You want a clear path for turning a custom lithium battery pack for your robot from concept to mass production. Every phase matters, from defining power needs to supporting your product after launch. Innovations like 3D printing and automated assembly speed up development and boost quality in robotics projects. Key cost factors include certification, manufacturing setup, and material selection.

The average timeline for each stage appears below:

Stage of Development | Time Required |

|---|---|

Electrical Design Timeline | 4 to 6 weeks |

Battery Prototypes | 4 to 6 weeks |

Mechanical Design | 4 to 6 weeks |

Software/Firmware Design | 4 to 5 weeks |

3D Printing Modeling Process | 5 to 10 days |

Injection Molded Enclosure Tooling | 8 to 10 weeks |

UN38.3 Transportation Certification | 6 to 8 weeks |

UL/IEC Certification | 6 to 8 weeks |

Production and Test NRE’s | 6 to 8 weeks |

Case Studies show how successful teams avoid common pitfalls and optimize each step.

Key Takeaways

Understand your robot’s power needs. Choose battery features like high energy density and long cycle life to match specific applications.

Utilize rapid prototyping and 3D printing. These methods allow for quick design iterations and testing, reducing costs and improving final product quality.

Ensure compliance with safety standards. Certifications like UN38.3 and UL 2054 are crucial for safe operation and market entry.

Implement robust quality control systems. Regular testing and monitoring during production help maintain consistent battery performance and reliability.

Plan for post-production support. Regular maintenance and technical assistance extend the lifespan of your battery packs and ensure optimal performance.

Part 1: Robot Power Needs

1.1 Battery Requirements

When you design a custom lithium battery for a robot, you must match the battery’s features to your application. In robotics, you often need high energy density, long cycle life, and advanced battery management. The table below shows what to look for in a quality custom lithium battery pack:

Key Features of a Quality Robot Battery Pack | Description |

|---|---|

High Energy Density | More energy storage in a compact size. |

Long Cycle Life | Designed for thousands of charge and discharge cycles. |

Real-time monitoring of voltage, current, and temperature. | |

Thermal Management | Keeps the battery at an optimal operating temperature. |

Robust Housing | Durable casing protects against dust, moisture, and impact. |

Custom Communication Protocols | CAN, SMBus, or UART integration for smart robots. |

Scalability | Compatible with different voltage and current requirements. |

You can choose from several lithium chemistries, such as LiFePO4 for safety and long life, or NMC for higher energy density. Custom modular packs work well for large robots in industrial or medical settings.

1.2 Performance Goals

You want your custom lithium battery to deliver consistent power and meet strict performance targets. Key metrics include:

Run time: A 2.3 kWh pack can provide up to 5 hours of operation at peak performance.

Mass and volume efficiency: Compact designs allow for more flexible robot platforms.

Fast charge: Some custom lithium battery packs support 2 kW fast charging with active cooling.

Reliability: The battery must survive tough environmental and mechanical tests.

Tip: Always test for efficiency, capacity, and lifecycle. Efficiency testing checks for energy loss. Capacity testing measures total energy storage. Lifecycle testing shows how many cycles the battery can handle before losing capacity.

1.3 Safety Criteria

Safety is critical in robotics, especially for custom lithium battery packs. You must meet global and industry-specific standards before mass production. The table below lists key certifications:

Test / Certification | Required For | Applies To |

|---|---|---|

UN38.3 | Global transport (Air & Sea) | All lithium battery packs |

IEC 62133 | CE/CB certification, India BIS | Consumer & industrial battery packs |

UL 1642 / UL 2054 | US compliance, product liability | Embedded battery modules |

IP67/IP68 | Outdoor/wet use products | Tools, e-mobility, smart sensors |

You should always verify that your custom lithium battery meets these standards to ensure safe operation in robotics, medical, and industrial environments.

Part 2: Prototyping & 3D Printing

2.1 Rapid Prototyping

You can accelerate your custom lithium battery development by using rapid prototyping. This approach lets you create a prototype quickly, so you can test fit, function, and safety before moving to mass production. In robotics, medical devices, and industrial automation, you need to see how your battery pack performs in real-world conditions. Rapid prototyping helps you identify design flaws early. You can make changes to the prototype without high costs or long delays. This process reduces risk and improves your final battery design.

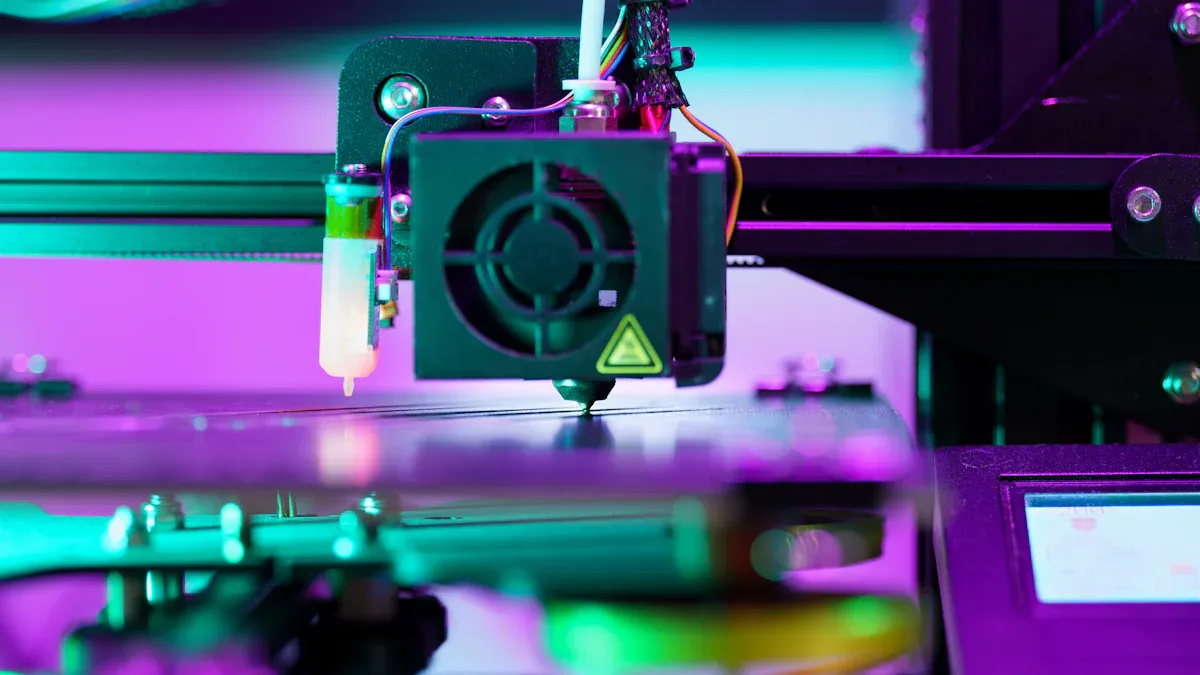

2.2 3D Printing in Battery Design

3D printing has transformed how you design and build battery enclosures. You can create complex shapes that traditional manufacturing cannot achieve. This flexibility is valuable for robotics and security systems, where space and weight matter. You can also iterate designs faster, which means you get a better prototype in less time. However, you should know the limitations of 3D printing:

Limitation Type | Description |

|---|---|

Material Selection | Choosing the right material is crucial for durability, heat resistance, and electrical insulation. Each material has trade-offs. |

Precision and Quality | Printed enclosures may have visible layer lines, impacting aesthetics and functionality. Accuracy in dimensions is crucial for fitting. |

Scalability for Production | 3D printing is slower than injection molding, making it unsuitable for large orders requiring short lead times. Consistency can also be a challenge. |

You should select materials that match the thermal and electrical needs of your lithium battery chemistry, such as LiFePO4 or NMC, especially for medical and industrial applications.

2.3 Initial Testing

After you print your prototype, you need to test it in small batches. This step checks if your lithium battery pack meets safety and performance goals. You can evaluate thermal management, enclosure fit, and electrical connections. Testing in real application scenarios, like robotics or infrastructure, gives you feedback to refine your prototype. You should repeat this process until your battery meets all requirements.

Tip: Small batch testing helps you avoid costly mistakes before mass production.

Part 3: Validation & Small Batch Testing

3.1 Safety Validation

You need to ensure safety and reliability before moving your lithium battery pack into mass production. Safety validation starts with quality assurance during both development and production. After assembly, you must handle and store the battery correctly to prevent damage. When your end customer receives the device, they should check for cell leakage and monitor temperature.

Common safety validation procedures include:

Low-pressure simulation for both primary and secondary cells.

Testing battery integrity under extreme temperatures and rapid changes.

Vibration simulations to mimic transport conditions.

Shock and vibration testing for transport durability.

External short circuit simulation.

Impact and crush testing.

Overcharge simulations for rechargeable batteries.

Force discharge testing.

These steps help you catch issues early and protect your robotics or medical devices from failure. You should also test the circuitry after manufacturing the printed circuit board. During assembly, test the battery management system (BMS) to ensure all connections and software work as intended. For more on BMS, see BMS and PCM.

3.2 Performance Testing

You want your lithium battery to deliver consistent battery performance in real-world applications. Battery cycling tests help you evaluate health, state of charge, and internal impedance. You should run these tests in small batches to spot any weak points. In robotics, security systems, and industrial settings, you need to confirm that the battery can handle repeated charging and discharging without losing capacity. Always monitor temperature and voltage during these tests to ensure safe operation.

3.3 Compliance Checks

You must meet strict regulatory standards before shipping your lithium battery packs. Each market and application may require different certifications. The table below summarizes the most common compliance checks for lithium battery packs in robotics and related sectors:

Certification | Purpose |

|---|---|

UN38.3 | Mandatory for air and sea transport |

CE | Required for access to EU markets |

UL 2054 | Essential for U.S. consumer safety compliance |

IEC 62133 | Widely accepted in Asia and global electronics |

RoHS | Focuses on environmental and hazardous material restrictions |

Note: Passing these compliance checks ensures your battery meets global safety and environmental standards. This step protects your business and your customers.

Part 4: Mass Customization & Manufacturing

4.1 Design for Manufacturability

You need to design your custom lithium battery packs with mass production in mind. Design for manufacturability (DFM) helps you reduce costs, improve quality, and speed up your production lines. When you plan your battery design, you should consider the following:

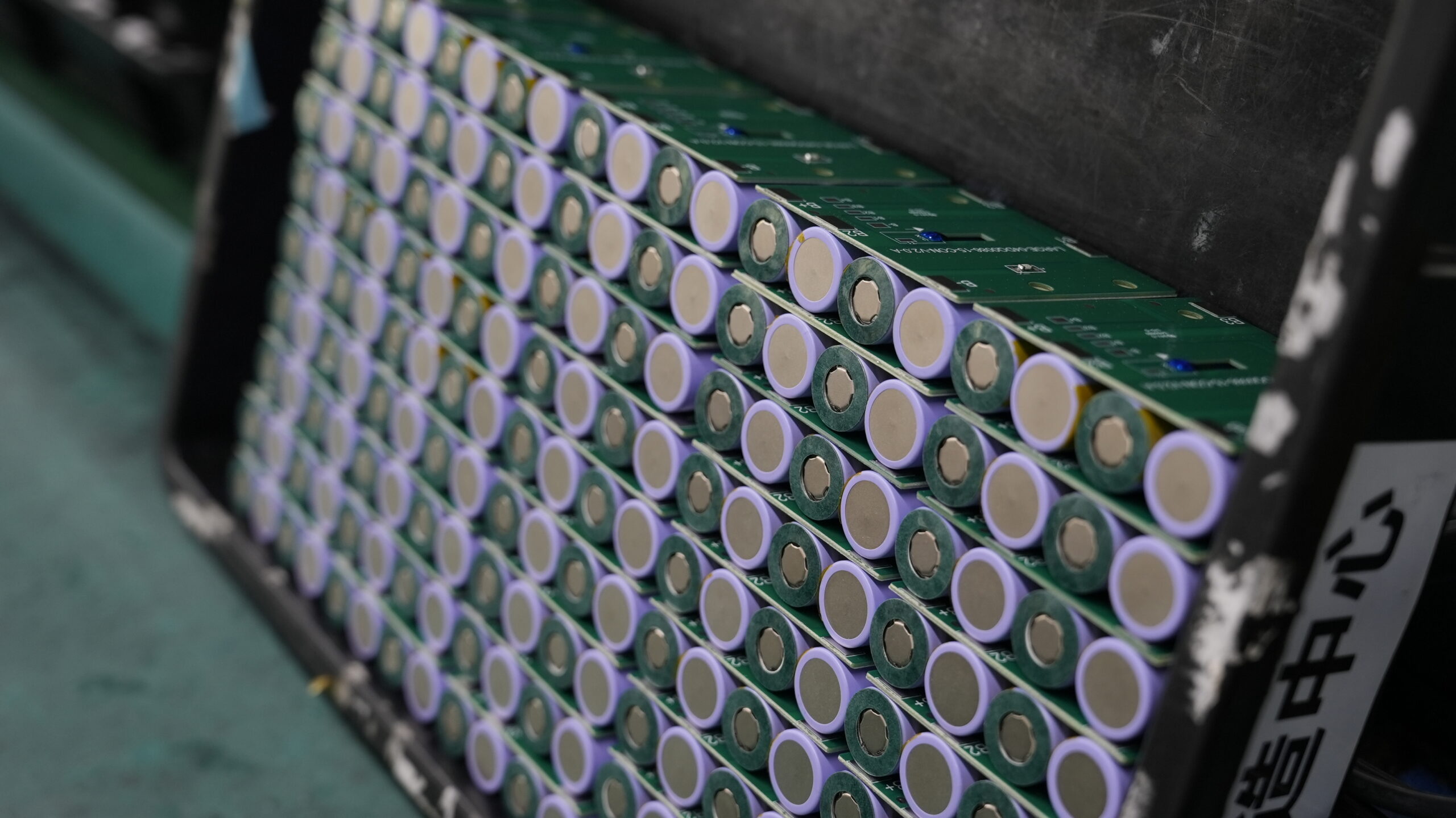

Choose standardized cell formats, such as 18650 or 21700, to simplify assembly.

Select materials that support both safety and durability, especially for robotics and medical devices.

Optimize the layout for efficient heat dissipation and easy integration into robot enclosures.

Ensure your design supports automated assembly and testing.

A well-designed battery pack allows you to scale from prototype to mass production without major redesigns. You can also reduce waste and improve efficiency by using modular designs. This approach supports both small-batch runs and large-scale manufacturing.

Tip: Early collaboration with your manufacturing partner helps you identify potential issues before they impact your production schedule.

4.2 Mass Customization in Battery Production

Mass customization lets you deliver tailored battery solutions for different robot applications while keeping the benefits of mass production. You can adjust capacity, voltage, and size to match the unique power needs of each robot. This flexibility is essential for robotics, medical, and industrial sectors, where requirements can vary widely.

You can optimize battery performance by matching the chemistry—such as LiFePO4 for long life or NMC for high energy density—to the specific application.

Lithium-ion and lithium-polymer batteries offer versatility for diverse power requirements.

Custom battery solutions help you maximize efficiency and minimize downtime in robotic applications.

Feature | Mass Customization Benefit | Example Application |

|---|---|---|

Capacity | Adjusts to robot’s run-time needs | Industrial AGVs |

Voltage | Matches motor and sensor requirements | Medical robots |

Size & Shape | Fits unique enclosure constraints | Security drones |

Communication Protocol | Integrates with custom robot controls | Infrastructure monitoring |

You can use modular battery packs to support upgrades and maintenance. This approach also helps you respond quickly to changing market demands. Mass customization ensures you meet the power and efficiency targets for each robot without sacrificing scalability.

4.3 Automated Assembly

Automated assembly has transformed battery manufacturing for robotics and industrial sectors. You can now achieve high efficiency and consistent quality at scale. Modern production lines use advanced robotics and software to handle complex assembly tasks.

Digital twins let you simulate and optimize battery assembly before you start physical production. You can test different scenarios and improve your process.

Automation software, such as NeuroCAD, uses machine learning to select the best components for assembly.

Modular programming systems like PiTaSC make it easier to program industrial robots for various assembly tasks.

Dry-coating processes for battery electrodes lower production costs and support automation.

Protective covers for robots keep the assembly environment clean and safe.

Fully automated battery module assembly systems can produce up to 300,000 modules per year. Their modular design gives you flexibility for different battery types.

You can also improve quality control with automated testing rigs. These systems perform precise, repetitive tests on every battery pack. IoT technology enables real-time monitoring and data analysis, so you can catch issues early and ensure power consistency.

Automation Feature | Benefit | Impact on Mass Production |

|---|---|---|

Digital Twin Simulation | Process optimization | Faster setup, fewer errors |

Automated Testing Rigs | Consistent, precise quality checks | Higher reliability |

IoT Integration | Real-time monitoring and data collection | Immediate feedback, traceability |

Modular Assembly Systems | Flexible production for custom packs | Scalability, reduced downtime |

Note: Increased automation in battery assembly, testing, and packaging helps you meet the rising demand for high-quality batteries in robotics and industrial markets.

You should always monitor your production lines for efficiency and quality. Automated systems let you scale up mass production while maintaining strict standards for power, safety, and reliability.

Part 5: Quality Control & Power Assurance

5.1 Quality Control Systems

You need robust quality control systems to ensure every lithium battery pack meets the highest standards in robotics, medical, and industrial applications. Quality control starts at the module and rack assembly stage. Here, you check electrical balancing and mechanical integrity. You then move to rack-level battery testing, which includes charge and discharge cycles, temperature monitoring, and insulation resistance checks. Cleanroom environments, precision robotics, and inline laser inspection help you prevent common manufacturing defects. Adhering to industry standards like ISO, UN, UL, and IEC gives you confidence in your production process.

Quality Control Process | Description |

|---|---|

Module and Rack Assembly | Cells are assembled into modules and racks, checking electrical balancing and mechanical integrity. |

Rack-Level Battery Testing | Includes charge/discharge tests, temperature monitoring, and insulation resistance tests. |

Common Manufacturing Defects Prevention | Utilizes cleanroom environments, precision robotics, and inline laser inspection to minimize defects. |

Industry Standards Compliance | Adherence to ISO, UN, UL, and IEC standards ensures safety and quality assurance in production. |

Tip: Early detection of defects saves time and reduces costs in mass production.

5.2 Power Consistency

You want every battery pack to deliver reliable power in demanding robotics environments. Smart instrumentation lets you measure weight, temperature, and pressure in real time. Sensors monitor the thickness of electrode coatings, so you can adjust production parameters instantly. Automated systems and robotic assembly lines reduce human error and keep your output consistent.

To maintain power consistency, you should use several testing methods:

Electrical performance testing checks voltage, current, and capacity.

Thermal analysis and safety testing ensure the battery operates within safe temperature ranges.

Impedance and health analysis detect early signs of cell degradation.

BMS data logging and simulation track battery behavior under different loads.

Environmental and mechanical testing confirm the battery can withstand shocks, vibrations, and humidity.

Note: Consistent power delivery is critical for robotics, security systems, and medical devices where failure is not an option.

5.3 Regulatory Approval

You face strict regulatory hurdles when bringing a new lithium battery pack to market. Compliance requirements differ across countries and regions. In the United States, recent changes have aligned standards for battery packs in mobile robots with those for battery electric vehicles (BEVs). You must stay updated on these evolving regulations to avoid delays and ensure smooth market entry.

Regulatory approval often requires:

Passing safety and environmental tests according to UN38.3, UL, and IEC standards.

Providing documentation for traceability and quality assurance.

Meeting additional requirements for specific sectors, such as medical or infrastructure.

Callout: Regulatory compliance protects your business and your customers. Always work with experienced partners who understand the latest standards in robotics and lithium battery technology.

Part 6: Case Studies & Best Practices

6.1 Robot Battery Success Stories

You can learn a lot from real-world case studies that highlight the journey from prototype to mass production. One standout example comes from Advanced Robotic Engineering (ARE). These companies worked together to solve a common challenge in the demolition industry. Traditional cable-powered machines slowed down work and required extra operators. By integrating custom lithium battery packs, ARE created a more efficient solution for their demolition robots.

Here is a summary of this case study:

Aspect | Details |

|---|---|

Collaboration | ARE partnered with Vanguard to integrate custom battery packs into demolition robots. |

Challenge | Cable-powered machines were cumbersome and needed multiple operators, reducing efficiency. |

Solution | ARE adopted 48V battery packs, enabling cable-free movement and greater operational efficiency. |

Operational Flexibility | Swappable and fixed battery packs allowed quick changes, minimizing downtime. |

Efficiency Gains | Operators saved at least one hour per eight-hour shift compared to cable-operated robots. |

Industry Impact | This innovation is expected to transform demolition work, making operations smoother across job sites. |

These case studies show how custom lithium battery packs can drive efficiency and flexibility in demanding environments. You see how the right battery solution can change the way teams work and help you stay ahead in your industry.

6.2 Lessons Learned

You can apply several best practices from these case studies to your own projects:

Start with a clear understanding of your robot’s power needs and operational environment.

Collaborate early with battery manufacturers to design for manufacturability and scalability.

Use modular battery designs to support quick swaps and reduce downtime.

Test prototypes in real-world conditions before scaling up production.

Monitor performance data and gather feedback to refine your battery packs.

Tip: Reviewing case studies from your sector helps you avoid common mistakes and adopt proven strategies for success.

By following these lessons, you can improve your own battery development process and achieve reliable results in robotics, medical, and industrial applications.

Part 7: Post-Production Support

7.1 Technical Support

You need reliable technical support after mass production to keep your lithium battery packs running at peak performance. Most requests involve safety features, system diagnostics, and performance checks. A robust Battery Management System (BMS) monitors charge and discharge cycles, preventing overcharging and ensuring long-term reliability for robotics, medical, and industrial applications.

Safety Feature | Description |

|---|---|

Overcharge Protection | Stops charging when the battery is full to prevent overheating or explosions. |

Thermal Cutoffs | Disconnects power if temperatures exceed safe limits, protecting sensitive equipment. |

Short Circuit Protection | Breaks the circuit to prevent fire hazards or robot damage during a short circuit. |

You often need support for voltage, capacity, and discharge rate checks. Simulation of different operating conditions helps you predict performance in real-world scenarios. Endurance testing through repeated charge and discharge cycles ensures your battery packs meet demanding industry standards.

Tip: Proactive technical support reduces downtime and extends the lifespan of your lithium battery packs.

7.2 Maintenance & Upgrades

Regular maintenance keeps your battery packs safe and efficient. You should schedule periodic inspections to check for wear, connector integrity, and BMS updates. In robotics and security systems, firmware upgrades can unlock new features or improve energy management. Modular battery designs allow you to swap out aging cells or upgrade to newer chemistries like LiFePO4 or NMC without replacing the entire system.

Inspect connectors and wiring for signs of corrosion or damage.

Update BMS firmware to enhance safety and performance.

Replace modules as needed to maintain capacity and reliability.

Note: Preventive maintenance lowers the risk of unexpected failures and supports compliance with industry regulations.

7.3 Recycling

Recycling Method | Description | Challenges |

|---|---|---|

Direct Recycling | Extracts anode and cathode materials before chemistry degrades. | Not yet commercialized due to feedstock isolation issues. |

Pyrometallurgy | Burns batteries to recover metals. | High energy use and lower recovery rates. |

Hydrometallurgy | Uses acids to recover materials after shredding. | Energy-intensive and involves hazardous chemicals. |

Manual Disassembly | Human workers take apart packs to module level. | Dangerous and slow, limiting efficiency. |

Automated Disassembly | Robots disassemble packs, improving safety and speed. | Requires advanced technology and investment. |

A robotic disassembly system can reduce processing time by up to 90% compared to manual methods. Automated solutions improve safety and efficiency, especially for large-scale industrial and infrastructure deployments. For a deeper look at sustainable practices, visit Our Approach to Sustainability.

Callout: Responsible recycling protects your business, meets regulatory demands, and supports a circular economy for lithium battery packs.

You can move from prototype to mass production in custom lithium battery packs by following these key steps:

Optimize your design and select the right materials.

Run pilot batches and validate performance.

Use 3D printing for fast prototyping and gather customer feedback.

Collaborate with engineers and manufacturing teams.

Innovation | Benefit for Robotics & Industrial Sectors |

|---|---|

3D Printing | Rapid design changes, complex geometries |

Mass Customization | Tailored packs for unique robot needs |

Automated Assembly | Consistent quality, scalable production |

For complex projects, expert consultation in battery manufacturing and robotics development helps you avoid common pitfalls and ensures reliable results.

FAQ

What lithium battery chemistry should you choose for industrial robots?

Chemistry | Key Benefit | Typical Use Case |

|---|---|---|

LiFePO4 | Long cycle life | Industrial robots |

NMC | High energy density | Medical devices |

LTO | Fast charging | Security systems |

Choose based on your robot’s power, safety, and cycle life needs.

How does 3D printing improve battery prototyping?

You can use 3D printing to create custom enclosures quickly. This method allows you to test fit and function before mass production. You save time and reduce costs by making design changes early.

What certifications do lithium battery packs require for robotics?

You need certifications like UN38.3 for transport, UL 2054 for U.S. safety, and IEC 62133 for global compliance. These ensure your battery packs meet safety and environmental standards in robotics and industrial sectors.

How can you ensure consistent battery performance in mass production?

You should use automated assembly, inline testing, and smart sensors. These tools help you monitor voltage, temperature, and capacity. Consistent processes reduce defects and ensure each pack meets your power requirements.

What is the best way to recycle lithium battery packs from robots?

Method | Efficiency | Safety Level |

|---|---|---|

Automated Disassembly | High | High |

Manual Disassembly | Low | Low |

Hydrometallurgy | Medium | Medium |

Automated disassembly offers the safest and fastest recycling for large-scale industrial and infrastructure deployments.