Fast-Charging Battery technology lets you keep automated guided vehicles running longer and more efficiently. When you shift to lithium-ion solutions, you gain several advantages:

Longer lifespan with up to 5,000 charge cycles

Faster charging, often within two hours

Lower maintenance and improved safety from built-in management systems

Advanced charging systems, such as modular docking stations and distributed charging bays, help your AGVs work around the clock. You need to select battery technology that matches your industrial automation needs. Use the table below to compare important criteria:

Criteria | Description |

|---|---|

LiFePO₄ Technology | Greater thermal stability and electrical safety |

High Energy Density and Deep Discharge | High performance in deep cycles |

Professional Control Electronics (BMS) | Manages cells and safety |

Prepared for Demanding Environments | Resists extreme temperatures |

Scalability | Modular capacity increases |

Active Safety | Early fault detection systems |

Compliance with Regulations | Meets safety and traceability standards |

Key Takeaways

Fast-Charging Battery technology boosts AGV uptime, allowing for more tasks completed per hour and increased productivity.

Lithium-ion batteries, like LiFePO4, charge quickly in 1-2 hours, reducing downtime and enabling opportunity charging during short breaks.

Selecting the right battery type is crucial; lithium-ion batteries offer longer lifespans and lower maintenance compared to traditional lead-acid batteries.

Advanced Battery Management Systems enhance safety and performance by monitoring battery health and optimizing charging schedules.

Strong vendor support is essential for successful battery integration, ensuring reliable performance and maintenance for your AGV fleet.

Part1: Fast-Charging Battery Benefits

1.1 Uptime and Productivity

You want your automated guided vehicles to work as much as possible. Fast-Charging Battery technology helps you achieve this goal. When you use lithium-ion batteries, such as LiFePO4 or NMC, you get quick recharging and long cycle life. AGVs spend less time at charging stations and more time moving goods.

Amazon increased warehouse productivity by using fast-charging systems. AGVs completed more tasks per hour and fulfilled orders faster.

Walmart improved inventory turnover by charging AGVs during loading and unloading. This method keeps vehicles available for work.

Tip: Quick recharging means you can schedule AGVs for more shifts without worrying about battery limitations.

You can expect:

Increased uptime for your AGVs.

Higher throughput, which means more goods moved every hour.

Flexible operations that adapt to changing workloads.

1.2 Reduced Downtime

Downtime hurts your bottom line. Traditional lead-acid batteries need 6-8 hours to charge and another 8 hours to cool. That means over 12 hours when your AGVs cannot work. Fast-Charging Battery solutions, especially lithium chemistries like LiFePO4, charge in 1-2 hours. You can recharge AGVs during short breaks or shift changes.

Fast-charging lithium batteries let you use opportunity charging. AGVs recharge during brief pauses, so they return to service quickly.

In 24-hour warehouses, fast-charging batteries help AGVs resume tasks with minimal delay.

Less idle time means more tasks completed.

Seamless transitions between jobs keep your workflow smooth.

Improved scheduling lets you plan AGV availability with confidence.

According to the MHI 2024 Automation Survey, opportunity charging increases AGV utilization by up to 35%. You get more value from your fleet.

1.3 Operational Flexibility

Your operations need to adapt to changing demands. Fast-Charging Battery technology gives you the flexibility to adjust schedules and workloads. High-turnover fleets, such as those in logistics and manufacturing, benefit from reduced interruptions.

Charger Type | Typical Use | Advantages | Limitations |

|---|---|---|---|

DC EV Chargers | Buses, heavy trucks, AGV fleets | Fast charging, less downtime | Higher installation costs |

Smart monitoring systems optimize charging schedules. You can deploy AGVs for urgent tasks without waiting for long charging cycles. Fast charging minimizes downtime and supports continuous operations.

High-turnover fleets stay productive.

Smart systems help you plan charging and deployment.

You respond quickly to new demands in your facility.

Note: Fast-Charging Battery systems support flexible, scalable operations in industrial, medical, and security sectors.

Part2: Battery Types for AGVs

2.1 Lithium-Ion vs. Lead-Acid

You need to choose the right battery for your AGV fleet. Lithium-ion batteries have become the preferred choice in industrial sectors, including medical, robotics, and security systems. These batteries offer higher energy density, longer cycle life, and much faster charging compared to lead-acid batteries.

Feature | Lithium-Ion Batteries | Lead-Acid Batteries |

|---|---|---|

Energy Density | 100 – 260 Wh/kg | 40 – 60 Wh/kg |

Cycle Life | 4000 cycles to 100% DOD | Significantly lower |

Charging Speed | 1 – 2 hours | 8 – 10 hours |

Lithium-ion batteries help you maximize AGV uptime and reduce maintenance costs. Lead-acid batteries may cost less upfront, but they slow down operations and require frequent replacement.

2.2 Fast-Charging Battery Types

You can select from several Fast-Charging Battery types for AGVs. Lithium Iron Phosphate (LiFePO4) and Nickel Manganese Cobalt (NMC) batteries are popular in logistics, infrastructure, and industrial automation. Flash Battery and Lithium BLUE are advanced lithium solutions designed for high-demand AGV fleets.

Battery Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 V | 90 – 160 | 2000 – 7000 |

NMC | 3.7 V | 150 – 220 | 1000 – 2000 |

LCO | 3.7 V | 150 – 200 | 500 – 1000 |

LMO | 3.7 V | 100 – 150 | 300 – 700 |

LTO | 2.4 V | 70 – 80 | 7000 – 20000 |

Solid-State | 3.7 V | 250 – 500 | 2000 – 10000 |

Lithium Metal | 3.7 V | 300 – 500 | 1000 – 2000 |

Lithium batteries allow for higher charging rates without reducing lifespan.

Pure-Lead batteries support high-current, opportunity charging and require little maintenance.

Lithium batteries charge much faster than AGM or GEL batteries, often reaching 100% in about 1.5 hours.

You can deploy Fast-Charging Battery systems in medical robots, security patrol AGVs, and consumer electronics for reliable, continuous operation.

2.3 C-FACTOR Impact

The C-FACTOR determines how quickly you can charge and discharge your AGV batteries. You need to understand this metric to optimize fleet performance.

Cell performance affects the C-rate. Higher capacity cells lower the C-rate for the same current.

Battery chemistry and structure influence the maximum safe charging speed.

Effective thermal management keeps batteries cool during fast charging.

A smart Battery Management System (BMS) monitors current and voltage, improving safety and performance.

Charger quality and ambient temperature impact charging speed. Cold environments slow charging, while high temperatures risk overheating.

State of Charge (SOC) matters. Lower SOC allows faster charging, but high SOC requires slower rates to prevent damage.

Tip: Choose batteries with optimized C-FACTOR and advanced BMS to support Fast-Charging Battery technology in industrial and robotics applications.

Part3: Charging Technology Advances

3.1 High-Power Charging

You can boost AGV productivity with high-power charging solutions. Lithium-ion batteries, including LiFePO4 and NMC, enable rapid charging and reduce turnaround times. Fast-charging stations let your AGVs recharge during short breaks, which minimizes downtime and keeps your operations running smoothly. Modern battery management systems enhance these capabilities, making continuous operation possible in industrial and logistics environments.

Lithium-ion batteries support quick energy replenishment.

Fast-charging stations allow opportunity charging during brief pauses.

Battery management systems optimize charging for maximum uptime.

Wireless charging systems, such as etaLINK, provide contactless energy transfer, letting AGVs charge seamlessly while in motion.

Ultra-fast charging impacts production line efficiency by maximizing uptime and reducing maintenance. You can expect up to five times faster charging compared to lead-acid batteries, a long life cycle of 3,000–5,000+ cycles, and maintenance-free operation. These features support uninterrupted workflows in manufacturing, medical robotics, and security patrol fleets.

3.2 Inductive and Wireless Charging

Inductive and wireless charging technologies are transforming AGV operations. etaLINK offers a contactless solution, allowing AGVs to charge without physical connectors. This technology increases reliability and reduces wear on charging ports.

Charging Method | Efficiency | Reliability |

|---|---|---|

Non-Resonant Inductive | Preferred for quick power supply | Faster charging, less downtime |

Resonant Inductive | Flexible over distance | Lower efficiency due to flux leakage |

You can integrate IoT-enabled systems for real-time monitoring and adaptive frequency tuning. Dynamic load adaptation ensures optimal power transfer based on your AGV’s energy demand. These advances support flexible deployment in infrastructure, medical, and industrial sectors.

3.3 Battery Management Systems

Battery Management Systems (BMS) play a critical role in Fast-Charging Battery safety and longevity. You benefit from real-time monitoring of battery health, voltage, and temperature. The BMS communicates with chargers to adjust parameters, preventing overcharging and overheating. Smart systems schedule charging during off-peak hours, reducing energy costs and supporting preventive maintenance.

Accurate state of charge (SoC) calculations improve charging precision.

State of health (SoH) monitoring enables preventive maintenance.

Cell balancing maintains safe charge limits for each battery.

You can learn more about BMS in our Battery Management Systems guide.

3.4 Safety Innovations

Safety innovations in lithium battery technology protect your AGVs from overheating and electrical hazards. LiFePO4 chemistry offers superior thermal and chemical stability, reducing the risk of thermal runaway. Advanced BMS provides real-time monitoring and immediate action if irregularities occur.

Safety Innovation | Description |

|---|---|

Thermal Management Systems | Regulate battery temperature, prevent overheating, and distribute heat evenly |

Built-in Fail-safes | Cut off power during faults or short circuits to protect AGVs |

Intelligent BMS | Monitor voltage, temperature, and charge cycles for safe operation |

You should follow safety protocols, such as wearing PPE, verifying charger compatibility, and maintaining a clean charging area. Regular inspections and correct charging procedures help prevent accidents and extend battery life. These innovations support safe, reliable AGV operations in industrial, medical, and security environments.

Part4: Choosing Fast-Charging Battery

4.1 Operational Needs

Selecting the right fast-charging battery for your AGV fleet starts with understanding your operational requirements. You need to match battery specifications to your fleet size, usage patterns, and charging strategy. Consider the following factors:

Category | Considerations |

|---|---|

Fleet Requirements | Number of AGVs, Battery voltage and amp-hour capacity, Charging strategy |

Environment | Indoor/outdoor usage, Dust, moisture, or corrosive exposure, Temperature ranges |

Infrastructure Readiness | Power grid capacity and wiring, Physical space for charging docks, Ventilation and fire safety compliance |

Software and Communication | Compatibility with AGV control systems, Support for CAN bus or other protocols, Data integration into Warehouse Management Systems (WMS) |

Future Expansion | Scalable design that grows with fleet size, Modular components for easy upgrades |

You should assess your AGV fleet’s daily workload and peak demand. For example, a logistics center running three shifts will need batteries with high energy density and rapid recharge capability, such as LiFePO4 or NMC. In medical robotics or security systems, you may prioritize reliability and safety features. Always plan for future expansion by choosing modular battery systems that scale with your operations.

Tip: Align your battery choice with your AGV control software to enable real-time monitoring and efficient fleet management.

4.2 Environment and Infrastructure

Your facility’s environment and infrastructure play a critical role in battery selection. Environmental factors, such as dust, moisture, and temperature extremes, can affect battery performance and lifespan. Lithium-ion batteries, especially LiFePO4, offer robust performance in harsh industrial settings and comply with strict safety standards.

Stringent regulations encourage the use of cleaner battery technologies like lithium-ion, supporting your sustainability goals.

Sustainable practices in battery recycling and disposal are increasingly important. You can learn more about our sustainability approach and how it shapes battery selection.

Fast-charging infrastructure, including high-capacity power supplies and safe charging docks, is essential for maximizing AGV uptime.

You should evaluate your facility’s power grid capacity and ensure proper ventilation and fire safety compliance. In infrastructure and industrial sectors, physical space for charging docks and integration with existing systems are key considerations. For medical and consumer electronics applications, clean environments and precise temperature control may be required.

Note: Choose batteries and charging systems that meet both operational and environmental requirements to ensure long-term reliability.

4.3 Cost and ROI

Cost remains a major factor in your decision. Lithium-ion batteries, such as LiFePO4 and NMC, have a higher upfront cost than lead-acid batteries. However, they deliver significant savings over the lifecycle of your AGVs due to fast charging, low maintenance, and long lifespan.

Lithium-ion batteries require less maintenance, reducing operational costs.

Despite higher initial investment, you benefit from lower total cost of ownership.

Lead-acid batteries may seem budget-friendly, but they lack the long-term cost benefits and efficiency of lithium-ion technology.

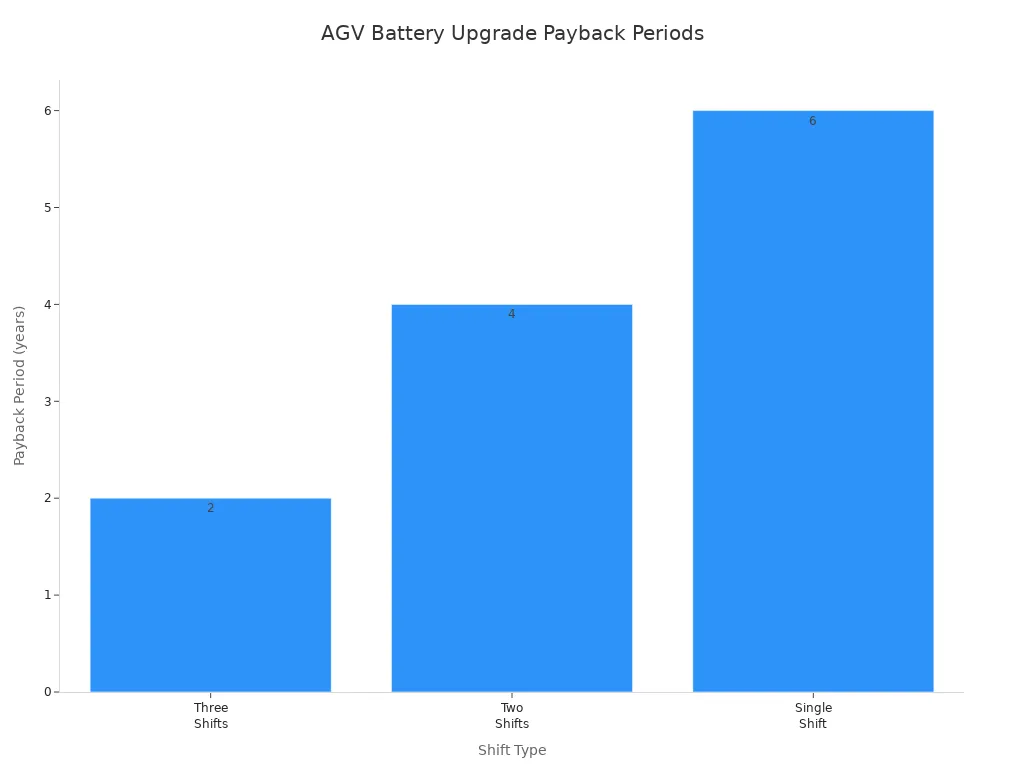

Shift Type | Estimated Payback Period |

|---|---|

Three Shifts | ~2 years |

Two Shifts | ~4 years |

Single Shift | ~6 years |

You maximize production and throughput with continuous operation. Reduced labor costs and the long-term value of AGVs as depreciable assets further improve your return on investment. In sectors like logistics, manufacturing, and infrastructure, upgrading to fast-charging lithium-ion batteries often pays for itself within two to four years for multi-shift operations.

Callout: Consider the full lifecycle cost, not just the purchase price, when evaluating battery options for your AGV fleet.

4.4 Vendor Support

Strong vendor support ensures the long-term reliability and performance of your fast-charging battery systems. You should partner with suppliers who offer comprehensive technical support, from installation to ongoing maintenance.

Key Factor | Description |

|---|---|

Technical Support and Service | A good supplier should provide excellent customer service and technical support. They should be available to assist with installation, troubleshooting, and maintenance. |

Look for vendors with proven experience in your industry, whether you operate in medical robotics, security, or industrial automation. Reliable vendors help you integrate batteries with AGV control systems, provide timely troubleshooting, and offer training for your staff.

Tip: Choose a vendor who supports your sustainability initiatives and offers guidance on battery recycling and safe disposal.

Part5: Implementation Tips

5.1 Fleet Integration

You can integrate fast-charging lithium batteries into your AGV fleet with minimal disruption by following best practices. Start by evaluating your operational needs. Choose between DC fast chargers, which deliver 80–90% charge in 20–30 minutes, and Level 2 chargers, which suit overnight charging. Many industrial and infrastructure facilities use a hybrid strategy, combining both charger types for flexibility. Invest in robust fleet management software to streamline operations and plan for future growth.

Common integration issues include misalignment, dirt, and debris that disrupt charging efficiency. Interference can cause inconsistent power delivery. Scheduling and task assignment complexities often arise in heterogeneous fleets, especially in medical robotics and security systems.

Best Practice | |

|---|---|

DC Fast Chargers | Provide rapid charging for high-usage fleets. |

Level 2 Chargers | Cost-effective for overnight charging. |

Hybrid Charging Strategy | Combine both for optimal flexibility. |

Invest in Robust Software | Integrate fleet and charging management. |

Plan for Future Growth | Ensure infrastructure supports expansion. |

Tip: Diversify charging options to support AGVs in industrial, medical, and consumer electronics environments.

5.2 Charging Logistics

You optimize AGV fleet availability by managing charging logistics carefully. Integrate charging strategies into AGV scheduling to reduce bottlenecks in high-throughput sectors like manufacturing and infrastructure. Use large neighborhood search algorithms to schedule AGVs while considering battery constraints.

Plan charging area layouts to minimize congestion and keep workflows smooth. In robotics and security systems, well-designed charging zones prevent delays and maximize uptime.

Key Factor | Description |

|---|---|

Charging Strategies | Integrate charging into AGV scheduling for better availability. |

Scheduling Algorithms | Use metaheuristics for battery-aware AGV scheduling. |

Charging Area Layouts | Design layouts to minimize operational bottlenecks. |

Note: Smart charging systems optimize energy use based on operational priorities.

5.3 Performance Monitoring

You track the health and efficiency of fast-charging batteries using advanced monitoring tools. Real-time data communication, such as PROTRXion systems, provides instant updates on battery performance. Battery management systems record temperature and state of charge, helping you prevent downtime in industrial, medical, and consumer electronics applications.

Performance tracking enables you to monitor efficiency and optimize job site functionality for your AGV fleet.

Feature | Description |

|---|---|

Real-time Data Communication | Provides instant battery performance updates. |

Battery Management System | Records temperature and state of charge. |

Performance Tracking | Monitors efficiency and optimizes fleet functionality. |

Callout: Use performance monitoring to extend battery life and maintain high AGV uptime across all sectors.

Fast-charging lithium batteries, such as LiFePO4 and NMC, help you boost AGV uptime and reduce costs. You gain faster charging, continuous operation, and improved safety.

Benefit | Description |

|---|---|

Reduced Charging Durations | AGVs spend less time charging, increasing productivity. |

Enhanced Safety | Automated charging systems lower risks and meet regulations. |

Labor Dependency Reduction | Automated systems minimize manual intervention, improving efficiency. |

To maximize results:

Analyze your energy needs and charging strategy.

Place charging stations near AGV work zones.

Choose battery types that support high-current charging.

Emerging trends include longer operational hours, safer battery technologies, and a focus on sustainability for automation in logistics, medical, and industrial sectors.

FAQ

What makes LiFePO4 batteries suitable for industrial AGVs?

LiFePO4 batteries offer high thermal stability and long cycle life. You gain reliable performance in harsh environments, such as manufacturing and logistics. These batteries support fast charging and minimize downtime for your AGV fleet.

How does fast charging affect battery lifespan?

You can use fast charging with lithium batteries like NMC and LiFePO4 without reducing lifespan. Advanced battery management systems control charging rates and temperature. Proper management helps you maintain up to 5,000 cycles.

Which lithium battery chemistry is best for medical robots?

LiFePO4 and LTO batteries work well in medical robots. You get high safety, stable voltage, and long cycle life. These chemistries support frequent charging and reliable operation in sensitive healthcare environments.

How do lithium batteries compare for cycle life and energy density?

Chemistry | Cycle Life (cycles) | Energy Density (Wh/kg) |

|---|---|---|

LiFePO4 | 2,000–7,000 | 90–160 |

NMC | 1,000–2,000 | 150–220 |

LTO | 7,000–20,000 | 70–80 |

You choose based on your sector’s needs for durability and energy storage.