Maximizing handheld device runtime in your business demands more than just frequent charging. Smart battery management, especially with lithium battery packs, plays a vital role in keeping devices reliable and efficient. You benefit from advanced Battery Management Systems (BMS) that protect cells, balance battery aging, and maintain safe operating conditions. Holistic strategies, such as combining thorough battery testing, robust maintenance plans, and safe storage practices, help you achieve longer battery lifespan and stable performance.

Key Takeaways

Implement smart battery management systems to optimize device runtime and enhance productivity in business environments.

Utilize intelligent Battery Management Systems (BMS) for real-time monitoring and adaptive charging to extend battery lifespan.

Incorporate IoT technologies to collect data on battery performance, enabling informed decisions and improved operational efficiency.

Adopt adaptive power modes to conserve energy based on device usage, leading to longer battery life and reduced charging frequency.

Focus on staff training and best practices to ensure proper handling and maintenance of batteries, maximizing their efficiency and reliability.

Part 1: Smart Battery Management

1.1 Handheld Device Runtime Impact

Smart batteries play a crucial role in business environments where handheld device runtime directly affects productivity. You face many factors that can shorten device operation during critical tasks. The table below highlights the most common factors impacting handheld device runtime in business settings:

Factor | Description |

|---|---|

Connectivity issues | Maintaining stable network connections is challenging, leading to lost productivity and delayed data synchronization. |

Software updates | Frequent updates are necessary for critical applications, but manual updates can be time-consuming and error-prone. |

Device misuse | Unauthorized use for personal activities drains battery life and distracts from work, impacting productivity. |

Downtime and maintenance | Device failures due to damage lead to productivity loss and increased operational costs for repairs. |

Battery management | Ensuring devices remain charged during long shifts is a logistical challenge, as dead batteries halt workflow. |

You can see that battery management stands out as a key challenge. Smart batteries with advanced BMS help you optimize battery runtime and keep your operations running smoothly. In sectors like medical, robotics, security, and industrial automation, reliable handheld device runtime ensures safety and efficiency.

1.2 Battery Challenges

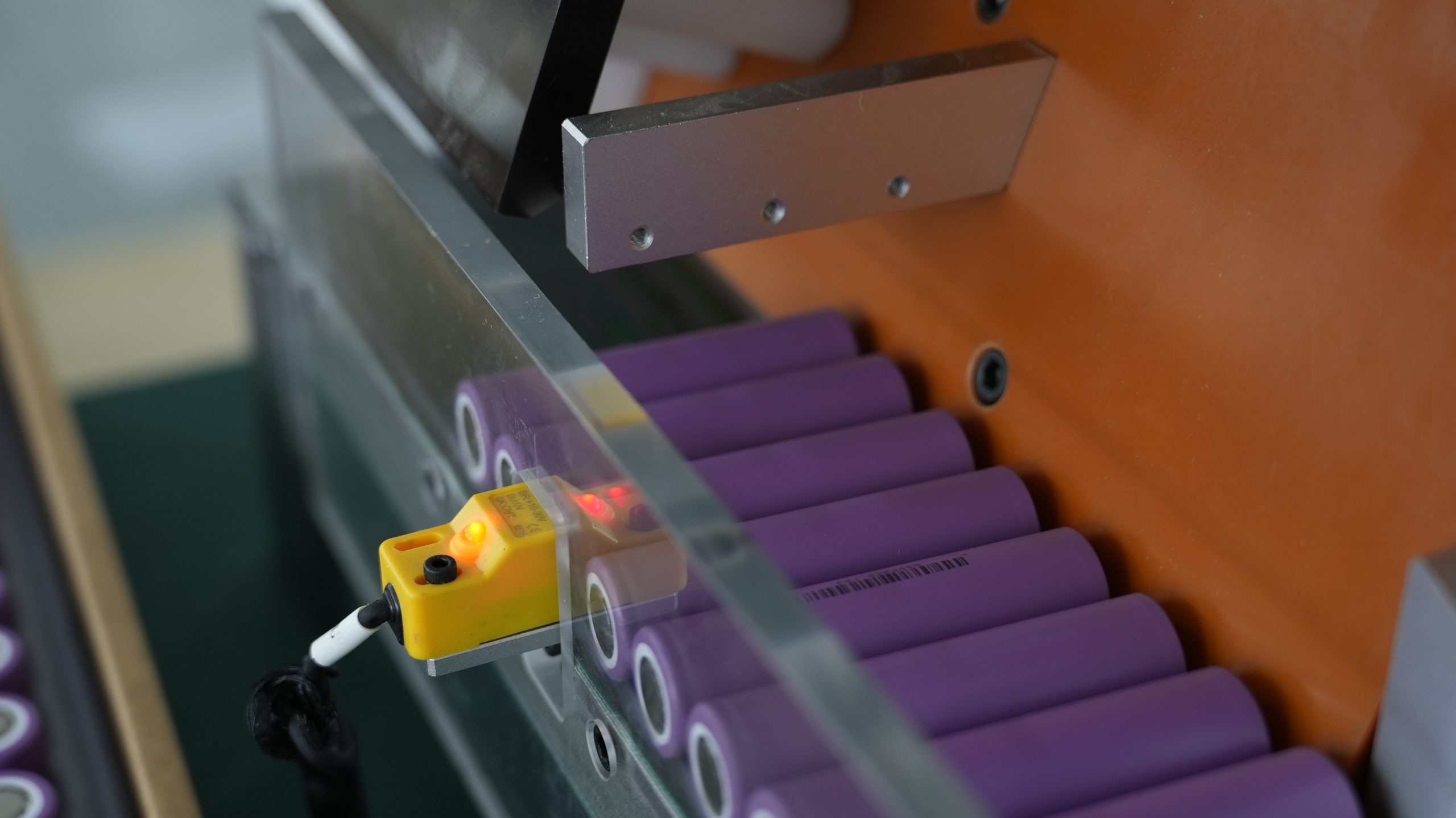

Lithium battery packs power most business handheld devices today. You must address several challenges to maintain battery performance and extend battery life:

Safety concerns, such as thermal runaway, require careful monitoring.

Battery aging reduces capacity over time, affecting device reliability.

Temperature sensitivity impacts battery efficiency in harsh environments.

Charging limitations demand precise control to avoid overcharging.

Environmental impact and conflict minerals (see conflict minerals statement) raise sustainability questions.

Limited resource availability can disrupt supply chains.

Smart batteries use advanced BMS to tackle these issues. You benefit from features like early fault detection, predictive maintenance, and adaptive control strategies. These systems use real-time data to adjust charging and discharging, keeping your battery healthy and your devices reliable.

Below is a comparison of common lithium battery chemistries used in business handheld devices:

Chemistry | Energy Density | Cycle Life | Safety | Cost | Application Scenarios |

|---|---|---|---|---|---|

LCO | High | Moderate | Moderate | Moderate | Consumer electronics |

NMC | High | High | Good | Moderate | Medical, robotics, industrial |

LiFePO4 | Moderate | Very High | Excellent | Moderate | Security, infrastructure, robotics |

LMO | Moderate | Moderate | Good | Low | Power tools, industrial |

LTO | Low | Extremely High | Excellent | High | Medical, infrastructure, robotics |

Solid-state | Very High | High | Excellent | High | Next-gen medical, security |

Lithium metal | Highest | TBD | Developing | High | Advanced R&D, future robotics |

Tip: Choosing the right chemistry for your application helps you optimize battery runtime and reliability.

Smart batteries and advanced system design, such as adaptive resource management and low-power components, further improve battery performance. You gain longer handheld device runtime and fewer interruptions in your workflow.

Part 2: Optimize Battery Runtime

2.1 Intelligent BMS

You can maximize handheld device runtime by using intelligent Battery Management Systems (BMS). These systems monitor and control lithium battery packs in real time. You benefit from advanced features that keep your smart batteries safe and efficient.

Key features of intelligent BMS include:

Real-time monitoring of battery parameters such as voltage, current, and temperature.

Efficient charging algorithms that optimize charging speed while protecting battery health.

Adaptive operation that adjusts power supply based on device requirements to save energy.

Safety enhancements that prevent overcharging, overheating, and other risks.

Intelligent BMS solutions support handheld devices in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. You see improved battery performance and fewer interruptions during critical operations. Smart batteries with these systems help you maintain stable device operation and extend battery lifespan.

Tip: Intelligent BMS not only protects your battery but also helps you plan maintenance and avoid unexpected downtime.

2.2 IoT and Sensing

You can further optimize battery runtime by integrating IoT and sensing technologies with your smart batteries. IoT-enabled systems collect real-time data on battery performance, which helps you make informed decisions and improve operational efficiency.

Longer battery life sets your devices apart in the market.

Advancements in battery technology enhance portable IoT device performance.

Mobile sensing devices in crowd sensing monitor battery management systems.

Energy Management Systems (EMS) optimize electricity use and prevent overcharging.

IoT integration allows real-time data collection on battery performance.

Monitoring overcharging, state of health, and other metrics ensures reliability.

IoT-enabled battery management systems offer several advantages over traditional systems:

Feature | IoT-Enabled BMS | Traditional BMS |

|---|---|---|

Real-time Monitoring | Yes (condition-based maintenance, fewer site visits) | Limited |

Extended Lifespan | Early issue detection, adds years to battery life | Reactive maintenance |

Predictive Maintenance | Forecasts capacity and lifespan | Manual scheduling |

Operational Efficiency | Usage pattern analysis, improved productivity | Basic tracking |

Safety Protocols | Data-driven diagnostics, risk prevention | Standard safety checks |

Cycle Management | Maximizes operational lifespan and reliability | Basic cycle tracking |

Simulation Capabilities | Battery emulators for long-term performance | Limited simulation |

Performance Measurement | Real-world consumption profile testing | Standard testing |

You can use IoT-enabled smart batteries in medical devices for patient monitoring, in robotics for autonomous operation, in security systems for surveillance, and in industrial settings for asset tracking. These technologies help you enhance battery lifespan and reduce maintenance costs.

2.3 Adaptive Power Modes

You can extend handheld device runtime by using adaptive power modes. These modes adjust energy use based on your habits and device activity. Smart batteries work with operating systems to limit background activity and prioritize energy for essential functions.

Android’s Adaptive Battery feature learns which apps you use most and restricts background activity for others. This conserves battery power when your device is idle. iOS 26 introduces Adaptive Power, which analyzes your habits and app usage. It prioritizes energy for frequently used apps and minimizes background activity for less-used ones. This approach reduces unnecessary battery drain and extends battery lifespan by lowering wear from frequent charging cycles.

Adaptive power modes work with smart batteries in medical, robotics, security, infrastructure, consumer electronics, and industrial handheld devices. You see longer battery life and improved reliability during long shifts or critical operations.

Note: Adaptive power modes help you get the most out of your smart batteries by matching energy use to your workflow.

Part 3: Enhance Battery Lifespan

3.1 Thermal Management

You can extend the usable life of lithium battery packs in handheld devices by focusing on thermal management. High temperatures accelerate battery aging and reduce performance. You need to control temperature to slow down degradation and improve reliability. The following table shows how effective thermal management improves key performance metrics:

Performance Metric | Improvement / Value | Description / Impact |

|---|---|---|

Battery aging rate reduction | Up to 22% | Slower degradation due to temperature control |

Cooling energy consumption reduction | Up to 26.9% | Efficient cooling lowers energy use |

Equivalent battery life extension | 15% | Direct extension of usable lifespan |

You can use advanced cooling systems and temperature sensors to maintain optimal battery conditions. In medical, robotics, and industrial sectors, you see fewer device failures and longer service intervals. You also reduce energy costs by using efficient cooling methods.

Tip: Keep battery packs within recommended temperature ranges to maximize performance and safety.

3.2 Universal BMS

Universal Battery Management Systems (BMS) help you maintain battery health across different device types and chemistries. You benefit from continuous monitoring and automatic adjustments that keep batteries operating safely.

A BMS is critical for maintaining the battery’s health over its lifetime. It continuously monitors the battery’s state, such as its voltage, temperature, and charge levels, and adjusts the parameters to ensure optimal conditions. This prolongs the battery’s life and enhances its performance and safety.

A Battery Management System directly impacts the safety, longevity, and efficiency of rechargeable batteries. Maximizing Battery Lifespan: Batteries degrade over time. The system optimizes battery charge and discharge cycles, ensuring the battery operates within safe limits and extending its usable life.

You can deploy universal BMS solutions in medical devices, robotics, security systems, infrastructure, and industrial handheld equipment. You see improved reliability and fewer unexpected shutdowns. Universal BMS technology supports multiple lithium battery chemistries, making it easier to standardize maintenance and monitoring across your fleet.

3.3 Predictive Maintenance

You can maximize battery lifespan by using predictive maintenance strategies. These methods rely on real-time data and smart algorithms to prevent failures before they happen.

Optimize charge and discharge cycles. Maintain battery levels between 20% and 80% to extend lifespan.

Regular monitoring. Use a Battery Management System (BMS) to track voltage, temperature, and charge cycles.

Staff training. Ensure personnel are educated on best practices for battery care.

Avoid full discharge. Prevent stress on battery cells by recharging before dropping below 20%.

You can implement predictive maintenance in medical, robotics, security, and industrial sectors. You reduce downtime and lower replacement costs. You also improve safety by catching issues early.

Note: Predictive maintenance helps you plan service schedules and avoid unexpected device failures.

If you want to learn more about sustainable battery practices, visit our approach to sustainability.

Part 4: User and IT Best Practices

4.1 Training and Habits

You improve battery efficiency and device reliability by investing in structured staff training programs. These sessions teach your team how to handle, charge, and store smart batteries safely. You start with a facility-wide assessment and inventory of all handheld devices. After the assessment, you develop clear policies and train staff to follow them.

Staff learn emergency response procedures for lithium battery incidents.

Training covers charging schedules and proper storage to prevent battery degradation.

You encourage habits that support long operational lifespan and minimize downtime.

User habits play a major role in battery health. Fast charging reduces downtime and boosts operational efficiency. High energy density in smart batteries allows for compact device designs, which helps in tight spaces. Long operational lifespans mean fewer replacements and continuous use.

User Habit Type | Impact on Battery Health and Runtime |

|---|---|

Usage Modes | Different modes lead to varying degradation profiles affecting SoH. |

Charging Habits | Improper charging can accelerate battery degradation. |

Runtime in Usage Mode | Directly correlates with the battery’s Remaining useful Lifetime (RuL). |

Tip: You maximize battery efficiency by training staff and promoting good charging habits.

4.2 Battery Health Monitoring

You maintain smart batteries by using reliable battery health analysis techniques. Coulomb counting helps you estimate battery capacity by measuring energy flow. Calibration corrects tracking errors after random usage. Fuel gauges show charge levels, but they may not reflect actual capacity.

Monitoring internal impedance and capacity over time gives you a clear picture of battery health. Advanced algorithms, such as Feed-forward and Recurrent Neural Networks, predict state-of-health (SoH) accurately. Life cycle and Electrochemical Impedance Spectroscopy (EIS) tests help you understand charge-discharge characteristics.

Technique | Description |

|---|---|

Voltage | Reflects state-of-charge in an open circuit condition. |

Ohmic test | Measures internal resistance to identify defects. |

Full cycle | Involves charge/discharge to read battery capacity. |

Rapid-test | Uses pulses and frequencies to observe ion-flow. |

BMS | Estimates SoC by monitoring voltage, current, and temperature. |

Coulomb counting | Relates Full Charge Capacity to SoH. |

Read-and-Charge | Reads SoC and counts coulombs for charging. |

SOLI | Estimates battery life by counting delivered coulombs. |

Note: Regular battery health monitoring helps you extend battery lifespan and reduce power consumption.

4.3 Replacement Protocols

You keep your handheld device fleet running smoothly by following strategic battery replacement protocols. A proactive asset replacement plan reduces unexpected breakdowns and lowers maintenance costs. You optimize your maintenance budget and improve safety by updating devices regularly.

Predictive analytics help you detect potential issues early, schedule replacements at convenient times, and focus repairs based on data. You minimize downtime and avoid unnecessary replacements.

You maintain consistent budgeting and maximize resale value by timing disposals effectively.

These strategies lower total cost of ownership and improve reliability for medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Callout: You achieve better battery efficiency and operational performance by combining predictive analytics with regular replacement cycles.

Part 5: Future of Battery Technology

5.1 AI and Machine Learning

You see rapid progress in AI and machine learning for battery management. These technologies transform how you monitor and maintain lithium battery packs in business environments.

AI and ML enable predictive maintenance by forecasting failures and tracking battery degradation.

You benefit from continuous, real-time battery health assessments.

Adaptive algorithms adjust to your device’s usage patterns, optimizing performance and reliability.

Predictive analytics improve safety by detecting failures early and scheduling maintenance based on actual battery health.

AI-driven battery management systems outperform traditional systems. Traditional BMS offer basic monitoring and protection. AI-driven BMS use machine learning for predictive maintenance and adaptive charge-discharge cycles. This approach extends battery life and improves performance.

Tip: You can increase device uptime and reduce maintenance costs by adopting AI-powered battery management.

5.2 Advanced Lithium Chemistry

You gain significant advantages from new lithium battery chemistries. These innovations boost energy density, runtime, and charge efficiency for your handheld devices. The table below compares the latest chemistries:

Lithium-sulfur batteries can power devices for up to five days on a single charge. Lithium-silicon batteries attract investment from automotive and industrial sectors. Solid-state batteries promise long service life and high safety, making them ideal for critical business applications.

Note: For responsible sourcing and sustainability, review our approach to sustainability and our conflict minerals statement.

5.3 Smart Battery Trends

You notice several trends shaping the future of smart batteries in business handheld devices:

Intelligent charging systems now monitor multiple parameters, improving device efficiency.

About 56% of manufacturers use smart chips for battery performance monitoring.

Enhanced charging systems deliver a 42% improvement in field performance for portable diagnostic equipment.

Over 33% of enterprises focus on energy optimization in battery design.

Sustainability and regulatory compliance drive the adoption of eco-friendly chemistries and better end-of-life management. Smart battery management systems with IoT connectivity allow real-time diagnostics and proactive maintenance. Businesses in healthcare, logistics, and industrial sectors use these advancements to extend battery lifespan and improve safety.

Callout: You can future-proof your operations by investing in smart batteries and advanced management systems that support real-time monitoring and optimization.

You boost handheld device runtime and extend battery lifespan by combining smart battery management, advanced BMS, IoT integration, and strong user practices. You see greater efficiency and reliability in medical, robotics, security, infrastructure, consumer electronics, and industrial applications.

Ongoing evaluation and adoption of new battery technologies increase energy density, safety, and sustainability.

These improvements lower costs and enhance device performance.

Solid-state, sulfur, and aqueous batteries offer promising low-carbon solutions for reliable operations.

Stay ahead by regularly assessing your battery systems and adopting innovations that drive business efficiency.

FAQ

What is the main advantage of using lithium battery packs in business handheld devices?

You gain high energy density, long cycle life, and reliable performance. Lithium battery packs support medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Tip: Choose lithium battery chemistry based on your device’s runtime and safety needs.

How does a Battery Management System (BMS) improve device reliability?

A BMS monitors voltage, temperature, and charge cycles. You prevent overcharging and overheating. You extend battery lifespan and reduce downtime in critical business operations.

Which lithium battery chemistry is best for industrial handheld devices?

Chemistry | Energy Density | Cycle Life | Safety | Application Scenario |

|---|---|---|---|---|

LiFePO₄ | Moderate | Very High | Excellent | Industrial, robotics |

NMC | High | High | Good | Medical, infrastructure |

You select LiFePO₄ for safety and long life. NMC suits high energy needs.

How often should you replace lithium battery packs in business devices?

You should monitor battery health regularly. Replace packs when capacity drops below 80% or after 500–1,000 cycles. Predictive analytics help you schedule replacements and avoid unexpected failures.

What steps help you maximize battery lifespan in handheld devices?

You keep batteries cool, avoid full discharges, and use adaptive charging. Train staff on best practices.

Note: Regular monitoring and maintenance extend battery life in medical, robotics, security, and industrial applications.