You witness the fast-charge revolution transforming warehouse robotics. The ability to reach 80% charge in 15 minutes changes how you manage operations. The fast-charge revolution delivers faster processing, higher accuracy, and lower labor costs. You see robots adapting quickly, simplifying returns, and providing better analytics. How does the fast-charge revolution achieve this?

Key Takeaways

Fast-charging lithium batteries enable robots to reach 80% charge in just 15 minutes, significantly reducing downtime and improving operational efficiency.

Advanced charging protocols and real-time battery monitoring enhance battery health and optimize charging speed, allowing for continuous robot operation.

Implementing safety systems and best practices ensures reliable and safe operations, minimizing risks associated with high-speed charging in warehouse environments.

Part 1: Fast-Charge Revolution in Warehouse Robotics

1.1 Battery Innovations

You see the heart of the fast-charge revolution in the latest lithium battery packs. These battery packs drive robotics to new heights in warehouse operations. Over the past three decades, lithium-ion batteries have tripled their energy density, now reaching about 0.25 kilowatt-hours per kilogram. This progress enables your robots to handle more picking cycles per charge, supporting continuous operations in demanding warehouse environments.

New lithium-ion batteries improve by about 7% each year, steadily increasing both energy density and charge rates.

In 1991, lithium-ion batteries offered 80 watt-hours per kilogram. Today’s commercial versions deliver three times that, supporting longer picking sessions and faster charging cycles.

Next-generation chemistries, such as lithium-sulfur and metal-air, promise even higher energy densities, potentially matching the endurance of biological systems.

You must also consider the chemistry behind these advancements. Lithium iron phosphate (LiFePO4) batteries are gaining traction in industrial robotics due to their safety, efficiency, and long cycle life. As you plan your charging infrastructure, you need to evaluate the trade-offs between different chemistries. The table below compares key battery types used in robotics:

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Level | Fast-Charge Capability | Typical Application Scenarios |

|---|---|---|---|---|---|

LiFePO4 | 90-160 | 2000+ | High | Excellent | Robotics, Industrial, Security |

NMC | 150-220 | 1000-2000 | Moderate | Good | Robotics, Consumer Electronics |

LCO | 150-200 | 500-1000 | Low | Moderate | Consumer Electronics |

LMO | 100-150 | 500-1000 | Moderate | Good | Medical, Robotics |

LTO | 70-80 | 7000+ | Very High | Outstanding | Infrastructure, Industrial |

Lithium plating, influenced by ion conduction and diffusion rates in the electrolyte, as well as reaction kinetics at graphite surfaces, is temperature-dependent. This factor significantly impacts the feasibility of fast charging in industrial robots.

As you deploy more robots for picking and sorting, you benefit from these chemistry improvements. You achieve higher throughput and more reliable operations, even as your robotics fleet grows.

1.2 Charging Protocols

You rely on advanced charging protocols to maximize the efficiency of your warehouse robotics. Real-time battery monitoring forms the backbone of these protocols. Your robots use intelligent battery management systems (BMS) to optimize charging speed and maintain battery health. These systems monitor voltage, current, and temperature, adjusting charging rates dynamically to prevent degradation.

Real-time battery monitoring optimizes charging speed and preserves battery health.

Intelligent task allocation allows robots to manage picking and sorting tasks efficiently, reducing downtime and enhancing productivity.

Adaptive charge control techniques, such as constant current/constant voltage profiles and real-time thermal monitoring, prevent overcharging and ensure safe charging practices.

The integration of handshake protocols between the docking station and the robot’s BMS ensures safe charging based on the battery’s state. This communication avoids overcharging and logs data for fleet maintenance, which is essential for optimizing charging speed while preserving battery health.

Wireless and inductive charging technologies are transforming your charging infrastructure. With wireless charging, you support fully automated workflows. Compact inductive charging stations can be placed throughout the warehouse, allowing robots to charge opportunistically during picking operations. This approach reduces downtime and enables lighter battery designs, enhancing robot mobility and efficiency.

Wireless power transfer integrates charging into daily workflows, allowing robots to charge while on standby.

Recent advancements in magnetic transfer designs have improved energy efficiency, achieving around 90% efficiency in power transfer.

Inductive charging supports a shift from automated to genuinely autonomous workflows in warehouse robotics.

You also address common failure modes in fast-charging systems by adopting power-in-motion solutions and modular antennas. These innovations minimize downtime, reduce the need for oversized fleets, and reclaim valuable warehouse floor space.

Failure Mode | Description | Mitigation Strategy |

|---|---|---|

Charging Downtime | Robots must dock to charge, causing inefficiencies and delays. | Power-in-Motion allows charging while in motion. |

Oversized Fleets | Extra robots are needed to compensate for charging downtime. | 15% smaller fleets with continuous charging. |

Reduced Throughput | Slower order fulfillment due to robots waiting for a charge. | Continuous power delivery maintains workflow speed. |

Wasted Floor Space | Charging stations occupy valuable warehouse space. | Modular antennas reclaim 150-250 sq ft per charger. |

Hidden Costs | Increased maintenance and inefficiencies due to charging methods. | 32% lower total cost of ownership with new tech. |

Misalignment and Dirt in Charging | Traditional systems struggle with misalignment and debris. | High misalignment tolerance and resilient design. |

1.3 Safety Systems

You prioritize safety in every aspect of warehouse robotics operations. Fast-charging systems for robots integrate multiple safety mechanisms to prevent overheating and electrical faults.

Lithium-ion batteries with thermal shutdown features automatically shut off when reaching critical temperatures, preventing overheating and potential explosions.

Health monitoring sensors continuously check the robot’s operational status, providing early warnings for overheating and allowing for timely interventions.

Thermally conductive materials, such as advanced rubber compounds, manage heat dissipation effectively, ensuring excess heat is managed before it becomes a problem.

You also ensure compliance with international safety standards and certifications. The table below summarizes key standards relevant to fast-charging lithium batteries in industrial robotics:

Standard | Scope | Key Tests |

|---|---|---|

UL 2580 | Complete rechargeable battery packs in electric vehicles and mobile platforms | Electrical abuse, Mechanical abuse, Thermal abuse, Environmental |

IEC 62619 | Individual cells and complete battery assemblies in industrial settings | Electrical safety, Mechanical endurance, Thermal stress, Functional safety |

By adhering to these standards, you guarantee reliable and safe operations for your robotics fleet. You minimize risks and maintain high productivity in your warehouse.

As you look to the future, lithium iron phosphate (LiFePO4) batteries are positioned to play a central role in powering industrial vehicles, including electric forklifts and autonomous delivery robots, due to their high efficiency and long life cycle.

You see that the fast-charge revolution in warehouse robotics is not just about speed. It is about building a robust, safe, and scalable foundation for your picking and sorting operations. You gain a competitive edge by leveraging the latest battery innovations, advanced charging protocols, and comprehensive safety systems.

Part 2: Warehouse Efficiency and Robot Operations

2.1 Reduced Downtime

You experience a dramatic reduction in downtime when you deploy fast-charging robot fleets in your warehouse. Lithium battery packs, especially those using LiFePO4 and NMC chemistries, enable rapid charging cycles. Your robots can reach 80% charge in just 15 minutes, which keeps picking operations running smoothly. You no longer need to schedule lengthy charging sessions or maintain oversized fleets to compensate for idle time.

Opportunity charging during short breaks keeps robots available for picking tasks throughout the day.

Frequent partial charges do not harm lithium batteries, so you maintain continuous robot operation without sacrificing battery health.

AI-driven solutions predict energy demand and optimize charging schedules, reducing downtime and improving shift patterns.

Wireless charging stations placed strategically across your warehouse allow robots to recharge while waiting for the next picking assignment. This approach supports dynamic logistics workflows and maximizes equipment availability. You see robots operating efficiently across multiple shifts, with minimal interruptions for charging.

You benefit from advanced chargers that reduce the time forklifts and robots spend charging, leading to better scheduling and improved resource utilization.

2.2 Productivity Gains

You notice a significant boost in productivity as fast-charging technology transforms your warehouse operations. Robots equipped with high-performance lithium batteries complete more picking cycles per shift. You achieve higher throughput and faster order fulfillment, especially during peak logistics periods.

Fast-charging robots outperform conventional systems by minimizing idle time and maximizing equipment usage. Opportunity charging systems provide quick energy bursts during brief operational pauses, further optimizing efficiency. Your warehouse achieves superior throughput compared to facilities using traditional charging methods.

Fast charging technologies cut down charging times, leading to enhanced equipment availability and throughput in warehouse operations. In high-demand settings, rapid battery replenishment is crucial for maintaining performance.

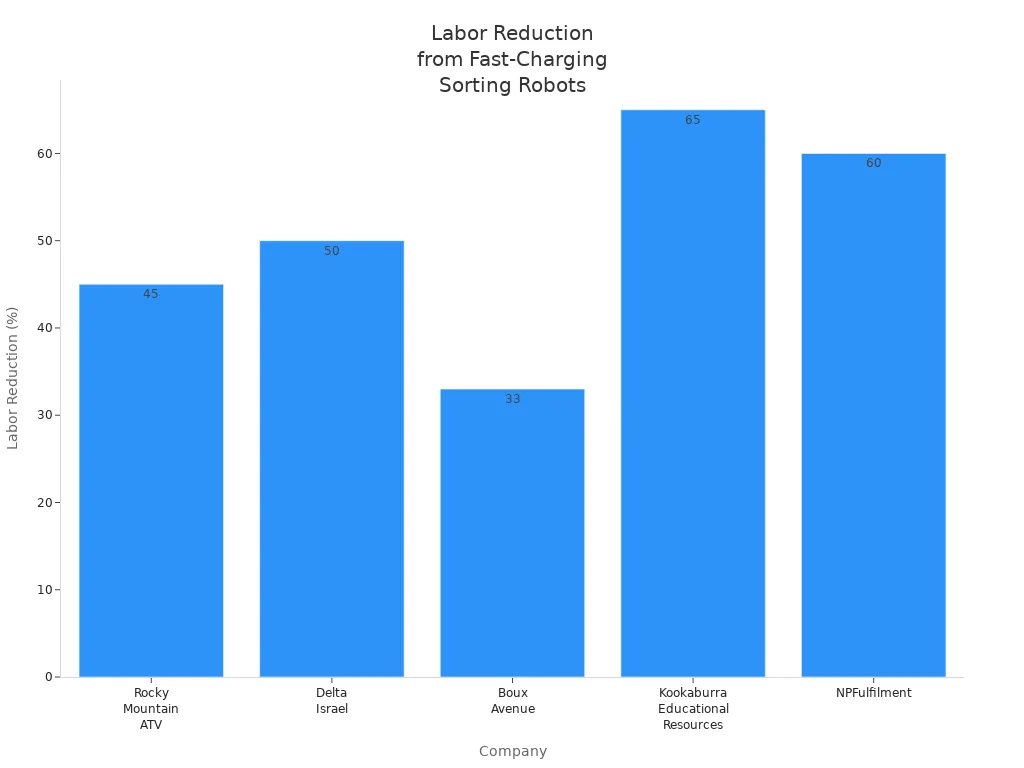

You see robots handling picking, sorting, and logistics tasks with greater speed and accuracy. Your team reallocates labor to higher-value activities, reducing manual intervention and improving overall performance. The table below highlights operational improvements across industries using fast-charging sorting robots:

Company | Industry | Labor Reduction | Efficiency Improvement | ROI Timeframe |

|---|---|---|---|---|

Bleckmann | 3PL | N/A | Increased operational efficiency | N/A |

Rocky Mountain ATV | Automotive OEM Parts Distribution | 45% | Increased order fulfillment speed | Rapid ROI |

Delta Israel | Apparel E-commerce | 50% | Improved order processing speed and accuracy | 24 months |

Boux Avenue | Apparel Retail and E-commerce | 33% | High order throughput | Fast ROI |

Kookaburra Educational Resources | Kitting & Fulfillment | 65% | Sorting rates of 2,400 items/hour | N/A |

NPFulfilment | E-commerce and 3PL | 60% | Handled 4x peak-season volume | N/A |

You achieve rapid ROI when you automate picking and logistics workflows. Over 50% of mobile robot users report ROI within 18 months. You realize the greatest returns when robots address costly issues such as labor and downtime. Even automating 30-50% of workflows delivers strong results.

2.3 Real-World Impact

You see the real-world impact of fast-charging robots across diverse industries, including Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial sectors. Your warehouse operations become more resilient and scalable as you deploy robots with advanced lithium battery packs.

You manage safety risks associated with high-speed charging by implementing best practices:

Dedicated ventilation systems prevent hydrogen gas accumulation during charging.

High-visibility floor markings separate charging zones from active traffic, reducing collision risks.

Fire suppression and spill response setups include extinguishers and emergency equipment.

Battery storage and charging racks prevent tipping and trip hazards.

Continuous gas monitoring systems detect hydrogen levels and trigger alarms.

Access control systems ensure only certified personnel handle high-voltage charging.

Real-time monitoring and alerts provide immediate notifications for any charging issues.

You also address battery lifespan concerns. Lithium batteries in robots last 8-10 years, far exceeding the 2-3 year lifespan of standard lead-acid batteries. You benefit from shorter charging times, with autonomous mobile robots achieving a full charge in 1-2 hours. Advanced chemistries deliver even faster cycles, supporting continuous picking and logistics operations.

Battery Type | Average Lifespan |

|---|---|

Lithium Batteries | 8-10 years |

Standard Lead-Acid | 2-3 years |

You optimize warehouse efficiency and performance by leveraging fast-charging technology. Your robots deliver consistent picking rates, minimize downtime, and support scalable logistics workflows. You see measurable improvements in throughput, labor reduction, and ROI across real-world operations.

You transform your warehouse operations by adopting fast-charging lithium battery packs. Robots deliver higher throughput and reliability, driving operational efficiency across Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial sectors.

Strategic Advantage | Description |

|---|---|

Increased Productivity | Robots operate at two to three times traditional rates, speeding order fulfillment. |

24/7 Reliability | Over 98% uptime ensures continuous service for demanding logistics. |

Quick ROI | Automation yields returns in under two years, reducing labor costs. |

Over the next five years, lithium battery technology will advance in chemistry, digital integration, and sustainability. Manufacturers invest in new cell formats and silicon anode technologies, enabling longer cycle life and faster recharge rates.

The adoption of fast-charging lithium batteries reduces harmful emissions and supports eco-friendly initiatives. You align your warehouse with green energy policies and improve safety for your team. For tailored solutions, explore custom battery consultation on our custom solution page.

FAQ

What makes fast-charging lithium battery packs essential for autonomous mobile robots in automated logistics?

You gain continuous operation with fast-charging lithium battery packs. These packs support autonomous mobile robots in automated logistics, boosting picking productivity and enabling seamless goods-to-person picking.

How do safety systems in robot technology ensure reliable continuous operation in industrial and medical sectors?

You rely on advanced safety systems in robot technology. These systems monitor temperature and voltage, ensuring continuous operation for robotic sorting and stacking in industrial, medical, and security environments.

Can Large Power customize ai-powered robotic solutions for your warehouse management systems and picking process?

You can request custom ai-powered robotic solutions from Large Power. These solutions integrate with warehouse management systems, optimizing the picking process for continuous operation. Request a custom battery consultation.