High energy density and smart monitoring push Future Trends in medical batteries. You see rapid growth in the global medical battery market, with values reaching USD 4.7 billion in 2025 and an expected climb to USD 7.6 billion by 2032. Advancements in high energy density allow medical devices to become smaller and more efficient. Smart monitoring enables real-time data collection, which improves patient outcomes and streamlines workflows. You benefit from innovations that balance safety with performance, especially as lithium battery packs become more relevant in medical settings.

Market highlights:

USD 4.7 billion value in 2025

USD 7.6 billion expected by 2032

7.1% CAGR from 2025 to 2032

Impact on medical care:

Enhanced real-time monitoring

Improved patient outcomes

Streamlined healthcare workflows

Key Takeaways

High energy density batteries enhance the performance of medical devices, making them smaller, lighter, and more efficient.

Smart monitoring technologies provide real-time data, improving patient outcomes and ensuring device reliability.

Predictive maintenance helps prevent battery failures, extending the lifespan of medical devices and reducing downtime.

Solid-state batteries offer increased safety and energy density, transforming the landscape of medical battery technology.

Sustainability practices, including recycling and ethical sourcing, are essential for reducing environmental impact in the medical battery industry.

Part1: High Energy Density in Medical Batteries

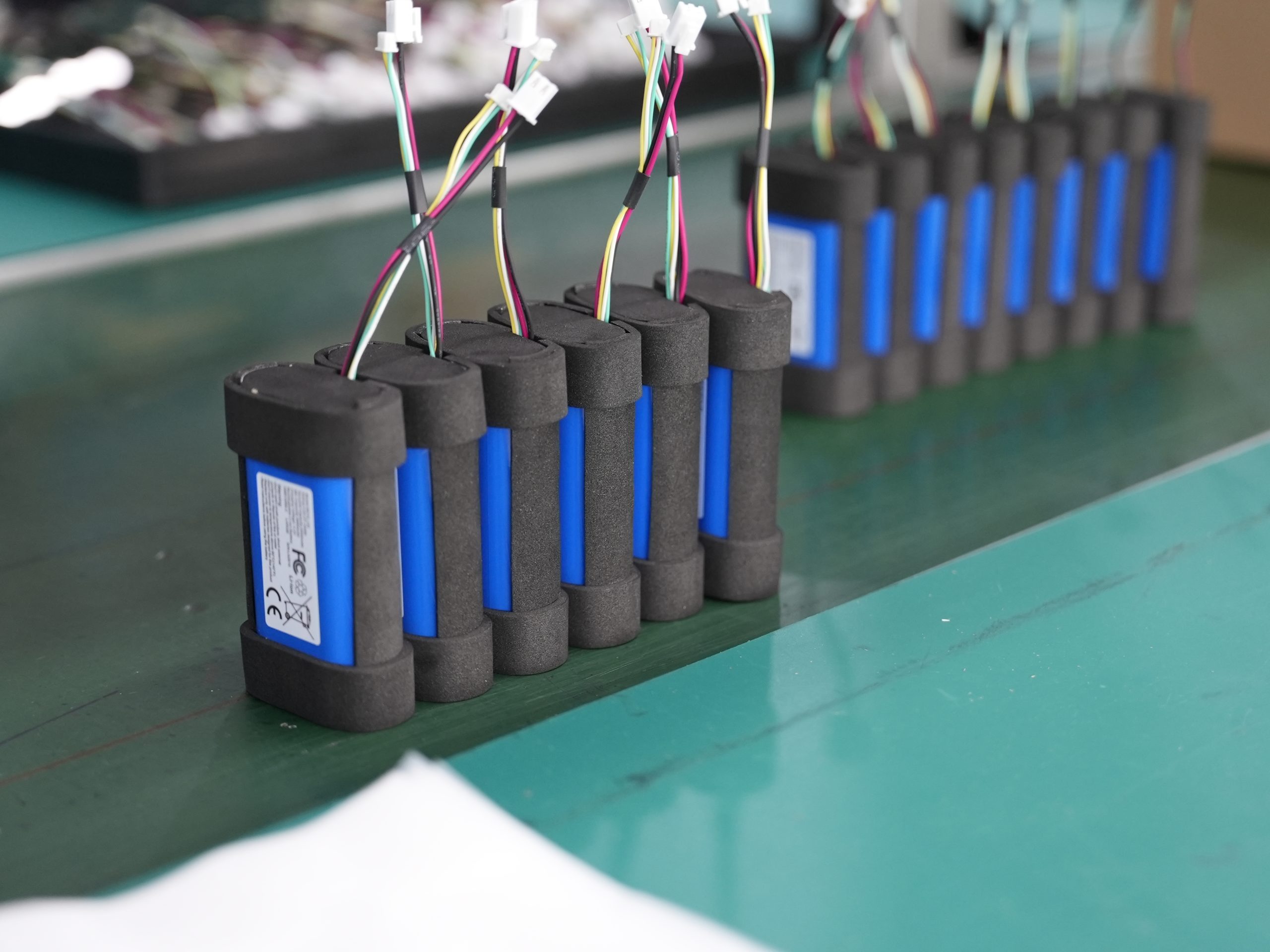

High energy density batteries drive innovation in handheld medical devices. You see these batteries powering compact devices that deliver reliable performance in hospitals, clinics, and emergency settings. The demand for smaller, lighter, and more efficient battery solutions grows as the medical sector expands. You benefit from batteries that last longer and charge faster, supporting critical devices such as infusion pumps, portable monitors, and surgical tools.

1.1 New Materials

You notice that new materials play a major role in boosting energy density. Lithium-ion batteries remain the standard for medical devices because they deliver more power in a smaller package. Advanced materials increase power density while maintaining energy storage, which helps you design devices that are both lightweight and powerful. Nickel-cadmium and nickel-metal hydride batteries offer unique advantages for specific applications, but lithium-ion batteries dominate due to their superior energy density.

Tip: Choosing the right battery material can improve device performance and extend operational life.

Material Type | Key Features | Contribution to Energy Density |

|---|---|---|

Lithium-ion (Li-ion) | High energy density, long-lasting battery life, fast charging | Delivers more power in a smaller and lighter package |

Advanced Materials | Incorporation of energy-dense materials | Increases power density while maintaining energy storage |

Nickel-cadmium | Unique advantages for specific medical applications | N/A |

Nickel-metal hydride | N/A | N/A |

You often compare battery chemistries to find the best fit for your devices. The table below shows how NMC and LFP batteries differ in energy density and safety features. NMC batteries offer higher energy density, which suits handheld medical devices that require long runtimes. LFP batteries provide enhanced safety, making them ideal for devices where reliability is critical.

Battery Type | Energy Density (Wh/kg) | Safety Features |

|---|---|---|

NMC | 150-220 | Higher energy density but safety concerns |

LFP | 90-160 | Lower energy density but enhanced safety features |

1.2 Design Strategies

You apply advanced design strategies to maximize energy density in compact medical battery solutions. Electrode design optimizes energy and power density, which helps you create batteries that fit into small devices. Microstructure optimization uses 3D modeling to enhance efficiency, allowing you to store more energy in less space. Mass loading increase raises theoretical capacity, which supports longer device operation. Laser perforation improves lithium ion transport and enables fast charging, which is essential for devices that need quick turnaround times.

Strategy | Description |

|---|---|

Electrode Design | Optimizes energy and power density through innovative concepts |

Microstructure Optimization | Uses 3D modeling to enhance efficiency in energy storage systems |

Mass Loading Increase | Raises theoretical capacity for better energy storage systems |

Laser Perforation | Improves lithium ion transport and fast charging |

You also address miniaturization and portability challenges by using thermal management and safety mechanisms. Effective thermal management maintains battery performance and safety, especially in compact devices. Safety mechanisms such as thermal fuses and current limiters ensure that even small batteries operate safely. Advanced materials allow you to create smaller batteries without sacrificing energy density.

Design Strategy | Description |

|---|---|

Thermal Management | Maintains battery performance and safety, balancing heat dissipation with miniaturization needs |

Safety Mechanisms | Features like thermal fuses and current limiters ensure safe operation in small batteries |

Advanced Materials | Enhance energy density, allowing for smaller batteries without loss of performance |

You see these strategies applied in medical devices, robotics, and security systems, where compact and efficient batteries are essential.

1.3 Safety Balance

You must balance energy density with safety when designing batteries for medical devices. High energy density batteries can overheat or fail if not managed properly. You rely on battery management systems (BMS) to monitor charge and discharge rates, voltages, and temperatures. Power conversion systems (PCS) isolate the battery during anomalies and disconnect faulted batteries quickly. Thermal management and fire suppression systems maintain safe temperatures and extinguish flames early. Robust enclosures and venting prevent pressure build-up and contain gases safely.

Battery management system (BMS) monitors charge/discharge rates, voltages, and temperatures.

Power conversion system (PCS) isolates the battery system during anomalies.

Thermal management and fire suppression maintain safe temperatures and extinguish flames.

Robust enclosure and venting prevent pressure build-up.

You notice that battery failures in medical devices are rare, but the number of reported incidents has increased. From 2006 to 2016, the average was 11 incidents per year. In the current decade, the average has risen to over 60 incidents per year, a 500% increase. You mitigate these risks by implementing battery management systems, protection circuit modules, and strict quality control during production. Risks include leaks, fumes, and blasts that can lead to device failure or patient injury. Careful selection and design of battery systems help you avoid these problems.

Note: Safety mechanisms and strict quality control are essential for reliable medical devices.

You see high energy density batteries powering handheld medical devices in hospitals, clinics, and field operations. These batteries also support robotics, security systems, infrastructure, consumer electronics, and industrial sectors. You rely on advanced materials, design strategies, and safety mechanisms to deliver compact, efficient, and safe battery solutions.

Part2: Smart Monitoring for Medical Batteries

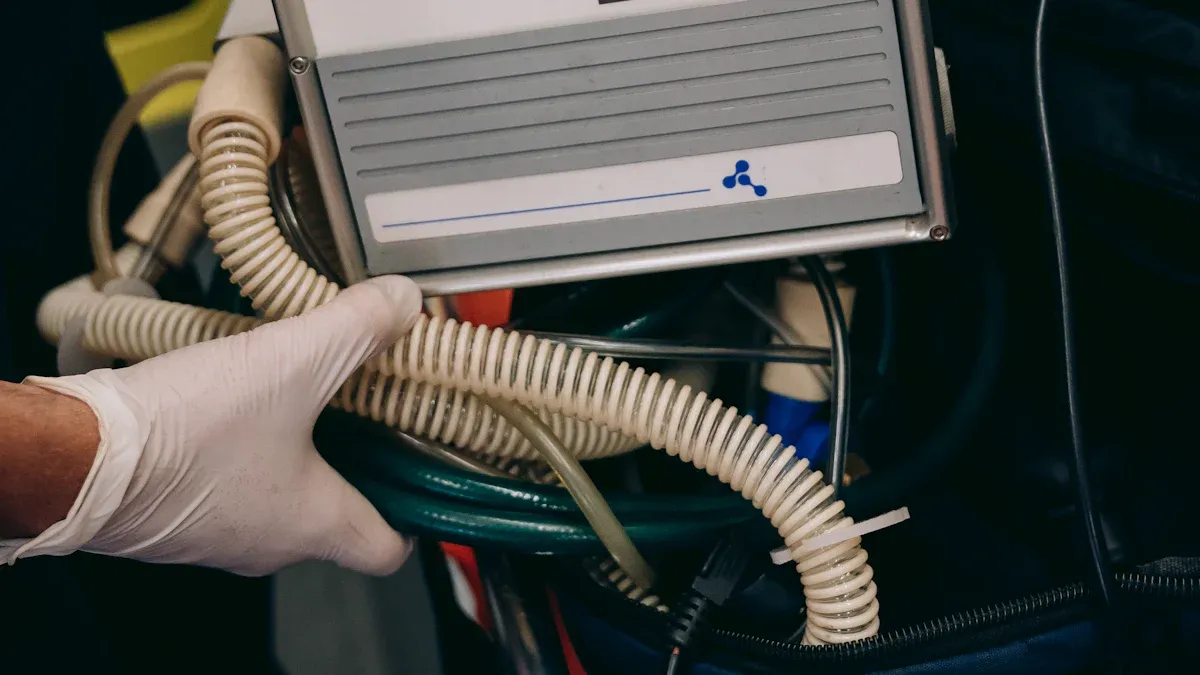

Smart monitoring transforms how you manage high-capacity battery systems in medical devices. You gain the ability to track energy performance, predict failures, and ensure safety and reliability. This section explores the latest sensing technologies, the value of real-time data, and the impact of predictive maintenance on next-generation batteries.

2.1 Sensing Technologies

You rely on advanced sensing technologies to monitor the health and performance of batteries in medical devices. These sensors provide critical information about energy flow, temperature, and internal stress. You use this data to prevent failures and maintain safety and reliability in high-capacity battery systems.

Stress sensors detect changes in pressure inside lithium battery packs, helping you identify swelling or potential short circuits.

Temperature sensors monitor heat generation, which allows you to prevent overheating and thermal runaway in next-generation batteries.

Gas sensors identify the release of gases, signaling early warning signs of battery degradation or failure.

You benefit from these sensing methods because they give you a complete picture of battery health. By monitoring key parameters, you reduce the risk of safety incidents and extend the operational life of your devices. These advances support emerging trends in battery technology across medical, robotics, and security systems.

Tip: Integrating multiple sensor types into your battery management system increases the accuracy of your monitoring and enhances safety and reliability.

2.2 Real-Time Data

You collect real-time data from every high-capacity battery in your medical devices. This data includes voltage, current, temperature, and state of charge. You use this information to optimize energy use and prevent unexpected failures.

Fuel gauge accuracy ensures you always know the exact energy level in your batteries, preventing sudden shutdowns in critical devices.

Battery diagnostics allow you to analyze performance data during charge and discharge cycles, helping you identify trends and potential issues.

Remote monitoring lets you track battery status from any location, which supports centralized management of next-generation batteries in large healthcare facilities.

End-of-life estimation uses real-time data to predict when a battery will need replacement, reducing downtime and improving device availability.

You see real-time data as a foundation for operational efficiency. By monitoring battery health continuously, you detect faults early and take corrective action before problems escalate. This approach improves safety and reliability for all your devices, from infusion pumps to portable monitors.

Real-Time Data Type | Application in Medical Devices | Benefit to Operations |

|---|---|---|

Voltage & Current | Monitors energy flow and detects anomalies | Prevents overcharging and failures |

Temperature | Tracks heat generation in high-capacity battery systems | Avoids overheating and thermal risks |

State of Charge | Measures remaining energy in next-generation batteries | Ensures device uptime |

Diagnostic Logs | Records battery performance during use | Supports predictive maintenance |

Note: Real-time data collection is essential for maximizing the lifespan and efficiency of your batteries.

2.3 Predictive Maintenance

You use predictive maintenance to keep your medical devices running smoothly. This strategy relies on real-time data and advanced analytics to forecast potential battery failures before they happen. You shift from reactive repairs to proactive care, which saves time and money.

Condition-monitoring sensors gather real-time data on battery health.

AI-based algorithms analyze this data to detect anomalies in energy performance.

Proactive monitoring reduces the risk of equipment failure, ensuring continuous operation and safety during patient care.

You minimize unexpected downtime by addressing minor issues early. This approach extends the lifespan of your high-capacity battery systems and maximizes your investment in next-generation batteries. In clinical settings, predictive maintenance keeps essential devices available for patient diagnosis and treatment.

Callout: Predictive maintenance not only improves safety and reliability but also supports scalability as you deploy more devices across your organization.

You see predictive maintenance as a key driver for emerging trends in battery technology. By leveraging real-time data and smart monitoring, you ensure that your batteries deliver consistent energy and performance in every application—from medical and robotics to security and industrial sectors.

Part3: Next-Generation Batteries and Technologies

3.1 Solid-State

You see solid-state batteries transforming the landscape for medical devices. These batteries eliminate hazards like leakage and fires, which ensures safety in critical healthcare environments. Fast charging capabilities allow you to recharge devices quickly, improving patient convenience and workflow efficiency. Compact design supports smaller devices without sacrificing energy, which is ideal for portable monitors and surgical tools. Sterilizable battery designs meet strict medical standards, supporting greater sustainability in device manufacturing.

Key Advancement | Description |

|---|---|

Elimination of Battery Hazards | Solid-state batteries remove risks like leakage and fires, ensuring safety in medical devices. |

Fast Charging Capabilities | These batteries allow for quick recharging of devices, enhancing patient convenience. |

Compact Design | High energy density enables smaller devices without sacrificing power, ideal for medical use. |

Sterilizable Device Design | The design of these batteries supports sterilization, crucial for healthcare applications. |

Solid-state batteries offer energy density from 250 to 800 Wh/kg, compared to lithium-ion batteries (LiFePO4, NMC, LCO, LMO, LTO) at 160-250 Wh/kg. You benefit from longer device runtimes and reduced maintenance. These batteries also provide a lifespan of 8,000 to 10,000 cycles, far exceeding conventional lithium-ion batteries. Safety improves with non-flammable solid electrolytes, which is essential for medical, robotics, and security systems.

Feature | Lithium-Ion Batteries | Solid State Batteries |

|---|---|---|

Energy Density | 160-250 Wh/kg | 250-800 Wh/kg |

Safety | Risk of overheating and flammability due to liquid electrolyte | Significantly reduced fire risk, non-flammable solid electrolyte |

Lifespan | 1,500 to 2,000 cycles | 8,000 to 10,000 cycles |

3.2 Nanotechnology

You leverage nanotechnology to enhance the performance and safety of batteries in medical devices. Nanoscale electrolytes and interfaces improve ion conductivity and stability, which boosts energy efficiency. Nanostructuring lithium metal anodes reduces dendrite formation, increasing safety for implantable devices. Increased surface area from nanostructuring allows better lithium-ion interaction, which improves energy storage and battery performance.

Nanotechnology improves energy density and electrochemical performance in batteries.

Implantable batteries require high safety and stability due to their placement in the human body.

Nanomaterials help achieve complete packaging with no leakage and low self-discharge rates, supporting greater sustainability and long battery life.

Recent advancements target devices like leadless pacemakers, where reliability and safety are critical.

You see these innovations applied in medical, robotics, and industrial sectors, where advanced batteries support demanding applications.

3.3 Battery Management

You rely on advanced battery management systems (BMS) to optimize charging speed and power management in medical devices. Sophisticated charge control algorithms and monitoring techniques track voltage, current, temperature, and state of charge. This approach allows you to maximize battery performance and safety. Predictive maintenance features estimate battery health and remaining useful life, which improves device usability and longevity.

Recent developments in BMS emphasize integration with the Internet of Things (IoT). You gain real-time monitoring of battery status and predictive maintenance for critical devices, which enhances patient safety and operational efficiency. For more details on BMS and protection circuit modules, visit this resource.

You see these systems supporting medical, security, infrastructure, and consumer electronics sectors, where reliable batteries are essential for continuous operation and greater sustainability.

Tip: Advanced battery management systems help you achieve smarter power management and faster charging, supporting next-generation medical devices across multiple industries.

Part4: Sustainability and Regulation in Medical Batteries

4.1 Eco-Friendly Solutions

You see future trends in medical batteries focusing on eco-friendly solutions. Manufacturers now use advanced recycling methods to recover valuable materials from lithium battery packs, including LiFePO4, NMC, LCO, LMO, and LTO chemistries. A recent development in metal extraction uses hydrometallurgy, which operates at room temperature and achieves high recovery rates—99.6% for zinc and 86.1% for manganese. This process supports a circular economy by reusing materials and reducing waste. You benefit from energy-efficient extraction and improved battery development, which lowers the environmental impact of medical devices. For more on sustainability, visit our approach to sustainability.

Aspect | Description |

|---|---|

Environmental Impact | Improved sourcing and battery design reduce negative effects throughout the lifecycle. |

Innovations in design and recycling support sustainability for medical applications. | |

Circular Economy | Enhanced recycling and responsible sourcing minimize resource depletion and environmental harm. |

You also see ethical sourcing practices, including conflict minerals management. Responsible mining and labor practices help you minimize carbon emissions and environmental damage. Learn more about conflict minerals at this statement.

4.2 Compliance

You must follow strict regulatory standards to ensure battery safety and performance in medical applications. Regulatory bodies such as the FDA, EU, and ISO set requirements for lithium battery packs used in medical devices. You prepare technical documentation and declarations of conformity to meet these standards. New regulations require batteries to be removable and replaceable, which improves device maintenance and supports future trends in battery development.

You adapt to evolving compliance requirements by updating your battery development processes and documentation. You ensure your lithium battery packs meet durability, safety, and labelling standards across regions.

4.3 Recycling

You recognize recycling as a key part of future trends in medical battery development. Efficient recycling programs recover cobalt, lithium, and other valuable materials from used batteries. This reduces the need for mining and prevents hazardous waste from polluting ecosystems. You focus on proper disposal and recycling to protect the environment and support sustainability in medical applications. Improved battery design leads to longer lifespans and less waste, which benefits medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. For more on sustainability and recycling, visit our approach to sustainability.

Tip: Proper recycling and lifecycle management help you meet regulatory standards and support environmental goals in battery development.

Part5: Future Trends and Industry Impact

5.1 Reliability

You rely on battery technology to deliver consistent performance in medical devices. Advanced lithium batteries, including LiFePO4, NMC, LCO, LMO, and LTO chemistries, provide high energy density and stable storage. You see innovations in battery chemistry, such as new lithium-ion batteries, improving safety and reliability. Battery monitoring system features, like real-time diagnostics and predictive analytics, help you prevent failures and extend device life. You benefit from energy harvesting technologies, including biofuel cells, which support long-term stability and safe storage. Safer battery designs avoid toxic materials and offer a stable shelf life exceeding one year. Cross-industry partnerships drive new battery technologies and manufacturing methods, ensuring compliance with strict standards.

You use advanced lithium batteries for reliable storage in medical, robotics, and security systems.

Battery monitoring system integration supports continuous safety and performance.

Novel catholyte electrolytes reduce weight and increase battery life by up to 50%.

Stable storage and safer designs minimize risks in critical applications.

Note: Reliable battery technology ensures uninterrupted operation for medical devices and supports patient safety.

5.2 Patient Outcomes

You improve patient outcomes by adopting smarter battery technology in medical devices. Battery monitoring system features allow you to track device status and predict maintenance needs. You use lithium batteries with enhanced storage to power portable monitors, infusion pumps, and surgical tools. Real-time battery monitoring system data helps you avoid device downtime and maintain continuous care. You see battery technology supporting remote patient monitoring and wearable healthcare solutions, which increase access to care and reduce hospital visits. Stable storage and advanced battery management systems ensure devices operate safely and efficiently.

Application Scenario | Battery Technology Benefit | Impact on Patient Outcomes |

|---|---|---|

Portable Medical Devices | Reliable storage, long cycle life | Continuous monitoring, fewer interruptions |

Remote Monitoring | Real-time battery monitoring system | Early detection, improved safety |

Wearable Healthcare | Lightweight lithium batteries | Increased mobility, better comfort |

Tip: You achieve better patient outcomes by using battery technology that supports reliable storage and smart monitoring.

5.3 Market Growth

You see strong market growth for medical batteries driven by advancements in battery technology and increased demand for portable diagnostic devices. The medical batteries market is projected to grow at a CAGR of over 5.31% from 2025 to 2034. You expect the market size to rise from USD 1.74 billion in 2025 to approximately USD 2.77 billion by 2034. You benefit from new battery technologies that support wearable healthcare, remote monitoring, and efficient storage. Manufacturers gain opportunities to develop lithium batteries with improved energy density and longer cycle life. You see battery monitoring system features becoming standard in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors.

Advancements in battery technology drive market expansion.

Increased use of lithium batteries supports portable and remote medical applications.

Battery monitoring system integration creates new opportunities for manufacturers.

Growing demand for efficient storage fuels innovation in battery technologies.

Callout: You position your organization for success by investing in battery technology that meets future medical needs and supports reliable storage.

You see high energy density and smart monitoring changing the future of medical batteries. These innovations help you improve device reliability, safety, and patient care. Next-generation batteries, such as solid-state and lithium-sulfur, offer higher energy density and longer cycle life for medical applications. Smart battery management with AI supports predictive maintenance and real-time monitoring. You use batteries in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. The table below highlights key features and impacts:

Innovation Type | Key Features | Impact on Medical Batteries |

|---|---|---|

High Energy Density | Up to 700 Wh/kg | Better performance and reliability |

Smart Battery Management | AI for predictive maintenance | Fewer failures and optimal operation |

Solid-State Batteries | 500-700 Wh/kg | Compact design for medical devices |

Lithium-Sulfur Batteries | 2500 Wh/kg theoretical capacity | Longer lifespan and less maintenance |

You prepare for ongoing innovation and market growth in medical batteries. 🚀

FAQ

What makes lithium battery packs ideal for medical devices?

You choose lithium battery packs for medical devices because they offer high energy density (up to 250 Wh/kg), long cycle life (1,500–2,000 cycles), and stable platform voltage. These features support reliable performance in hospitals, clinics, and emergency settings.

How does smart monitoring improve battery safety?

You use smart monitoring to track voltage, temperature, and charge status in real time. This technology helps you detect faults early, prevent overheating, and maintain safe operation in medical, robotics, and security systems.

Which lithium battery chemistry suits portable medical equipment best?

You select NMC batteries for portable medical equipment. NMC provides high energy density (150–220 Wh/kg) and long cycle life. You benefit from lightweight design and extended runtime, which are critical for handheld diagnostic tools and wearable healthcare devices.

What role does predictive maintenance play in battery management?

You rely on predictive maintenance to analyze battery health data. This approach lets you schedule replacements before failures occur. You reduce downtime and improve reliability for devices in medical, infrastructure, and industrial sectors.

How do recycling programs support sustainability in medical batteries?

You implement recycling programs to recover valuable materials like lithium and cobalt from used battery packs. These efforts reduce waste, lower environmental impact, and support sustainability goals across medical, consumer electronics, and industrial applications.