Explosion-proof lithium batteries protect you from explosive risks in hazardous locations. You face strict regulations when deploying battery systems in explosive atmospheres. ATEX and IECEx standards define explosive zone requirements for lithium battery packs. You must prioritize certification, safety, and compliance with regulations in all explosive environments to prevent incidents.

Key Takeaways

Explosion-proof lithium batteries must meet strict certifications like ATEX in the EU, IECEx globally, UL in North America, and GB in China to ensure safety in hazardous locations.

Follow rigorous testing and safety features such as overcharge protection, battery management systems, and thermal controls to prevent fire and explosion risks.

Verify certifications carefully, perform regular quality checks, and stay updated with regulations to maintain compliance and protect your business in explosive environments.

Part 1: Certifications for Explosion-proof Lithium Batteries

Explosion-proof lithium batteries must comply with strict certifications and standards to ensure safe operation in explosive atmospheres. You need to understand the differences between global and regional certification systems to select the right lithium battery packs for hazardous environments. This section breaks down the most important certifications: ATEX, IECEx, UL, and GB, and explains their relevance to lithium battery certification and regulatory compliance.

1.1 ATEX and IECEx Overview

ATEX and IECEx are the two most recognized certification systems for explosion-proof lithium batteries used in potentially explosive atmospheres. You will encounter these standards when deploying battery packs in industries such as Industrial, Infrastructure, and Security.

Note: ATEX certification is mandatory under EU ATEX regulations for any lithium battery pack used in hazardous locations within the European Union. IECEx certification system is internationally recognized and often preferred for multinational projects.

Here is a comparison of the main features of ATEX and IECEx certifications for explosion-proof lithium batteries:

Feature | ATEX Certification | IECEx Certification |

|---|---|---|

Region | Mandatory and legally valid only in the EU | Internationally recognized (Australia, Asia, Middle East, etc.) |

Legal Requirement | Mandatory within the European Union | Optional but widely accepted globally |

Certification Format | EU Declaration of Conformity | Certificate of Conformity (CoC) issued by IECEx Management Committee |

Regulatory Bodies | EU Notified Bodies | IECEx Management Committee |

Equipment Use | Best suited for EU-based operations | Preferred for multinational compliance |

Interchangeability | Legal and insurance restrictions apply unless dual certification is present | Same as ATEX; interchangeability depends on jurisdiction |

Standards Followed | EN 60079 | IEC 60079 |

Applicability to Batteries | Batteries in hazardous areas must be certified under these standards to ensure safety | Same as ATEX; applies to explosion-proof lithium batteries as electrical equipment in hazardous zones |

You must use ATEX certification for lithium battery packs in the EU, as required by the ATEX Directive 2014/34/EU. IECEx certification is accepted in many regions outside the EU, including Australia, Asia, and the Middle East. In the United States, you will follow different regulations, such as the National Electrical Code (NEC) and MSHA, instead of ATEX. Both ATEX and IECEx require that batteries used in explosive atmospheres meet strict safety and performance requirements.

1.2 UL Standards

In North America, you will rely on UL standards for explosion-proof lithium batteries. UL standards focus on rigorous safety testing and are essential for compliance with U.S. regulations. These standards address fire, electrical, and mechanical risks in lithium battery packs used in explosive environments.

Here is a summary of the key UL standards relevant to explosion-proof lithium batteries:

UL Standard | Focus Area | Relevance to Explosion-Proof Lithium Batteries |

|---|---|---|

UL 1642 | Safety requirements for lithium batteries, testing to prevent fire or explosion risks | Directly addresses fire and explosion prevention in lithium batteries |

UL 2054 | Safety for household and commercial lithium battery applications | Covers safe use, handling, and storage, relevant to explosion risk mitigation |

UL 4200A | Safety for secondary lithium batteries in high-performance applications | Ensures safety in demanding environments, indirectly supporting explosion-proof design |

UL 60086-4 | Safety and performance for primary lithium batteries | Focuses on safe operation under intended and foreseeable use, reducing explosion risk |

UL 1973 | Safety for stationary and motive battery systems | Addresses electrical safety, thermal management, fire containment, and thermal runaway mitigation, critical for explosion-proof systems |

UL 9540 | Safety of entire energy storage systems including batteries and inverters | Integrates electrical, mechanical, and fire safety, supporting explosion-proof system design |

UL 9540A | Test method for thermal runaway fire propagation in battery energy storage systems | Critical for assessing and mitigating thermal runaway and fire propagation, key to explosion-proof safety |

UL 2054 includes more tests and tougher conditions than international IEC standards. You will find that UL standards are more demanding, especially for lithium battery packs used in industrial and stationary energy storage applications. UL 1973 and UL 9540A are particularly important for large-scale battery systems, as they address thermal runaway and fire containment, which are critical for explosion-proof lithium batteries.

1.3 GB and Regional Standards

If you operate in China, you must comply with GB standards for explosion-proof lithium batteries. These standards are mandatory for battery packs used in energy storage systems and electric vehicles, especially in hazardous locations.

Key GB standards include:

GB 44240-2024: Governs explosion-proof lithium batteries in energy storage systems over 100 kWh. Covers the entire battery lifecycle, including design, manufacturing, testing, installation, and recycling. Requires 23 specific safety tests, such as overcharge, forced discharge, nail penetration, and thermal abuse.

GB/T 31485-2015 and GB/T 31486-2015: Focus on safety and electrical performance testing of battery modules.

GB/T 31467 series: Based on ISO 12405, applies to battery packs and systems, covering safety test procedures and thermal runaway prevention.

GB/T 31484-2015: Dedicated to cycle life testing of power batteries for electric vehicles.

MIIT’s 2016 ‘Safety Technical Specifications for Electric Buses’: Introduces additional testing for thermal runaway and propagation.

Tip: GB 44240-2024 aligns with international standards such as IEC, UL, and UN, making it easier for you to achieve global compliance if you manufacture or integrate lithium battery packs for export.

Regional standards differ from global standards like ATEX and UL in legal enforceability, classification systems, and certification authorities. The table below summarizes the main differences:

Certification Standard | Region/Scope | Classification System | Legal Status | Certification Body | Key Notes |

|---|---|---|---|---|---|

ATEX | European Union | Zones (0,1,2) | Mandatory in EU | EU Notified Bodies | Uses EN 60079 standards; legally binding in EU only |

UL/FM | North America | Divisions (1,2) | Mandatory in US/Canada | OSHA/NRTL, FM Global | Based on NEC 500/505; regionally focused |

CSA | Canada | Divisions | Mandatory in Canada | CSA Group | Canadian Electrical Code (CEC) based |

INMETRO | Brazil | Zones/IEC based | Mandatory in Brazil | National Institute of Metrology | Local adaptation of IEC standards |

IECEx | Global | Zones (0,1,2) | Voluntary but globally recognized | IECEx Management Committee | Harmonized global standard based on IEC 60079; facilitates multinational acceptance |

You must ensure that explosion-proof lithium batteries meet the appropriate certification and standards for your target market. This approach guarantees compliance with local regulations and provides the highest level of safety in explosive atmospheres.

Part 2: Compliance and Safety Requirements

2.1 Testing Protocols

You must follow rigorous testing protocols to achieve certification for explosion-proof lithium battery packs. These protocols ensure that your products meet the highest safety standards and can withstand explosive risks in hazardous environments. The IEC 60079 series, especially IEC 60079-35-1 and IEC 60079-31, sets the global benchmark for testing lithium batteries used in explosive atmospheres. These standards focus on ignition risk, construction, and marking of equipment, including lithium battery packs.

Key testing protocols under IEC 60079 include:

Evaluation of battery construction and recharging methods.

Protection against deep discharge and overcharge.

Determination of temperature class to prevent ignition.

Testing of thermal protection and electronic circuitry.

Short circuit withstand current and malfunction condition testing for sealed cells.

Surface temperature limits for enclosures in explosive dust atmospheres.

You must also consider UL 1642 and IEC 62133 when certifying lithium battery packs. These standards differ in scope and testing focus. The table below highlights their main differences:

Feature | UL 1642 | IEC 62133 |

|---|---|---|

Standard Type | Safety standard for lithium batteries | International standard for nickel and lithium batteries |

Testing Focus | Cell safety: overcharging, short-circuit, high temperature, mechanical abuse | Battery pack safety: protection circuits, vibration, altitude, thermal abuse |

Testing Procedures | Environmental, electrical, mechanical assessments | Comprehensive tests including vibration and altitude simulation |

Market Recognition | North America | Global (Europe, Asia, others) |

Application | Consumer electronic lithium cells | Portable rechargeable batteries including packs |

Explosion-proof and environmental test chambers support both UL 1642 and IEC 62133, providing wide temperature and humidity control. This ensures your lithium battery packs are tested under conditions that simulate real-world hazards, including thermal runaway events and fire.

When you ship lithium-ion batteries, you must comply with UN 38.3, which covers transporting lithium batteries by air, sea, and land. This standard requires tests for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. These tests help prevent fire and explosion during shipping lithium-ion batteries.

2.2 Safety Features

Explosion-proof design for lithium battery packs requires advanced operational safety features. UL 2271 mandates a comprehensive set of protections to minimize fire and explosive risks in hazardous locations. You must integrate the following safety features into your battery packs:

Overcharge protection to prevent failure during charging.

Short circuit protection to withstand accidental shorts safely.

Over discharge protection to avoid damage from excessive depletion.

Current and voltage limits to maintain safe operation.

Battery Management System (BMS) for real-time monitoring and control.

Mechanical protections such as vibration, shock, and drop resistance.

Environmental protections including temperature cycling, humidity, and thermal shock resistance.

Chemical safety tests for electrolyte leakage and corrosion resistance.

Abuse tests like crush, penetration, and forced discharge to prevent thermal runaway.

Functional safety evaluation of BMS software and hardware.

You should also implement operational safety features such as:

Temperature sensors to prevent overheating.

Current limiters to avoid dangerous power spikes.

Emergency disconnect systems for rapid shutdown.

Physical protection against mechanical damage.

Proper storage conditions play a critical role in explosion-proof design. Store lithium battery packs at room temperature, away from direct sunlight, and indoors to reduce overheating. Use automatic sprinkler systems, weather protection, and proper ventilation to control fire and dissipate hazardous gases. Advanced fire suppression agents like F-500 Encapsulator Agent can absorb thermal energy, halt thermal runaway, and prevent explosive off-gas production. Always follow NFPA standards for fire protection and inspect batteries regularly for damage or leaks.

2.3 Verification and Selection

Selecting certified explosion-proof lithium battery packs requires a systematic verification process. You should follow these steps to ensure compliance and safety:

Inspect the battery’s exterior and packaging for defects, clear labeling (brand, model, voltage, capacity, production date, standards), and certification marks.

Measure battery capacity using professional instruments. Fully charge and discharge the battery to confirm actual capacity is within ±5% of the rated value.

Evaluate voltage stability by performing load tests. Monitor voltage changes during discharge to ensure smooth performance.

Assess charging and discharging performance. Verify normal charging time, absence of abnormal heating or smoke, and stable discharge.

Verify safety performance through controlled overcharge and over-discharge tests. Check for bulging, leakage, smoke, fire, or explosion.

Ensure all tests are conducted by professionals with electrical expertise.

To maintain ongoing compliance, you must:

Establish factory quality controls after initial certification.

Maintain comprehensive technical documentation, including design details, BMS integration, and test reports.

Implement continuous quality control processes to monitor production consistency.

Adhere to regular testing protocols simulating operational and fault conditions.

Consult accredited testing laboratories for guidance and re-testing.

Stay updated with regulatory changes to ensure conformity with explosion-proof lithium battery standards.

Third-party testing laboratories such as UL Solutions, TÜV Rheinland, Intertek, and SGS provide independent verification of compliance. Their expertise and accreditation help you access international markets and reduce the risk of product failures or recalls.

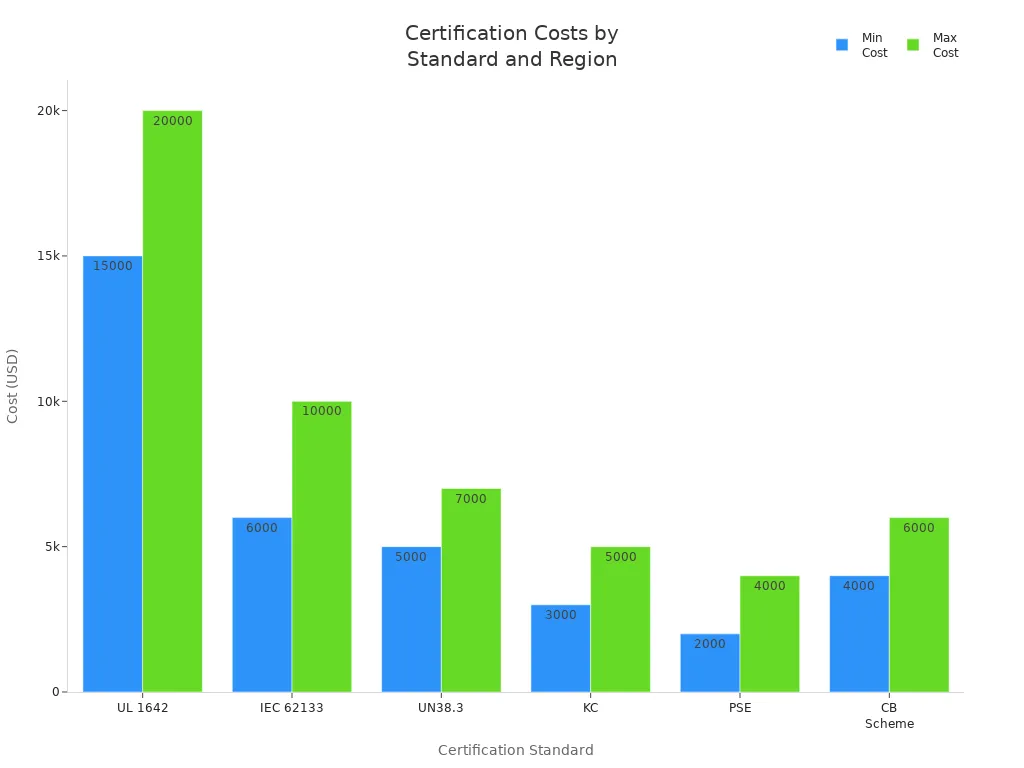

Certification costs and timelines vary by region and standard. The table below summarizes typical costs:

2.4 ATEX Directives

ATEX directives define the strictest requirements for explosion-proof lithium battery packs in the European Union. You must comply with EN 60079 series standards, including EN 60079-0 for general requirements, EN 60079-11 for intrinsically safe circuits, and EN 60079-7/18 for increased safety or encapsulation of battery enclosures.

The main ATEX directives include:

2014/34/EU (Equipment Directive): Requires design, manufacturing, and testing by EU-notified bodies.

1999/92/EC (Workplace Directive): Classifies hazardous zones (Zone 0/1/2) for battery deployment.

You must classify and mark your battery packs according to equipment category (Group II, subgroups IIA, IIB, or IIC) and temperature class (e.g., T4) to ensure surface temperatures remain below autoignition thresholds. ATEX directives enforce intrinsic safety, energy limitation, thermal management, and structural protection of battery enclosures. Detailed markings and longer certification timelines are mandatory for EU market access.

ATEX directives impact your design and manufacturing process by requiring intrinsic safety features that prevent sparks or heat from igniting flammable gases or dust. You must use protection circuits to limit currents, heat, and sparks. Hazardous areas are classified by zones, which influence your safety requirements and material choices. Temperature codes (T1 to T6) specify maximum surface temperatures, affecting your selection of components and enclosure materials.

You must also address the challenges of overlapping and evolving standards, rigorous documentation, and the complexity of legal liability. Explosion-proof design for lithium battery packs demands specialized fire protection, explosion suppression, and strict maintenance schedules. You should partner with accredited testing laboratories and stay informed about regulatory updates to maintain compliance with ATEX directives and other global safety standards.

Explosion-proof lithium battery certification protects your business in hazardous locations. You gain safer products, legal assurance, and global market access. To ensure compliance, always verify certification, review safety features, and monitor regulatory updates. Prioritize certified lithium battery packs and consult experts to stay ahead in evolving industrial markets.

FAQ

1. What certifications do you need for explosion-proof lithium battery packs in industrial and medical sectors?

You need ATEX or IECEx for the EU, UL for North America, and GB for China. Always verify certification for your application, such as Medical or Industrial.

2. How do ATEX and IECEx certifications compare for lithium battery packs?

Feature | ATEX (EU) | IECEx (Global) |

|---|---|---|

Legal Status | Mandatory in EU | Voluntary, accepted |

Application | EU industries | Multinational use |

3. Where can you get customized explosion-proof lithium battery solutions?

You can contact Large Power for tailored lithium battery packs. Click for a customized consultation and expert support for your robotics, security, or infrastructure projects.