You face unique challenges when powering underwater cleaning robots. Reliability, efficiency, and safety matter most in these tough environments. Waterproofing and pressure resistance protect sensitive electronics from underwater hazards. Advanced lithium battery packs, such as LiFePO4 and NMC, play a key role in delivering consistent energy. Environmental factors like water pressure and temperature impact power systems every day. The growth in the global underwater cleaning robot market shows that industries now prioritize reliable power systems to boost operational performance and safety.

Key Takeaways

Choose advanced lithium battery packs like LiFePO4 and NMC for reliable power in underwater cleaning robots. These batteries offer high energy density and long cycle life, ensuring efficient operation.

Implement robust waterproofing techniques to protect sensitive electronics from water damage. Use conformal coatings and pressure-resistant enclosures to maintain operational integrity.

Prioritize safety by using battery management systems and waterproof connectors. These features help prevent overheating and short circuits during underwater operations.

Consider the operational environment when selecting between tethered and untethered robots. Each option has unique advantages that affect range, flexibility, and cleaning efficiency.

Stay updated on emerging battery technologies and charging methods. Innovations like wireless charging and self-breathing batteries can enhance robot performance and extend mission durations.

Part 1: Powering Underwater Cleaning Robots

1.1 Energy Sources

You need to select the right energy sources when powering underwater cleaning robots. The choice impacts operational reliability, cleaning effectiveness, and safety. Most underwater robots rely on advanced lithium battery packs, including chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. These batteries deliver high energy density and long cycle life, which are essential for hull cleaning tasks in harsh underwater environments.

Tip: Lithium battery packs outperform traditional lead-acid and silver-zinc batteries in underwater applications. You gain longer operational time and reduced maintenance costs.

Here is a comparison of battery types used for powering underwater cleaning robots:

Aspect | Lithium-ion Batteries | Lead-acid Batteries | Silver-zinc Batteries |

|---|---|---|---|

Energy Density | High | Low | High |

Cycle Life | Long | Short | Short |

Maintenance Costs | Reduced | Higher | Higher |

Pressure Compensation | Designed for high hydrostatic pressures | Not designed | Limited |

Structural Design | Pressure compensated structures | Standard designs | Standard designs |

You see lithium battery packs used in medical devices, robotics, security systems, infrastructure monitoring, consumer electronics, and industrial machinery. For underwater hull cleaning, these batteries provide the power needed for persistent cleaning and navigation.

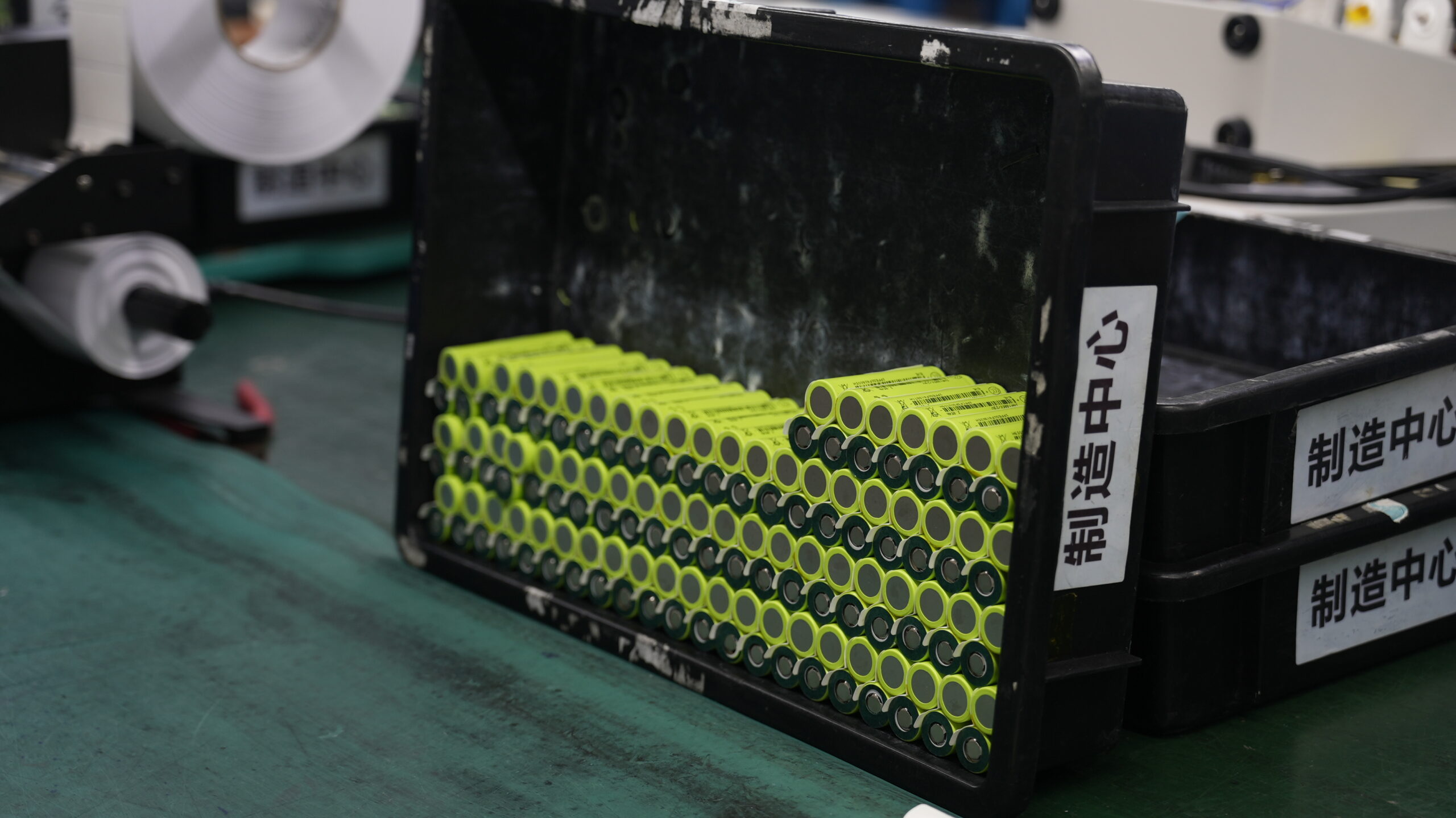

1.2 Lithium Battery Packs

Lithium battery packs play a central role in powering underwater cleaning robots. You benefit from several advancements in battery technology:

Feature | Description |

|---|---|

High Energy Density | Store more energy in a smaller, lighter package compared to lead-acid batteries. |

Long Cycle Life | Last several years with proper management, reducing replacement frequency. |

Rapid Charging Capability | Charge quickly, enhancing operational readiness. |

Environmental Impact | More environmentally friendly than alternatives. |

Innovative Designs | Operate effectively at high pressures and low temperatures. |

The U.S. Navy deploys lithium-ion batteries in Virginia-class submarines.

Japan and Germany research lithium-ion solutions for underwater vehicles.

You must address several challenges when using lithium battery packs for hull cleaning:

Safety Concerns: Lithium-ion batteries can experience thermal runaway. You need robust battery management systems.

Pressure and Temperature Variability: Batteries must withstand significant changes in underwater conditions.

Cost: Lithium battery packs cost more initially, but you gain long-term benefits.

Lithium-ion batteries offer energy and power density comparable to silver-zinc batteries. You get improved cycle life, shelf life, and lower maintenance requirements. These advantages make lithium battery packs the preferred choice for powering underwater cleaning robots in industrial and commercial hull cleaning operations.

1.3 Tethered vs. Untethered

You must decide between tethered and untethered solutions when powering underwater cleaning robots. Each option affects operational range, flexibility, and cleaning efficiency.

Type | Advantages | Disadvantages |

|---|---|---|

Tethered ROVs | – Uninterrupted Power Supply | – Limited Range |

– High Data Transmission Rates | – Risk of Entanglement | |

– Enhanced Control and Stability | – Increased Drag | |

– Reliable Communication | – Logistical Challenges | |

Untethered ROVs | – Extended Range | – Limited Operational Time |

– No Risk of Entanglement | – Data Transmission Delays | |

– Greater Maneuverability | – Autonomy and Navigation Challenges | |

– Simplified Deployment | – Communication Limitations |

You gain uninterrupted power and reliable communication with tethered robots, but you face limited range and risk of cable entanglement. Untethered robots offer extended range and greater maneuverability for hull cleaning, but you must manage limited operational time and data transmission delays.

Existing autonomous underwater vehicles (AUVs) cannot perform long-range hull cleaning at close proximity to the ocean floor. You need disruptive new technologies for persistent navigation and cleaning near the bottom. When you require physical samples or real-time data, tethered remotely operated vehicles (ROVs) provide reliable solutions, but only within a limited range.

Note: Your choice between tethered and untethered solutions depends on the specific hull cleaning task, operational environment, and power requirements.

Part 2: Battery Endurance Challenges

2.1 Battery Life Limits

You rely on lithium battery packs to power underwater cleaning robots during biofouling removal. Battery capacity directly affects how long your robot can operate underwater before needing a recharge. Most lithium batteries in robotic pool cleaners deliver up to 120 minutes of continuous cleaning on a single charge. Commercial underwater robots show a range of operating times, as seen below:

Model | Operating Time |

|---|---|

Entry-level models | 45 to 90 minutes |

Beatbot AquaSense 2 Pro | Up to 180 minutes |

AquaSense 2 Ultra | Up to 180 minutes |

Battery degradation impacts performance and maintenance schedules. You should regularly monitor battery life and charging efficiency. Avoid overcharging or letting the battery drain completely. Always use the charger recommended by the manufacturer to prevent damage.

2.2 Cleaning Duration

Cleaning duration depends on battery capacity and several operational factors. You must consider hull material, biofouling, cleaning techniques, vessel size, hull condition, diver experience, equipment maintenance, water conditions, environmental regulations, and preparation time. The table below highlights how these factors influence cleaning duration for underwater robots:

Factor | Influence on Cleaning Duration |

|---|---|

Hull Material | Different materials may require specific cleaning methods. |

Biofouling | Presence of marine growth affects cleaning efficiency. |

Cleaning Techniques | Various methods impact time efficiency. |

Vessel Size and Type | Larger vessels generally require more time and effort. |

Hull Condition | Condition before cleaning impacts duration. |

Diver Experience | Skilled divers optimize cleaning processes and timing. |

Equipment | Proper maintenance enhances performance. |

Water Conditions | Depth, current strength, and visibility affect cleaning. |

Environmental Regulations | Compliance can influence the methods and time required. |

Preparation and Inspection | Thorough prep is crucial for effective cleaning operations. |

You see that battery endurance and cleaning duration are closely linked. If your robot runs out of power underwater, cleaning stops and operational efficiency drops.

2.3 Extending Endurance

You can maximize battery life and extend operational endurance by using several strategies:

Energy management systems utilize multi-energy acquisition strategies to improve battery efficiency and longevity. These systems optimize battery usage by managing charging and discharging states based on load power and mixed energy output.

Refined cleaning methods, such as low-energy techniques, help minimize damage and maximize efficiency.

Advanced control technologies use lightweight materials and optimized designs to improve flexibility and endurance in complex underwater environments.

Strategy | Description |

|---|---|

Energy Efficiency | Enhance energy management and develop energy recovery systems. |

Refined Cleaning Methods | Implement low-energy cleaning techniques for maximum efficiency. |

Advanced Control Tech | Use lightweight materials and optimized designs for better endurance. |

Tip: Consider integrating a battery management system (BMS) to monitor and control lithium battery packs.

You need reliable solutions to ensure your underwater robots complete biofouling removal tasks efficiently. By focusing on battery endurance, you improve operational performance and reduce downtime.

Part 3: Charging Methods for Underwater Robots

3.1 Underwater Charging Stations

You need reliable charging stations to keep your underwater cleaning robots operational. Several types of underwater charging stations support different equipment and mission profiles:

Subsea Drone Docking Station (SDS): Blue Logic developed this station for universal, open-standard subsea drones. SDS works well for shallow deployments but faces challenges in deeper waters and requires complex equipment.

New Conceptual Subsea Charging Station: This design uses ocean energy to generate electricity in situ. It employs ultrasonic technology for efficient energy transmission and can serve multiple underwater devices at once.

Multi-device Charging Capability: The latest stations allow you to charge various underwater equipment types simultaneously, improving efficiency and supporting sustainable operations.

Charging stations play a critical role in extending the working time of lithium battery packs. You can deploy these stations at strategic locations to minimize downtime and maximize cleaning coverage.

3.2 Wireless Charging

Wireless charging offers promising solutions for underwater cleaning robots. You can recharge robots remotely and contactlessly, which helps extend mission durations. Wireless power transfer (WPT) systems, such as magnetically coupled resonant wireless power transfer (MCR-WPT), provide stable and adaptable energy supply underwater. Traditional contact-based charging methods often struggle with corrosion, limited battery life, and operational interruptions. MCR-WPT stands out for its high efficiency and adaptability in underwater environments. However, microwave radiation WPT and electric field coupling WPT lose significant energy in seawater, making them less suitable for high-power applications.

You face several technical challenges with wireless charging underwater. Water salinity causes energy loss during transmission. Alignment between the robot and charging station can be difficult. You must use durable materials that withstand underwater conditions. These factors impact the reliability and efficiency of wireless charging solutions.

Wireless charging technology (MCR-WPT) delivers stable energy supply and supports continuous operation.

Contact-based charging methods face corrosion risks and frequent interruptions.

Microwave and electric field coupling WPT are less efficient due to seawater properties.

3.3 Safety Concerns

You must prioritize safety when recharging underwater cleaning robots. High-pressure environments and water exposure increase the risk of short circuits and equipment failure. Lithium battery packs require robust management systems to prevent overheating and thermal runaway. You should use waterproof connectors and pressure-resistant housings to protect sensitive electronics. Regular inspection and maintenance help you avoid accidents and ensure reliable operation. Safety protocols and advanced monitoring systems support safe charging practices for all underwater solutions.

Tip: Always follow manufacturer guidelines for charging lithium battery packs in underwater environments. Proper procedures reduce risks and extend battery life.

Part 4: Environmental and Operational Challenges

4.1 Waterproofing Electronics

You face constant threats from water ingress when you deploy underwater cleaning robots. Moisture can cause current leakage, corrosion, and catastrophic failure of sensitive electronics. You need robust waterproofing techniques to protect lithium battery packs and control systems during cleaning operations.

Conformal coatings provide a protective layer over electronic components. These coatings prevent current leakage and reduce corrosion, although they allow some moisture to penetrate. You often use dielectric grease in connectors and switches to create a moisture barrier. Silicone grease works well in extreme underwater conditions. You rely on enclosures with rubber gaskets and silicone sealants to block water entry. For high-voltage devices, the potting method offers strong protection against heat and vibration. You should select materials and application methods that meet IPC standards to ensure long-term reliability.

Tip: Regular inspection of seals and coatings helps you maintain the integrity of your underwater robots and avoid unexpected downtime.

4.2 Pressure and Temperature

You operate underwater cleaning robots in environments with high pressure and fluctuating temperatures. These factors challenge the durability of lithium battery packs and electronic systems. You must design robots to withstand hydrostatic pressure and thermal stress during marine maintenance and marine infrastructure maintenance.

Feature/Material | Description |

|---|---|

Composite Hull | |

Mechanical Cleaning Methods | Traditional methods improve efficiency and reduce surface damage. |

Cavitation Jet Cleaning | Cavitation jets clean surfaces without causing harm. |

You optimize the robot’s body shape for hydrodynamic performance. This design minimizes resistance and helps the robot withstand strong currents. You analyze existing designs, develop new hydrodynamic shapes, and conduct experimental evaluations to test pressure resistance. You must balance pressure resistance with maneuverability and energy efficiency.

You evaluate hydrodynamic performance to ensure the robot survives high-pressure environments.

You compromise in design to meet both pressure resistance and operational requirements.

Temperature changes affect battery performance. You select lithium battery chemistries such as LiFePO4 and NMC for their stability in varying temperatures. You monitor battery temperature during cleaning operations to prevent overheating and extend battery life.

4.3 Navigation and Obstacles

You encounter complex underwater environments filled with obstacles, strong currents, and limited visibility. Navigation systems must guide robots safely and efficiently during marine maintenance tasks. You use advanced sensors, sonar, and cameras to detect obstacles and map the cleaning area.

You need reliable navigation algorithms to avoid collisions and optimize cleaning paths. Strong currents can push robots off course, so you design control systems that adjust for environmental changes. You select lightweight materials and streamlined shapes to improve maneuverability and reduce energy consumption.

Note: You should test navigation systems in real-world conditions to ensure consistent performance during underwater cleaning operations.

4.4 Data Management

You generate large volumes of data during underwater cleaning missions. Data includes sensor readings, video footage, and operational logs. You must store and transmit this data securely and efficiently.

Underwater environments limit wireless communication. You often rely on tethered connections for high-speed data transfer. Untethered robots store data locally and upload it when they surface. You face challenges with data integrity and transmission delays.

You implement robust data management systems to organize and protect mission-critical information. You use encryption and redundancy to safeguard data against loss or corruption. You analyze collected data to improve future cleaning operations and optimize robot performance.

Tip: You should schedule regular data backups and system checks to maintain data reliability in underwater environments.

Part 5: Underwater Cleaning Robot Market and Innovations

5.1 Market Trends

You see rapid growth in the underwater cleaning robot market across shipping, defense, and oil & gas industries. This expansion comes from technological advancements, stricter regulations, and a global push for environmental sustainability. The Asia Pacific region leads the underwater cleaning robot market, with a projected value of USD 470 million in 2024 and a CAGR of 12.1% through 2033. Strong maritime activity and government support drive this trend. North America and Europe also show robust market values, at USD 340 million and USD 290 million, respectively. These regions emphasize advanced technologies and regulatory compliance. Over the past five years, demand for underwater cleaning robots has surged. You notice this especially in the underwater ship cleaning robot sector, where companies invest in product development and marketing to meet new challenges.

5.2 Safety and Reliability

You must prioritize safety and reliability when deploying underwater cleaning robots in industrial settings. The underwater cleaning robot market values simple, robust designs with fewer components to reduce the risk of failure. You often design robots to meet specific subsea project requirements. You select materials and configurations that withstand harsh underwater conditions. You incorporate safety features such as redundancy and fault tolerance. These strategies help you maintain operational reliability and minimize downtime. You also see a growing focus on real-time monitoring systems, which allow you to track robot performance and battery status during missions.

Design robots for project-specific needs

Choose durable materials and configurations

Add redundancy and fault tolerance for safety

5.3 Future Technologies

You can expect emerging battery technologies to transform the underwater cleaning robot market. New solutions like the self-breathing battery promise greater efficiency and new capabilities.

Emerging battery technologies, particularly the self-breathing battery, could significantly enhance the capabilities of underwater cleaning robots by providing efficient energy solutions and facilitating automatic diving and surfacing mechanisms. The Self-BAAAB battery operates by using oxygen gas in the routine discharge process, which triggers a sharp density variation, driving an automatic snorkeling feature in underwater electronic equipment, helping the machine it powers surface.

You will see lithium battery packs such as LiFePO4 and NMC continue to dominate, but new chemistries and smart battery management systems will improve endurance and safety. You may also benefit from advanced wireless charging and modular power systems, which support longer missions and easier maintenance. The underwater cleaning robot market will rely on innovation to overcome power challenges and deliver reliable, efficient solutions for industrial applications.

You face several power and operational challenges when deploying underwater cleaning robots.

Efficient power management requires advanced lithium battery packs such as LiFePO4 and NMC.

Reliable waterproofing protects sensitive electronics from water damage.

Safety features like central relay systems and sealed enclosures help prevent failures.

Ongoing innovation in battery technology and waterproofing lets you extend robot autonomy and reduce downtime. You benefit from new charging methods and improved connectors, which support longer missions and greater reliability.

Continuous improvement drives the underwater cleaning robot market forward, helping you meet demanding industrial needs.

FAQ

What lithium battery chemistries work best for underwater cleaning robots?

You should consider LiFePO4 and NMC lithium battery packs. These chemistries offer high energy density, long cycle life, and strong performance under pressure. They also provide better safety and reliability for industrial underwater cleaning operations. Consult Large Power for tailored battery solutions for your underwater cleaning robots.

How do lithium battery packs handle underwater pressure?

Manufacturers design lithium battery packs with pressure-compensated housings. You benefit from robust seals and advanced materials that protect cells from water ingress and crushing forces. This ensures reliable power delivery during deep-water cleaning tasks.

What is the typical operational time for robots using lithium battery packs?

Most underwater cleaning robots powered by lithium battery packs operate for 90 to 180 minutes per charge. Actual duration depends on battery capacity, cleaning intensity, and environmental conditions. You can extend runtime by optimizing energy management systems.

How do you safely recharge lithium battery packs underwater?

You use waterproof connectors and pressure-resistant charging stations. Wireless charging systems, such as magnetically coupled resonant wireless power transfer (MCR-WPT), reduce corrosion risks. Always follow manufacturer safety protocols to prevent short circuits and battery damage.

How do lithium battery packs compare to other battery types for underwater robots?

Battery Type | Energy Density | Cycle Life | Pressure Resistance | Maintenance |

|---|---|---|---|---|

Lithium (LiFePO4, NMC) | High | Long | Excellent | Low |

Lead-acid | Low | Short | Poor | High |

Silver-zinc | High | Short | Limited | High |

You gain longer operational time, better safety, and lower maintenance with lithium battery packs compared to other options.