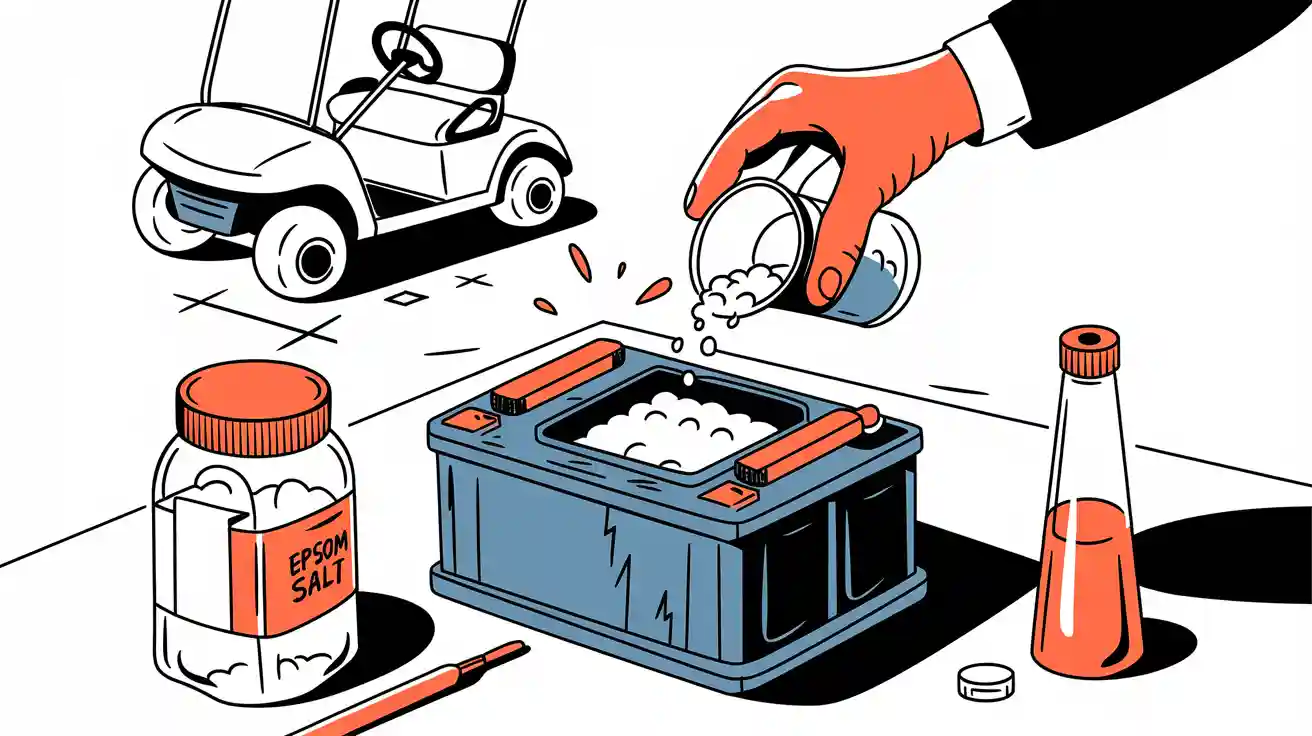

You can restore golf cart batteries with Epsom salt and desulfation, especially when dealing with lead acid types. Many choose golf cart battery restoration to avoid high replacement costs and reduce environmental impact. Regeneration technology extends lead acid battery lifespan and improves solution efficiency.

Epsom salt, desulfation, and battery repair liquids provide practical solution options for lead acid battery restoration.

Key Takeaways

You can restore lead-acid golf cart batteries by using Epsom salt treatments and desulfation devices to dissolve sulfate crystals and improve battery life.

Regular maintenance like checking water levels, cleaning terminals, and proper charging prevents sulfation and extends battery performance.

Electronic desulfation devices offer a reliable way to remove sulfate buildup, boost battery capacity, and reduce replacement costs over time.

Part 1: Golf Cart Battery Restoration

1.1 Battery Types and Common Issues

You encounter several battery types in golf cart battery restoration. Flooded lead-acid batteries remain the most common. These require regular maintenance and often show leaks or corrosion if neglected. AGM batteries, a sealed lead-acid solution, offer faster charging and longer battery life but cost more. Gel lead-acid batteries use a gel solution for leak-proof protection and perform well in extreme temperatures.

Common issues include improper charging, which leads to a sulfated battery, and physical damage from vibration or shock. Overcharging or undercharging causes sulfation and corrosion, reducing battery life. You may notice slow charging, poor acceleration, leaks, or visible damage as signs of a sulfated battery.

1.2 Sulfation in Lead Acid Batteries

Sulfation occurs when lead sulfate crystals form on the plates during discharge. If you leave a battery discharged or deeply discharge it often, these crystals grow large and insulating. This process blocks the solution from reaching the lead plates, increasing resistance and reducing battery life. Charging reverses some sulfation, but a heavily sulfated battery loses capacity. Additives like lithium sulfate or zinc sulfate can sometimes help break down these crystals, but deep sulfation and corrosion often require more advanced treatment.

Tip: Regular charging and avoiding deep discharges help prevent a sulfated battery and extend battery life.

1.3 Restore Golf Cart Batteries

You can restore golf cart batteries using several methods. Epsom salt additives, desulfation devices, and battery repair liquids all target the sulfated lead plates. These solutions dissolve sulfate crystals and improve battery rejuvenation. For B2B users and fleet managers, golf cart battery restoration reduces costs and downtime. Regular health checks, predictive maintenance, and proper additives keep your lead-acid solution working longer.

Additives play a key role in every treatment. They break down sulfated crystals, restore battery life, and extend the solution’s effectiveness. By using the right additives and maintenance routines, you restore golf cart batteries, reduce sulfation and corrosion, and maximize battery life for your fleet.

Part 2: Methods to Extend the Life of a Lead Acid Battery

2.1 Epsom Salt Treatment

Epsom salt treatment remains a popular method to restore the performance of a sulfated battery. You can use this approach to dissolve the buildup of lead sulfate on the plates and boost battery life. The process involves adding magnesium sulfate as a chemical additive to the electrolyte solution. This treatment can provide a temporary performance boost, especially for older lead-acid batteries that show signs of sulfation.

Step-by-step instructions for Epsom salt treatment:

Disconnect all chargers from the battery terminals to ensure safety.

Open the battery cell caps carefully.

Prepare an Epsom salt solution by dissolving the salt in warm distilled water.

Fill each cell with about 1/8 cup of the solution until the plates are submerged.

Allow the solution to sit for 8 to 24 hours to let the chemical additives interact with the sulfate crystals.

After waiting, top off each cell with distilled water.

Charge the battery as usual, using the recommended charger voltage and amperage.

Safety Tips:

Always perform this treatment in a well-ventilated area to avoid hydrogen gas buildup.

Wear gloves and eye protection to prevent contact with acid or solution.

Never add undissolved Epsom salt directly to the battery.

Avoid overfilling cells and check water levels regularly.

Do not inhale dust from Epsom salt, as it may irritate your respiratory system.

Scientific studies show that Epsom salt methods work by allowing magnesium sulfate to chemically interact with lead sulfate crystals. This reaction helps reduce the internal resistance of the battery and can improve the performance of lead-acid batteries. However, this treatment does not repair physical damage or replace the original electrolyte solution. You should view it as a temporary solution for battery rejuvenation, not a permanent fix. Excessive use of additives or high concentrations can cause corrosion of the lead plates and connectors, so always follow recommended guidelines.

2.2 Desulfation Techniques

Desulfation techniques aim to restore battery performance by removing sulfate deposits from the lead plates. You can choose between manual and electronic desulfation methods, each with unique benefits and limitations.

Aspect | Electronic Desulfators | Manual Desulfation Techniques |

|---|---|---|

Mechanism | Emit pulsating DC current to remove sulfate deposits and prevent buildup | Not specified |

Benefits | Continuous maintenance, prevention of sulfation buildup, potential restoration of sulfated batteries, faster and deeper charging, extended battery life | Not clearly defined |

Battery Types Supported | All lead-acid types including sealed, gel cell, AGM | Not specified |

Environmental Impact | Longer battery life reduces hazardous waste | Not discussed |

Proven Effectiveness | Supported by lab, field tests, and military use | No data available |

Electronic desulfators use high-frequency pulses to dissolve sulfate crystals without damaging the lead plates. This technology can boost battery life, improve battery performance, and reduce the risk of premature failure. Research shows that repeated desulfation with electronic devices can increase battery capacity by up to 96% and extend operational life. Manual desulfation methods lack scientific support and may not provide consistent results. You should consider electronic desulfators for ongoing maintenance and battery rejuvenation, especially for fleet applications.

Note: Proper desulfation does not cause electrolyte loss or harmful heat. When performed correctly, it preserves battery health and supports long-term performance.

2.3 Battery Repair Liquids

Golf cart battery repair liquid products claim to restore battery performance by using chemical additives to break down sulfate crystals and improve conductivity. These solutions often contain proprietary blends of additives designed to boost battery life and rejuvenate sulfated batteries.

User experiences with golf cart battery repair liquid vary. Some report noticeable improvements in battery performance and a temporary performance boost, while others see minimal change. Scientific evidence suggests that these liquids can help dissolve sulfate buildup and reduce the internal resistance of the battery. However, the effects are usually temporary, and the treatment does not address physical damage or severe corrosion.

You should use golf cart battery repair liquid as a last resort when other methods fail. Always follow manufacturer instructions and avoid mixing different chemical additives, as this can damage the lead plates or reduce battery life. Consider the cost-benefit of using these products versus investing in a new battery, especially for newer models that already contain suitable additives.

2.4 Maintenance Tips

Consistent maintenance is the most effective way to extend the life of a lead acid battery and improve battery performance. You can prevent sulfation and maximize battery life by following these best practices:

Inspect batteries monthly for cracks, leaks, or distortions.

Clean terminals and containers with a solution of distilled water and baking soda to remove corrosion.

Check terminal connections for tightness and safety; clean corrosion with a wire brush.

Monitor water levels monthly and refill with distilled water, keeping fluid above the plates but below the vent wells.

Avoid overfilling cells to prevent electrolyte overflow during charging.

Charge batteries fully after each use and avoid leaving them discharged for long periods.

Use a charger compatible with your battery type and voltage, preferably a smart charger with automatic shut-off.

Store batteries in a cool, dry place and disconnect cables during long-term storage.

Recharge batteries to 100% if charge falls below 80% during storage.

For sealed AGM or lithium chemistries (LiFePO4, NMC, LCO, LMO, LTO), check connections and update BMS software as needed.

Regular maintenance and the use of suitable additives can boost battery life, reduce sulfation, and improve the performance of lead acid batteries. By following these methods, you ensure reliable operation and reduce the need for frequent replacement.

You achieve the best battery life and performance by choosing lithium-ion chemistries (LiFePO4, NMC, LCO, LMO, LTO) over lead-acid batteries.

Regular maintenance, correct solution levels, and safe use of additives protect battery longevity. Always follow safety guidelines when handling lead-acid solution and additives to maximize performance.

Aspect | Lead-Acid Batteries | Lithium-Ion Batteries (LiFePO4, NMC, LCO, LMO, LTO) |

|---|---|---|

Lifespan | 2–5 years | Up to 12 years, over 4,000 charge cycles |

Charging Time | Up to 14 hours | 1–3 hours |

Energy Efficiency | 20-60% | Approximately 99% |

Maintenance | Requires regular watering and cleaning | Virtually maintenance-free |

Replacement Frequency | Frequent replacements every 2-3 years | Minimal replacements due to longer lifespan |

FAQ

1. Can you restore any lead acid battery with Epsom salt solution?

You can restore many lead acid batteries using an Epsom salt solution. This method works best when the solution addresses sulfation, not severe physical damage or plate corrosion.

2. How often should you check the solution in your lead acid battery?

You should check the solution in your lead acid battery every month. Regular checks help you spot low solution levels and prevent lead plate exposure.

3. Does a desulfation device work better than a chemical solution for lead acid batteries?

A desulfation device can restore lead acid batteries more effectively than a chemical solution. The device targets lead sulfate buildup, while the solution may only provide a temporary fix.