Digital twin technology changes how you manage lithium battery packs in mobile devices. You gain access to high-fidelity virtual replicas that mirror every detail of your battery systems. Real-time monitoring helps you track battery health, performance, and safety with precision. Digital twin technology brings significant gains for your operations. Recent industry reports show:

Metric | Improvement |

|---|---|

Cost Savings | Up to 80% |

Development Efficiency | 25% |

Additional Cost Reduction | 15% (testing) |

With digital twin technology, you unlock new levels of efficiency and cost savings. You see better reliability and easier decision-making for battery management.

Key Takeaways

Digital twin technology provides real-time monitoring of lithium batteries, helping you track health and performance to prevent issues before they escalate.

Implementing digital twins can lead to cost savings of up to 80% in production and a 25% increase in development efficiency, making operations more profitable.

Predictive maintenance through digital twins reduces downtime by up to 70%, extending the lifecycle of battery systems and lowering operational costs.

Digital twins support sustainability by optimizing battery lifecycle management, reducing emissions by 50%, and enhancing recycling efforts.

Adopting digital twin technology gives you a competitive edge, allowing for faster innovation cycles and improved accuracy in battery management.

Part 1: Digital Twin Technology in Battery Management

1.1 Digital Twin Definition

You need a clear understanding of digital twin technology to optimize lithium battery management in mobile devices. A digital twin is a virtual representation of a lithium battery. You use this technology to monitor performance, predict outcomes, and improve operations. Digital twins synchronize with real-time operational conditions. You gain insights into the battery’s internal dynamics and can forecast future states using battery analytics. This approach supports battery management systems for LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal chemistries. You rely on digital twins to track state of charge and state of health, which are critical for maintaining battery reliability and safety.

Tip: Digital twins help you identify issues before they impact device performance. You can use adaptive digital twin models to adjust to changing battery conditions and extend battery life.

1.2 How Digital Twins Work

You create a digital twin by integrating real-time sensor data with high-fidelity simulations. This process allows you to mirror the physical battery’s behavior and predict future performance. You use battery analytics to analyze data from sensors, including temperature, voltage, and current. Advanced simulation capabilities enable you to model complex battery chemistries and operating environments. Hybrid digital twin approaches combine physical models with data-driven analytics for more accurate predictions.

Here is a breakdown of the key components and processes involved in digital twins for lithium battery systems:

Key Components/Processes | Description |

|---|---|

Real-time sensor data | You integrate live data for accurate predictions and decision-making. |

Modeling | You use models to create asset-specific predictions and optimize battery performance. |

Standardized data sharing | You share data transparently among stakeholders for effective collaboration. |

Uncertainty quantification | You quantify uncertainty from sensors and models to improve prediction reliability. |

Physical understanding retention | You maintain knowledge of critical parameters for precise measurement and control. |

Data immutability | You ensure data integrity, often using digital ledger technology for secure records. |

You benefit from high-fidelity simulations that allow you to test battery performance under different conditions. Battery analytics help you optimize charging cycles and predict degradation. Digital twins support lifecycle management and sustainability by providing actionable insights for recycling and resource management.

Part 2: Core Technologies and Real-Time Monitoring

2.1 Data Integration

You rely on digital twins to bring together multiple types of data for lithium battery management. This integration forms the backbone of accurate modeling and monitoring. You collect experimental data from real-world battery tests, sensor data from devices in operation, and model generation data from simulations. These sources help you build a digital twin that reflects the true state of your battery packs.

Data Type | Description |

|---|---|

Experimental Data | Data obtained from real-world experiments related to battery performance and behavior. |

Sensor Data | Information collected from sensors monitoring battery conditions in real-time. |

Model Generation Data | Data used to create and refine the digital twin model based on simulations and theoretical models. |

You also use real data from charge-discharge cycles and aging datasets, such as those from NASA Ames Prognostics Center of Excellence. This comprehensive approach ensures your digital twins remain accurate and reliable across different lithium battery chemistries, including LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal.

2.2 Real-Time Monitoring

Digital twins excel at real-time monitoring. You track battery health, temperature, voltage, and current as they change. Real-time monitoring lets you calibrate your models against actual battery behaviors. You use multi-physics simulation engines to align digital twins with real-world conditions. These engines generate high-quality synthetic datasets and synchronize operational profiles. You conduct calibrated simulation campaigns that produce multi-domain information in time series.

Note: Real-time monitoring enables continuous calibration, which improves the accuracy and reliability of your digital twins. You gain interactive feedback and can optimize battery performance and safety.

You detect anomalies early and take corrective actions before issues escalate. This proactive approach supports predictive maintenance and reduces downtime for your battery systems.

2.3 Cloud-Based Systems

Cloud-based systems play a vital role in digital twin solutions for battery management. You process and analyze vast amounts of data using big data analytics. Artificial intelligence helps you predict maintenance needs and detect anomalies. Augmented reality and virtual reality tools provide immersive visualization, making it easier to understand complex battery systems.

Advantage | Description |

|---|---|

Big Data Analytics | Enables processing and analysis of vast data to extract insights for optimizing processes and predicting maintenance needs. |

Artificial Intelligence (AI) | Enhances functionalities like predictive maintenance and anomaly detection through machine learning algorithms that analyze data for operational optimization. |

Augmented Reality (AR) and VR | Provides immersive visualization and interaction with digital twins, aiding in understanding complex systems and supporting collaborative decision-making. |

Data Integration and Interoperability | Ensures smooth data flow between various systems, providing a holistic view of physical assets represented in the digital twin. |

Communication and Networking | Facilitates reliable data transfer between physical assets and cloud infrastructure using robust communication protocols and standards. |

You benefit from seamless data integration and interoperability, which gives you a holistic view of your battery assets. Reliable communication and networking ensure that real-time data flows smoothly between your physical battery packs and cloud infrastructure. These technologies enable advanced analytics and predictive maintenance, helping you optimize battery performance and extend lifecycle.

Part 3: Benefits for Battery Performance

3.1 Efficiency and Cost Reduction

You gain measurable improvements in efficiency and cost reduction when you implement digital twins for lithium battery management. Digital twins allow you to simulate real-world conditions, optimize charging cycles, and identify inefficiencies in your energy storage systems. You can use adaptive models to adjust to changing operational demands, which leads to better performance optimization and reduced waste.

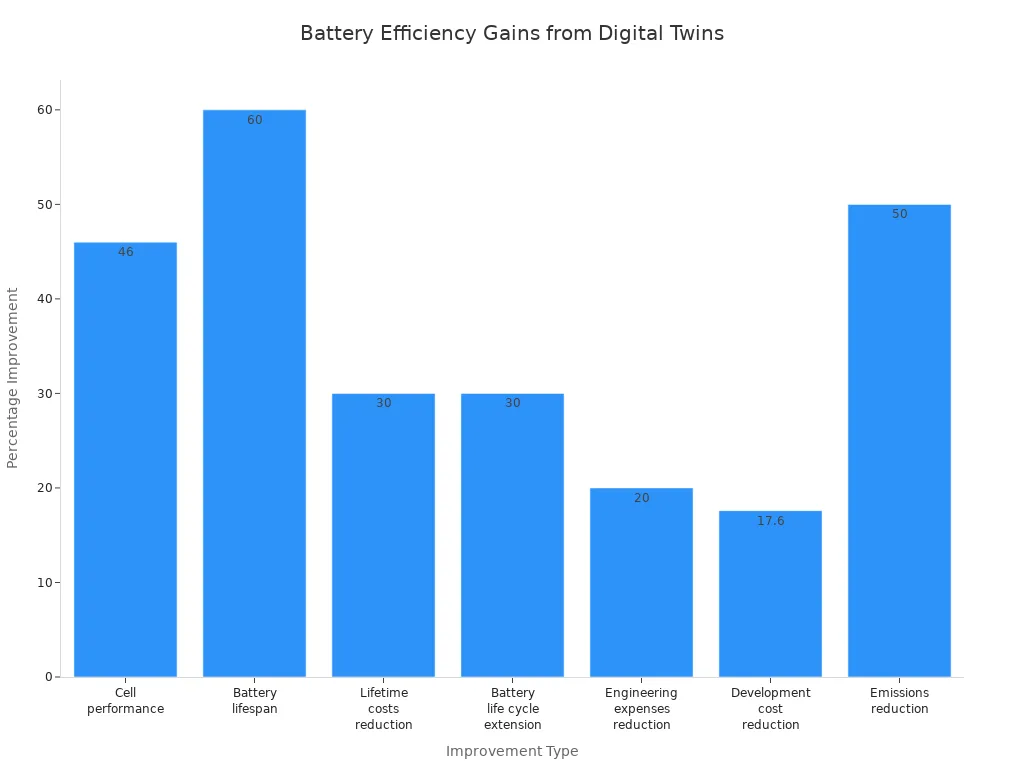

Improvement Type | Percentage Improvement |

|---|---|

Cell performance | 46% |

Battery lifespan | 60% |

Lifetime costs reduction | 30% |

Battery life cycle extension | 30% |

Engineering expenses reduction | 20% |

Development cost reduction | 17.6% |

Time to market reduction | From 36-60 months to 9-15 months |

Emissions reduction | 50% |

You see these benefits across multiple sectors, including medical devices, robotics, security systems, and industrial automation. Digital twins help you reduce production costs by up to 80%. You also improve development efficiency by 25% and cut testing costs by 15% compared to traditional methods. These gains translate into faster time to market and lower total cost of ownership for your lithium battery packs.

Cost savings of up to 80% in production costs through digital twin technology.

Enhancement of development efficiency by 25%.

Additional cost reduction of 15% in testing operations compared to traditional methods.

You achieve operational efficiency by integrating digital twins with your battery management systems (BMS). This integration ensures real-time data flows between your physical assets and digital models, supporting continuous optimization and adaptive control.

3.2 Predictive Maintenance

Digital twins transform your approach to predictive maintenance. You use real-time data and simulation to monitor battery health and predict failures before they occur. This proactive strategy reduces downtime and extends the lifecycle of your energy storage assets.

Evidence Description | Impact on Battery Performance |

|---|---|

Real-time data acquisition and dynamic model evolution enable accurate life prediction | Reduces battery failure rates and extends lifespan |

Maintenance cost reductions of 62.0% and 52.5% for L1 and L6 batteries, respectively | Indicates economic benefits of predictive maintenance |

You can reduce equipment breakdowns by up to 70% with predictive maintenance. This approach leads to a 10-15% reduction in operational costs for manufacturers. You also achieve up to 25% reduction in maintenance costs through optimized scheduling. Uptime improvements of 10-20% directly enhance your production output and revenue.

Leading organizations generate over 50% of maintenance work through predictive methods.

Energy sectors can achieve 38% savings, while transportation can cut unplanned downtime by 50%.

You rely on adaptive digital twins to evolve with your battery systems. These models use continuous simulation and real-time feedback to support lifecycle optimization and performance improvement. You can apply these benefits in infrastructure, consumer electronics, and industrial sectors, where reliability and uptime are critical.

3.3 Lifecycle and Sustainability

You address sustainability and resource management by leveraging digital twins for lifecycle optimization. Digital twins provide a complete view of your battery’s lifecycle, from design and manufacturing to operation, recycling, and end-of-life management. You use simulation to predict degradation patterns and plan for recycling or repurposing, which supports circular economy goals.

You extend the lifecycle of your lithium battery packs by up to 30%. You also reduce emissions by 50%, which aligns with global sustainability targets. Digital twins help you manage energy storage assets more responsibly, ensuring efficient use of raw materials and minimizing waste.

Digital twins support recycling initiatives by tracking battery health and usage history.

You optimize resource allocation and reduce environmental impact through data-driven decision-making.

Lifecycle optimization enables you to meet regulatory requirements and improve your brand reputation.

You see these sustainability benefits in sectors such as medical, robotics, and infrastructure, where energy storage reliability and environmental responsibility are essential. Digital twins empower you to make informed decisions that balance performance, cost, and sustainability throughout the entire lifecycle of your lithium battery systems.

Part 4: Industry Challenges and Applications

4.1 Pre-Production and Design

You face many challenges during the pre-production phase of lithium battery development for mobile devices. Digital twins serve as digital replicas of physical products. You use these virtual models to analyze and predict the lifecycle of lithium battery packs. By comparing your actual product with its digital counterpart, you quickly identify and diagnose issues. This approach leads to more efficient problem resolution and better resource management.

Challenge | Digital Twin Solution |

|---|---|

Optimizing material movement | Simulates processes to optimize the movement of materials during critical production phases. |

Integrating quality analytics and traceability | Provides a holistic view by integrating data from various departments, enhancing quality control. |

Reducing commissioning time for new lines | Allows pre-commissioning of production lines in a virtual environment, reducing delays and costs. |

You gain the ability to simulate production scenarios before physical implementation. This reduces commissioning time and helps you avoid costly mistakes. You also improve traceability and quality analytics by integrating data from multiple departments.

4.2 Degradation and Risk Management

You use digital twins to monitor and manage battery degradation and associated risks. Real-time monitoring integrates sensor data for continuous visibility into battery performance. You spot anomalies early and take corrective action. Predictive maintenance calculates metrics like state of health (SoH) to forecast degradation trends and remaining useful life. Safety simulations allow you to test stress conditions and detect precursors to thermal runaway, improving safety compliance.

Method | Description |

|---|---|

Real-time Monitoring | Integrates sensor data for continuous visibility into battery performance, spotting anomalies early. |

Predictive Maintenance | Calculates metrics like state of health (SoH) to forecast degradation trends and remaining useful life. |

Safety Simulations | Simulates stress conditions to detect precursors to thermal runaway, improving safety compliance. |

You benefit from a secure and transparent battery data framework. This reduces asset risk and can lead to cheaper capital availability through international green bonds. Enhanced residual value of batteries at the end of their first life supports better financial outcomes. Lower financing costs can reduce EMI outgo for fleet operators, potentially boosting EV sales and adoption. Organizations using digital twins for predictive maintenance have reported a reduction in unplanned downtime by up to 15%.

4.3 Adoption Trends

You see rapid adoption of AI-powered digital twin technology in the mobile device battery industry. Manufacturers use virtual models to predict battery performance and degradation, which significantly reduces development time and costs.

Foundation model-based digital twins enable extensive simulations of various driving conditions, enhancing the accuracy of battery aging predictions.

The technology allows parallel processes in development, so you can incorporate new technologies into battery designs more quickly.

This shift towards real-time, predictive modeling provides a competitive edge in the EV market.

You gain faster innovation cycles and improved accuracy in battery management. Digital twins help you stay ahead in a competitive industry by enabling smarter, data-driven decisions for lithium battery packs.

Part 5: Future Trends for Digital Twins in Battery Management

5.1 Evolving Standards

You see new standards emerging for digital twin technology in lithium battery management. These standards focus on optimizing charging processes and integrating user preferences. You use hybrid models to track both the charging state and health state of lithium-ion batteries. This approach extends battery lifespan and meets performance requirements. The latest frameworks address the challenge of balancing charging efficiency with battery service life. You gain enhanced stability and safety for your energy systems.

Aspect | Description |

|---|---|

Focus | Optimization of charging processes and integration of user preferences |

Methodology | Hybrid model for digital twin of lithium-ion battery charging state and health state |

Key Findings | Proposed framework extends battery lifespan while meeting performance requirements |

Implications | Addresses contradiction between charging efficiency and battery service life, enhancing stability |

5.2 Competitive Advantage

You gain a strong competitive edge by adopting digital twin technology for lithium battery management. You improve accuracy in tracking the state of health, which leads to better management decisions. You identify optimal charging and discharging strategies, maximizing energy throughput. You shift from reactive to proactive maintenance by modeling battery degradation. You detect anomalies early and intervene before issues escalate.

Competitive Advantage | Description |

|---|---|

Improved Accuracy in State of Health | You enhance precision in tracking battery health, leading to better management decisions. |

Enhanced Performance Optimization | You identify optimal charging and discharging strategies, maximizing energy throughput. |

Proactive Maintenance Strategies | You optimize maintenance scheduling, shifting from reactive to proactive approaches. |

Advanced Anomaly Detection Capabilities | You identify early signs of degradation, allowing for timely interventions. |

You also unlock new opportunities for innovation. Digital twins let you simulate and optimize operations in real time. For example, you can resolve critical battery cooling issues in days instead of weeks. You test products under various conditions without physical prototypes. You refine workflows and identify product issues early, speeding up resolution.

You simulate and optimize operations in real time.

You resolve battery issues faster, improving efficiency.

You test products under different conditions without physical testing.

You refine workflows and identify product issues early.

5.3 Market Outlook

You operate in a rapidly growing market. Digital twin technology is crucial for improving production efficiency and reducing costs in the lithium battery sector. The global battery industry is expected to grow from $112 billion in 2021 to $424 billion by 2030. Demand for electric vehicles will increase sixfold during this period. You must address supply chain vulnerabilities to meet this demand.

You see a surge in demand for advanced battery management solutions.

You invest in cybersecurity to protect sensitive battery data.

You develop your workforce to handle advanced technologies.

You form strategic partnerships and foster innovation to stay competitive.

Implication | Description |

|---|---|

Increased Demand for Solutions | You face a surge in demand for advanced battery management solutions. |

Investment in Cybersecurity | You invest in cybersecurity to protect sensitive battery data and maintain user trust. |

Workforce Development | You develop your workforce to handle advanced technologies. |

Strategic Partnerships and Innovation | You form partnerships and foster innovation to maintain a competitive edge. |

You position your organization for success by embracing digital twin technology. You meet market demands, improve operational efficiency, and drive innovation in lithium battery management.

Digital twin technology changes how you manage lithium battery packs. You improve efficiency, cut costs, and support sustainability across LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal chemistries. To choose the right solution, follow these steps:

Step | Description |

|---|---|

1 | Identify essential features of the digital twin solution. |

2 | Design scoring guidelines for each feature. |

3 | Calculate a weighted average score based on evaluated attributes. |

4 | Rank the solutions based on the final score to determine the best fit for your needs. |

Consider these questions before you adopt digital twin technology:

What ethical concerns could arise, especially in sensitive sectors?

Who leads adoption, and what challenges do they face?

Where will digital twins have the greatest impact?

When will digital twins become mainstream?

Why do some industries adopt digital twins faster than others?

FAQ

What is a digital twin in lithium battery management?

A digital twin is a virtual model of your lithium battery pack. You use it to monitor performance, predict failures, and optimize operations for chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal.

How does real-time monitoring improve battery reliability?

You track battery health, temperature, and voltage in real time. This lets you spot issues early, reduce downtime, and extend battery life. Real-time data helps you make fast, informed decisions for your battery systems.

Which lithium battery chemistries benefit most from digital twins?

You see strong benefits for LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal chemistries. Digital twins help you optimize cycle life, energy density, and safety across these platforms.

Can digital twins support predictive maintenance for battery packs?

You use digital twins to predict maintenance needs before failures occur. This approach lowers costs, reduces unplanned downtime, and improves asset reliability for your lithium battery packs.

What challenges should you consider when adopting digital twin technology?

You must address data integration, cybersecurity, and workforce training. You also need to ensure compatibility with your existing battery management systems and follow industry standards for lithium battery chemistries.