You will find an electric powertrain replaces the traditional engine with advanced electric components that move your vehicle efficiently.

-

The main powertrain components include the battery pack, traction inverters, and electronic control units, which work together to deliver power to the wheels.

Today’s electric vehicles rely on a rechargeable battery with much higher energy density than early models, thanks to lithium-ion technology.

Key Takeaways

-

Electric powertrains use batteries and electric motors to move vehicles efficiently, replacing traditional engines with cleaner, quieter technology.

-

Key components like the battery pack, inverter, and control system work together to deliver smooth power and enable features like regenerative braking for better energy use.

-

Electric vehicles offer lower maintenance, higher efficiency, and zero tailpipe emissions, making them cost-effective and environmentally friendly compared to gasoline-powered cars.

Part 1: Electric Powertrain Basics

1.1 What Is an Electric Powertrain

You encounter the term “electric powertrain” frequently in the context of modern electric vehicles. An electric powertrain refers to the system that propels a vehicle using electrical energy instead of burning fuel. This system replaces the internal combustion engine with a combination of advanced components that work together to deliver smooth, efficient motion.

In simple terms, an electric powertrain uses an electric motor to convert electrical energy from a battery into mechanical power that moves your vehicle. Unlike traditional systems that rely on fuel combustion, electric powertrains draw energy from rechargeable batteries, making them cleaner and quieter.

Historically, electric powertrains have roots dating back to the early 20th century. The Detroit Electric, for example, used lead acid and nickel-iron (NiFe) batteries to power its vehicles. These early systems laid the foundation for today’s advanced powertrain components, which now feature high-performance lithium battery packs.

You find several fundamental principles that set electric powertrains apart from other propulsion systems:

-

Electric powertrains use electric motors to generate mechanical power.

-

Batteries or generators serve as the primary energy source.

-

Power electronic converters, such as inverters, manage the flow and conversion of electrical energy.

-

The system enables precise control of speed and torque without the need for complex gear changes.

-

Electric powertrains rely on electrical energy rather than direct fuel combustion.

1.2 How It Works

You can think of an electric powertrain as a well-coordinated team. The battery pack stores electrical energy, which flows to the electric motor through a series of electronic components. The electric motor then transforms this energy into motion, driving the wheels.

Here’s a simplified flow of how power moves through the system:

-

The battery pack supplies direct current (DC) electricity.

-

The inverter converts DC into alternating current (AC), which the electric motor requires.

-

The electric motor uses this AC power to generate torque and spin the wheels.

-

When you slow down or brake, the electric motor acts as a generator, sending energy back to the battery through regenerative braking.

Regenerative braking captures kinetic energy during deceleration and converts it into electrical energy, which recharges the battery. This process increases overall efficiency and extends the driving range of electric vehicles.

The control system manages every step. When you press the accelerator, the system sends precise signals to the inverter and motor, adjusting torque and speed instantly. This approach delivers smooth acceleration and efficient power delivery, without the lag or vibration found in traditional engines.

1.3 Key Components

You will find several essential powertrain components in every electric vehicle. Each plays a specific role in ensuring reliable and efficient operation. The table below summarizes the main elements:

|

Component |

Role and Description |

|---|---|

|

Battery Pack |

Stores and supplies electrical energy; modern systems use lithium-ion batteries for high energy density. |

|

Electric Motor |

Converts electrical energy into mechanical torque to move the vehicle; also functions as a generator during regenerative braking. |

|

Power Inverter |

Converts DC from the battery to AC for the motor and manages bidirectional power flow during regenerative braking. |

|

DC-DC Converter |

Steps down high voltage from the battery pack to power auxiliary systems and recharge the 12V battery. |

|

Control System |

Uses electronic signals to manage torque, speed, and efficiency; ensures smooth and responsive operation. |

|

Charging Connector |

Allows you to connect the vehicle to external power sources for recharging the battery pack. |

You may also encounter additional components such as battery management systems (BMS), which monitor battery health and safety.

Tip: The choice of battery chemistry—such as NMC Lithium battery, LiFePO4 Lithium battery, or LCO Lithium battery—affects energy density, cycle life, and performance. For example, NMC Lithium battery offers a platform voltage of 3.6-3.7V, energy density of 160-270Wh/Kg, and cycle life of 1000~2000 cycles, making it suitable for demanding applications in medical, robotics, security, infrastructure, mobile DVR,consumer electronics, and industrial sectors.

The integration of these powertrain components enables electric vehicles to deliver precise control, high efficiency, and low emissions. As battery technology continues to advance, you benefit from longer driving ranges, faster charging, and improved reliability. For businesses seeking custom battery solutions, consult our OEM/ODM experts to tailor battery packs and powertrain systems for your specific needs.

Part 2: Electric Vehicles vs. ICE

2.1 Main Differences

You will notice fundamental differences between electric vehicles and those powered by internal combustion engines. ICE vehicles generate motion by burning fuel inside engine cylinders, using a four-stroke cycle to convert chemical energy into mechanical movement. In contrast, electric vehicles use an electric motor powered by a rechargeable battery, eliminating the need for combustion and complex mechanical systems.

|

Aspect |

Electric Vehicles (EVs) |

Internal Combustion Engine (ICE) Vehicles |

|---|---|---|

|

Power Source |

Battery and electric motor |

Gasoline or diesel engine |

|

Key Components |

Fewer moving parts, no exhaust system |

Many moving parts, exhaust, transmission |

|

Maintenance |

Lower, fewer fluids, less wear |

Higher, requires oil changes, more repairs |

|

Emissions |

Zero tailpipe emissions |

CO2, NOx, particulate matter |

|

Range |

Improving, varies by battery capacity |

Generally longer, quick refueling |

|

Refueling/Charging |

Home/public charging, longer time |

Fast refueling at gas stations |

You experience quieter operation, instant torque, and smoother acceleration with electric vehicles. ICE vehicles, on the other hand, produce engine noise and require more frequent maintenance.

2.2 Advantages of Electric Powertrains

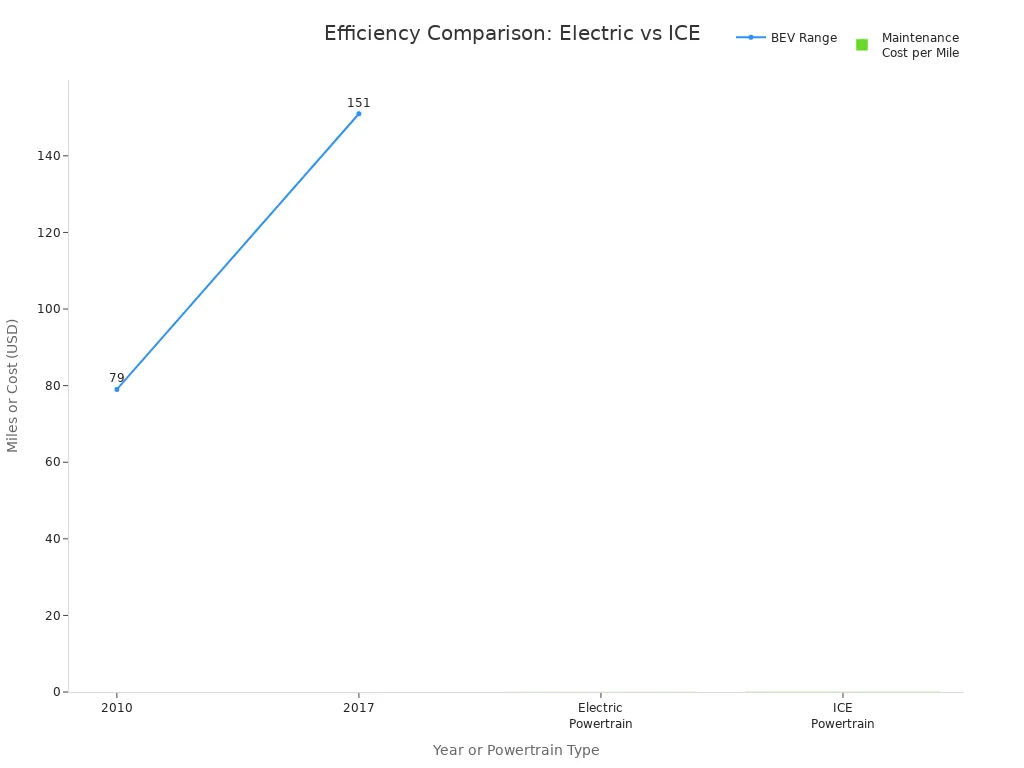

You benefit from several key advantages when you choose electric vehicles for your business. Electric powertrains deliver higher efficiency, converting over 85% of electrical energy into motion, compared to about 30% for ICE systems. This efficiency translates into lower operating costs and reduced maintenance.

|

Aspect |

Electric Powertrains (BEVs) |

ICE Powertrains |

|---|---|---|

|

Maintenance Cost per Mile |

$0.06 |

$0.10 |

|

Vehicle Longevity |

Longer lifespan |

Shorter lifespan |

|

Operating Costs |

Lower |

Higher |

|

Range (2010-2017) |

79 → 151 miles |

N/A |

Electric vehicles also support sustainability goals by producing zero tailpipe emissions. Over their lifecycle, battery electric vehicles emit significantly less CO2 than ICE vehicles, especially as electricity grids become cleaner.

2.3 Battery Technology Evolution

You have seen rapid advancements in battery technology, which directly impact the range and performance of electric vehicles. Early models used lead acid or nickel-metal hydride batteries, but modern vehicles rely on lithium-ion batteries for their superior energy density and lifespan. Lithium-ion batteries enable high-performance EVs with longer range, faster charging, and lighter weight.

|

Battery Type |

Energy Density (Wh/Kg) |

Cycle Life (cycles) |

Typical Range Impact |

|---|---|---|---|

|

Lead Acid |

30–50 |

300–500 |

Short |

|

NiMH |

60–120 |

500–1000 |

Moderate |

|

Lithium-ion |

160–270 (NMC) |

1000–2000 |

Long |

“Lithium-ion batteries offer a lighter and more efficient alternative to traditional battery technologies, addressing the limitations of battery life and enhancing the performance of electric cars.” – Electric Car Magazine

You can expect further improvements with solid-state batteries, which promise even higher energy density and safety. For custom battery solutions tailored to your industry, consult our experts.

You gain a clear advantage by adopting advanced powertrain systems built around lithium battery technology. Businesses benefit from lower costs, improved efficiency, and support for sustainable transportation.

-

Recent innovations include modular powertrain designs, next-generation battery chemistries, and improved recycling processes.

|

Market Trend |

Insight |

|---|---|

|

Electrified Powertrain Share |

41.3% and rising globally |

FAQ

1. What factors affect the range of high-performance EVs?

You influence range through battery technology, vehicle weight, and driving conditions. Advanced lithium battery packs and efficient powertrains help maximize range for high-performance EVs in commercial applications.

2. How does rechargeable battery technology support sustainable transportation?

You enable sustainable transportation by choosing rechargeable battery systems with long cycle life and high energy density. These solutions reduce emissions and support green initiatives.

3. What should you consider when planning electric vehicle charging for your business?

You should evaluate charging speed, infrastructure compatibility, and battery management systems. Reliable lithium battery packs ensure safe, efficient electric vehicle charging for fleets.