You rely on emergency medical equipment to support patient safety during critical moments. The battery inside your device determines if life-saving technology performs as expected. Lithium-ion batteries and LFP batteries, preferred in medical applications, deliver consistent power, long runtime, and high energy density. You require dependable solutions that meet strict standards and withstand emergency conditions. High reliability ensures your team stays prepared for any challenge.

Key Takeaways

Choose lithium batteries for emergency medical equipment. They provide high energy density and long runtime, ensuring reliable operation during critical moments.

Regularly test and maintain battery backup systems. This practice minimizes downtime and ensures your equipment is always ready for emergencies.

Comply with international safety standards for battery packs. Meeting these standards protects patient safety and enhances the reliability of medical devices.

Train staff on emergency protocols and battery handling. Well-prepared teams can respond quickly to power interruptions, safeguarding patient care.

Select suppliers who prioritize quality and compliance. Reliable suppliers help ensure your battery systems perform consistently and safely.

Part1: Reliability in Emergency Medical Equipment

1.1 Critical Battery Performance

You depend on emergency medical equipment to deliver consistent performance in high-pressure environments. Lithium battery packs power critical care equipment, including infusion pumps, ventilators, and defibrillators. These batteries provide long runtime, high energy density, and stable platform voltage, which are essential for uninterrupted power supply during emergencies. You need battery backup solutions that guarantee continuous operation, even when the main power supply fails.

When you select lithium batteries for medical devices, you must consider chemistry, cycle life, and energy density. The table below compares common lithium battery chemistries used in medical, robotics, security systems, infrastructure, and industrial sectors. This comparison helps you evaluate which chemistry best supports reliability and backup emergency power in life-critical applications.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO (LiCoO₂) | 3.7 | 150-200 | 500-1,000 |

NMC (LiNiMnCoO₂) | 3.7 | 180-220 | 1,000-2,000 |

LiFePO₄ (LFP) | 3.2 | 90-140 | 2,000-5,000 |

LMO (LiMn₂O₄) | 3.7 | 100-150 | 300-700 |

LTO (Li₄Ti₅O₁₂) | 2.4 | 70-110 | 7,000-20,000 |

Solid-State | 3.7 | 250-350 | 2,000-10,000 |

Lithium Metal | 3.7 | 350-500 | 500-1,000 |

Tip: LiFePO₄ batteries offer exceptional cycle life and thermal stability, making them ideal for protecting critical equipment in demanding care settings. NMC batteries deliver higher energy density, which supports compact medical devices requiring lightweight battery backup.

You must operate batteries in controlled environments to maximize reliability and safety. Temperature, humidity, and vibration can affect battery performance. You should monitor these factors to ensure your emergency medical equipment remains ready for deployment.

1.2 Standards and Safety

You must comply with strict international standards to guarantee patient safety and reliability in life-critical devices. Regulatory bodies require medical devices to meet rigorous safety and performance criteria for battery packs. The table below summarizes key standards governing battery safety and reliability in medical applications:

Standard | Application |

|---|---|

IEC 62133 | Rechargeable batteries in medical devices |

IEC 60601-1 | Medical devices with rechargeable batteries |

IEC 60086-4 | Non-rechargeable lithium batteries in devices |

UL 1642/2054 | Devices sold exclusively in North America |

You must verify that your battery backup solutions meet these standards before integrating them into critical care equipment. Compliance ensures that your devices perform reliably during emergencies and protect patient safety.

You should also address ethical sourcing of battery materials. Conflict minerals can enter the supply chain, affecting the integrity of your medical devices. You can review your supplier’s conflict minerals statement to ensure responsible sourcing.

Note: Regular audits and supplier evaluations help you maintain high standards for battery reliability and safety. You protect your patients and your reputation by prioritizing compliance and ethical sourcing.

Part2: Protecting Critical Equipment in Care Settings

2.1 Critical Care Equipment Backup

You face constant pressure to maintain uninterrupted operation of emergency medical equipment in critical care environments. Battery backup systems serve as your first line of defense against unexpected power supply failures in intensive care units (ICUs) and operating rooms. These systems activate instantly when the main power source drops, protecting life support systems and other vital devices.

You rely on battery backup solutions to bridge the gap during outages. Some uninterruptible power supply (UPS) systems provide 30-60 minutes of backup, giving your team time to restore power or transfer patients. Larger battery banks, especially those paired with solar energy, can sustain critical equipment for several hours or even days. This extended coverage ensures patient safety and supports continuous care during emergencies.

Tip: Regularly test your battery backup systems to confirm they meet the runtime requirements of your facility. You minimize risk and maximize readiness by maintaining a robust backup strategy.

You see lithium battery packs used not only in medical settings but also in robotics, security systems, infrastructure, and industrial sectors. Their reliability and long cycle life make them the preferred choice for critical applications where downtime is not an option.

2.2 Battery Integration

You integrate lithium batteries into a wide range of medical devices to guarantee continuous operation. Mobile medical carts, infusion pumps, defibrillators, and diagnostic monitors all depend on advanced battery technology. Large Power’s LiFePO₄ batteries deliver consistent and efficient power to critical equipment, including medication delivery systems and life support systems.

You enhance the efficiency of your healthcare team by choosing reliable battery solutions. These batteries support rapid deployment and mobility, allowing you to respond quickly in emergency situations. You also see similar integration in robotics and industrial automation, where lithium battery packs power essential systems and maintain operational continuity.

Device Type | Lithium Battery Chemistry | Application Scenario | Runtime (Typical) |

|---|---|---|---|

Infusion Pump | LiFePO₄ | ICU, Operating Room | 8-12 hours |

Defibrillator | NMC | Emergency Response | 6-10 hours |

Mobile Medical Cart | LiFePO₄ | Hospital, Clinic | 10-16 hours |

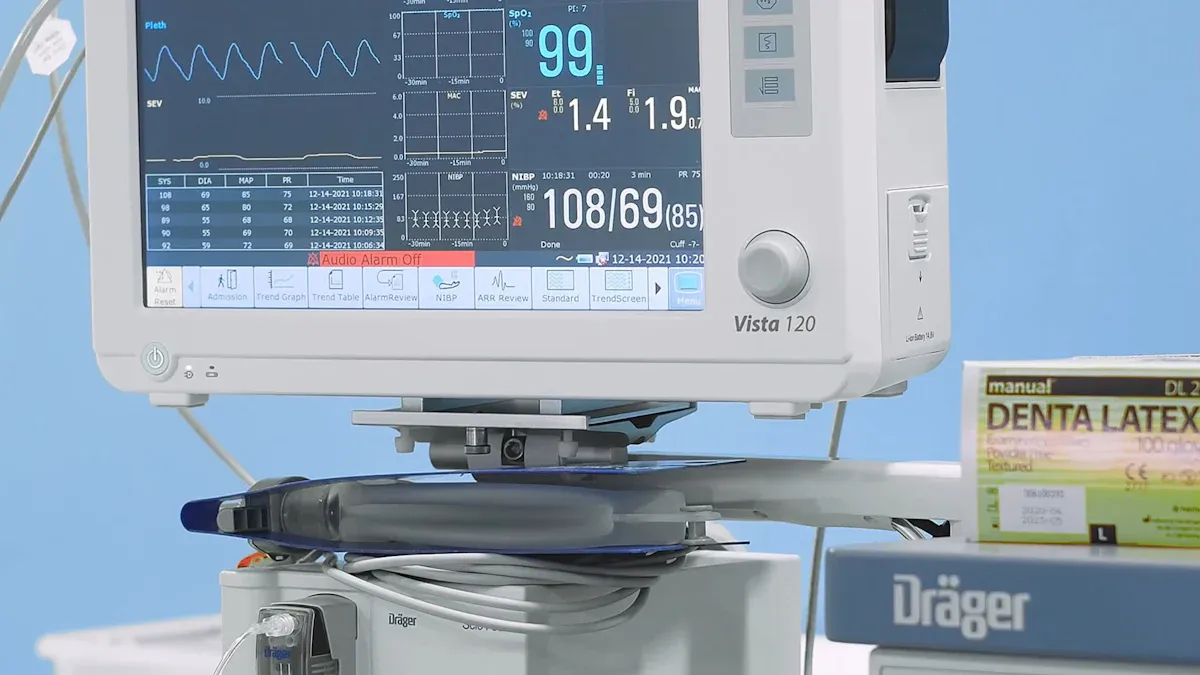

Diagnostic Monitor | NMC | ICU, ER | 8-14 hours |

Life Support Systems | LiFePO₄ | ICU, Transport | 12-24 hours |

You prioritize battery integration that meets strict safety and reliability standards. You select chemistries like LiFePO₄ for their thermal stability and long cycle life, and NMC for higher energy density in compact devices. You ensure every battery pack supports patient safety and critical care needs.

Note: If you want to learn more about sustainable battery solutions for medical devices and other sectors, visit Our Approach to Sustainability.

Part3: Life Support Systems and Biomedical Safety

3.1 Powering Life Support Systems

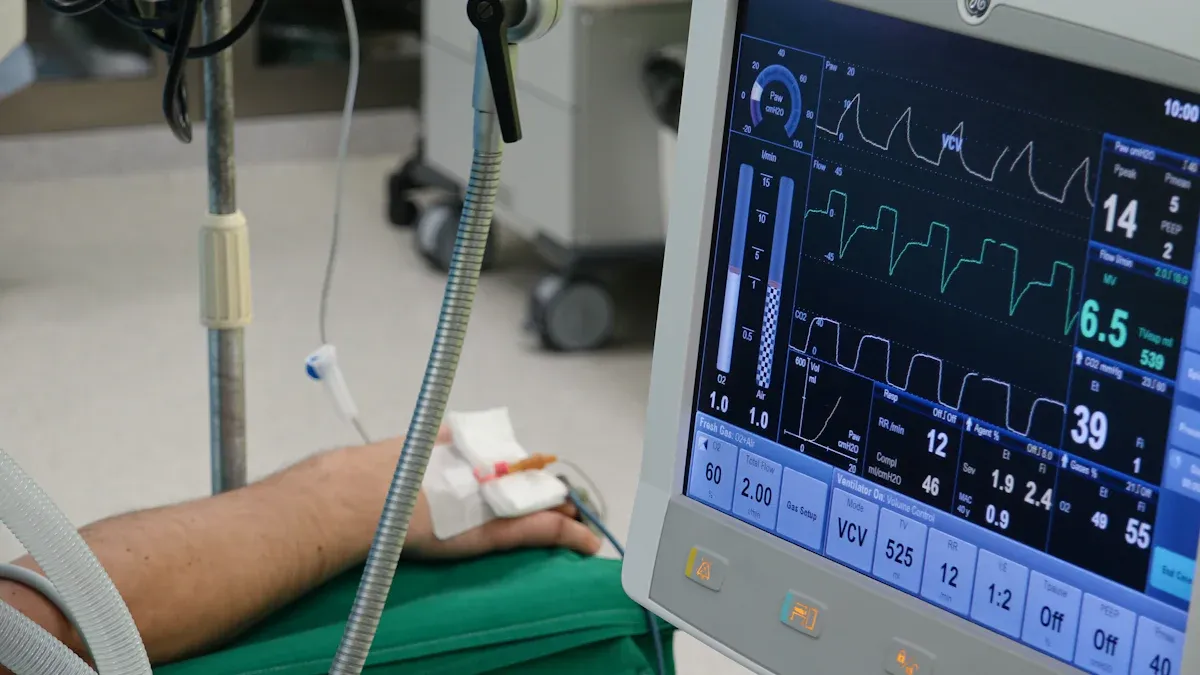

You rely on battery backup solutions to maintain continuous operation of life support systems in emergency medical equipment. These systems include ventilators, cardiac monitors, and dialysis machines. You must prevent outages that threaten patient safety. Lithium battery packs, such as LiFePO₄ and NMC, deliver stable power supply and long runtime. You choose these chemistries for their reliability and ability to withstand demanding conditions.

You see the following benefits when you use lithium battery packs in critical care:

Rapid activation during power interruptions

Consistent voltage output for sensitive devices

Extended cycle life for minimizing downtime

Life Support Device | Battery Chemistry | Runtime (Typical) | Application Scenario |

|---|---|---|---|

Ventilator | LiFePO₄ | 12-24 hours | ICU, Transport |

Cardiac Monitor | NMC | 8-14 hours | Emergency, ICU |

Dialysis Machine | LiFePO₄ | 10-18 hours | Critical Care, Home Care |

You improve patient outcomes by selecting battery backup solutions that meet strict safety standards and deliver reliable performance during emergencies.

3.2 Safeguarding Biomedical Materials

You protect biomedical materials, such as vaccines, blood products, and laboratory samples, from temperature fluctuations and outages. You use battery backup systems to maintain refrigeration and controlled environments. Lithium battery packs provide the necessary power supply to refrigeration units and storage devices.

You minimize risk by implementing backup strategies that support uninterrupted operation. You monitor battery status and schedule regular maintenance to ensure readiness. You reduce downtime and safeguard valuable biomedical assets.

Schedule battery checks for all storage units

Use lithium battery packs with high cycle life

Train staff to respond quickly during outages

Tip: You enhance reliability by choosing battery chemistries with proven thermal stability, such as LiFePO₄, for critical storage applications.

You see similar strategies in robotics, security systems, and industrial sectors, where lithium battery packs protect sensitive materials and equipment from power interruptions.

Part4: Minimizing Downtime and Ensuring Readiness

4.1 Battery Monitoring

You must monitor battery status in all emergency medical equipment to ensure uninterrupted operations. Real-time monitoring systems help you track voltage, temperature, and charge cycles. These systems alert you to potential failures before they cause downtime or outages. In intensive care units and emergency departments, you rely on battery management systems (BMS) to provide a seamless power transition during unexpected conditions. BMS technology supports backup power protection by balancing cells and preventing overcharge or deep discharge. For more details on BMS, visit BMS and PCM.

You should implement automated alerts for backup power needs. These alerts notify your team when batteries approach end-of-life or require replacement. By using advanced monitoring, you maintain a reliable power supply for critical equipment and minimize the risk of emergency disruptions.

Tip: Schedule regular reviews of monitoring data to identify trends and address issues before they impact continuous power supply.

4.2 Maintenance and Training

You reduce downtime by establishing a proactive maintenance schedule for all lithium battery packs in medical devices. Routine inspections help you detect early signs of wear or damage. You should replace batteries according to manufacturer guidelines to guarantee backup emergency power and uninterrupted power supply.

You must train your staff to respond quickly to power events. Training programs should cover backup power solutions, safe battery handling, and emergency protocols. Well-trained teams ensure backup power protection for critical equipment in all care settings.

Inspect batteries monthly for physical damage or swelling

Test backup systems quarterly to confirm reliable operation

Update staff on emergency procedures and battery replacement steps

You support reliability by maintaining strict protocols and investing in ongoing education. Your efforts keep critical equipment ready for deployment, even during the most challenging conditions.

Part5: Strategies for Reliable Performance

5.1 Testing and Replacement

You must implement a robust testing schedule for every battery in your emergency medical equipment. Routine testing helps you identify performance issues before they lead to downtime or outages. You should use diagnostic tools to check voltage, capacity, and cycle life. These checks allow you to predict when a battery will fail and plan for timely replacement.

You can follow these steps to maintain reliable backup emergency power:

Test batteries monthly using manufacturer-recommended procedures.

Record test results in a centralized log for easy tracking.

Replace batteries that show reduced capacity or abnormal voltage.

Dispose of old batteries according to environmental regulations.

Tip: You reduce risk by scheduling battery replacements before reaching end-of-life. This strategy ensures your critical equipment remains ready for deployment.

The table below compares recommended replacement intervals for lithium battery chemistries in medical, robotics, and industrial applications:

Chemistry | Typical Replacement Interval | Application Scenario |

|---|---|---|

LiFePO₄ | 3-5 years | Medical, Robotics |

NMC | 2-4 years | Medical, Security Systems |

LCO | 1-2 years | Consumer Electronics |

LTO | 5-10 years | Infrastructure, Industrial |

5.2 Supplier Selection

You must choose suppliers who meet strict quality and compliance standards for lithium battery packs. Reliable suppliers provide documentation for safety certifications and performance data. You should evaluate suppliers based on their track record in delivering batteries for critical applications.

Consider these factors when selecting a supplier:

Certification to IEC and UL standards

Proven experience in medical and industrial sectors

Transparent sourcing of battery materials

Support for custom backup emergency power solutions

Note: You strengthen your supply chain by partnering with suppliers who prioritize quality and compliance. This approach reduces the risk of outages and ensures continuous operation of your critical equipment.

You maintain operational continuity by regularly reviewing supplier performance and conducting audits. This strategy supports long-term reliability for all battery-powered systems in your facility.

You recognize the necessity of reliable batteries in emergency medical equipment. Lithium battery solutions deliver safety, efficiency, and cost savings for your healthcare facility. The table below shows how battery pack prices have dropped, making backup emergency power more affordable:

Year | Battery Pack Price (USD/kWh) | Price Change (%) |

|---|---|---|

2010 | 1,100 | – |

2020 | 137 | -89% |

2030 | Projected to drop by over 50% | – |

You improve patient safety by choosing lithium batteries with long lifespan and high energy density. You ensure reliability by implementing routine inspections, staff training, and supplier evaluation. Take action now to prioritize battery reliability and protect every patient.

FAQ

What makes lithium battery packs ideal for emergency medical equipment?

You benefit from lithium battery packs because they provide high energy density, long runtime, and stable voltage. These features ensure your critical equipment, such as ventilators and infusion pumps, operates reliably during power interruptions in medical settings.

How often should you replace lithium battery packs in critical care devices?

You should follow a strict replacement schedule based on battery chemistry. For example, LiFePO₄ batteries last 3–5 years, while NMC batteries require replacement every 2–4 years. Regular testing helps you maintain optimal performance.

Chemistry | Typical Replacement Interval |

|---|---|

LiFePO₄ | 3–5 years |

NMC | 2–4 years |

LCO | 1–2 years |

LTO | 5–10 years |

Which application scenarios require the most robust battery backup?

You need robust battery backup in intensive care units, operating rooms, robotics, security systems, and industrial automation. These environments demand continuous operation and cannot tolerate downtime. Lithium battery packs support these critical applications with reliable power.

How do you ensure battery safety and compliance in your facility?

You verify that all lithium battery packs meet international standards, such as IEC 62133 and UL 1642. You also conduct regular audits and supplier evaluations. This approach ensures your batteries deliver safe, reliable performance in every application.

What are the main advantages of LiFePO₄ batteries for critical equipment?

You gain several advantages with LiFePO₄ batteries: exceptional cycle life, thermal stability, and reliable performance. These qualities make them ideal for medical, robotics, and industrial sectors where safety and long-term reliability matter most.

Tip: Choose LiFePO₄ batteries for applications that require frequent cycling and high safety margins.