You operate in sectors where every watt counts. Energy optimization drives success for portable power testing terminals using lithium battery packs. You minimize energy waste through operational audit, simulation, and advanced battery engineering. Power analyzers help you track energy precisely. You achieve Energy Optimization while maintaining safety and reliability.

Key Takeaways

Establish a reliable energy baseline using simulation-based methodologies to predict energy needs and optimize consumption.

Utilize power analyzers for precise energy tracking and measurement, ensuring accurate calibration for reliable data.

Implement dynamic charging strategies and routine maintenance to enhance battery life and operational reliability.

Part1: Energy Baseline & Consumption Measurement

1.1 Simulation-Based Energy Calculation

You establish a reliable energy baseline by combining operational audits with simulation-based methodologies. Dynamic simulation modeling projects energy consumption patterns for portable power testing terminals. You model the terminal’s dynamic workload, track active quay cranes per hour, and count container moves executed by battery-powered vehicles. You determine hourly energy consumption patterns and test different charging strategies under varying conditions. This approach helps you predict energy needs and optimize consumption for lithium battery packs in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Tip: Simulation-based energy calculation allows you to identify inefficiencies and adjust operational parameters before deploying terminals in the field.

1.2 Power Analyzers & Instrumentation

You rely on power analyzers to track and optimize energy consumption with precision. Instruments such as Fluke 1775 and Fluke Norma 6004+ provide accurate measurements and automated reporting. The table below compares key features:

Feature | Fluke 1775 | Fluke Norma 6004+ |

|---|---|---|

Type | Three-Phase Power Quality Analyzer | Portable Power Analyzer |

Connectivity | WiFi/BLE, USB, Ethernet | N/A |

Reporting | Automated, one-touch | N/A |

Measurement | Energy consumption, power quality | High accuracy power measurements |

Portability | In-workshop, in-the-field | Designed for field use |

Impedance mismatch, linearity, and calibration factor contribute to measurement uncertainty in power analyzers. At lower power levels, noise and zero errors become more pronounced. Calibration at the standard level of 0 dBm is critical for accurate energy consumption tracking.

1.3 Battery Performance & Safety Testing

You ensure lithium battery performance and safety through standardized protocols. Hipot testing confirms electrical insulation integrity, essential for compliance and safety. You conduct the following tests:

Dielectric Withstand Test: Confirms insulation integrity against shock hazards.

Insulation Resistance Test: Ensures insulation meets safety requirements.

Ground Continuity Test: Verifies the effectiveness of ground connections.

Ground Bond Test: Tests the integrity of protective ground connections.

You use a Hipot tester, high-voltage test leads, ground bond test adapter, and performance verification device to maintain accuracy and compliance. For advanced battery management, you integrate a BMS (Battery Management System) to monitor energy consumption and protect lithium battery packs.

Comparative data for lithium battery chemistries:

Chemistry | Platform Voltage | Energy Density | Cycle Life |

|---|---|---|---|

3.2V | 100~180 Wh/kg | 2000-5000 cycles | |

NMC | 3.6~3.7V | 160~270 Wh/kg | 1000~2000 cycles |

LCO | 3.7V | 180~230 Wh/kg | 500~1000 cycles |

LMO | 3.7V | 120~170 Wh/kg | 300~700 cycles |

LTO | 2.4V | 60~90 Wh/kg | 10,000~20,000 cycles |

/ | 300~500 Wh/kg | / | |

Lithium metal | / | 300~500 Wh/kg | / |

You select the chemistry that matches your energy consumption profile and safety requirements for portable power testing terminals.

Part2: Factors Influencing Power & Optimization Strategies

2.1 Equipment Specs & Operational Patterns

You optimize energy consumption by selecting equipment with precise voltage and current ratings. Accurate definition and measurement of electrical performance parameters are vital for the reliability of high-voltage portable power testing terminals. You use high-quality measurement systems, such as NI modules, to enhance the reliability of power consumption data. You consider all operating ranges, including steady state, in-rush, start-up, and fault conditions, because these factors directly impact power usage.

You manage safety risks by ensuring equipment meets exact voltage and current specifications.

You improve operational reliability by using direct measurement capabilities.

You reduce energy waste by matching equipment specs to your operational demands.

Environmental conditions also affect energy efficiency. You simulate real-world conditions during environmental testing to prevent product failures and maintain operational reliability. The table below summarizes how temperature and humidity influence energy optimization:

Factor | Impact on Portable Power Testing Terminals |

|---|---|

Temperature Fluctuations | Can lead to mechanical fatigue and changes in electrical performance. |

Material Degradation | High temperatures can cause insulation and conductivity issues. |

Humidity Effects | Moisture can cause corrosion and electrical leakage, reducing efficiency. |

You avoid releasing products that may fail under specific temperature or humidity conditions. You maintain high energy efficiency by controlling environmental variables during operational audits and field deployment.

Tip: You improve power measurement accuracy by calibrating instruments regularly and monitoring environmental factors.

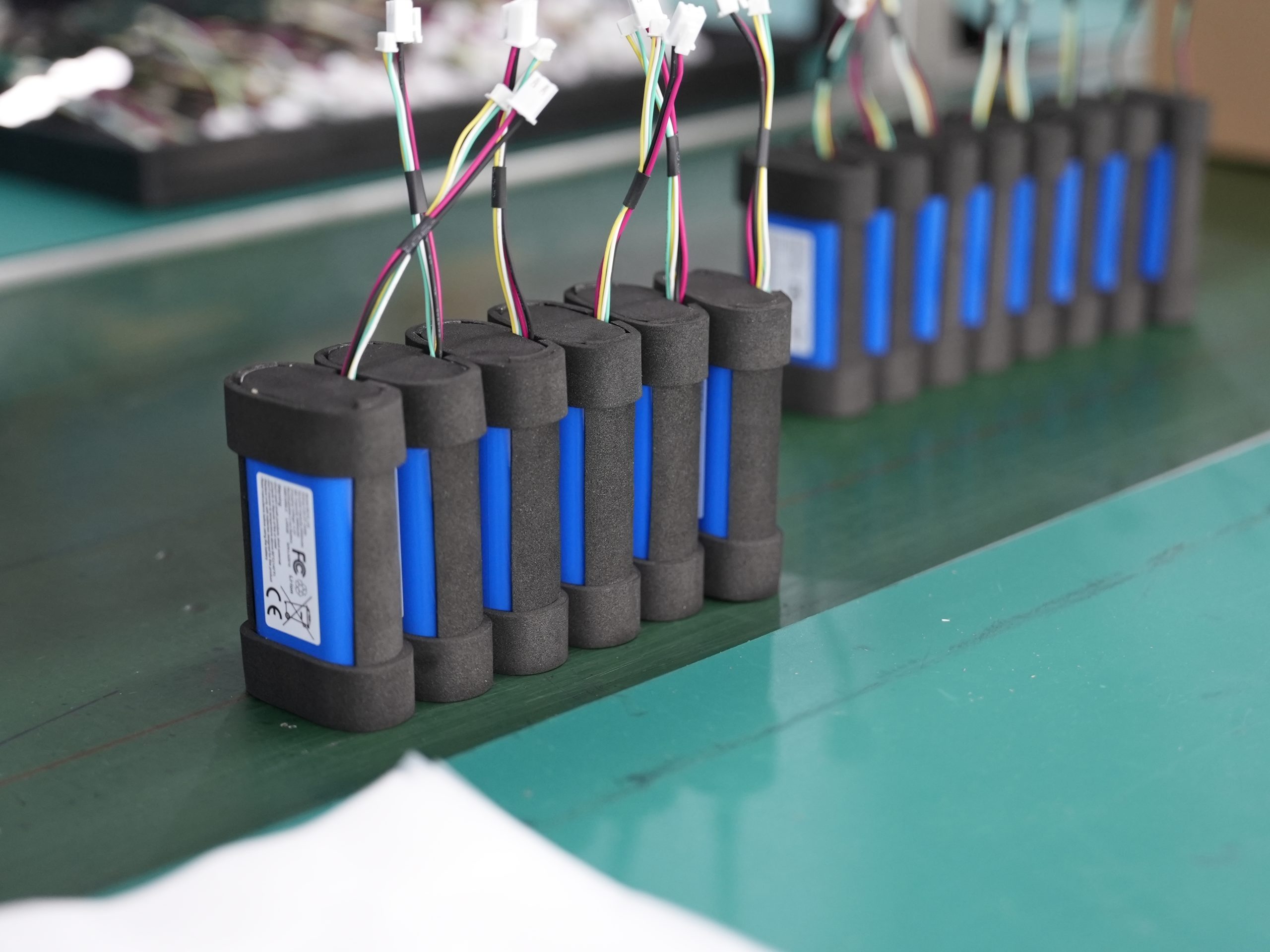

2.2 Advanced Battery Engineering

You achieve energy optimization by applying advanced battery engineering techniques. You select lithium battery chemistries and cell designs that match your operational demands. You focus on material selection and cell architecture to maximize energy density and efficiency. For high-energy-density Li-based batteries, you use multiscale design principles and empirical processing techniques, such as advanced parametrization and polymer electrolytes.

Technique | Description |

|---|---|

Advanced Parametrization | Multiscale design principles for high-energy-density Li-based batteries. |

Solid-State Batteries | Replace liquid electrolytes with solid electrolytes for safety and density. |

Electrode Design | Optimize ionic/electronic percolation and interfacial area for performance. |

Multi-Stacked Cell Design | Enable prismatic and cylindrical cell form factors for commercial viability. |

You integrate solid-state batteries to enhance safety and energy density. You follow electrode design guidelines to improve ionic and electronic percolation. You use multi-stacked cell designs to support various form factors in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Thermal management systems play a critical role in extending battery life and efficiency. You implement hybrid thermal management systems to distribute heat evenly and minimize hotspots. You prevent energy loss and material degradation by improving thermal conductivity and insulation.

You prolong battery life by managing heat effectively.

You enhance energy efficiency by minimizing hotspots and energy loss.

You maintain operational reliability by preventing thermal-related failures.

2.3 Energy Optimization Technologies

You deploy energy optimization technologies to maximize power efficiency and meet operational demands. You use intelligent software to monitor and control energy consumption in real time. You implement dynamic charging strategies to adapt to fluctuating workloads and operational patterns. You integrate regenerative technologies to recover energy during idle or low-load periods.

You automate charging cycles to reduce downtime and extend battery life.

You use predictive analytics to forecast energy needs and optimize charging schedules.

You recover energy from braking or idle states to improve overall efficiency.

You combine these energy strategies with advanced battery management systems to monitor power usage and maintain safety. You leverage simulation modeling to test energy optimization strategies before field deployment. You plan for scalability by integrating modular systems that support future expansion and evolving operational demands.

You maintain a competitive edge by adopting energy optimization strategies that align with your operational goals and sector requirements. You ensure that portable power testing terminals deliver reliable performance, safety, and energy efficiency across all application scenarios.

Part3: Balancing Operational Demands & Energy Efficiency

3.1 Dynamic Charging & Maintenance

You face the challenge of meeting operational requirements while optimizing energy use in automated terminals. Dynamic charging strategies help you adapt charging capabilities to peak operational demands. You schedule charging sessions based on real-time data, which reduces downtime and extends the life of lithium battery packs. You also prioritize routine maintenance to prevent unexpected failures in automated terminals.

Best practices for maintenance scheduling include:

Create a maintenance calendar to track routine tasks.

Conduct routine inspections to catch problems early.

Adjust maintenance schedules for seasonal changes.

Schedule yearly maintenance services for thorough checks.

Track maintenance intervals using digital tools and logs.

Maintenance Task | Frequency |

|---|---|

Overall float voltage measured at the battery terminals | Monthly, Quarterly, Yearly |

Charger output current and voltage | Monthly, Quarterly, Yearly |

DC float current (per string) | Monthly, Quarterly, Yearly |

Ambient Temperature | Monthly, Quarterly, Yearly |

Temperature of the negative terminal of each cell | Quarterly, Yearly |

Cell/unit internal ohmic values | Quarterly, Yearly |

Cell-to-cell and terminal connection detail resistance | Yearly |

AC ripple current and/or voltage | Yearly |

You use digital tools to monitor maintenance intervals and train operators for effective maintenance. This approach ensures your automated terminals maintain high operational reliability in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

3.2 System Integration & Scalability

You integrate system components to balance operational efficiency and energy use in automated terminals. Compact designs improve portability but can increase heat and electromagnetic interference. You address these challenges by adopting wide bandgap semiconductors, such as GaN and SiC, which enhance efficiency and reduce size. However, you must conduct extensive testing to ensure reliability and compliance.

Simulation modeling supports your planning for future scalability. You evaluate how automated terminals will perform under increased operational loads. You also consider sustainability and conflict minerals when selecting materials for lithium battery packs. For custom battery solutions, you can consult with our experts to optimize system integration and scalability.

Tip: You achieve long-term operational success by combining simulation modeling, dynamic charging strategies, and robust maintenance with scalable system integration.

You optimize energy in portable power testing terminals by combining simulation, battery engineering, and power analyzers. You measure performance, integrate systems, and plan for future scalability. Advanced technologies and AI improve reliability and efficiency in terminals. You benefit from faster charging, bi-directional power, and custom solutions for terminals.

AI and automation enhance terminals’ reliability and operational efficiency.

Battery advancements and modular energy solutions support scalable terminals.

Faster charging and proactive maintenance reduce downtime in terminals.

Smart monitoring and system integration optimize terminals for medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

FAQ

What factors determine the energy needs of portable power testing terminals?

You assess energy needs by evaluating equipment specifications, operational demand, and infrastructure. Monitoring helps you match energy requirements to lithium battery packs for medical, robotics, and infrastructure sectors.

How does charging infrastructure impact energy management and monitoring?

You optimize energy management by designing robust charging infrastructure. Monitoring charging cycles ensures you meet energy requirements and demand in security, consumer electronics, and industrial applications.

Where can you get custom solutions for energy needs and infrastructure monitoring?

You consult Large Power for tailored lithium battery pack solutions. Consult with our experts for energy requirements, charging infrastructure, and monitoring in demanding B2B environments.