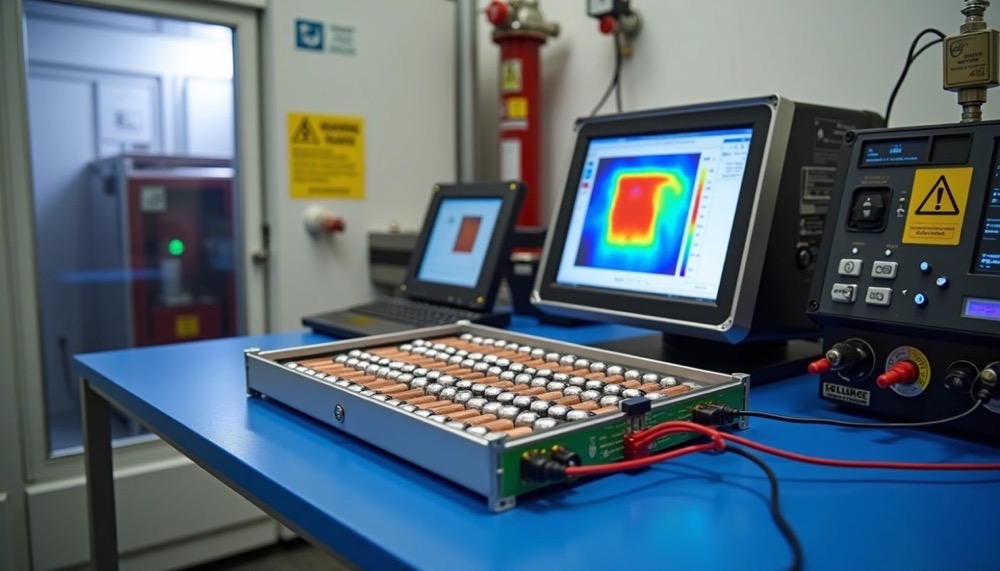

Custom lithium-ion battery packs have generated approximately 25,000 documented instances of fire or overheating incidents over the past five years. Between 2021 and 2022, New York City alone recorded 10 fatalities and 226 injuries directly attributable to these battery failures. These statistics demonstrate why certification represents a fundamental safety requirement rather than an administrative procedure.

The certification process for lithium battery design encompasses multiple regulatory frameworks. UN38.3 establishes transport safety requirements, IEC 62133 governs consumer applications, UL standards control U.S. market access, and CE marking enables European distribution. Each certification standard mandates specific testing protocols including altitude simulation, vibration resistance, impact testing, and overcharge protection verification.

Battery pack certification failures prevent market entry and can result in complete product redesigns. Companies that fail to meet essential standards face significant delays, increased development costs, and potential liability issues. The certification landscape requires thorough understanding of technical requirements, testing methodologies, and regulatory compliance timelines.

This technical guide addresses the critical certification requirements for custom lithium-ion battery pack development. The following sections examine how design decisions affect certification readiness, compare custom versus standard battery solutions, and detail the specific testing requirements for major certification standards. Understanding these requirements during the initial design phase allows engineers to build compliant battery packs while avoiding costly post-development modifications.

Battery Design Decisions and Certification Impact

“Products with a UL Listing have been tested to meet nationally-recognized safety standards. They have been tested as complete final products and found to be free from reasonably foreseeable risk of fire, electric shock and other hazards.” — Flux Power Blog Editorial Team, Industry battery safety experts, Flux Power (UL-certified lithium-ion battery manufacturer)

Image Source: MDPI

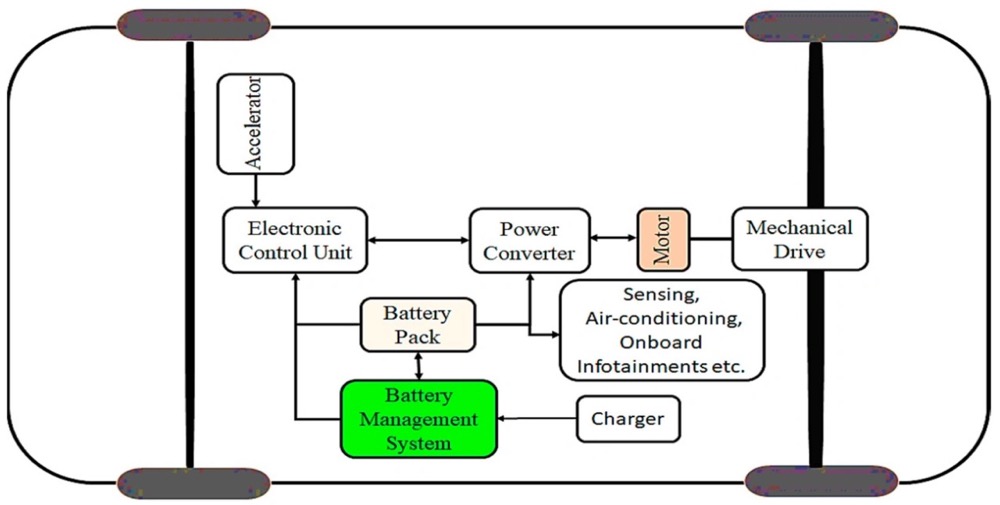

Battery design decisions establish the foundation for certification success or failure. Early engineering choices determine whether a custom lithium-ion battery pack will meet mandatory safety standards or require costly redesigns during the certification process.

Thermal Runaway Prevention Through Design

Thermal runaway initiates when battery cells exceed 160°C, creating uncontrollable exothermic reactions. A single 18650 cell can release 80 kJ of thermal energy during this process. The cascade failure mechanism produces:

- Cell venting with ejection of molten materials and flames

- Temperature spikes exceeding 300°Cwithin seconds

- Emission of toxic and flammable gas mixtures

- Risk of explosive cell rupture

Mechanical damage from crushing or puncturing, electrical abuse through overcharging or short circuits, and external thermal exposure represent the primary thermal runaway triggers. Battery state of charge directly correlates with hazard severity—higher charge states increase hydrogen and carbon monoxide generation while reducing safer carbon dioxide emissions.

Chemistry selection significantly affects safety characteristics. NCA and LCO chemistries generate higher flame propagation speeds and maximum overpressures compared to LFP chemistry during venting events. LFP cells demonstrate superior safety through higher lower flammability limits, reducing ignition probability.

Cell Spacing and Enclosure Engineering

Physical cell separation provides essential thermal runaway containment. Cylindrical cells require minimum 2mm spacing to prevent cell-to-cell thermal propagation. Side-vented cells demand additional clearance between adjacent units to accommodate gas release patterns.

Gas venting capacity represents a critical design parameter—batteries typically release 1-2 liters of gas per Ah of capacity. Chemistry-specific venting volumes vary significantly:

- NMC/LMO chemistries: 780 liters/kg during thermal events

- LFP chemistries: 42 liters/kg

Enclosure design must incorporate controlled pressure relief mechanisms. Environmental pressure equalization proves inadequate for safety—rupture disks calibrated to specific pressure thresholds are necessary to prevent catastrophic pressure buildup.

Thermal barriers between cells limit event propagation. Intumescent materials and radiant heat shields effectively isolate thermal incidents. Battery enclosures require integration of:

- IP/NEMA-rated environmental sealing

- Mechanical securing systems

- Electrical grounding connections

- Certification standard compliance features

Early Integration of Certification Requirements

Delayed consideration of certification standards creates development bottlenecks and cost overruns. Each standard establishes specific design constraints that must be addressed during initial engineering phases.

UN38.3 certification mandates transport safety validation through eight test protocols: altitude simulation, thermal cycling, vibration resistance, shock tolerance, external short circuit protection, impact resistance, overcharge protection, and forced discharge safety. IEC 62133-2 addresses operational safety including overcharge protection, discharge cutoff, short circuit protection, and thermal runaway containment.

Battery management system design directly affects certification readiness. Complete BMS implementations provide monitoring and control capabilities beyond basic protection circuit modules, enabling compliance with advanced safety requirements.

The European Union implemented IEC 62133-2 requirements in March 2021, establishing mandatory compliance for portable lithium-ion batteries in EU markets. Certification preparation requires:

- Pre-certified component selection to minimize testing scope

- Thermal management safety margins in design calculations

- Documentation aligned with certification standard requirements

- Project planning that accounts for certification timelines and costs

Custom Battery Pack Development versus Standard Solutions: Certification Requirements

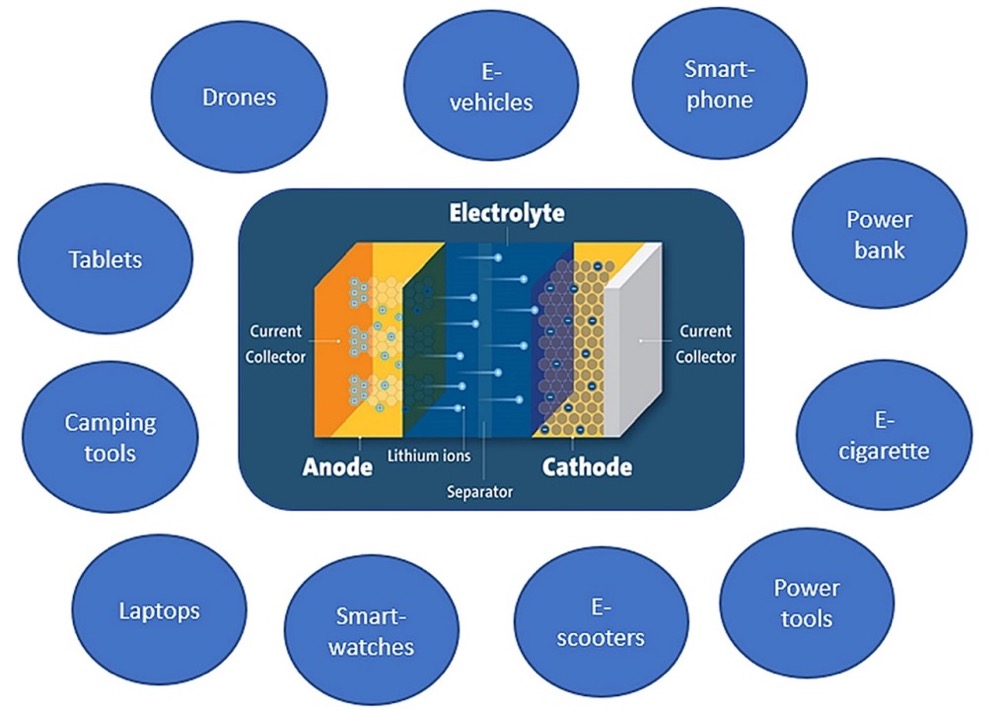

Image Source: Large Battery

Battery pack selection represents a critical decision point that directly impacts certification pathways and development timelines. The choice between custom lithium-ion battery packs and standard solutions determines testing requirements, regulatory compliance strategies, and market entry schedules.

Custom Battery Pack Design Advantages for Certification

Custom lithium-ion battery packs address specific certification requirements during the initial design phase rather than adapting existing solutions to meet standards. This approach allows engineers to build safety features directly into the battery architecture, eliminating retrofit modifications that often complicate certification processes.

Custom battery manufacturers can integrate industry-specific safety requirements from the beginning of development. Medical device applications, for example, require different safety protocols than consumer electronics or aerospace systems. Custom designs accommodate these varying standards without compromise, ensuring certification success for specialized applications.

Technical documentation development becomes more straightforward with custom designs. Mechanical configurations, electrical schematics, and safety protocols can be developed specifically to address certification requirements. This targeted documentation approach reduces review cycles and accelerates approval processes.

Strategic Use of Pre-certified Components

The strategic selection of pre-certified components can significantly reduce testing timeframes and sample requirements. Battery management systems, protection circuits, and individual cells that have already passed certification testing allow manufacturers to focus testing efforts on system-level integration rather than component-level validation.

Certification testing timelines vary substantially by standard and testing organization:

- UN 38.3 certification: 17 sample packs, 6-8 weeks testing duration

- UL 2054 certification: 55 sample packs, 12-14 weeks testing period

- IEC 62133 certification: 33 sample packs, 8-10 weeks testing cycle

Pre-certified component integration can reduce these testing requirements and associated sample quantities, thereby shortening development timelines without compromising safety validation.

Cost and Manufacturing Partnership Considerations

Custom battery development involves significant certification costs, with UN 38.3 testing alone ranging from $460 to $700,000. Design modifications after initial testing require complete recertification, potentially doubling development costs and extending timelines.

Manufacturing partnerships directly affect certification validity. Changing battery manufacturers necessitates recertification even with identical designs, since certification reports include specific manufacturer details. This requirement makes manufacturing partner selection a critical long-term decision that should evaluate certification capabilities, production facilities, and quality management systems.

Standard battery solutions may accelerate initial product development but often lack certifications required for specialized applications. The decision between custom and standard battery packs requires careful analysis of certification requirements, development costs, timeline constraints, and long-term market objectives.

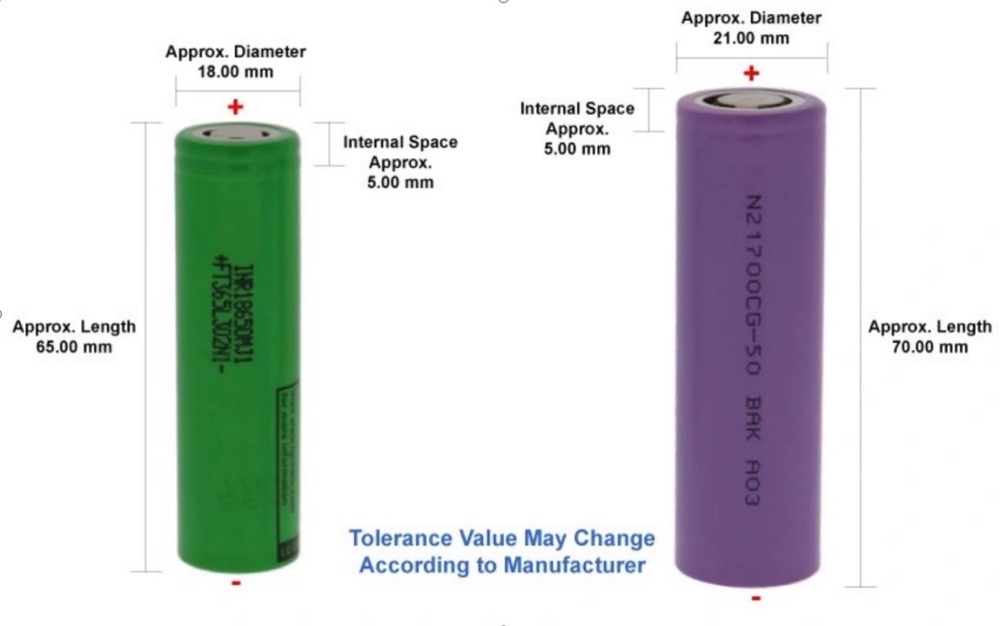

Battery Chemistry and Form Factor Selection for Certification

Image Source: Epec Engineered Technologies

Battery chemistry and form factor decisions establish the foundation for certification pathways. These selections determine both performance parameters and testing requirements throughout the validation process.

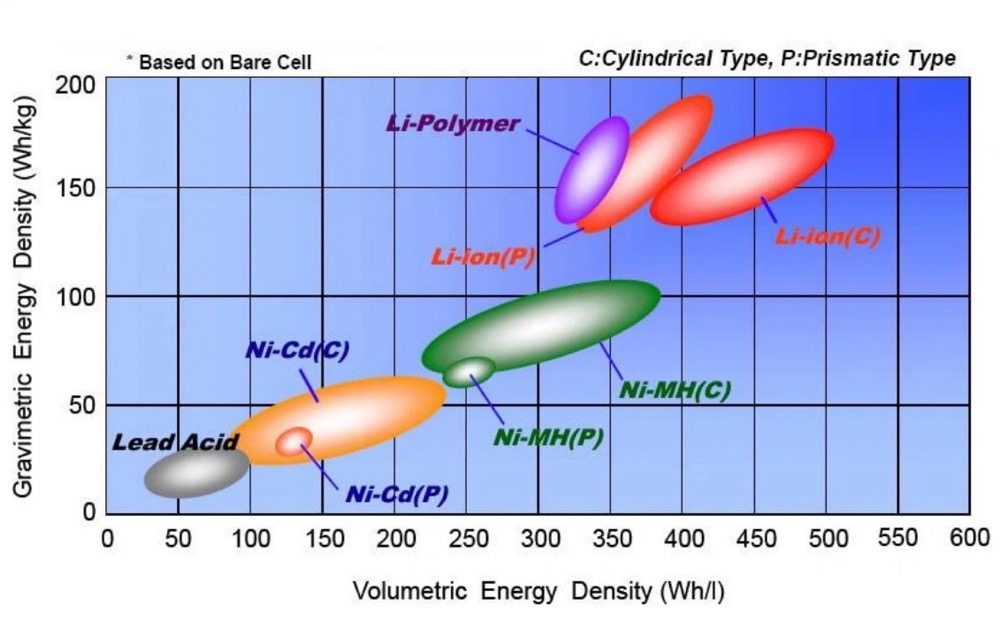

Chemistry Selection: Performance vs. Safety Trade-offs

Li-Ion chemistries with NMC (Nickel Manganese Cobalt) configurations offer energy densities of 150-220 Wh/kg, while NCA (Nickel Cobalt Aluminum) variants achieve 200-260 Wh/kg for NCA. The certification requirements for these chemistries differ significantly based on their thermal characteristics.

NMC cells demonstrate superior thermal stability, simplifying the certification process for safety-critical applications. This stability reduces the complexity of protection circuit requirements and thermal management validation. NCA cells require additional safety circuitry and more extensive testing protocols, particularly for electric vehicle applications.

LiPo (Lithium Polymer) batteries provide lightweight construction with high discharge capabilities but necessitate more rigorous power management protocols during certification. Test data indicates that NCA and LCO chemistries generate higher flame speeds during thermal events compared to LFP chemistry, directly influencing the scope of safety testing requirements.

Form Factor Impact on Mechanical Testing Requirements

Cylindrical cells utilize metal casings with tubular construction, providing exceptional resistance to physical stress and vibration testing. The uniform internal pressure distribution prevents deformation under mechanical loads, reducing certification complications. Individual pressure relief vents release gas from single cells rather than entire battery assemblies.

Prismatic cells maximize space efficiency through rectangular packaging but demonstrate increased susceptibility to expansion effects over operational life. The flat surfaces and corner geometries may require enhanced enclosure protection during impact and crush testing protocols.

Pouch cells present the most challenging certification requirements due to flexible polymer packaging. Without rigid casings or integrated venting mechanisms, these cells typically fail catastrophically under pressure conditions. Certification testing must therefore include extensive protective measures and failure mode analysis.

BMS Integration Requirements by Form Factor

The selected form factor determines Battery Management System complexity and associated testing protocols. Cylindrical cells require sophisticated monitoring networks due to higher cell counts in multi-cell configurations, but their thermal stability simplifies temperature management verification.

Prismatic cells with capacities ranging from 50-100Ah reduce interconnection requirements while demanding higher current handling capability from protection circuits. This configuration affects both the BMS design complexity and the extent of overcurrent protection testing.

Pouch cells necessitate the most advanced BMS implementations since they lack inherent safety mechanisms. Certification testing must validate puncture resistance, expansion accommodation, and failure containment across various abuse conditions.

Battery Management Systems and Safety Protocols

Image Source: MDPI

Battery management systems function as the electronic control center for custom lithium-ion battery packs, monitoring critical operational parameters and implementing safety protocols required for certification compliance. The sophistication of the BMS directly influences certification success across multiple testing standards.

Protection Circuit Module (PCM) vs Full BMS

Protection Circuit Modules provide basic safety functions through analog circuitry that prevents overcharging, deep discharging, and short circuits. PCMs operate on predetermined voltage and current thresholds without intelligent monitoring capabilities or software-based decision making.

Full Battery Management Systems incorporate microcontroller-based monitoring with advanced algorithms for state of charge (SoC) and state of health (SoH) calculations. BMS systems provide comprehensive data logging, fault detection, and communication capabilities essential for meeting certification documentation requirements. The electronic complexity of a full BMS enables precise control over charging parameters, temperature monitoring, and cell balancing functions.

Cell balancing and SoC estimation for safety

Cell balancing maintains voltage uniformity across all cells in series configurations, preventing individual cell degradation that can lead to safety failures during certification testing. Passive balancing systems dissipate excess energy as heat through resistive circuits, suitable for applications with lower balancing current requirements. Active balancing redistributes charge between cells through switching circuits, achieving higher efficiency and faster balancing rates.

State-of-Charge estimation accuracy directly affects battery pack safety and certification compliance. Coulomb counting methods integrate current flow over time to calculate remaining capacity, while voltage-based estimation uses open circuit voltage measurements. Advanced BMS implementations employ Kalman filter algorithms to process multiple sensor inputs and compensate for measurement uncertainties and temperature variations.

Communication protocols for real-time monitoring

Communication interfaces enable real-time data exchange between BMS components and external systems, meeting certification requirements for monitoring and fault reporting. CAN Bus protocols provide multi-master communication with error detection and automatic retransmission, suitable for automotive and industrial certification standards. UART interfaces offer point-to-point communication for simpler applications, while RS485 supports long-distance communication up to 1.2km for distributed battery systems.

Wireless communication through Bluetooth enables remote diagnostics and monitoring capabilities within a 100m range, though power consumption considerations must be evaluated for battery-powered applications. The selection of communication protocols depends on certification requirements, system complexity, and environmental conditions.

Certification Standards for Custom Battery Pack Development

“Prior to 2019, shippers were only required to confirm that batteries had passed the UN 38.3 test. However, since January 21, 2022, lithium cell and battery manufacturers and distributors must have test summaries available.” — Dimerco Editorial Team, Global logistics and battery shipping experts, Dimerco

Image Source: Tritek battery

Lithium battery certification represents a mandatory requirement rather than an optional enhancement. Each certification standard addresses distinct safety considerations throughout the battery lifecycle, from manufacturing through end-of-life disposal.

UN38.3 Transport Safety Testing

UN38.3 certification is mandatory for air freight shipment of any lithium battery products. The standard requires completion of eight specific tests designated T1 through T8: altitude simulation, thermal cycling, vibration resistance, shock testing, external short circuit, impact resistance, overcharge testing, and forced discharge evaluation.

Batteries must demonstrate no leakage, venting, disassembly, rupture, or ignition during testing. Additionally, cells must retain at least 90% of pre-test voltage capacity to achieve certification.

Recent regulatory changes effective January 2022 require manufacturers to provide lithium battery test summaries for all cells and batteries manufactured since 2008. UN38.3 certifications maintain validity for one year from the test completion date.

IEC 62133-2 International Safety Standards

IEC 62133-2:2017 establishes safety requirements for portable sealed secondary lithium cells and batteries containing non-acid electrolytes. This internationally-recognized standard evaluates overcharge resistance, short-circuit protection, mechanical durability, and thermal stability performance.

The revised standard incorporates coin cell testing requirements, vibration and mechanical shock protocols based on UN38.3 methodology, and modified overcharge test conditions. The European Union adopted IEC 62133-2 in March 2021, establishing mandatory compliance for all new portable lithium batteries sold within EU markets.

Regional Certification Requirements

UL2054 certification evaluates household and commercial battery safety for United States markets. The standard requires comprehensive testing of all battery components, making it among the most rigorous certification processes.

CE marking demonstrates manufacturer compliance with European Union safety, health, and environmental protection standards. This mandatory conformity marking for European market access typically remains valid for five years.

Emerging Recycling and Identification Requirements

Battery identification and recycling regulations continue evolving rapidly. The Environmental Protection Agency issued guidance in 2023 clarifying that most lithium-ion batteries qualify as hazardous waste under Resource Conservation and Recovery Act regulations. The agency subsequently announced plans to establish a dedicated universal waste category specifically for lithium-ion batteries.

These regulatory developments address increasing concerns about battery fires during waste management operations. Custom battery pack developers must incorporate these emerging requirements into certification planning processes.

Technical Summary

Custom lithium-ion battery pack certification demands systematic attention to design specifications and regulatory requirements. The certification process requires integration of safety considerations from initial design phases through final testing protocols.

Thermal management systems, cell spacing requirements, and controlled venting mechanisms form the foundation of certifiable battery pack designs. These engineering decisions directly determine whether battery packs can meet the rigorous testing standards imposed by UN38.3, IEC 62133-2, UL 2054, and regional certification requirements.

Chemistry selection affects certification pathways significantly. NMC cells provide superior thermal stability characteristics compared to NCA alternatives, while form factor choices influence mechanical safety validation requirements. Cylindrical cells demonstrate better structural integrity under testing conditions than prismatic or pouch configurations.

Battery Management Systems represent critical certification components. Full BMS implementations offer substantial advantages over basic Protection Circuit Modules through advanced monitoring capabilities, cell balancing functions, and precise state-of-charge determination. These systems often determine certification success for complex battery applications.

The regulatory framework continues expanding with enhanced transport safety requirements, environmental compliance standards, and emerging recycling regulations. Companies developing custom battery packs must account for these evolving standards during design specification phases to avoid costly recertification cycles.

Battery pack certification addresses fundamental safety requirements that prevent thermal runaway events, electrical failures, and mechanical damage scenarios. The technical standards established by certification organizations provide essential guidelines for safe battery operation across diverse application environments. Proper certification ensures battery packs meet established safety thresholds and regulatory compliance requirements for global market access.

Key Takeaways

Understanding certification requirements early in the design process is crucial for avoiding costly redesigns and ensuring market readiness for custom lithium-ion battery packs.

- Design for safety from day one: Integrate thermal management, proper cell spacing (minimum 2mm), and controlled venting systems to prevent thermal runaway and pass certification tests.

- Choose chemistry and form factors strategically: NMC cells offer better thermal stability than NCA, while cylindrical cells provide superior mechanical protection compared to prismatic or pouch configurations.

- Leverage pre-certified components: Using already-certified elements can reduce testing time from 12-14 weeks to 6-8 weeks and minimize sample requirements for certification.

- Implement comprehensive BMS over basic PCM: Full Battery Management Systems provide advanced monitoring capabilities essential for meeting stringent safety standards and certification requirements.

- Plan for multiple certifications: UN38.3 (transport), IEC 62133-2 (global safety), UL (US markets), and CE (European markets) each require specific testing protocols and documentation.

The certification landscape continues evolving with new recycling regulations, making early compliance planning essential for long-term market success and user safety.

FAQs

Q1. What is UL1642 certification for lithium-ion batteries? UL1642 is a safety standard created by Underwriters Laboratories that sets rigorous testing requirements for lithium-ion batteries. It ensures these batteries meet strict safety standards through a series of electrical, mechanical, and environmental tests.

Q2. What are the key standards for testing lithium-ion battery packs? The primary standard is IEC 62133, which outlines safety and performance requirements for portable lithium-ion batteries. It covers electrical, mechanical, and chemical safety aspects, including tests for overcharging, short-circuiting, and thermal stability.

Q3. What are the main certification requirements for custom lithium-ion battery packs? Custom lithium-ion battery packs typically require multiple certifications, including UN38.3 for transport safety, IEC 62133-2 for global compliance, UL certification for US markets, and CE marking for European distribution. Each standard involves specific testing protocols and documentation.

Q4. How do battery chemistry and form factor choices affect certification? Battery chemistry and form factor significantly impact certification pathways. For example, NMC cells offer better thermal stability than NCA cells, while cylindrical cells provide superior mechanical protection compared to prismatic or pouch configurations. These choices influence testing requirements and safety validation processes.

Q5. What role does the Battery Management System (BMS) play in certification? A comprehensive BMS is crucial for certification, offering advanced monitoring capabilities beyond basic protection circuits. It provides detailed data on cell balancing, state of charge estimation, and real-time monitoring, which are essential for meeting stringent safety standards and certification requirements.