The type of lithium battery required for industrial applications is determined by the specific requirements of the equipment being powered: device voltage, load-current, capacity requirements, environmental considerations, physical space constraints, and operational safety parameters. The “Guide to Lithium-ion Battery Solutions” by Shimadzu Corporation provides detailed methodologies for testing and analyzing lithium-ion battery performance across these critical parameters. Our engineering team has designed custom battery solutions for industrial applications for more than two decades, and we understand that proper cell selection and battery pack configuration directly affects system reliability, operational costs, and equipment service life.

The type of lithium battery required for industrial applications is determined by the specific requirements of the equipment being powered: device voltage, load-current, capacity requirements, environmental considerations, physical space constraints, and operational safety parameters. The “Guide to Lithium-ion Battery Solutions” by Shimadzu Corporation provides detailed methodologies for testing and analyzing lithium-ion battery performance across these critical parameters. Our engineering team has designed custom battery solutions for industrial applications for more than two decades, and we understand that proper cell selection and battery pack configuration directly affects system reliability, operational costs, and equipment service life.

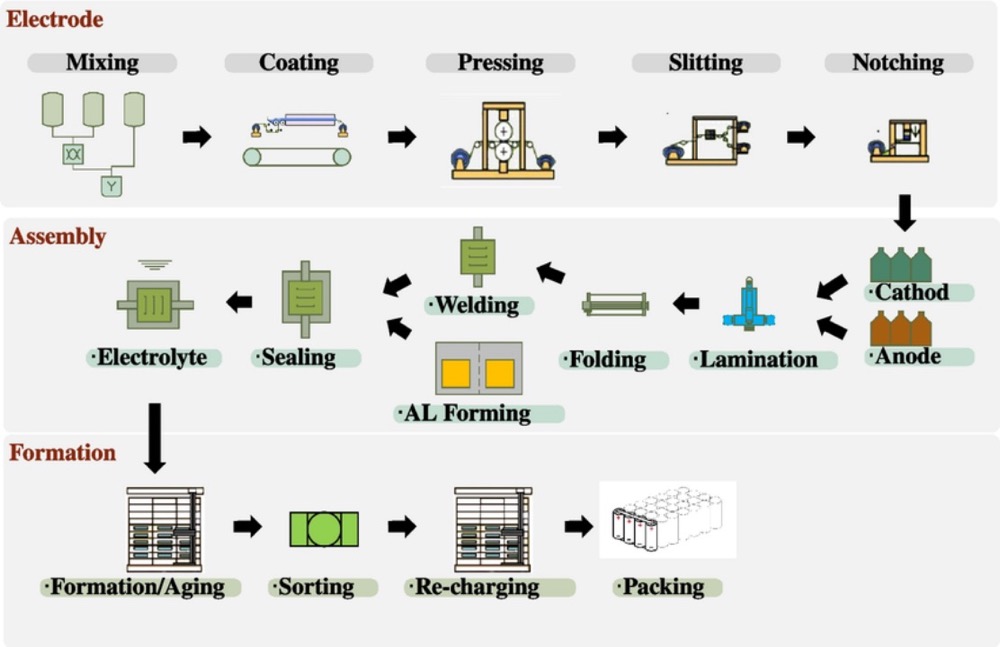

Custom lithium battery solutions require thorough analysis across multiple technical dimensions to meet industrial specifications. Testing protocols must evaluate material properties, thermal characteristics, electrochemical performance, and mechanical durability under actual operating conditions. Each industrial application presents unique electrical, mechanical, and environmental challenges that cannot be addressed with off-the-shelf battery solutions. The battery pack design process involves selecting appropriate chemistry, configuring cells to meet voltage and capacity requirements, integrating protection circuits, and developing enclosures that provide adequate thermal management and physical protection.

The selection process begins with a detailed assessment of your application requirements. Voltage requirements, current draw patterns, duty cycle characteristics, temperature range, physical dimensions, and regulatory compliance needs all influence the optimal battery configuration. This technical guide outlines the critical factors that determine battery pack performance in industrial environments. We will examine application-specific requirements, compare performance characteristics across different lithium chemistries, and discuss customization options that address specific operational challenges. The objective is to provide you with the technical knowledge required to specify battery systems that deliver reliable performance, meet safety requirements, and provide cost-effective operation for your industrial application.

Application Requirements Assessment

Image Source: ResearchGate

Image Source: ResearchGate

Battery pack design requirements are determined by three fundamental application parameters: energy-power characteristics, operational duty cycles, and physical installation constraints. Each parameter directly influences cell chemistry selection, pack configuration, and protection circuit design.

Energy Density vs Power Density Requirements

Industrial applications typically require either high energy density for extended runtime or high power density for rapid discharge—rarely both characteristics simultaneously. Lithium-ion batteries excel in energy density applications where consistent energy delivery over extended periods is essential. These cells provide superior energy storage capacity while maintaining lower weight compared to alternative chemistries.

Applications requiring immediate high-power output for brief periods—such as UPS systems delivering substantial power for seconds or minutes—may benefit from different chemistry selections. Nickel-zinc batteries deliver equivalent power output to lead-acid batteries while occupying half the physical space. The trade-off involves reduced energy capacity for increased power capability.

Operational Duty Cycles and Runtime Parameters

Equipment operational patterns determine battery configuration requirements. Continuous high-power applications require different cell arrangements than intermittent-use equipment. Testing data shows cells operating under high-performance duty cycles exhibit accelerated characteristic changes compared to standard cycle operation.

Runtime specifications vary significantly across industrial applications. Pallet truck operations may require continuous 24-hour availability, while emergency backup systems need reliable operation for specific duration periods. Properly selected lithium-ion batteries can reduce overall energy consumption by 20% compared to lead-acid alternatives. Industrial lithium-ion cells maintain performance consistency across wide temperature ranges, providing reliable operation in variable environmental conditions.

Physical Space and Mounting Configuration

Installation requirements often determine final battery pack configuration. Industrial lithium solutions accommodate multiple mounting configurations:

- 19-inch rack mountingfollows industry standards with 3U or 5U height specifications, allowing installation into existing infrastructure without custom mounting hardware • DIN rail installationprovides secure mounting on standard 35mm rails within industrial control panels and enclosures

• Wall-mounted configurations optimize vertical space utilization while eliminating floor space requirements and maintaining proper ventilation

Space-constrained installations benefit from compact high-capacity solutions delivering over 5kWh in minimal footprints—as small as 3U × 420mm dimensions.

Battery Performance Characteristics and Selection Criteria

Image Source: MDPI

Image Source: MDPI

Performance evaluation across multiple technical parameters determines the suitability of custom lithium battery solutions for industrial applications. Battery performance varies significantly based on chemistry, cell construction, and operating conditions, requiring systematic comparison of discharge characteristics, thermal behavior, and cycle life expectations.

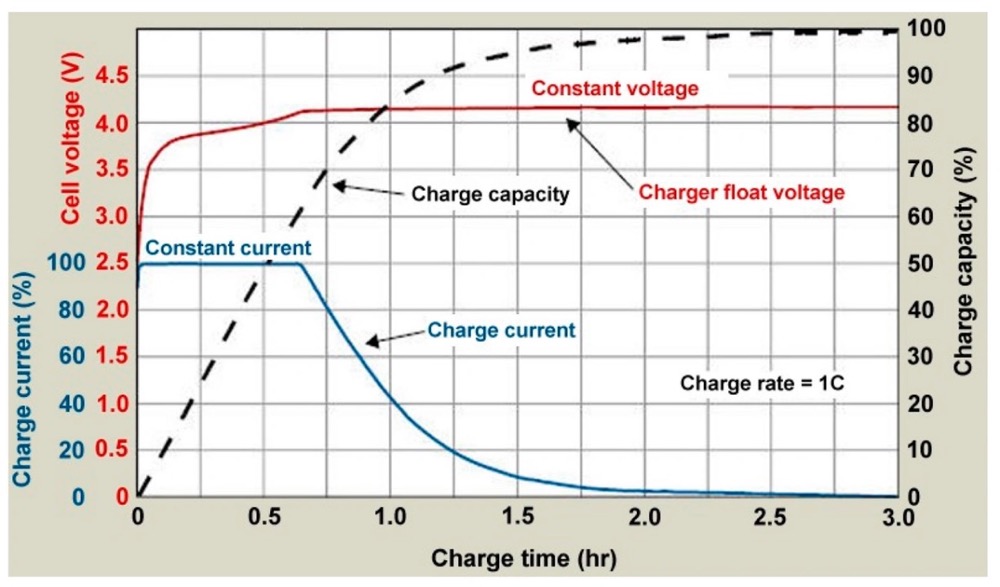

Discharge Rate Performance and Energy Efficiency

The C-rate defines the charge and discharge speed relative to battery capacity. A 1C rate completely charges or discharges a battery in one hour, while 4C represents a 15-minute charge time. Higher C-rates typically accelerate capacity degradation. Li-ion batteries demonstrate exceptional efficiency under optimal conditions, achieving coulombic efficiency exceeding 99%. Efficiency decreases to approximately 97% at 0.5C discharge rates and drops further at 1C. Electric vehicle applications typically achieve 86% energy efficiency in real-world conditions.

Different lithium chemistries exhibit distinct performance characteristics. Lithium cobalt cells cannot exceed their specified C-rating during charging or discharging without thermal issues, whereas lithium iron phosphate cells tolerate higher currents with minimal heat generation. Industrial applications requiring high-rate discharge capability typically specify lithium batteries rated at 10C or higher.

Temperature Operating Windows and Thermal Management Requirements

Operating temperature directly affects both battery performance and service life. Lithium-ion batteries function optimally between 15°C and 35°C. Power capacity decreases dramatically at low temperatures—from 800 W/L at 25°C to 10 W/L at -40°C. High temperatures accelerate degradation and create safety risks, with thermal runaway possible at temperatures above 80°C.

Thermal management requirements depend on application duty cycles and environmental conditions. Passive cooling systems provide adequate temperature control for intermittent-use equipment, while continuous high-power applications require active cooling systems. Custom lithium battery solutions integrate appropriate thermal management—resistive heating elements for cold environments and active cooling for high-discharge applications.

Cycle Life Specifications and Degradation Mechanisms

Cycle life varies dramatically among lithium chemistries. Standard lithium-ion batteries provide approximately 2,000 cycles, equivalent to 3-5 years of service. Lithium titanate (LTO) batteries offer exceptional longevity with up to 10,000 cycles. Some lithium chemistries provide only 500 cycles under similar conditions.

Battery degradation accelerates due to deep discharge cycles, overcharging conditions, extreme temperature exposure, and high C-rate operation. Capacity fade and resistance increase demonstrate strong correlation (r<−0.8 in 97% of cases), indicating that aging mechanisms simultaneously affect both parameters. Monitoring either capacity or internal resistance provides reliable battery health assessment.

Lithium iron phosphate (LFP) batteries represent the optimal choice for industrial applications requiring maximum service life, offering extended cycle life, enhanced safety characteristics, and cost-effective operation.

Custom Battery Pack Development and Configuration Options

Image Source: tritek battery

Image Source: tritek battery

Battery pack customization addresses specific industrial challenges that standard off-the-shelf solutions cannot meet. Our engineering team designs custom battery configurations to match exact electrical, mechanical, and environmental requirements rather than forcing applications to adapt to available products.

Modular Voltage and Capacity Design

Custom battery pack development begins with configuring cells to achieve the required voltage and capacity specifications. Modular battery designs permit capacity increases in 5P increments and voltage configurations from 7S (24V) up to 224S (830V). This approach allows precise matching of electrical characteristics to load requirements. Standard building blocks include 24V configurations (25.2V/22.5Ah/567Wh) and 48V variants (50.4V/22.5Ah/1.134kWh) that can be combined for higher voltage or capacity systems.

The number of cells, the size of the cell, and how the cells are assembled defines the electrical characteristics and physical dimensions of the pack. Series connections increase voltage while parallel connections increase capacity. Custom configurations optimize both parameters to meet specific application demands without oversizing the battery system.

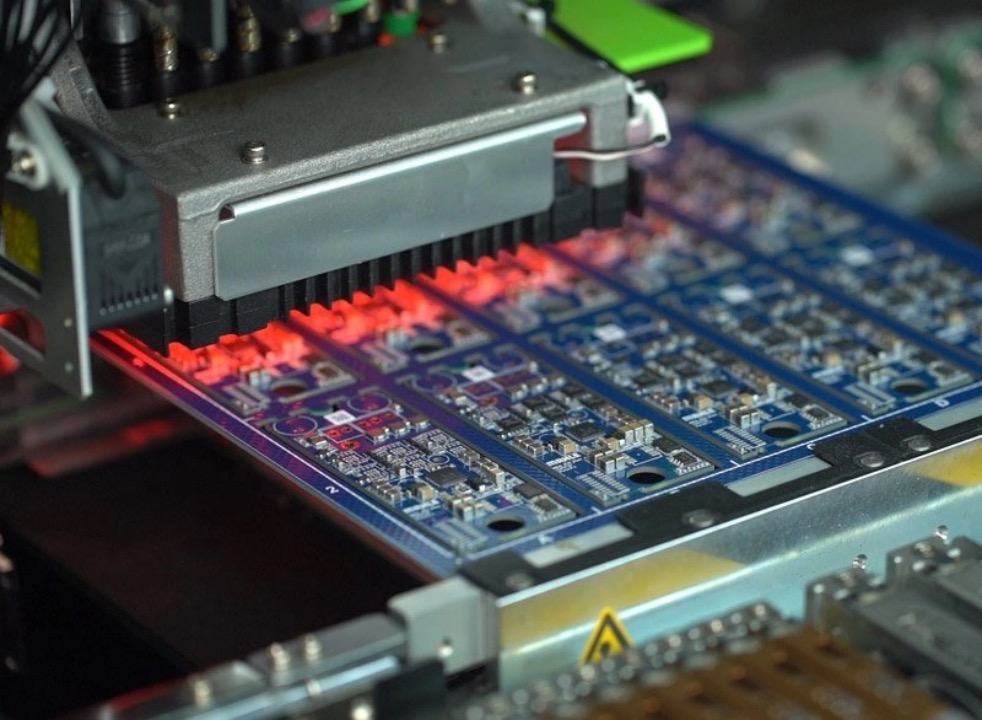

Battery Management System Integration

Advanced battery management systems provide sophisticated monitoring and control functions essential for industrial applications. Custom BMS designs include:

- Continuous monitoring of voltage, current, temperature, and state of charge

- Communication interfaces including CAN bus, RS485, or Bluetooth protocols

- Data logging capabilities for predictive maintenance programs

- Programmable alert systems for operational parameters

BMS functionality can be tailored to specific application requirements. Simple applications may require only basic protection circuits, while complex systems benefit from full communication integration with facility monitoring systems.

Mechanical Design and Environmental Protection

Industrial battery enclosures must protect cells and electronics from harsh operating environments. Custom enclosure designs provide:

- IP54 or higher ingress protection ratingsfor dust and moisture resistance

- Operating temperature ranges from 32°F to 140°F

- Mechanical protection against shock, vibration, and corrosive conditions

- Compliance with required certifications including UL, UKCA, CE, IEC, and UN38.3

Enclosure materials are selected based on environmental conditions and regulatory requirements. For applications with extreme conditions, specialized materials and construction methods ensure reliable long-term operation.

System Integration and Compatibility

Modern lithium battery solutions integrate with existing power infrastructure through standardized interfaces and communication protocols. This includes SCADA system compatibility for facility-wide monitoring and direct replacement capability for legacy lead-acid installations. Proper system integration requires careful consideration of voltage compatibility, communication protocol requirements, and physical mounting specifications.

Battery Selection: Cost Analysis, Safety Requirements, and Manufacturing Support

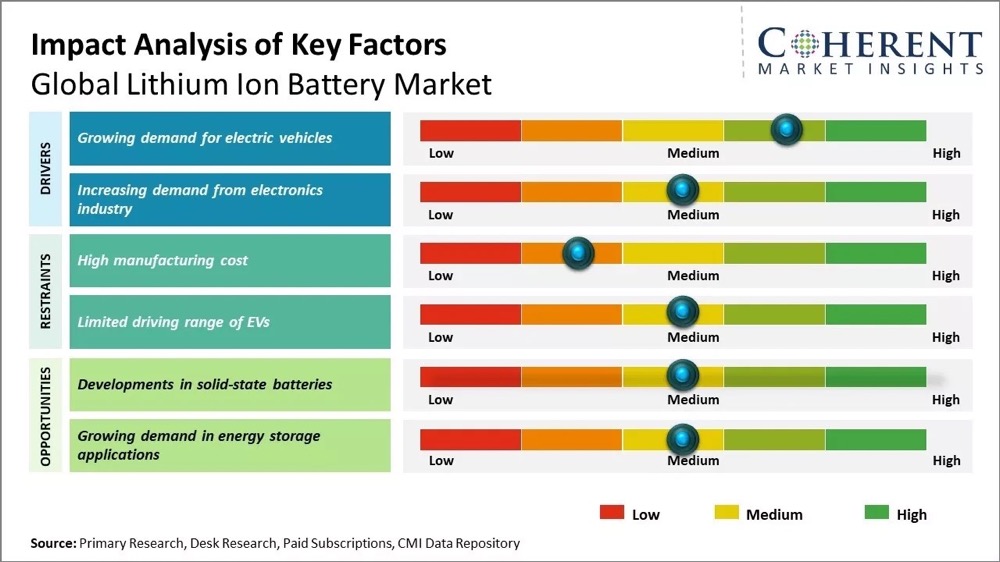

Image Source: Coherent Market Insights

Image Source: Coherent Market Insights

The final battery selection decision requires evaluation of three critical factors beyond technical specifications: long-term cost analysis, mandatory safety certifications, and manufacturer support capabilities. Our experience with hundreds of industrial battery installations has demonstrated that these factors often determine project success more than initial technical performance metrics.

Total Cost Analysis and Long-Term Value

Initial battery costs represent only a fraction of total ownership expenses over the system’s operational life. Lithium batteries typically cost 2-3 times more upfront than lead-acid alternatives, but their total cost of ownership proves substantially lower due to extended service life and reduced maintenance requirements. Lead-acid batteries average 500-1000 cycles before replacement, while lithium iron phosphate batteries deliver 4000+ cycles under similar operating conditions.

Operating efficiency creates additional cost advantages. Lithium batteries achieve 96% charging efficiency compared to 75% for lead-acid systems. This 21% efficiency difference translates directly to reduced electricity costs throughout the battery’s service life. Maintenance requirements also differ significantly—lithium systems require virtually no scheduled maintenance, while lead-acid batteries need regular electrolyte monitoring and periodic replacement.

The faster you discharge or the more extreme the operating temperature, the greater the cost advantage of properly selected lithium chemistry. For applications with high discharge rates or challenging environmental conditions, the total cost advantage of lithium systems increases substantially.

Regulatory Compliance and Safety Certifications

Lithium batteries are considered hazardous materials and are subject to various regulations. Essential certifications for industrial applications include:

- UN38.3 for transportation safety—required for all lithium battery shipments • UL/CSA standards for North American installations • IEC certifications for European market compliance • Industry-specific requirements such as ABYC E-13 for marine applications

These certifications verify that battery packs have passed rigorous testing including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge conditions. The certification process involves significant testing fees and documentation requirements, but proper certification is mandatory for commercial deployment and reduces liability exposure.

New regulations continue to evolve, particularly for air transport. Regulations passed in 2016 tightened requirements for lithium battery shipments and prohibited lithium batteries on passenger aircraft. Companies planning international distribution must factor these shipping restrictions into their logistics planning.

Manufacturer Support and Service Capabilities

Technical support quality varies dramatically among battery manufacturers. Evaluate potential suppliers based on their engineering support capabilities, warranty coverage, and long-term business stability. Established manufacturers offer comprehensive warranties extending to 4 years with full replacement guarantees. The financial stability of your battery manufacturer affects continued parts availability and technical support throughout your system’s operational life.

Consider whether the manufacturer handles the complete development process in-house or subcontracts critical functions to third parties. Companies that manage design, prototyping, testing, and manufacturing internally provide better control over quality, lead times, and design modifications. Manufacturers who pass off portions of the process to other suppliers may introduce additional costs and lead time complications.

Finding out which parts of the development and production will be performed in-house with the manufacturer, and which components will be passed off to other shops, will help you understand what additional costs and lead times will be needed for your project.

You can always trust Large Power as your next lithium battery supplier, contact us for more details!

Conclusion

Custom lithium battery solutions for industrial applications require systematic evaluation of electrical, mechanical, and operational parameters to ensure optimal system performance. Our technical staff has worked with customers across diverse industries to generate battery specifications that meet demanding application requirements while maintaining cost-effectiveness and regulatory compliance.

The battery selection process must begin with clearly defined operational parameters. Voltage requirements, current draw patterns, duty cycle characteristics, and environmental conditions determine the appropriate cell chemistry and configuration. Applications requiring high energy density benefit from lithium-ion chemistries, while high-power applications may require different cell configurations or alternative chemistries entirely. The faster you discharge or the lower the temperature, the lower the capacity of the battery will be, which directly impacts system performance calculations.

Performance evaluation requires examining charge/discharge rates, temperature tolerance, and cycle life characteristics across different lithium chemistries. Standard lithium-ion batteries average 2,000 cycles, while specialized chemistries like LTO can deliver up to 10,000 cycles, significantly affecting total cost of ownership calculations. Cell capacity is rated in amp-hours, and the calculation of run time versus current provides the foundation for determining appropriate battery sizing.

Custom battery pack development offers significant advantages over off-the-shelf solutions when specific performance criteria must be met. Tailored voltage configurations, specialized battery management systems, and custom enclosures address unique application challenges that cannot be resolved with standard products. Smart battery pack functionality provides the device with information for charge management, error reporting, and run-time prediction through communication protocols like SMBus or CAN bus.

Total cost of ownership considerations often favor lithium solutions despite higher initial investment costs. The extended cycle life, reduced maintenance requirements, and superior energy efficiency create substantial savings over the operational life of the equipment. Our experience demonstrates that properly specified lithium battery systems typically provide better long-term value compared to alternative technologies.

Regulatory compliance remains essential for all lithium battery applications. UN38.3 transportation safety certification, UL standards, and IEC certifications verify that battery designs meet rigorous testing requirements including altitude, thermal, vibration, shock, and short circuit conditions. These certifications are mandatory for commercial deployment and require careful coordination during the development process.

Technical support and manufacturing capabilities should factor into your supplier selection process. The battery industry continues advancing rapidly, with new cell technologies and safety requirements emerging regularly. Working with an established battery manufacturer ensures access to current technology, proper testing facilities, and ongoing technical assistance throughout your product lifecycle.

The objective for any battery design is to meet performance requirements while maintaining cost-effectiveness and regulatory compliance. Our engineering team works with customers to finalize specifications and develop custom solutions that address specific application challenges while ensuring reliable operation in demanding industrial environments.

Key Takeaways

Choosing the right lithium battery solution for industrial applications requires balancing technical specifications with operational requirements and long-term value considerations.

- Assess application-specific needs first: Match energy vs power requirements, duty cycles, and space constraints to determine optimal battery configuration for your specific industrial use case.

- Prioritize total cost of ownership over initial price: Despite higher upfront costs, lithium batteries deliver 4x longer lifespans and 96% charging efficiency compared to lead-acid alternatives.

- Leverage customization for optimal performance: Tailored voltage configurations, smart BMS features, and custom enclosures transform batteries into intelligent system components that prevent failures.

- Ensure proper certifications and support: UN38.3, UL/CSA, and IEC certifications are non-negotiable, while manufacturer stability ensures continued technical support throughout operational life.

- Consider performance metrics carefully: Charge/discharge rates, temperature tolerance, and cycle life (ranging from 2,000 to 10,000+ cycles) directly impact operational efficiency and system reliability.

The key to successful lithium battery selection lies in working with experienced manufacturers who understand that proper matching of battery specifications to application requirements delivers superior long-term value through reduced maintenance, extended equipment life, and improved operational efficiency.

FAQs

Q1. What factors should I consider when choosing a lithium battery for industrial applications? When selecting a lithium battery for industrial use, consider your specific energy and power requirements, duty cycles, space constraints, operating temperature range, and expected lifespan. Also, evaluate the total cost of ownership, safety certifications, and after-sales support.

Q2. How do lithium batteries compare to lead-acid batteries in terms of efficiency and lifespan? Lithium batteries offer superior efficiency and longevity compared to lead-acid batteries. They typically have a charging efficiency of 96% versus 75% for lead-acid, and can last for 4000+ cycles compared to 500-1000 cycles for lead-acid batteries.

Q3. What are the benefits of customized lithium battery solutions? Customized lithium battery solutions offer tailored voltage and capacity configurations, smart BMS features for remote monitoring, custom enclosures for harsh environments, and seamless integration with existing power infrastructure. These features allow for optimized performance in specific industrial applications.

Q4. How important are certifications for industrial lithium batteries? Certifications are crucial for industrial lithium batteries. Key certifications include UN38.3 for transportation safety, UL/CSA standards for North American markets, and IEC certifications for European markets. These ensure the batteries meet rigorous safety and performance standards.

Q5. What is the optimal charging range for lithium batteries? For optimal performance and longevity, it’s generally recommended to keep lithium batteries charged between 20% and 80% of their full capacity. This practice, known as the 20-80% rule, can help extend the battery’s lifespan in many applications.