You face a tough challenge when Engineering Rugged Battery Packs for handheld industrial testers. These battery packs must stand up to shock, vibration, and extreme temperatures. Custom lithium-ion solutions help you meet strict industry or military standards. Advanced materials like aluminum chassis give extra strength. Smart battery management systems protect your investment. Focus on robust design choices and watch for common mistakes that can lead to early failure.

Tip: Use high-quality materials and advanced management to boost reliability in the field.

Key Takeaways

Choose the right lithium battery chemistry for your application to ensure optimal performance and longevity.

Use durable materials like aluminum for battery enclosures to protect against physical damage and environmental factors.

Integrate smart battery management systems to monitor health and extend battery life, reducing maintenance costs.

Conduct rigorous testing to validate battery packs against industry standards, ensuring safety and reliability in harsh conditions.

Plan for end-of-life recycling to meet environmental regulations and promote sustainability in battery management.

Part1: Defining Ruggedness in Battery Packs

1.1 Environmental & Mechanical Demands

You must design battery packs that survive tough conditions. Industrial testers face drops, shocks, and constant vibration. You see these challenges in robotics, medical devices, and infrastructure monitoring tools. Dust, moisture, and temperature swings also threaten battery life.

When you select lithium battery chemistries, you need to match them to your environment. For example, LiFePO4 offers high cycle life and thermal stability. NMC provides higher energy density for longer runtime. LCO and LMO suit applications where weight matters most.

Here is a quick comparison:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Best Use Case |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-120 | 2000+ | Medical, Security, Infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Robotics, Industrial, Security |

LCO | 3.7 | 150-200 | 500-1000 | Consumer, Lightweight Devices |

LMO | 3.7 | 100-150 | 300-700 | Power Tools, Portable Testers |

Note: You should always choose a chemistry that matches your operating environment and cycle requirements.

1.2 Electrical & Safety Standards

You must meet strict electrical and safety standards when Engineering Rugged Battery Packs. Industrial sectors require compliance with certifications like UL, IEC, and MIL-STD. These standards protect users and equipment from electrical faults, overheating, and short circuits.

You need to integrate features such as overcurrent protection, thermal cutoffs, and robust insulation. You should also consider ingress protection (IP ratings) for dust and water resistance.

You see these requirements in medical analyzers, security scanners, and industrial testers.

You can review standards from UL and IEC for more details.

Tip: Always validate your battery pack against the latest industry and military standards to ensure safety and reliability.

Part2: Engineering Rugged Battery Packs – Key Design Factors

2.1 Lithium Battery Chemistry Choices

You must select the right lithium battery chemistry to ensure your industrial testers perform reliably in the field. Each chemistry offers unique advantages for different applications. For example, LiFePO4 provides high cycle life and thermal stability, making it ideal for medical and infrastructure devices. NMC delivers higher energy density, which suits robotics and security equipment that require longer runtimes. LCO and LMO chemistries work best in lightweight or portable testers.

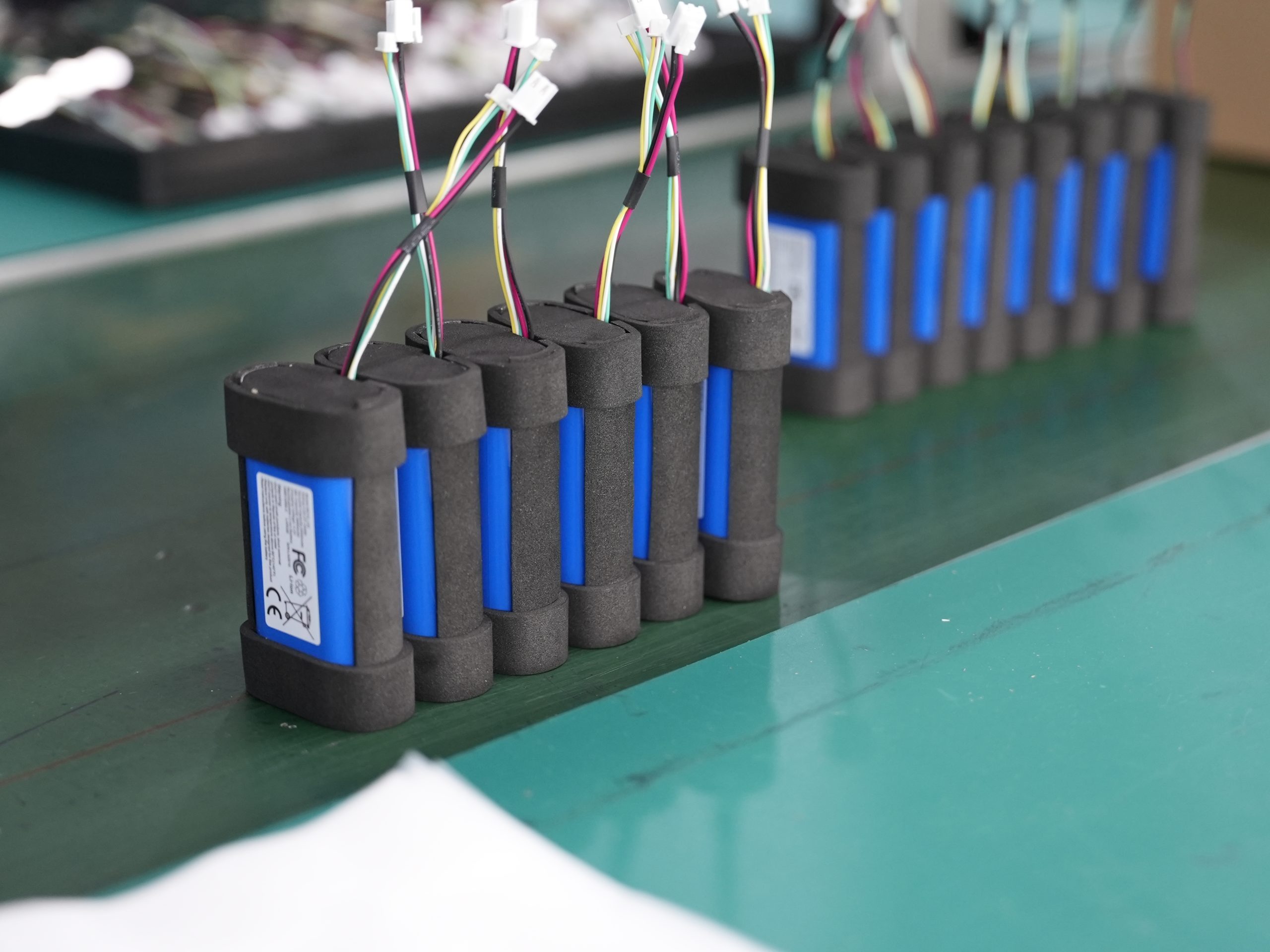

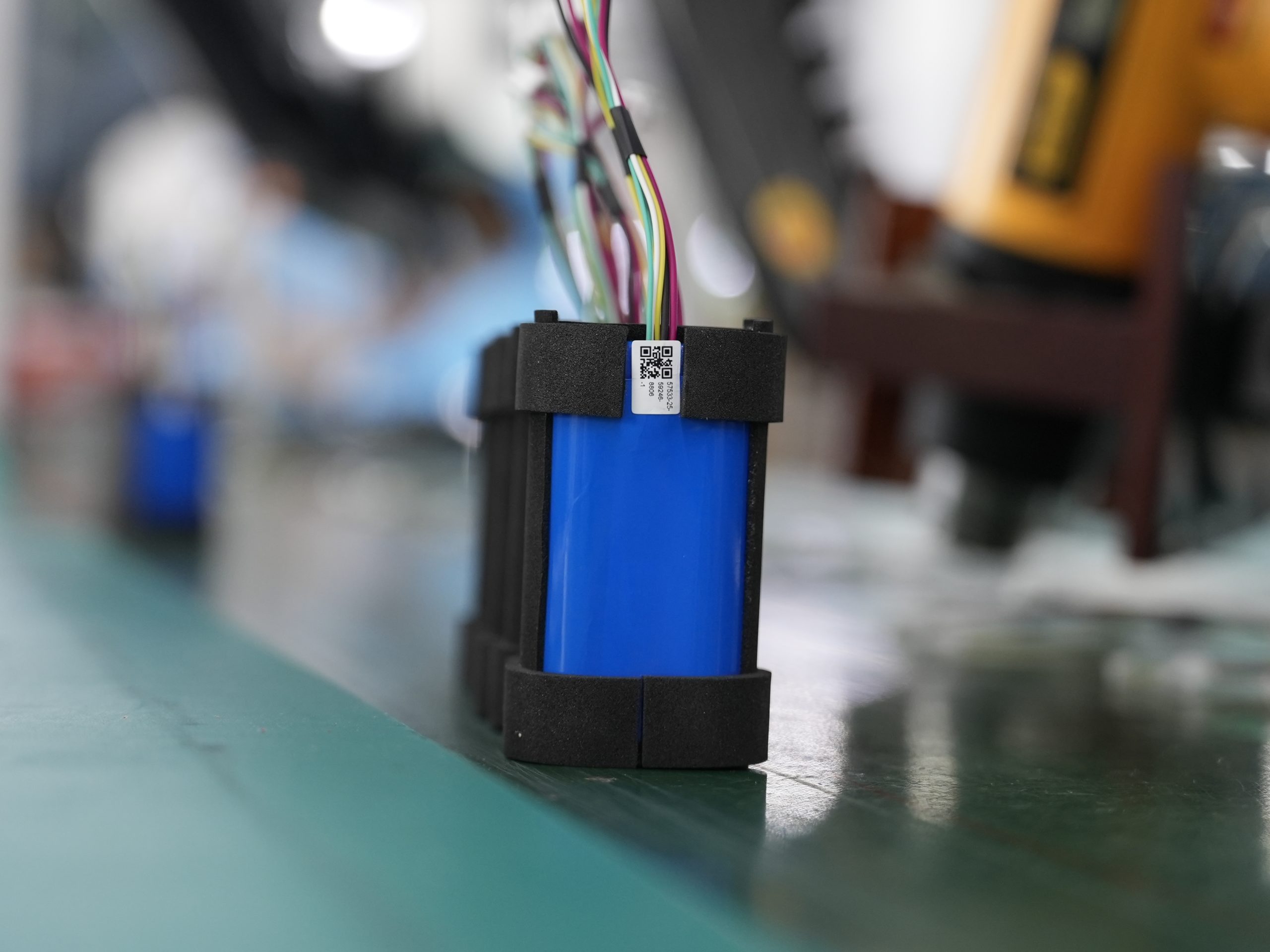

Custom lithium-ion solutions allow you to match the chemistry to your specific needs. You can use advanced design tools to optimize safety and reliability. In-house testing facilities rigorously evaluate battery performance under real-world conditions. This approach leads to superior quality control and helps you identify potential issues early.

Feature | Benefit |

|---|---|

Advanced Design Tools | Optimizes safety and reliability of battery packs |

Rigorous Testing | Ensures performance under various conditions, enhancing safety |

Tailored Engineering | Meets specific application needs, improving reliability |

Tip: Always choose a chemistry that aligns with your device’s operating environment and cycle requirements.

2.2 Rugged Chassis & Enclosure Materials

You need a strong enclosure to protect your battery pack from physical damage. Aluminum chassis offer excellent durability and resist deformation during drops or impacts. Many industrial testers use aluminum or reinforced polymers for their enclosures. These materials provide a balance of strength and weight, which is critical for handheld devices.

Military specifications often require battery packs to survive extreme conditions. You must consider these standards when selecting materials. For example, MIL-STD-810G outlines tests for shock, vibration, and temperature resistance. Meeting these requirements ensures your battery pack will perform in harsh environments.

Aluminum chassis resist corrosion and provide electromagnetic shielding.

Reinforced polymers add impact resistance without adding much weight.

Sealed gaskets and overmolded edges improve ingress protection.

Note: You should always verify that your enclosure materials meet both industry and military standards for ruggedness.

2.3 Electrical Protection & Thermal Management

You must integrate robust electrical protection to prevent failures in your battery pack. Overcurrent protection, thermal cutoffs, and short-circuit prevention are essential features. These systems protect both the battery and the connected device from electrical faults.

Thermal management plays a key role in Engineering Rugged Battery Packs. Industrial testers often operate in environments with wide temperature swings. You can use heat sinks, thermal pads, or phase change materials to manage heat. Smart battery management systems monitor temperature and adjust charging or discharging rates to prevent overheating.

Overcurrent protection stops damage from unexpected surges.

Thermal cutoffs disconnect the battery if temperatures rise too high.

Smart management systems extend battery life and improve safety.

Callout: Reliable electrical and thermal protection reduces downtime and maintenance costs for your business.

2.4 Environmental Resistance Features

You must design your battery pack to withstand dust, moisture, and vibration. Environmental resistance features, such as waterproofing, anti-vibration casings, and advanced thermal management, help your battery endure extreme conditions. These features ensure long-term reliability and efficiency, even when your testers face temperature fluctuations, moisture, or constant movement.

For example, you can use silicone seals to block water and dust. Anti-vibration mounts protect internal components during transport or operation. Advanced coatings prevent corrosion from humidity or chemicals.

Waterproofing keeps internal electronics safe from spills or rain.

Anti-vibration casings reduce wear and tear from constant movement.

Thermal management maintains performance in hot or cold environments.

Tip: Investing in environmental resistance features increases the lifespan and reliability of your battery packs.

Part3: Integration, Testing & Smart Management

3.1 Size, Weight & Ergonomics

You must balance size, weight, and ergonomics when Engineering Rugged Battery Packs for handheld testers. Industrial users need devices that fit comfortably in their hands and do not cause fatigue during long shifts. You can select lithium chemistries like LiFePO4 or NMC to optimize energy density and cycle life. Medical analyzers and robotics controllers often require lightweight packs for portability. Security and infrastructure testers benefit from compact designs that allow easy transport. You should always consider the end-user’s workflow when finalizing battery dimensions.

3.2 Connector Reliability

Connector reliability plays a critical role in industrial battery pack performance. You need robust connectors that withstand frequent mating cycles, vibration, and exposure to dust or moisture. Gold-plated contacts resist corrosion and maintain strong electrical connections. Locking mechanisms prevent accidental disconnection during operation. You see these features in medical devices, robotics, and security equipment. Reliable connectors reduce downtime and maintenance costs for your business.

Tip: Choose connectors rated for industrial environments to ensure consistent power delivery.

3.3 User-Replaceable vs. Sealed Packs

You face a choice between user-replaceable and sealed battery packs. User-replaceable packs offer high serviceability and extended runtime. You can swap them quickly in the field, which reduces downtime. Sealed packs provide a sleeker design but limit service options. The following table compares key features:

Feature | User-Replaceable Packs | Sealed Packs |

|---|---|---|

Extended Runtime | Yes | No |

Faster Recovery | Yes | No |

Cost Savings | Yes | No |

Eco-Friendly | Yes | No |

Bulkier Build | Yes | N/A |

Higher Initial Cost | Yes | N/A |

Serviceability | High | Low |

Longevity | High | Limited |

You should select the option that best fits your application and maintenance strategy.

3.4 Validation: Drop, Vibration, IP, Thermal

You must validate your battery packs through rigorous testing. Drop tests confirm resistance to impact. Vibration tests simulate transport and field use. IP ratings measure protection against dust and water. Thermal cycling checks performance in extreme temperatures. You see these tests in medical, robotics, and industrial sectors. Passing these tests ensures your lithium battery packs meet industry and military standards for ruggedness.

Note: Validation testing reduces risk of failure and increases customer confidence.

3.5 Cloud-Based Battery Monitoring

Smart management systems help you monitor and control battery health remotely. You can use cloud-based platforms to track charge cycles, temperature, and usage patterns. These systems alert you to potential issues before they cause downtime. For advanced monitoring, you should consider integrating a battery management system (BMS). Cloud-based monitoring supports predictive maintenance and extends the life of your lithium battery packs.

Callout: Remote monitoring improves reliability and reduces maintenance costs for industrial fleets.

Part4: Lifecycle, Maintenance & Pitfalls

4.1 Serviceability & Health Monitoring

You need to keep your lithium battery packs running at peak performance. Serviceability matters in industrial sectors like medical, robotics, and infrastructure. You can design packs with modular components for easy replacement. Health monitoring systems track voltage, temperature, and cycle count. These systems alert you to problems before they cause downtime. Smart battery management systems (BMS) help you schedule maintenance and predict failures. You reduce costs and improve reliability when you use real-time data. You also protect your investment by preventing unexpected breakdowns.

Tip: Choose battery packs with built-in health monitoring to simplify maintenance and extend service life.

4.2 End-of-Life & Recycling

You must plan for the end-of-life of your lithium battery packs. Industrial testers require responsible disposal and recycling. You can use several recycling methods to recover valuable materials:

Pyrometallurgy uses high heat to extract metals.

Hydrometallurgy relies on chemical solutions to separate components.

Direct recycling restores battery materials for reuse.

Remanufacturing and repurposing extend battery life in new applications.

Current recycling technologies face challenges, but you can improve sustainability by choosing partners who follow best practices. Learn more about sustainable battery management at Our Approach to Sustainability. You should also review your supply chain for conflict minerals. See the Conflict Minerals Statement for guidance.

Note: Responsible recycling and sourcing help you meet environmental regulations and protect your brand reputation.

4.3 Common Design Mistakes

You can avoid costly errors by understanding common design mistakes in lithium battery packs for industrial testers. The table below highlights frequent issues:

Error Type | Description |

|---|---|

Operator Errors | Incorrect setup, broken components, mislabelled channels, or wrong profiles. |

Sensor / Temperature Abnormalities | Sensors misaligned, temperature spikes/dropouts, sensor miswiring/misplacement. |

Electrical Errors | Overcharging, overdischarging, unexpected ageing, or defects. |

Mechanical Errors | Mechanical swelling, venting, misaligned contacts, interactions with degradation. |

You should train your team to spot these problems early. You can use automated testing and monitoring to catch errors before they affect your devices. You improve reliability and safety when you address these mistakes during the design phase.

Callout: Proactive design and testing reduce risk and increase uptime for your industrial battery packs.

You can achieve success in Engineering Rugged Battery Packs by selecting custom lithium-ion chemistries, using durable materials like aluminum chassis, and implementing smart battery management systems. Meeting industry and military standards ensures reliability in medical, robotics, security, and infrastructure sectors. You should watch for new trends shaping the future of rugged battery technology:

Trend | Description |

|---|---|

Higher voltage batteries | You gain better performance and faster charging with advanced testing methods. |

EV market growth | Rising electric vehicle sales drive demand for rigorous battery testing. |

Solid-state innovations | You need customized protocols for safety and performance. |

Safety regulations | Stricter standards require reliable testing processes. |

Advancements in battery management systems and thermal management will improve ruggedness.

New chemistries, such as higher-nickel cathodes and silicon-rich anodes, will increase energy density.

The global battery management system market is projected to grow rapidly, driven by demand for EVs and renewable energy.

Stay ahead by investing in robust design, smart management, and continuous validation.

FAQ

What lithium battery chemistry should you choose for industrial testers?

You should compare chemistries based on your application. See the table below:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Best Use Case |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-120 | 2000+ | Medical, Infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Robotics, Security |

LCO | 3.7 | 150-200 | 500-1000 | Consumer Electronics |

LMO | 3.7 | 100-150 | 300-700 | Power Tools |

How do you ensure battery packs meet industry standards?

You should validate your packs against UL, IEC, and MIL-STD requirements. These standards cover electrical safety, thermal stability, and mechanical durability. Review the latest guidelines at UL and IEC.

What features improve battery pack reliability in harsh environments?

You can use aluminum chassis, reinforced polymers, and silicone seals. These materials protect against shock, vibration, dust, and moisture. Smart battery management systems also monitor temperature and voltage for added safety.

Why is cloud-based battery monitoring important for industrial fleets?

Cloud-based monitoring lets you track battery health, charge cycles, and temperature in real time. You receive alerts for maintenance needs, which reduces downtime and extends battery life. This approach supports predictive maintenance for large deployments.

Can you recycle lithium battery packs from industrial testers?

Yes. You can recycle lithium battery packs using pyrometallurgy, hydrometallurgy, or direct recycling. Responsible recycling helps you recover valuable materials and meet environmental regulations.