Battery management system (BMS) design choices directly shape safety and reliability in medical devices for healthcare. You must address risks unique to lithium battery packs, including fire and electrical faults. Safety features and compliance with standards such as IEC 62133 and ISO 13485 protect healthcare operations.

Key Focus Areas | Description |

|---|---|

BMS Design Feature Matching | Align features with battery chemistry and design |

Compliance Checklist | Verify standards and documentation |

Expert Consultation | Seek guidance for risk assessment and BMS design |

Ongoing Review | Monitor performance and update systems |

Key Takeaways

Prioritize safety features in battery management systems to protect patients and healthcare operations from electrical faults and fire risks.

Implement real-time health checks and predictive diagnostics to monitor battery performance and extend lifespan, ensuring reliability in medical devices.

Maintain thorough documentation and compliance with medical standards to ensure safety and reliability in battery management systems.

Part1: Safety Features In Medical BMS

Safety features form the backbone of reliable battery management system design in medical environments. You must address risks that threaten patient safety and healthcare operations. A robust BMS architecture ensures that lithium battery packs deliver consistent performance and minimize hazards. In medical applications, safety features protect against electrical faults, fire, and insulation failures. You need to implement continuous fault monitoring and strong barriers for electrical safety. These measures help you maintain compliance with healthcare standards and safeguard both patients and staff.

1.1 Electrical Fault Prevention

Electrical faults can disrupt medical devices and compromise patient care. You must identify and address common faults in battery management systems to maintain safety. The following table outlines frequent electrical faults, their causes, and troubleshooting steps:

Fault Description | Possible Cause | Troubleshooting Steps |

|---|---|---|

Entire System Does Not Work After Powering Up | Power supply issues, short circuit or broken wires | Check external power supply and wiring |

BMS Cannot Communicate with ECU | BMU main control module not working | Ensure BMU is powered on and check CAN signal wire |

Unstable Communication Between BMS and ECU | Poor external CAN bus matching | Check bus matching resistors |

Insulation Detection Alarm | Battery or driver leakage | Measure insulation resistance |

Main Relay Does Not Engage After Power-Up | Load detection line not connected | Check load detection line connection |

Incorrect Battery Current Data | Loose or damaged Hall sensor signal wires | Inspect Hall sensor signal wire connections |

Battery Voltage Abnormalities | Faulty voltage sensor | Inspect voltage sensor and wiring |

You must integrate protection circuits into your BMS design to prevent overcharging, over-discharging, and short circuits. These safety features ensure safe operation of critical medical devices. Overheating prevention mechanisms minimize the dangers of explosion and maintain stable performance. Continuous fault monitoring systems provide early detection of anomalies, reducing the risk of severe failures and fires. You gain insights into equipment performance, allowing you to optimize maintenance and prevent unexpected downtime.

1.2 Isolation Monitoring

Isolation monitoring plays a vital role in medical safety. You need to separate electrical circuits in patient care areas from the building’s main system. This isolation minimizes the risk of electrical shock and fire in healthcare facilities. You must employ electrical isolation techniques in devices that have direct contact with patients, such as indwelling catheters. These techniques reduce the current flowing to the patient, protecting them from microshock during device failure or short-circuit conditions.

Hospital isolated power systems prevent faults from affecting patient care equipment.

Isolation ensures separation of high voltage from low voltage, which is crucial for preventing electrical shock.

Insulation safeguards both patients and operators in medical environments.

You must monitor insulation resistance continuously to detect leakage or faults early. Isolation monitoring systems help you comply with medical safety standards and maintain reliable healthcare operations.

1.3 Insulation And Fire Risk Mitigation

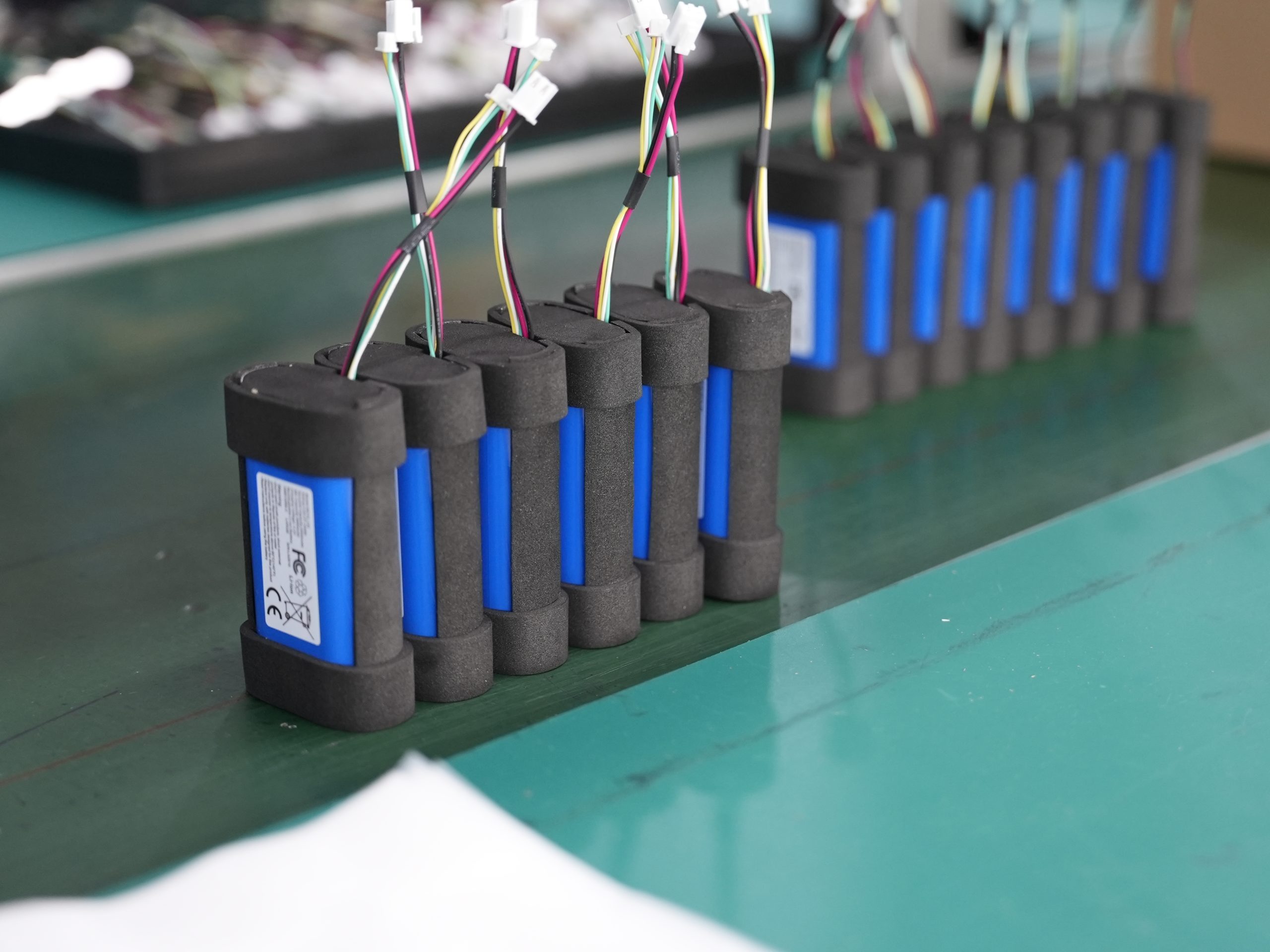

Insulation and fire risk mitigation are essential safety features in medical battery management system design. You must use robust encapsulation and insulation for lithium battery packs to protect against moisture, temperature changes, and mechanical stress. Potting compounds and insulating materials must be biocompatible and comply with biocompatibility standards to avoid adverse reactions in the body.

Biocompatible insulation materials prevent harm to patients and staff.

Encapsulation shields battery packs from environmental hazards in healthcare settings.

Insulation standards require compliance with IEC 62133, UL 2054, ISO 13485, and IEC 60601-1.

You must establish strict maintenance protocols for medical grade battery packs. Regular testing detects early signs of wear, swelling, or damage. Scheduled inspections and timely battery replacement ensure continued safety. Keeping detailed records of maintenance and testing activities supports traceability and regulatory compliance.

Tip: Serialization and traceability of battery packs help you prevent counterfeiting and maintain high safety standards in healthcare.

Safety features in BMS architecture protect medical devices from electrical faults, fire, and insulation failures. You must prioritize these elements in your design to ensure reliable healthcare operations and patient safety.

Part2: Battery Management System Monitoring

2.1 Real-Time Health Checks

You must implement real-time health checks in your battery management system to ensure safety and reliability in medical environments. You monitor voltage levels across individual cells and track current flow during charge and discharge cycles. Real-time processing identifies irregularities and triggers protective measures. Embedded fiber-optic sensors provide advanced monitoring of battery cells, measuring strain and temperature for early failure detection. This approach improves state of charge (SOC) and state of health (SOH) estimations, which are critical for compliance with regulatory standards in healthcare.

Monitoring Technique | Purpose | Benefits | Methodology | Predictive Capability |

|---|---|---|---|---|

Embedded fiber-optic sensors | Real-time monitoring of battery cells | Improved SOC/SOH estimations, early failure detection | Measures strain and temperature within cells | Tracks capacity loss, predicts degradation up to 10 cycles ahead |

You also monitor temperature gradients to prevent thermal runaway, which is essential for safety and regulatory compliance in medical devices.

2.2 Predictive Diagnostics

Predictive diagnostics extend battery life and improve reliability in medical applications. You use advanced algorithms, such as extended Kalman filters and particle filters, to predict the remaining useful life (RUL) of lithium battery packs. These prognostic tools optimize maintenance schedules and reduce lifecycle costs. Fusing diagnostic results enhances reliability and supports compliance with regulatory standards. You gain early warnings about potential failures, which helps you maintain safety and operational continuity in healthcare.

Tip: Predictive diagnostics help you meet regulatory requirements by providing data-driven insights for compliance documentation.

2.3 Cell Balancing For Lithium Packs

Cell balancing is essential for the safe and reliable operation of lithium battery packs in medical devices. You use active cell balancing techniques that leverage Charging State-of-Power (CSoP) and Discharging State-of-Power (DSoP) to address cell imbalance during charging and discharging. This method ensures all cells reach full charge and discharge, which is crucial for reliability and safety in healthcare.

Cell balancing equalizes charge levels among cells, preventing overcharging and over-discharging.

Balanced cells reduce the risk of thermal runaway and support compliance with regulatory standards.

Proper cell balancing extends battery lifespan and improves performance, which is vital for medical applications.

You must prioritize cell selection and balancing in your bms design to maintain compliance, safety, and reliability in healthcare operations.

Part3: Regulatory Compliance

3.1 Medical Device Standards

You must meet strict regulatory standards when you design a battery management system for medical devices. These standards protect patient safety and ensure reliability in healthcare environments. You need to address requirements from organizations such as IEC, ISO, and the FDA. Each standard focuses on different aspects of safety, reliability, and performance for lithium battery packs in medical applications.

ANSI/AAMI ES 60601-1 sets general requirements for basic safety and essential performance in medical devices.

IEC 60086-4 outlines safety tests for lithium batteries, including those used in healthcare.

IEC 62133 covers safety requirements for secondary lithium cells and batteries.

The FDA recognizes standards such as IEC 60086-5 and UL 1642 for battery-powered medical devices.

You must comply with ANSI/AAMI ES 60601-1, which requires risk management and safety assessments. The FDA mandates production in UL-certified facilities, ensuring higher reliability than industrial batteries. Medical batteries must include advanced battery management systems to prevent overheating and overcharging. You need to minimize electromagnetic interference to maintain compatibility with other medical devices. Consistent performance under emergency conditions is essential for life-saving healthcare equipment.

3.2 Documentation And Traceability

You must maintain thorough documentation and traceability throughout the design and manufacturing process. Regulatory compliance depends on your ability to provide detailed records for every stage of production. You need to follow cleanliness and cross-contamination protocols, especially in healthcare settings. You must document all manufacturing activities and implement strict controls to ensure safety and reliability.

Device Class | Risk Level | Examples |

|---|---|---|

Class 1 | Low | Plasters, bandages, wheelchairs |

Class 2A | Medium | Blood pressure monitors, stethoscopes |

Class 2B | High | Contact lenses, X-ray machines |

Class 3 | Very High | Joint replacements, pacemakers |

You must maintain full traceability of each component, from raw materials to finished products. This practice helps you address any issues that arise and supports compliance with ISO 13485 standards. Transparency is essential for verifying compliance with safety standards. You need to prepare technical documentation according to regulations to ensure safety and sustainability. Information must be machine-readable, structured, and searchable to facilitate market surveillance.

Requirement | Description |

|---|---|

Transparency | Essential for verifying compliance with safety standards. |

Technical Documentation | Must be prepared according to regulations to ensure safety and sustainability. |

Information Structuring | Information must be machine-readable, structured, and searchable. |

Tip: Serialization and traceability of lithium battery packs help you prevent counterfeiting and maintain high safety standards in healthcare applications.

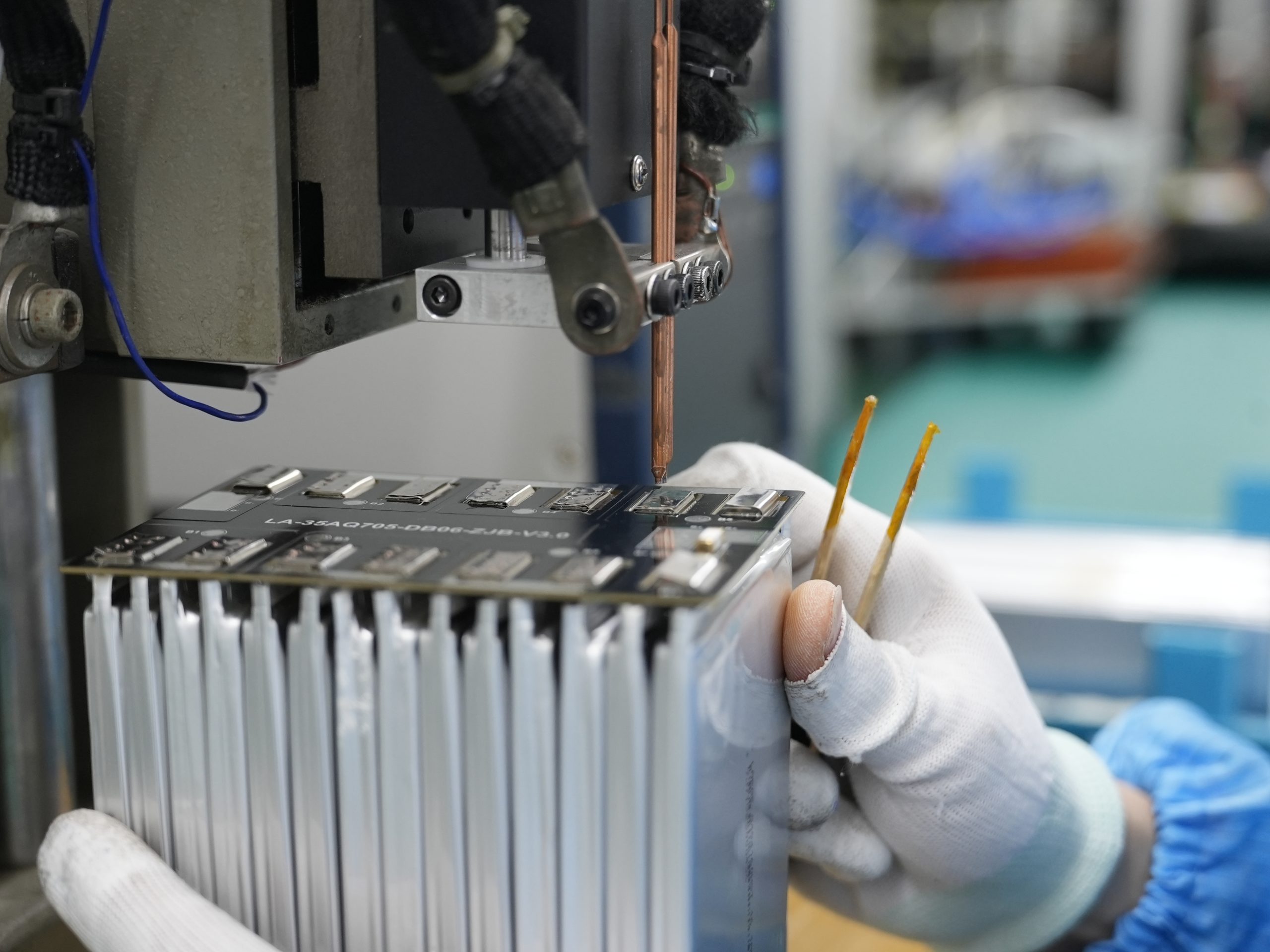

3.3 Testing And Validation

You must validate your battery management system through rigorous testing. Testing ensures safety, reliability, and regulatory compliance for medical devices. You need to monitor cell voltages, balance cells, and provide protective measures against damage. Testing involves structured steps to validate measurement accuracy and control logic under normal and fault conditions. Diagnostic checks confirm voltage thresholds, current limits, and temperature safeguards.

You test the battery management system for measurement accuracy and control logic.

You confirm voltage thresholds, current limits, and temperature safeguards.

You validate performance under normal and fault scenarios to ensure reliability in healthcare.

Testing and validation support regulatory approval and guarantee that your medical devices meet safety and reliability standards. You must document all test results and maintain records for regulatory audits. This process ensures that your bms design meets the demands of healthcare applications and protects patient safety.

Alert: Regular testing and validation of lithium battery packs are critical for maintaining compliance and reliability in medical environments.

Part4: Application-Specific BMS Needs

4.1 Portable Vs Stationary Devices

You must tailor battery management system design to meet the unique demands of portable and stationary medical devices. Portable devices, such as infusion pumps and implantable monitors, require miniaturization and high energy density. The lightweight profile of lithium-ion batteries supports mobility and patient comfort in healthcare settings. Safety features become critical in portable applications due to their direct contact with patients. Stationary devices, including diagnostic equipment, prioritize long cycle life and robust safety protocols over weight reduction. You need to match application requirements to the device type for optimal reliability.

Portable medical devices demand compact size and high energy density.

Safety is essential for sensitive healthcare applications.

Stationary devices focus on durability and reliability, with less emphasis on weight.

4.2 Environmental Factors

Environmental conditions play a significant role in battery management system performance for medical applications. You must consider temperature, humidity, and mechanical stress when designing for healthcare environments. Extreme temperatures degrade battery capacity and cycle life, while excessive humidity leads to electrolyte degradation and corrosion. Mechanical stress, such as vibration or impact, can shorten cycle life and compromise safety.

Environmental Factor | Impact on Battery Performance |

|---|---|

Temperature | Critical for efficiency; extreme temperatures degrade capacity and cycle life. |

Humidity | Excessive moisture leads to electrolyte degradation and corrosion. |

Mechanical Stress | Can shorten cycle life and cause irreversible capacity loss. |

You should select sealants and adhesives based on expected environmental conditions. Hazard analyses and testing under extreme scenarios validate your design choices. Efficient thermal management, such as liquid cooling systems with nano-enhanced phase change materials, reduces the risk of thermal runaway and improves safety in healthcare applications.

Tip: Quality assurance throughout the battery lifecycle ensures safe and reliable medical devices for healthcare environments.

4.3 Customization For Medical Use

Customization of battery management systems enhances patient safety and device reliability in medical applications. You can integrate advanced monitoring and control features for real-time state-of-charge and state-of-health data. Support for sleep modes and double protection minimizes unexpected failures. Tailored designs meet specific voltage, current, and thermal requirements for healthcare devices. Protection circuit modules and cell balancing improve safety and reliability. Fast-charging capabilities, managed by advanced charge control algorithms, support critical healthcare operations.

Feature | Benefit |

|---|---|

Advanced thermal management | Prevents overheating, ensuring safe operation of medical devices. |

Real-time monitoring | Detects faults early, allowing for proactive maintenance and reducing unexpected downtime. |

Cell balancing | Ensures uniform performance across battery cells, enhancing reliability. |

Compliance with safety standards | Reduces liability risks and ensures devices meet industry safety requirements. |

You must prioritize customization to address application requirements and maintain high safety standards in healthcare. Smart monitoring and diagnostics predict maintenance needs, avoiding unexpected device failures. Compliance with safety certifications ensures your medical devices meet industry standards, protecting patient safety and supporting reliable healthcare delivery.

You strengthen medical device reliability and patient safety by prioritizing robust BMS design, advanced safety features, and strict compliance in healthcare. Modular architecture isolates faults, supporting uninterrupted healthcare operations. Continuous monitoring and chemistry selection optimize medical battery packs. The table below highlights evolving BMS technology for healthcare applications.

Advancement Type | Description |

|---|---|

Improved Safety Features | Solid-state batteries eliminate safety risks found in traditional batteries. |

Miniaturization for Wearable Devices | Ultra-thin solid-state batteries integrate into flexible medical patches and wearable health monitors. |

Enhanced Energy Density | Specialized small-format batteries exceed 400 Wh/kg, suitable for medical devices. |

FAQ

What protection strategies help reduce threats and vulnerabilities in lithium battery packs for medical devices?

You implement multi-layer protection, including real-time monitoring, isolation, and advanced security protocols. These strategies minimize threats, vulnerabilities, and ensure patient care safety in medical environments.

How does Large Power address cybersecurity risks and security threats in internet of medical things applications?

Large Power integrates robust protection, security monitoring, and threat detection in lithium battery packs for medical IoT devices. You can request a custom consultation for your project.

Why is protection critical for patient care and security in medical lithium battery packs?

You rely on protection to prevent threats, vulnerabilities, and ensure safety. Security features in lithium battery packs support uninterrupted patient care and maintain compliance with medical safety standards.