The selection of appropriate battery protection circuitry represents a critical design decision that directly impacts both safety and operational performance. Protection Circuit Modules (PCMs) function as fundamental safety components within battery pack assemblies, particularly lithium-ion batteries. The primary function of a PCM involves protecting battery cells from electrical hazards that can result in permanent damage or create unsafe operating conditions. Battery Management Systems (BMS) represent a more sophisticated approach to battery protection, incorporating microcontroller-based electronics with integrated software algorithms for enhanced monitoring and control capabilities.

Lithium battery chemistry presents inherent safety risks when subjected to overcharge conditions or excessive discharge beyond safe operating parameters. These protection systems address these fundamental safety requirements through different approaches and levels of sophistication. PCM designs rely primarily on hardware-based electronic components to monitor and control charging and discharging functions within lithium battery packs. BMS technology extends beyond basic protection to include advanced safety features such as thermal monitoring and comprehensive fault detection capabilities, which become essential for mission-critical applications. The BMS architecture also provides bidirectional communication between the battery pack and the host device, enabling the system to distinguish between normal operating conditions and fault events.

This technical analysis examines the performance characteristics and operational differences between PCM and BMS protection systems to assist in selecting the appropriate solution for specific application requirements. The evaluation covers both basic PCM implementations and advanced BMS configurations for lithium-ion battery applications, with particular emphasis on safety protocols and functional performance parameters that influence design decisions.

Functional Analysis: PCM and BMS Protection Architectures

Image Source: EverExceed

Protection Circuit Modules and Battery Management Systems represent distinct approaches to battery protection, each with specific capabilities and limitations that determine their suitability for different applications. The fundamental differences between these technologies stem from their underlying design philosophy and implementation complexity.

Primary Protection Functions: Overvoltage, Overcurrent, and Short-Circuit Detection

Both PCM and BMS architectures implement essential protection functions, though through different methodologies. A PCM operates as a dedicated protection circuit that continuously monitors individual cell voltages and interrupts power flow when unsafe conditions are detected. The circuit design prevents batteries from exceeding dangerous voltage levels during charge cycles or discharging beyond safe operational thresholds, both conditions that can permanently damage cell chemistry and significantly reduce cycle life. Short-circuit protection represents another critical function, as these fault conditions can result in immediate thermal runaway events leading to fire hazards or complete system failure.

The PCM protection sequence activates when cell voltage reaches predetermined upper limits during charging, automatically terminating charge current flow until voltage returns to acceptable levels. During discharge operations, the PCM monitors for undervoltage conditions and disconnects the load when cell voltage drops below the minimum safe threshold.

Enhanced Monitoring Capabilities: State Estimation and Cell Balancing

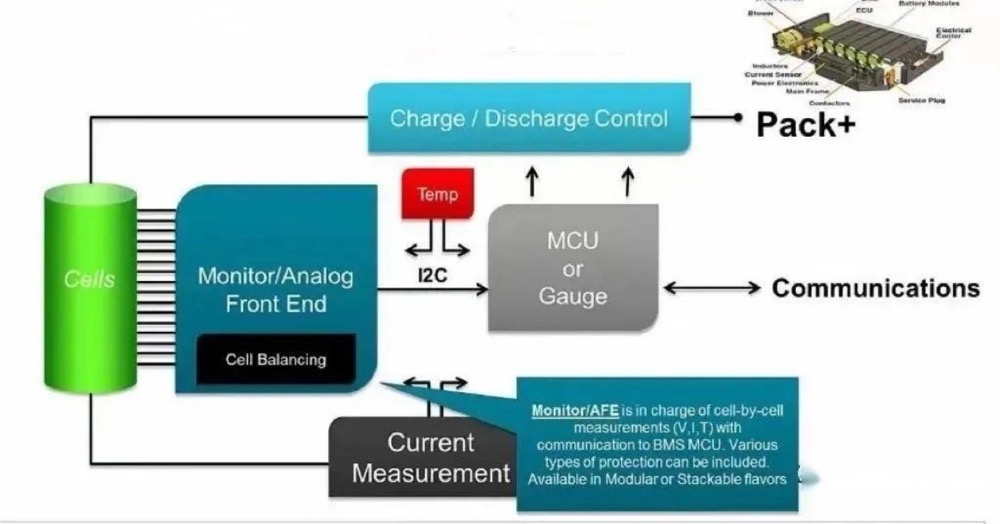

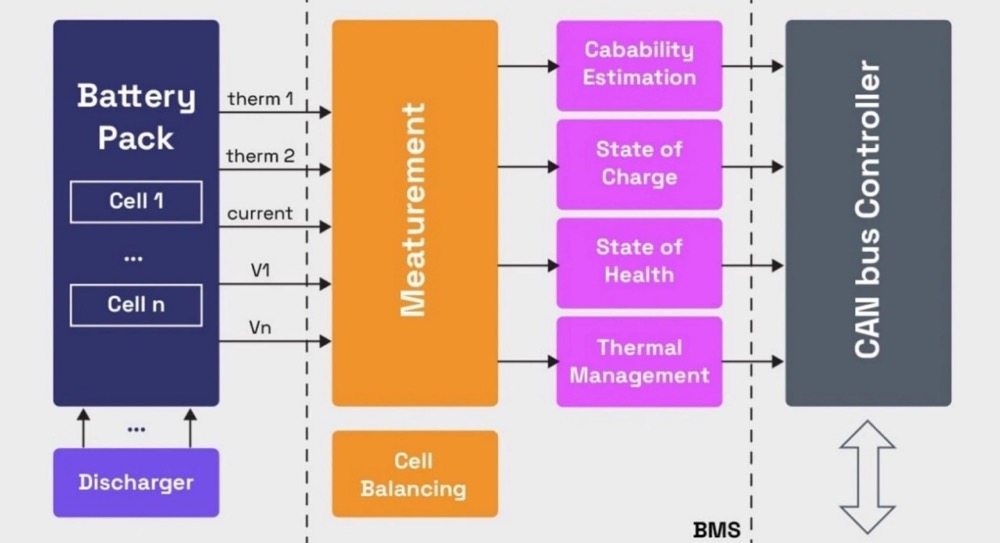

BMS technology extends beyond basic protection to include sophisticated monitoring and control functions. State of Charge (SOC) calculation represents a fundamental BMS capability, providing real-time assessment of available battery capacity relative to maximum rated capacity. This information enables accurate prediction of remaining operating time and optimal charge scheduling. State of Health (SOH) monitoring compares current battery performance against initial specifications.

Cell balancing functionality distinguishes BMS systems from PCM implementations by actively maintaining uniform charge distribution across all cells within the battery pack. This process prevents individual cell degradation that can compromise overall pack performance and extends operational lifespan through balanced charge and discharge cycles. The BMS maintains safe operation by continuously monitoring SOC parameters and ensuring operation within defined safety margins.

Communication Interface Architecture: Standalone vs Networked Operation

PCM designs typically operate as autonomous protection circuits without external communication capability, focusing exclusively on local safety functions without data exchange or status reporting. These systems function independently without software integration requirements.

BMS modules incorporate advanced communication protocols including CAN bus, SMBus, and I2C interfaces to transmit operational data to host controllers or central management systems. This communication capability enables coordinated control of charging systems and load management for optimized battery utilization. Real-time status monitoring and remote diagnostic capabilities are facilitated through these standardized communication protocols.

Performance and Safety Characteristics

“Thermal runaway is one of the most dangerous ways lithium-ion systems can fail. This chain reaction of heat-producing events needs detailed monitoring through carefully placed temperature sensors.” — Large Battery Engineering Team, Industry-leading battery engineering experts

Image Source: Large Battery

The operational performance characteristics between BMS and PCM technologies demonstrate measurable differences that directly impact battery pack safety and efficiency parameters.

Thermal Monitoring Capabilities

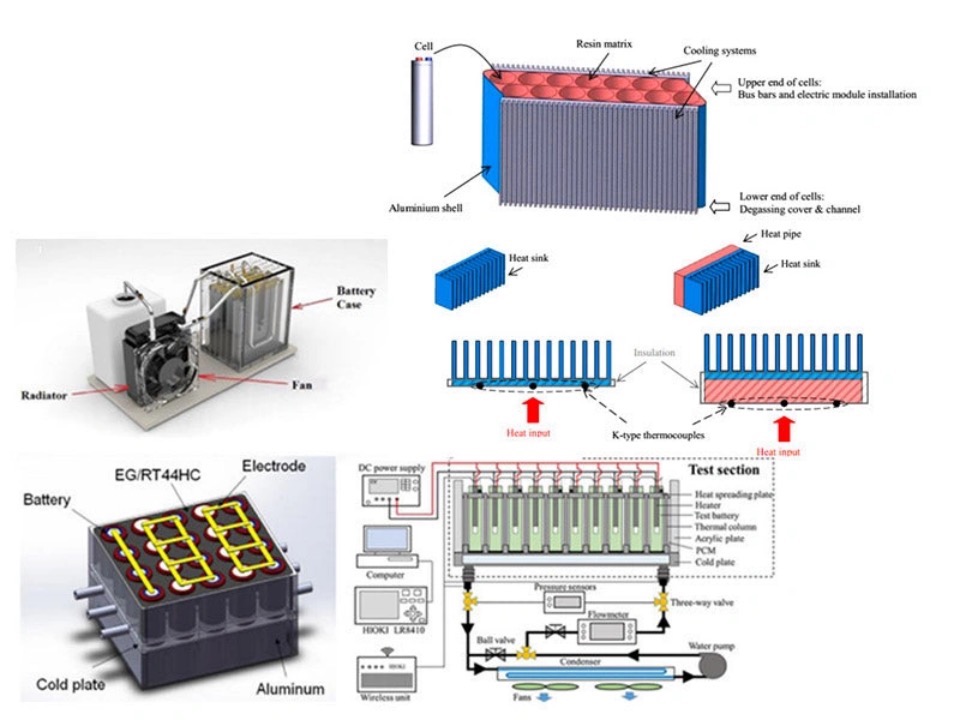

PCM implementations present a fundamental limitation in thermal protection due to the absence of temperature sensors in most designs. This design constraint leaves battery cells exposed to thermal runaway conditions without active monitoring or intervention capabilities. Temperature-related failures remain undetected until physical damage occurs, potentially resulting in catastrophic system failure. BMS architectures incorporate multiple temperature sensing points throughout the battery pack assembly, enabling real-time thermal monitoring and active cooling system control when predetermined temperature thresholds are exceeded.

Power Consumption Analysis

The power management characteristics of BMS and PCM systems show significant efficiency differences. BMS circuits employ intelligent power management algorithms that enable standby mode operation during periods of low activity. PCM designs maintain constant power consumption regardless of system activity levels. Measured power consumption data indicates that a 4s LiFePO4 BMS typically draws 50μA (0.000049 Amps) during standby operation. This consumption level represents negligible impact compared to the natural self-discharge characteristics of lithium-ion cells, which typically range from 2-3% per month.

Cell Balancing and Battery Life Extension

Active cell balancing represents a critical performance advantage of BMS technology over PCM implementations. The cell balancing function ensures uniform charge and discharge cycles across all cells within the battery pack assembly. This balancing process prevents individual cell degradation and extends overall pack service life. PCM circuits lack cell balancing capabilities, resulting in uneven cell utilization and premature capacity reduction. Advanced BMS designs utilize proportional-integral control algorithms to maintain cell voltage uniformity without requiring complex active balancing circuits.

Application Requirements and System Selection Criteria

“By managing the cell voltage, charge, temperature, current, and balancing, you can prolong the life of the battery pack and further understand the energy demands of your devices.” — Epec Engineering Team, Battery system design experts

Image Source: tycorun

The type of battery protection system required is determined by the requirements of the device being powered: application complexity, current demands, monitoring requirements, environmental considerations, and cost constraints. The battery protection system can be designed to meet these requirements by selecting the appropriate technology level and configuring the protection circuitry to meet the safety, performance, and communication requirements of the specific application.

Single-Cell and Low-Power Applications

Most applications where there is basic protection requirement and cost sensitivity is where PCM board modules excel. Single-cell battery packs and small consumer electronics such as power banks and handheld devices typically require only fundamental safety protection. These applications operate with lower current requirements and do not demand extensive monitoring capabilities or advanced communication features. The cost-effectiveness of PCM technology makes it the preferred choice for budget-conscious projects where basic overcharge, over-discharge, and short-circuit protection represents the primary safety concern.

High-Performance and Multi-Cell Systems

BMS Li-ion Battery systems become essential for applications requiring comprehensive battery management and advanced safety protocols. E-bikes, drones, robotics platforms, and other complex systems benefit from the sophisticated monitoring and control capabilities that BMS technology provides. The BMS architecture enables cell balancing, precise state-of-charge estimation, and performance optimization—capabilities that are absent in PCM-only implementations. Real-time data collection and performance monitoring allow for proactive maintenance scheduling and early detection of potential issues.

Industrial and Electric Vehicle Applications

For electric vehicles and industrial equipment, BMS Protection systems are not merely beneficial—they are mandated by safety regulations and performance requirements. The BMS maximizes operational efficiency through high-precision battery monitoring and enables safe operation through comprehensive diagnostic capabilities. High-voltage battery applications require intelligent BMS modules to meet safety standards and reduce risks associated with thermal runaway and other critical failure modes. The BMS architecture also enables cost optimization by supporting multiple battery chemistries and cell configurations within a single system. Industrial applications must comply with standards such as IEC 61508 and ISO26262, which require the advanced monitoring and control capabilities that only BMS technology can provide.

Economic and Technical Implementation Analysis

Economic factors frequently determine the final selection between PCM and BMS technologies for battery protection applications. The decision requires careful evaluation of immediate capital expenditure against long-term operational benefits and total cost of ownership considerations.

Capital Investment Analysis: PCM vs BMS Implementation Costs

PCM modules present significantly lower initial procurement costs compared to BMS circuits, creating appeal for cost-sensitive product development. The upfront investment for BMS li-ion battery systems requires higher capital allocation but provides measurable long-term financial returns. BMS implementations with active cell balancing demonstrate reduced total cost of ownership across the complete operational lifecycle. The economic advantage results from extended replacement intervals, minimized maintenance requirements, and reduced system downtime. BMS architectures achieve superior energy utilization rates—up to 95% versus 85% in passive protection systems—translating to substantial operational savings for commercial and industrial deployments.

Implementation Complexity: Design Integration Considerations

PCM board implementations offer simplified integration pathways with minimal system complexity requirements, making them suitable for basic electronics applications requiring fundamental protection. BMS modules present multiple architectural configurations—centralized, distributed, and hybrid topologies—requiring careful evaluation of complexity, cost, and functional benefit relationships. These architectural selections significantly influence BMS development requirements for specific battery configurations. The BMS circuit architecture provides extensive configurability through multiple communication protocol options, though requiring additional electrical engineering and software integration expertise.

Regulatory Compliance Requirements: Mandatory BMS Applications

High-voltage applications such as electric vehicles mandate BMS protection systems to meet safety regulation requirements. The automotive BMS market represents $8.1 billion in 2025 valuation with projected growth at 17.4% compound annual growth rate, reaching $34.2 billion by 2034. This market expansion reflects increasing regulatory emphasis on advanced battery safety standards across multiple industries. Specific industry segments maintain stringent regulations requiring BMS implementation to achieve mandated performance and safety compliance levels. BMS technology has become essential for maintaining operation within the specified Safe Operation Area parameters for lithium-ion cell applications.

Technical Specifications Comparison

| Parameter | PCM (Protection Circuit Module) | BMS (Battery Management System) |

| Protection Functions | Overcharge, over-discharge, overcurrent, and short-circuit protection | Complete protection suite with advanced monitoring and thermal management |

| Thermal Monitoring | Limited or no temperature sensing capability | Integrated temperature sensors with active thermal management |

| Communication Interface | No communication protocol support | CAN bus, SMBus, I2C protocol support for system integration |

| Cell Balancing | No balancing functionality | Active cell balancing with individual cell monitoring |

| Power Management | Continuous current draw during operation | Intelligent power management with 50μA standby consumption |

| Monitoring Capabilities | Basic voltage threshold detection | SOC, SOH determination, and comprehensive fault diagnostics |

| Target Applications | – Single-cell portable devices – Power bank applications – Basic handheld electronics – Cost-sensitive products |

– Electric vehicle systems – Industrial battery applications – E-mobility platforms – Unmanned aerial vehicles – High-performance systems |

| Economic Considerations | Lower initial investment cost | Higher development cost with superior long-term value |

| Energy Efficiency | Approximately 85% system efficiency | Up to 95% efficiency through optimized management |

| Implementation Complexity | Minimal integration requirements | Sophisticated configuration and programming requirements |

| Standards Compliance | Basic electrical safety standards | Advanced safety certifications (IEC 61508, ISO26262) |

Technical Assessment Summary

The selection between PCM and BMS protection systems requires careful evaluation of application-specific parameters and operational requirements. PCM technology provides adequate protection for applications with basic safety requirements, particularly single-cell configurations and low-complexity consumer electronics where fundamental overcharge and overcurrent protection meets operational specifications.

BMS technology represents the appropriate choice for applications demanding comprehensive battery management capabilities. The integrated monitoring functions—cell balancing, thermal protection, and diagnostic capabilities—deliver measurable performance improvements beyond basic circuit protection. These enhancements directly impact operational parameters: extended cycle life, improved safety margins, and optimized energy utilization across varying environmental conditions.

Economic analysis must consider total cost of ownership rather than initial component pricing. While PCM implementations require lower upfront investment, BMS systems provide superior energy efficiency ratings (95% versus 85%) and substantially reduce replacement frequency. Commercial applications benefit significantly from reduced maintenance intervals and minimized system downtime.

Regulatory compliance represents a non-negotiable factor for specific applications. High-voltage battery systems, particularly those in automotive applications, require BMS implementation to meet established safety standards. The automotive BMS market growth projection from $8.1 billion to $34.2 billion between 2025 and 2034 reflects increasing regulatory requirements for advanced battery management in critical applications.

Application evaluation should address specific technical parameters: battery chemistry compatibility, environmental operating conditions, current requirements, and regulatory compliance mandates. This assessment determines the appropriate protection architecture—PCM for straightforward protection requirements or BMS for applications requiring advanced monitoring and management capabilities. The selected system must align with both immediate functional requirements and long-term operational objectives to ensure optimal performance throughout the battery system’s service life.

For any custom battery pack service, please contact Large Power, a leading battery pack supplier.

Key Takeaways

Understanding the fundamental differences between BMS and PCM systems is crucial for selecting the right battery protection solution for your specific application needs.

- PCM provides basic protection only– handles overcharge, overcurrent, and short circuits but lacks temperature monitoring, cell balancing, and communication capabilities

- BMS offers comprehensive battery management– includes advanced features like SOC/SOH tracking, active cell balancing, thermal management, and communication protocols

- Energy efficiency differs significantly– BMS achieves up to 95% efficiency with smart standby mode, while PCM systems drain power constantly at only 85% efficiency

- Application determines the right choice– PCM suits simple, low-cost devices like power banks, while BMS is essential for complex systems like EVs and industrial equipment

- Long-term value favors BMS investment– despite higher upfront costs, BMS systems reduce total ownership costs through extended battery life and fewer replacements

- Regulatory compliance may mandate BMS– high-voltage applications and electric vehicles require BMS to meet safety standards like IEC 61508 and ISO26262

The choice between PCM and BMS should align with your project’s complexity, safety requirements, and budget considerations. While PCM offers cost-effective basic protection, BMS provides superior performance, safety, and long-term value for demanding applications.

FAQs

Q1. What are the key differences between PCM and BMS for battery protection? PCM (Protection Circuit Module) provides basic protection against overcharge, overcurrent, and short circuits. BMS (Battery Management System) offers advanced protection plus comprehensive monitoring, including cell balancing, thermal management, and communication capabilities.

Q2. How do PCM and BMS impact battery life and performance? BMS significantly extends battery lifespan through active cell balancing and optimization, while PCM lacks these capabilities. BMS also offers better energy efficiency (up to 95%) compared to PCM (around 85%), resulting in improved overall battery performance.

Q3. When should I choose PCM over BMS for my application? PCM is suitable for simple, low-cost devices like power banks and single-cell battery systems where basic protection is sufficient. For more complex applications requiring advanced monitoring and management, such as electric vehicles or industrial equipment, BMS is the better choice.

Q4. How do the costs of PCM and BMS compare? PCM has a lower initial cost, making it attractive for budget-conscious projects. BMS has a higher upfront cost but offers better long-term value through extended battery life, reduced maintenance, and improved energy utilization, especially for commercial applications.

Q5. Are there regulatory requirements that mandate the use of BMS? Yes, for high-voltage systems like electric vehicles, BMS is often required by safety regulations. Certain industries have strict standards that necessitate BMS implementation to meet performance and safety requirements, particularly for lithium-ion battery systems.