering-first approach, delivering bespoke power solutions where standard or off-the-shelf products cannot meet the rigorous performance, safety, and environmental requirements of advanced systems.custom-engineered lithium battery packs

Large Power company overview

With a global manufacturing footprint and a dedicated focus on the U.S. market, Large Power provides end-to-end design and production services for custom lithium-ion battery systems. Headquartered in the global electronics hub of Guangdong, China, the company maintains a robust logistics network ensuring reliable delivery to clients across the United States. Its operations are ISO 9001 certified, reflecting a commitment to mature quality management systems essential for industrial and medical-grade products. The core of its business model is collaborative engineering, working directly with U.S. design teams to solve complex power challenges from concept through to mass production.

Large Power hot products

Large Power’s portfolio is centered on application-specific, custom-designed battery packs rather than standard products. Key offerings include:

- Custom Lithium-Ion Packs:Tailored solutions using top-tier LiFePO4 cells for safety and cycle life, or NCM cells for maximum energy density, depending on the application’s needs.

- Ruggedized & Environment-Resistant Designs: Expertise in developing packs with robust enclosures (aluminum, specialized polymers) and high Ingress Protection (IP) ratings, such as IP67 for waterproof and dust-tight performance in harsh industrial or marine environments.

- Advanced Thermal Management: Integration of sophisticated heating and cooling systems (e.g., heating pads, liquid cooling channels, phase-change materials) to ensure optimal performance and safety in extreme temperature ranges.

- Smart Battery Management Systems (BMS): In-house development of “smart” BMS with custom firmware, enabling precise state-of-charge monitoring, active cell balancing, and integration with host devices via communication protocols like CAN bus and SMBus.

Large Power news updates

In 2025, Large Power expanded its U.S.-based engineering support team to provide enhanced, real-time collaboration with American OEMs on complex electrification projects. The company recently achieved UL 2054 certification for its new line of high-reliability medical battery packs, streamlining the compliance process for U.S. medical device manufacturers seeking to export globally. Additionally, Large Power launched a new rapid prototyping program that has been shown to reduce development timelines for U.S. clients by up to 30%, addressing the market’s need for accelerated product launches.

Batteries America

Batteries America operates as a specialized manufacturer serving niche market segments within the domestic battery industry. Founded in 1990 by E.H. Yost & Company in Sauk City, Wisconsin, the company maintains entirely U.S.-based ownership and manufacturing operations focused on .specialized battery products

Batteries America company overview

The company’s Mount Horeb, Wisconsin headquarters coordinates manufacturing, retail, wholesale, and design operations across thousands of battery product specifications. Batteries America’s business model addresses specific power requirements through device compatibility matching rather than mass production volumes, providing customers with battery selection based on equipment model numbers.

Manufacturing warranty coverage extends six months against material and workmanship defects for all company-produced products. Warranty exclusions apply to damage resulting from operational misuse including overcharging, over-discharging, reverse-charging, or physical damage.

Batteries America hot products

The company’s manufacturing portfolio encompasses multiple product categories:

- Power Banks: PB-20K-Qi Solar Power Bank Charger specifications include capacity designed for portable device charging applications20000mAh internal rechargeable Li-Po battery

- Travel Solutions: SL-308 Worldwide AC Travel Charger accommodates international wall outlet standards with 3 USB outputs and 1 Type C charging port

- Smart Chargers: Panasonic brand Smart Charger (BQ-CC17) for AA & AAA NiMH batteries provides independent charging capability for 1-4 cells

- Vehicle Chargers: DC-USB3+1 48W combined output vehicle charger supports phones, tablets, GPS devices, and computers

Batteries America news updates

The company continues serving specialized market segments including amateur radio, aviation, RC hobbies, and medical devices. While large-scale manufacturers focus on billion-dollar production investments, Batteries America maintains market position through where device compatibility and operational reliability requirements exceed standard specifications.tailored solutions for niche applications

Ultium Cells

Ultium Cells operates as a joint venture between General Motors and LG Energy Solution, focusing on domestic battery cell production for . The partnership addresses automotive industry requirements for scaled lithium-ion cell manufacturing within U.S. borders.zero-emissions vehicles

Ultium Cells company overview

Ultium Cells maintains production facilities in Warren, Ohio and Spring Hill, Tennessee, with a third Michigan location under development. The combined facility investment totals $2.50 billion, generating an estimated 6,000 construction positions and 5,100 permanent operations roles. The manufacturing network supports GM’s North American electric vehicle assembly capacity requirements.

Ultium Cells hot products

The company produces large-format pouch cells using nickel-cobalt-manganese-aluminum (NCMA) chemistry. Production technology expansion includes:

- – Cost-optimized chemistry with Tennessee facility production scheduled for late 2027 • Lithium manganese rich (LMR) prismatic cells – Advanced technology providing 33% higher energy density relative to LFP cells at equivalent cost structureLithium iron phosphate (LFP) cells

Ultium Cells news updates

Ultium announced commercial LMR prismatic cell production beginning in 2028. The Tennessee facility achieved UAW contract approval in 2024.

The Ohio manufacturing plant reached production. Ohio facility output projections indicate 100 million cells for 2024, with operational experience from this location informing Tennessee and Michigan plant development.100 million battery cell

U.S. Battery

U.S. Battery has maintained continuous deep cycle battery production since 1926, establishing manufacturing operations across Corona, California, Evans, Georgia, and Augusta, Georgia. The company holds ISO 9001:2005 certification for quality management systems and ISO 14001:2015 environmental certification at its Corona headquarters.

U.S. Battery company overview

The company reported in 2025, reflecting its position within the domestic battery manufacturing sector. U.S. Battery focuses on deep cycle battery technologies, serving applications requiring sustained power delivery over extended discharge periods.annual revenue reached USD 128.20 million

Manufacturing operations span multiple facilities, enabling production of both flooded lead-acid and absorbed glass mat battery technologies. The company’s product development emphasizes cycle life performance and capacity retention characteristics essential for deep discharge applications.

U.S. Battery hot products

U.S. Battery manufactures AGM batteries incorporating absorbed glass mat technology that eliminates electrolyte spillage risks. These valve-regulated designs provide enhanced vibration resistance and incorporate carbon-enhanced negative active material to improve cycle performance. Heavy-duty alloy grids resist corrosion and extend operational life.

The company’s flooded lead-acid batteries utilize XC2™ formulation and Diamond Plate Technology®. This design allows batteries to reach peak capacity in fewer initial cycles, extending overall service life. These batteries achieve 99% recyclability rates.

U.S. Battery news updates

U.S. Battery serves applications including aerial work platforms, floor cleaning equipment, marine installations, renewable energy storage systems, and backup power installations. The company’s deep cycle battery designs address requirements for sustained discharge rates and recovery characteristics essential for these applications.

Product development focuses on optimizing active material formulations and grid designs to maximize capacity retention and cycle life performance across varying discharge patterns and environmental conditions.

24M Technologies

24M Technologies addresses fundamental limitations in lithium-ion battery manufacturing through proprietary process innovations developed from MIT research. Founded in 2010 and headquartered in Cambridge, Massachusetts, the company focuses on eliminating manufacturing inefficiencies that contribute to battery cost and safety challenges.

24M Technologies company overview

24M operates as a technology licensing company with research and development capabilities spanning the U.S., Europe, and Asia. The company’s leadership includes battery industry scientists and entrepreneurs who developed the core technologies during MIT laboratory research. The business model provides resilience against supply chain disruptions through licensed manufacturing partnerships rather than direct production facilities.

Total funding raised reaches $253.83 million across multiple rounds, with strategic investments from KYOCERA, Asahi Kasei, and Mitsui O.S.K. Lines. The investor base reflects industry recognition of 24M’s technological approach to battery manufacturing process improvement.

24M Technologies hot products

The company’s SemiSolid manufacturing platform reduces conventional lithium-ion battery production steps by 50%, achieving cost reductions up to 40%. The technology portfolio addresses critical battery industry challenges:

- Impervio™ separator technology – Designed to prevent thermal runaway and catastrophic battery fires

- Eternalyte™ electrolyte systems – Enable battery designs supporting driving ranges exceeding 1,000 miles

- ETOP™ (Electrode to Pack) architecture – Eliminates traditional cell-to-module-to-pack assembly requirements

- LiForever™ recycling technology – Enables recovery of up to 98% of battery materials

24M Technologies news updates

Fast Company recognized 24M among the World’s Most Innovative Companies for 2025. The company’s Impervio separator technology received a 2025 World Changing Ideas Award for advances in battery fire prevention.

24M announced an expanded Eternalyte electrolyte portfolio in March 2025, targeting improved charge rates and cold temperature battery performance. These developments continue the company’s focus on addressing industry-wide challenges through process innovation rather than incremental chemistry improvements.

American Battery Solutions

American Battery Solutions (ABS) addresses underserved transportation market segments through specialized battery systems. Founded in 2019 by Subhash Dhar, the company operates manufacturing facilities in Lake Orion, Michigan and Springboro, Ohio.

American Battery Solutions company overview

by Komatsu America Corp. established the company as Komatsu’s battery technology center of excellence while maintaining independent operations. The organization employs over 300 workers with collective industry experience exceeding 340 years in high-voltage battery production. Leadership includes former executives from Toyota, General Motors, and BMW.ABS acquisition in December 2023

American Battery Solutions hot products

ABS produces two primary battery system categories:

- Alliance Intelligent Battery Series™ – Low-voltage lithium-ion systems for industrial equipment applications

- Proliance Intelligent Battery Series® – High-voltage propulsion batteries designed for commercial electric vehicles, industrial machinery, and marine applications

The T350-50 system configuration supports series connections up to five packs (708V/520kWh) or parallel arrangements up to ten packs (354V/520kWh).

American Battery Solutions news updates

ABS secured a $132 million contract with TICO for Proliance battery systems in electric terminal tractors during April 2025. The company established a partnership with SCAG Power Equipment for commercial mower applications the same month. Marine Travelift began utilizing ABS battery systems for electric boat hoists in November 2024.

Clarios

Clarios operates as a global leader in advanced low-voltage battery manufacturing, producing over 150 million batteries annually that power one-third of vehicles worldwide. The company maintains operations across more than 100 countries with approximately 16,000 employees.

Clarios company overview

Following its separation from Johnson Controls in 2019, Clarios established independent operations headquartered in Wisconsin. The company operates 16 manufacturing facilities throughout the United States, employing more than 5,500 domestic workers. Clarios manufactures energy storage solutions for automotive applications, heavy-duty vehicles, recreational equipment, and specialized adventure applications across road, snow, and water environments.

Clarios hot products

The company manufactures multiple battery technologies:

- Advanced lead-acid batteries marketed under the OPTIMA, VARTA, and Heliar brands

- Lithium-ion solutions, with production reaching one million 12-volt unitslithium-ion battery

- Supercapacitor systems, recently contracted by major automotive manufacturers

Clarios news updates

Clarios announced a $6 billion investment program spanning ten years to strengthen American manufacturing capabilities in 2025. The investment strategy allocates $2.5 billion for advanced battery expansion, $1.9 billion for critical minerals processing, and $600 million for facility modernization. The company plans to establish a Manufacturing Technology & Training Center focused on workforce development and manufacturing innovation.

SK Battery America

SK Battery America represents foreign investment in domestic battery manufacturing, establishing in Commerce, Georgia and Spring Hill, Tennessee through USD 2.60 billion in capital investment. This SK Innovation subsidiary contributes significant manufacturing capacity to American electric vehicle battery supply chains.state-of-the-art manufacturing facilities

SK Battery America company overview

The company maintains production facilities with combined capacity of 22 GWh, supporting approximately 300,000 electric vehicles annually through battery production. SK Battery America employs over 2,600 workers across its Georgia and Tennessee operations, with broader corporate commitments targeting USD 20.00 billion in U.S. investment by 2025. Strategic supply agreements with automotive manufacturers position the company within domestic battery production networks serving global vehicle platforms.

SK Battery America hot products

SK Battery America specializes in NCM9 battery technology, designated for its nickel, cobalt, and manganese composition with nickel content approaching 90%. The high-nickel formulation provides enhanced energy density characteristics and extended driving range capabilities for electric vehicle applications. Development programs target energy density specifications of 1,000 Wh/L or higher, addressing automotive industry requirements for improved battery performance metrics.

SK Battery America news updates

The parent organization completed a 2025 merger combining SK On with SK Trading International and SK Enterm to strengthen operational capabilities. SK Battery America secured a major supply contract with Nissan covering nearly 100 GWh of for the 2028-2033 period, representing USD 661.00 million in investment and supporting 1,700 U.S. manufacturing positions.high-performance batteries

Conclusion

Domestic battery manufacturing capabilities encompass diverse technologies from traditional lead-acid chemistries to advanced lithium-ion cell production. The manufacturing landscape spans established facilities like East Penn’s single-site operations and emerging gigafactories such as American Battery Factory’s planned Tucson facility.

Battery chemistry selection depends on specific application requirements. Lead-acid technologies from manufacturers like U.S. Battery and Clarios serve applications requiring proven reliability and cost-effectiveness. Lithium-ion solutions from Tesla, Ultium Cells, and SK Battery America address high energy density requirements for electric vehicle and energy storage applications. Specialized technologies like 24M Technologies’ SemiSolid approach and Stryten Energy’s vanadium redox flow batteries target specific performance parameters.

Manufacturing capacity varies significantly across domestic producers. Large-scale operations like Clarios’ 150 million annual battery production and Tesla’s 100 GWh cell factory capacity serve high-volume markets. Specialized manufacturers like American Battery Solutions and Batteries America focus on targeted applications with customized solutions.

Supply chain considerations include domestic content requirements, raw material availability, and production scalability. Companies with established recycling operations, such as East Penn’s 99% recycling rate, offer advantages in material sustainability. Vertically integrated manufacturers provide greater control over production quality and delivery schedules.

Technical specifications must align with application requirements including voltage, capacity, cycle life, temperature range, and safety standards. Battery management system integration capabilities vary among manufacturers, with some offering comprehensive systems and others focusing on cell production.

The domestic battery industry provides alternatives to imported products across multiple market segments. Selection criteria should include manufacturing location, technology roadmap, production capacity, quality certifications, and long-term supply chain stability. Each manufacturer addresses specific market requirements through distinct technological approaches and production capabilities.