When you want to know how to awaken a sleeping li-ion battery, always start by checking voltage and using a charger with boost mode. These methods help you wake up a li-ion pack safely. Improved cooling, as shown below, supports battery safety during the process.

Parameter | Before Improvement | After Improvement | Unit |

|---|---|---|---|

Battery cell temperature | 80 | 49 | °C |

Cooling efficiency | 10 | 14.2 | % |

If you lack experience, consult a professional before you attempt how to awaken a sleeping li-ion battery. Handle every li-ion battery with care to prevent risks. You can avoid future sleeping lithium battery issues by following strict maintenance protocols.

Key Takeaways

Always check the battery voltage first and use a charger with boost or recovery mode to safely wake up a sleeping li-ion battery.

Inspect the battery carefully for damage and monitor temperature and voltage during charging to avoid risks like overheating or fire.

Prevent future battery sleep by keeping batteries charged between uses, storing them properly, and performing regular maintenance checks.

Part 1: Why Lithium-Ion Batteries Sleep

1.1 Common Causes

You often encounter li-ion battery packs entering protection mode due to several triggers. The table below summarizes the most common causes and their technical explanations, based on recent industry studies:

Cause/Trigger | Explanation | Supporting Study/Source |

|---|---|---|

Over-discharge triggering protection circuit | The protection mode activates when cell voltage drops below 2.2–2.9V, disconnecting the pack to prevent damage. | Battery University BU-808a, BU-802b |

Self-discharge during storage | If you store a li-ion battery discharged, voltage drops gradually, eventually activating protection mode. | Battery University |

Prolonged low voltage (<1.5V/cell) | Extended periods below 1.5V/cell can cause internal copper shunts, leading to shorts and irreversible damage. | Battery University |

Empirical evidence from Cadex study | In a study of 294 mobile phone batteries, 30% needed a wake-up feature to exit protection mode; 91% recovered over 80% capacity. | Cadex study via Battery University |

1.2 Protection Mechanisms

Li-ion battery packs rely on advanced protection mode systems to ensure safety and reliability in demanding applications such as medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. You benefit from these mechanisms, which include:

Multiple layers of protection: limiting active material, built-in physical safety devices, and electronic circuits.

Physical devices:

PTC device to block high current surges.

Circuit Interrupt Device (CID) that opens the circuit if pressure exceeds 10 Bar.

Safety vent for controlled gas release during rapid pressure increases.

Electronic protection circuits: These disconnect charging above 4.30V per cell, stop current flow near 90°C, and prevent over-discharge below 2.50V per cell.

Historical recalls, such as the nearly six million lithium-ion battery packs in laptops, highlight the importance of robust protection mode design.

You can read more about battery management systems and their role in protection mode here.

Note: Lithium-ion battery packs account for a significant portion of vehicular battery failures, emphasizing the need for continuous safety improvements.

1.3 Risks of Revival

When you attempt to revive a li-ion battery pack from protection mode, you face several technical and safety challenges:

Li-ion cells that drop below 2.5V enter a deep discharge state and may not accept a charge or may lose significant capacity.

Cells under 2V are considered dead; at 0V, you should recycle them.

Reviving over-discharged batteries requires specialized chargers with a wake-up feature or careful manual charging at low currents.

Old or deeply discharged packs may have compromised protection mode circuits, increasing the risk of heating, swelling, or even fire.

Incorrect charging methods, especially in multi-cell packs, can lead to dangerous outcomes, including thermal runaway.

Always monitor revived packs for self-discharge and capacity loss, and use balance chargers to avoid overcharging individual cells.

If you need customized solutions for your li-ion battery packs, consult our OEM/ODM experts for professional guidance.

Part 2: How to Awaken a Sleeping Li-ion Battery

2.1 Initial Inspection

Before you attempt to wake up lithium battery packs, you must perform a thorough initial inspection. This step helps you identify visible faults and ensures a safer revival process. Use the following checklist to guide your inspection:

Examine the battery enclosure for cracks, swelling, corrosion, or leaks. Physical damage often signals internal faults.

Inspect all wiring and connectors for signs of wear, fraying, or corrosion. Faulty connections can cause electrical hazards.

Use thermal imaging to detect hotspots. Overheating may indicate failing cells or internal shorts.

Check ventilation and cooling systems. Proper airflow prevents overheating during the wake-up procedure.

Test fire suppression and alarm systems. Confirm that fire extinguishers are accessible and emergency protocols are in place.

You should also verify the accuracy of battery labels and ensure all safety documentation is up to date. In industrial and medical applications (medical battery solution), these inspections are critical for compliance and operational safety. For pouch cells, glare and wrinkles can make defect detection difficult, so consider using AI-powered machine vision or computational imaging for enhanced accuracy.

Inspection protocols in the li-ion industry include both full and sampling-based inspections. Full inspections catch defects early, while sampling-based methods help estimate defect rates and root causes. Upstream testing reduces wasted material, and downstream testing increases defect detectability. You may also use electrochemical, acoustic, electromagnetic, and even destructive methods for deeper analysis, though vision-based checks remain the most common for surface defects.

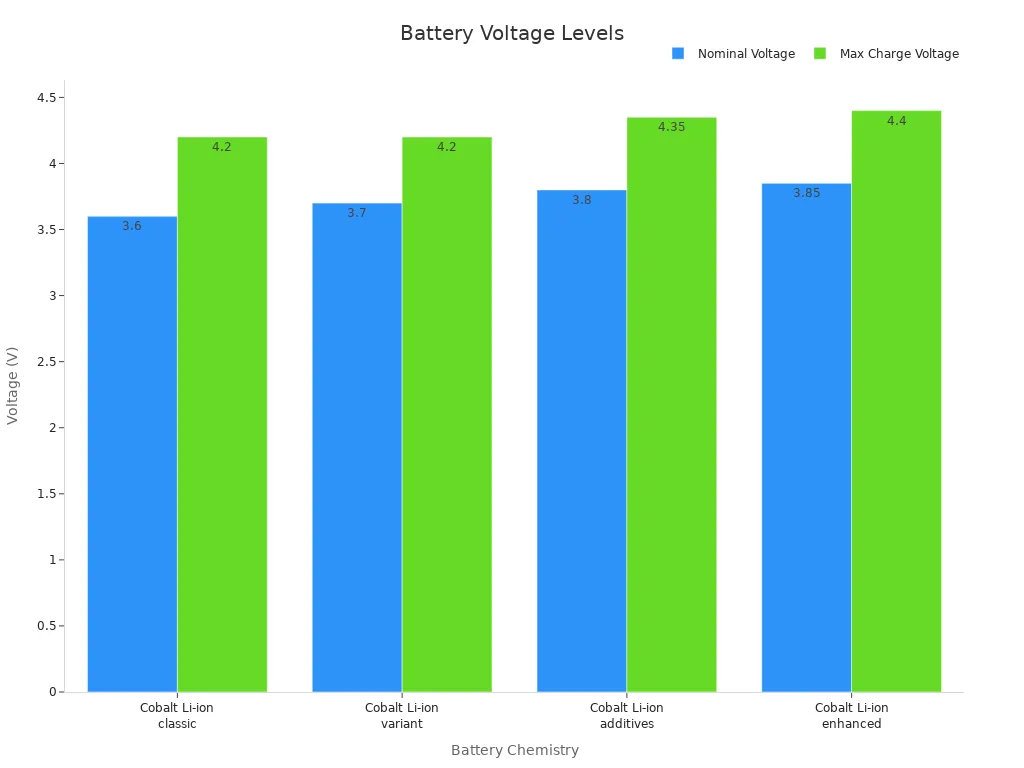

2.2 Check Battery Voltage

After the initial inspection, you need to check the battery voltage. This step determines if the li-ion pack is in deep discharge or sleep mode. Use a calibrated multimeter to measure the voltage at the battery terminals. Compare your readings to the recommended thresholds for each chemistry:

Battery Chemistry Type | Nominal Cell Voltage (V) | Typical End-of-Discharge Voltage (V) | Maximum Charge Voltage (V) | Notes |

|---|---|---|---|---|

LCO Lithium battery | 3.7 | 2.8 – 3.0 | 4.2 | Standard for consumer electronics |

NMC Lithium battery | 3.6 – 3.7 | 2.8 – 3.0 | 4.2 | Used in robotics, medical, and industrial packs |

LiFePO4 Lithium battery | 3.2 | 2.5 – 2.8 | 3.65 | Requires LiFePO4 charger |

LMO Lithium battery | 3.7 | 2.8 – 3.0 | 4.2 | Used in infrastructure and security systems |

LTO Lithium battery | 2.4 | 1.5 – 2.0 | 2.8 | High cycle life, industrial use |

If your battery voltage reads below 2.5V per cell, the pack is likely in sleep mode. For voltages under 2V per cell, you should not attempt to wake up the battery, as it may be unsafe or permanently damaged. Always use a dedicated lithium charger for accurate voltage detection and safe charging.

2.3 Use Boost or Recovery Mode

Many modern li-ion chargers feature a boost or recovery mode designed to safely wake up lithium battery packs from deep discharge. This function applies a controlled low current to the battery, gradually raising the voltage until it reaches a safe threshold for normal charging. Research confirms that boost and recovery modes can restore 3% to 34% of lost capacity, depending on the battery’s state of health and cycling history.

Extreme voltage hold techniques can re-homogenize lithium distribution, partially reversing capacity loss.

Machine learning models help predict recovery rates, supporting data-driven diagnostics.

Some advanced methods inject reagents to regenerate capacity without dismantling the pack, offering a sustainable alternative for large-scale recycling.

You should always monitor the battery voltage during this process. If the voltage recovers to around 3.2–3.3V per cell, you can resume standard charging. If the battery fails to respond, consult a professional or consider recycling the pack.

2.4 Wake Up Lithium Battery with Jump-Start

If boost mode is unavailable, you may consider a jump-start method to wake up lithium battery packs. This approach involves connecting the sleeping lithium battery to a healthy pack of the same chemistry and voltage using proper equipment. However, this method carries significant risks:

Overcharging or mismatched capacities can cause electrode damage, overheating, or even explosion.

High current discharge may raise internal temperatures, risking short circuits and electrolyte breakdown.

Physical pressure or improper connections can rupture internal structures.

Always use compatible chargers, multimeters, and protective gear. Never attempt to jump-start packs with similar amp-hour ratings without professional supervision. Reports of melted contacts and sparks highlight the dangers of improper jump-starting. For industrial, robotics (robot battery solution), or security system (security system battery solution) applications, you should prioritize safety and consult experts before using this method.

2.5 Sleeping Lithium Battery: Safety Tips

To safely wake up lithium battery packs, you must follow strict safety tips:

Measure battery voltage with a multimeter. If below 2.5–2.8V per cell, proceed with caution.

Use a charger compatible with your battery chemistry, such as a LiFePO4 charger for LiFePO4 lithium battery packs.

Set the charger to a low current (C/10 or less) and monitor voltage closely.

Gradually increase voltage, watching for signs of swelling, heat, or abnormal behavior.

Resume normal charging only when voltage stabilizes above 3.2V per cell.

Store batteries fully charged and at room temperature. Charge at the right time to avoid deep discharge.

Periodically recharge batteries in storage, at least every six months, to maintain health.

Consult battery experts or customization consultants if you notice abnormal performance.

⚠️ Always respect the battery management system (BMS) and its protection features. Improper handling can cause permanent damage or safety hazards. For more on BMS, see battery management system operation.

2.6 Preventing Sleep Mode

You can prevent future sleep mode issues in li-ion battery packs by following these best practices:

Fully charge batteries after each use to avoid deep discharge.

Store packs at room temperature in a dry environment.

Avoid overcharging by using chargers with automatic cutoff.

Schedule periodic maintenance and voltage checks, especially for packs in medical, infrastructure (infrastructure battery solution), or industrial (industrial battery solution) settings.

Use balance chargers for multi-cell packs to ensure even charging and prevent cell imbalance.

Train staff on emergency procedures and fire safety protocols.

For sustainable battery management, explore our approach to sustainability.

If you require tailored solutions for your li-ion battery packs, contact our OEM/ODM experts. Large Power provides professional guidance for all your battery needs.

You can safely revive a li-ion battery pack by following these steps:

Always check li-ion battery voltage with a multimeter.

Use a smart charger with recovery mode for li-ion packs.

Monitor li-ion temperature and voltage during charging.

Only professionals should jump-start li-ion batteries.

Replace li-ion packs if unresponsive.

Maintain li-ion charge between 20% and 80%.

Avoid deep discharge in li-ion storage.

Wear protective gear when handling li-ion packs.

Keep li-ion batteries cool for safety.

Schedule regular li-ion maintenance for best results.

FAQ

1. What should you do if a li-ion battery pack does not respond after using a recovery charger?

You should stop charging immediately. Do not attempt further revival. Contact a professional or consult Large Power’s customization experts for safe solutions.

2. Can you use any charger to awaken a sleeping li-ion battery pack?

No. You must use a charger designed for li-ion batteries with a recovery or boost mode. Using the wrong charger may damage the pack or cause safety risks.

3. How often should you check li-ion battery packs in industrial or medical applications?

You should check li-ion battery packs at least every six months. Regular inspections help you prevent deep discharge and extend the service life of your equipment.