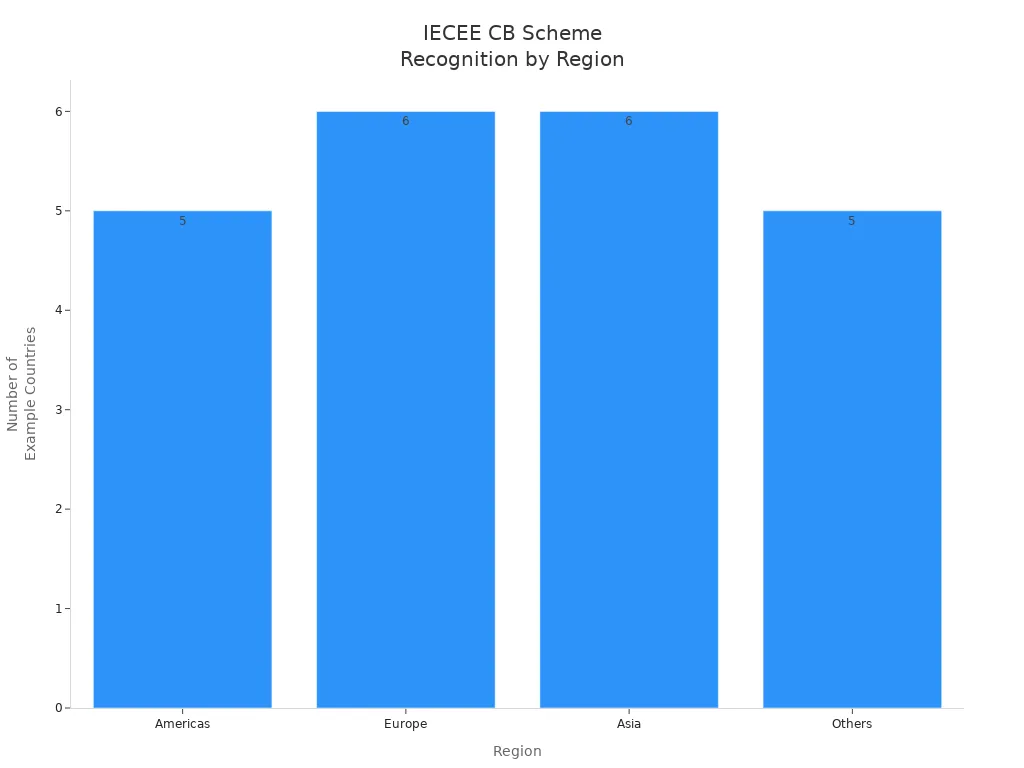

You face a rapidly expanding lithium battery market, with valuations reaching over USD 100 billion in 2024 and forecasts exceeding USD 578 billion by 2032. As a manufacturer or exporter, you rely on cb certification for lithium batteries through the cb scheme, recognized across 54 countries, to achieve international electrical product safety certification and global market access.

Region | Countries (examples) |

|---|---|

Americas | United States, Canada, Mexico, Brazil |

Europe | United Kingdom, Germany, France, Italy |

Asia | China, Japan, India, South Korea |

Others | Australia, South Africa, Israel |

Key Takeaways

CB certification proves your lithium batteries meet global safety and quality standards, helping you enter over 50 countries without repeated testing.

Following IEC standards like IEC 62133 ensures your batteries pass rigorous safety tests, reducing risks of failures and recalls.

Preparing detailed documentation and working with accredited labs speeds up certification, saving time and costs while boosting your product’s market trust.

Part 1: CB Certification for Lithium Batteries

1.1 Definition and Scope

You operate in a global market where safety and compliance drive business success. CB certification for lithium batteries stands as an internationally recognized system under the IECEE CB Scheme. This system covers electrical and electronic products, including lithium battery packs, and enables you to demonstrate compliance with international safety, performance, and mechanical standards. When your lithium ion battery products undergo CB certification, they receive comprehensive testing and assessment according to IEC standards. This process confirms that your batteries meet global requirements for electrical safety, reliability, and regulatory adherence.

CB certification for lithium batteries validates technical compliance and ensures your products meet legal and regulatory requirements. You gain assurance of safety and reliability, which is essential for entering new markets and building trust with partners.

The CB Scheme operates through mutual acceptance of product safety test reports and certificates among member countries. After your product passes testing by a CB Testing Laboratory, you receive a CB test certificate and report. These documents allow you to apply for national certification in any member country without duplicate testing, streamlining your path to global market access.

CB certification for lithium batteries covers a wide range of battery types and chemistries. You can certify portable sealed secondary battery cells and battery packs containing alkaline or non-acid electrolytes, such as lithium-ion, lithium iron phosphate (LiFePO4), lithium nickel manganese cobalt oxide (NMC), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), and lithium titanate (LTO). These chemistries offer different platform voltages, energy densities, and cycle lives:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 100-180 | 2,000-5,000 |

NMC | 3.7 | 160-270 | 1,000-2,000 |

LCO | 3.7 | 180-230 | 500-1,000 |

LMO | 3.7 | 120-170 | 300-700 |

LTO | 2.4 | 60-90 | 10,000-20,000 |

You find CB certification for lithium batteries applicable to products used in consumer electronics, industrial, medical, robotics, security, and infrastructure sectors. The certification scope includes portable lithium-ion batteries, industrial lithium batteries, energy storage batteries, and battery packs for electric vehicles. Some batteries for specialized applications, such as automotive and medical devices, may require additional standards.

1.2 IEC Standards and Lithium Ion Battery

You rely on IEC standards to ensure your lithium ion battery packs meet international safety and performance benchmarks. The most relevant standards include IEC 62133, IEC 62619, IEC 62620, IEC 61960, IEC 63056, and the UN Manual of Tests 38.3. IEC 62133 certification is the de facto requirement for portable lithium ion batteries, covering electrical, mechanical, and chemical safety aspects. This standard mandates rigorous testing, such as overcharge, over-discharge, short-circuit, thermal runaway, and mechanical abuse tests.

IEC Standard | Application Area | Key Safety/Performance Aspects |

|---|---|---|

IEC 62133-2 | Portable lithium batteries | Overcharge, short circuit, drop, temperature cycling |

IEC 61960-3 | Small portable lithium-ion batteries | Capacity, cycle life, discharge characteristics |

IEC 62619 | Industrial lithium-ion batteries | Thermal stability, overcharge protection, short circuit protection |

IEC 62620 | Industrial lithium-ion batteries | Battery capacity, charge/discharge cycles, storage life |

IEC 63056 | Household lithium battery energy storage systems | Overheat protection, structural design, protection circuits |

You must ensure your lithium ion battery packs comply with IEC 62133, which specifies tests such as external short-circuit, free fall, crush, overcharging, and forced discharge. These tests simulate hazards and mechanical stresses, verifying that your batteries remain safe under various conditions. The standard also requires advanced battery management systems (BMS) with features like overcharge protection, temperature monitoring, and short-circuit prevention.

The CB scheme simplifies your global market access. When your lithium ion battery packs pass IEC 62133 and other relevant IEC standards, you receive a CB test certificate. This certificate allows you to apply for national certifications in over 50 member countries without retesting, unless national differences require additional checks. The CB scheme promotes cost-effective, time-saving certification, enabling you to expand your business internationally with confidence.

Tip: You should always declare national differences during initial testing to avoid delays in certification for specific markets.

CB certification for lithium batteries, supported by robust IEC standards, gives you a competitive edge. You demonstrate your commitment to safety, quality, and regulatory compliance, making your products attractive to partners and customers worldwide.

Part 2: Importance of CB Certification

2.1 Safety and Quality Assurance

You operate in a market where safety and reliability define your reputation. The importance of cb certification for lithium battery packs cannot be overstated. As a manufacturer, you face significant risks from mechanical failures, thermal runaway, electrical faults, and fire hazards. These risks can lead to costly recalls, legal liabilities, and damage to your brand.

CB certification addresses these challenges by enforcing rigorous safety and quality assurance measures. You must implement strategies that target every stage of battery design and production:

Innate safety: You select stable materials for anode, cathode, electrolyte, and separators to reduce the likelihood of failure.

Protective devices: You integrate vents, fuses, circuit breakers, and current interrupt devices to prevent electrical faults.

Thermal management: You use air cooling, liquid cooling, or phase change materials to control heat and prevent thermal runaway.

Mechanical mitigation: You reinforce battery casings and structures to withstand mechanical stress.

Fire control: You install early fire detection systems and use effective extinguishing agents to suppress fires.

To achieve battery cb certification, you must pass a comprehensive set of quality assurance tests:

Electrical Safety Tests: Overcharge, external short circuit, and forced discharge tests confirm your battery’s ability to handle electrical stress.

Mechanical Safety Tests: Vibration, crush, and free fall tests verify your battery’s durability during handling and transport.

Environmental Adaptability Tests: Temperature cycling, low-pressure simulation, and damp heat exposure ensure your battery performs reliably in extreme conditions.

Thermal Abuse and Specialized Tests: High temperature exposure, electrostatic discharge, and high-rate charge protection tests validate additional safety features.

Procedural Recommendations: You develop standard operating procedures, collaborate with certification bodies, and stay updated with evolving regulations.

By meeting these requirements, you demonstrate your commitment to safety certification and quality, which is essential for entering regulated sectors such as consumer electronics, industrial, medical, robotics and security applications.

The benefits of cb certification extend beyond compliance. You build trust with distributors and end-users, reduce the risk of product recalls, and protect your business from costly liabilities. You also position your lithium battery packs as reliable solutions in demanding environments.

2.2 Global Market Access

You face increasing pressure to expand your lithium battery exports and enter new international markets. The importance of cb certification becomes clear when you consider the complexity of global regulations. Without harmonized certification, you would need to navigate separate national standards, duplicate testing, and lengthy approval processes for each country.

CB certification acts as your passport to global trade. Regulatory authorities in major markets recognize the CB Scheme, which harmonizes testing procedures and leverages internationally accepted IEC standards like IEC 62133 and IEC 62619. This recognition streamlines your path to market entry.

Key benefits of cb certification for global market access include:

CB certification provides recognized proof of compliance with international safety and quality standards.

The CB test certificate reduces redundant testing, lowers costs, and shortens your time to market.

You gain access to over 50 countries without the need for multiple national certifications.

Certified products stand out, giving you a competitive edge and attracting distributors who require internationally recognized certifications.

You reduce legal risks, product recalls, and liability issues, supporting smoother lithium battery exports.

The certification mark increases consumer and distributor confidence, enhancing your brand reputation.

You streamline export processes, as customs and regulatory bodies worldwide accept CB certificates.

Benefit | Impact on Your Business |

|---|---|

Reduced Testing | Lower costs, faster market entry |

International Recognition | Access to 50+ countries with one certification |

Enhanced Brand Reputation | Increased trust from partners and customers |

Competitive Advantage | Differentiation from non-certified competitors |

Lower Legal and Recall Risks | Fewer liabilities and disruptions |

Streamlined Exports | Easier customs clearance and regulatory acceptance |

The importance of cb certification lies in its ability to open new markets, foster strong business partnerships, and ensure your lithium battery packs meet the highest global standards.

Part 3: Battery CB Certification Process

You secure your place in the global supply chain by investing in battery cb certification. You demonstrate your commitment to safety, quality, and international compliance, which is essential for long-term growth in the medical, robotics, Security, infrastructure, consumer electronics, and industrial sectors.

3.1 Application and Testing

You begin the cb certification process by preparing a detailed application that outlines your lithium battery pack’s specifications, intended use, and compliance with relevant IEC standards. You must understand the requirements of the cb scheme, especially IEC 62133, which governs safety and performance testing for lithium-ion, lithium iron phosphate (LiFePO4), and other chemistries used in consumer electronics, medical, and industrial sectors.

To apply for cb scheme certification, you gather comprehensive documentation, including technical drawings, safety analysis, and prior test results. Early preparation of these documents helps you avoid delays, as the documentation speed directly affects the overall timeline. You should also conduct internal safety and performance testing before submitting your batteries to a recognized laboratory.

Leading laboratories such as:

CSA Group, accredited under the IECEE CB Scheme, offer evaluation, testing, and certification for lithium battery packs. Their global labs test to standards like IEC 62133, UN38.3 certification, and ce certification.

UL Solutions, a key player in battery safety and performance testing, provides global market access services. They test lithium-ion cells and packs to IEC/UL 62133-2, ce certification, and ul certification requirements.

You coordinate with these labs to ship untested batteries safely and resolve design or material issues. The cb certification process for IEC standards, including ce certification, typically takes 6 to 8 weeks, as shown below:

Certification Type | Typical Test Duration |

|---|---|

CE certification | 4 – 6 weeks |

IEC (CB Scheme) | 6 – 8 weeks |

UL certification | 10 – 12 weeks |

UN38.3 certification | 4 – 6 weeks |

Tip: Prior internal testing and strong documentation help you streamline the cb certification process and avoid costly retesting.

3.2 Certification and Acceptance

After successful safety and performance testing, the laboratory issues a cb certificate. This document confirms your lithium battery pack meets the strict requirements of the cb scheme. You can then use the cb certificate to apply for national certifications in over 50 countries, reducing the need for repeated ce certification or additional safety and performance testing.

The cb certification process relies on mutual recognition among member countries. Regulatory authorities and distributors in robotics, security, and infrastructure sectors accept the cb certificate as proof of compliance. This global acceptance streamlines your market entry and enhances your brand’s reputation for safety and reliability.

You gain a competitive advantage by completing the cb certification process, as your lithium battery packs stand out for meeting international safety and performance standards.

You gain the benefits of cb certification by streamlining international compliance, enhancing safety, and accelerating market access for lithium battery packs. Understanding IEC 62133 and the CB process helps you reduce costs and risks. For tailored solutions, request a custom battery consultation.

Key Benefit | Impact for B2B Clients |

|---|---|

Compliance | Simplifies global certification |

Safety | Reduces liability and market risks |

Market Expansion | Enables entry into 50+ countries |

FAQ

1. What is the typical timeline for CB certification of lithium battery packs?

You usually complete CB certification in 6 to 8 weeks. Preparation, documentation, and pre-testing with Large Power can help you avoid delays. Request a custom battery solution.

2. Which lithium battery chemistries can you certify under the CB Scheme?

You can certify lithium-ion, lithium iron phosphate (LiFePO4), lithium nickel manganese cobalt oxide (NMC), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), and lithium titanate (LTO) battery packs.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 100-180 | 2,000-5,000 |

NMC | 3.7 | 160-270 | 1,000-2,000 |

3.7 | 180-230 | 500-1,000 | |

LMO | 3.7 | 120-170 | 300-700 |

LTO | 2.4 | 60-90 |

3. Does CB certification cover all application scenarios for lithium battery packs?

CB certification applies to medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Some specialized uses may require additional standards.