Heavy equipment batteries deliver 1,150 cold cranking amps, substantially exceeding conventional automotive batteries that generate 500-600 cold cranking amps. This power differential demonstrates the specialized engineering requirements for construction and industrial applications.

Heavy equipment batteries deliver 1,150 cold cranking amps, substantially exceeding conventional automotive batteries that generate 500-600 cold cranking amps. This power differential demonstrates the specialized engineering requirements for construction and industrial applications.

Equipment batteries incorporate thicker casings and reinforced construction to withstand extreme vibration conditions on uneven terrain. These design specifications provide enhanced durability against harsh operating environments typical in construction and industrial settings. The enhanced construction addresses mechanical stress factors that standard automotive batteries cannot tolerate.

Selecting appropriate battery platforms can reduce procurement costs by approximately 30%. Maximizing return on investment requires understanding battery chemistry fundamentals and implementing proper maintenance protocols. Proper battery management practices can effectively double operational lifespan while reducing equipment downtime and maintenance expenses.

This technical guide presents proven methodologies for extending heavy equipment battery life, selection criteria for optimal battery chemistry matching specific equipment requirements, and maintenance technologies available for 2025 implementation. Fleet managers overseeing both small-scale operations and large industrial facilities will find these technical insights valuable for maximizing performance while controlling battery-related operational costs.

Critical Importance of Battery Life in Heavy Equipment Operations

“When fleet managers neglect battery maintenance, batteries may corrode or become unusable. Dead batteries will prevent machines from starting, resulting in costly downtime and repairs.” — EquipmentShare Parts Editorial Team, Heavy equipment maintenance experts and official parts supplier

Battery failure in heavy equipment represents a significant operational risk with measurable financial consequences. Premature battery failure costs organizations over $75 million annually in lost productivity and resources. This figure encompasses direct replacement costs plus the operational disruptions that cascade through equipment fleets.

Operational Impact of Battery Failure

Heavy equipment battery failure creates immediate operational paralysis across multiple systems. A single unexpected failure generates operational shutdowns, reduced output capacity, and increased labor expenses. These immediate effects extend beyond downtime to impact client relationships and contract fulfillment capabilities. Fleet operations experience exponential losses when battery-related breakdowns exceed acceptable thresholds.

Battery Replacement Cycles and Economic Analysis

Military vehicle applications require battery replacement approximately every 12 months. This replacement frequency significantly impacts long-term operational economics. Selecting appropriate industrial batteries requires evaluation of multiple performance criteria to optimize return on investment. Lithium-ion batteries typically deliver extended service life compared to lead-acid alternatives. Maintenance requirements represent a critical factor—sealed lead-acid and lithium-ion batteries eliminate routine maintenance tasks, reducing labor costs and service interruptions.

Safety Considerations for Battery System Failures

Failing batteries present substantial safety hazards beyond operational concerns. Lithium-ion batteries contain high energy density in compact configurations. Uncontrolled energy release generates excessive heat that can produce flammable and toxic gas emissions. Battery failures result from multiple failure modes:

- Physical damage or manufacturing defects

- Overcharging or excessive discharge cycling

- Extreme temperature exposure

- Incompatible charging systems or accessories

Damaged batteries exhibiting swelling, bulging, leakage, or cracking present fire hazards. Equipment battery fires burn at temperatures sufficient to melt metal and cause structural collapse. Monitoring protocols should detect warning indicators including excessive heat generation, abnormal sounds, or visible physical damage to prevent catastrophic failures.

Operational Practices for Extended Battery Life

Image Source: ToolSense

Image Source: ToolSense

Daily operational practices determine battery longevity in heavy equipment applications. These established methodologies reduce battery strain and prevent premature component failure through systematic operational controls.

Cranking Duration Management

Excessive cranking during engine starts generates substantial heat loads within starting circuits, accelerating battery and starter motor degradation. Extended cranking attempts create thermal stress that permanently damages battery cell structure and reduces available capacity.

Continued cranking beyond optimal parameters produces:

- Thermal buildup exceeding safe cell operating temperatures

- Mechanical stress on starter motor components

- Deep discharge conditions that reduce battery life cycles

Proper starting protocols limit individual cranking attempts to 5-10 second intervals with cooling periods between attempts. Overcrank protection systems provide automated safeguards that monitor cranking duration and temporarily isolate starting circuits when thermal limits are approached. These protection modules include visual indicators that inform operators when circuits are in thermal protection mode.

Auxiliary Load Isolation

Auxiliary equipment powered directly from starter batteries accelerates deterioration through deep discharge cycles during idle periods. Power demands from cab electronics, HVAC systems, and accessory equipment drain starter batteries below optimal charge levels, reducing cycle life significantly.

Battery management systems protect starter circuits by isolating auxiliary loads during idle operation, preventing deep discharge conditions. Auxiliary power modules supply these systems independently, eliminating unnecessary charge cycles from primary starting batteries. This isolation approach extends battery service life through complete equipment operational cycles.

Real-Time Monitoring Implementation

Onboard monitoring systems provide continuous measurement of voltage, current draw, and operating temperature to calculate state of charge and remaining capacity. These monitoring platforms capture operational data that predicts battery failure before complete discharge occurs.

Battery monitoring prevents no-start incidents that cost operators $900-$1,700 per occurrence in productivity losses and emergency service calls. Advanced monitoring systems measure current loads up to 3,000 amps while recording 1,000 voltage samples per second, performing comprehensive starting system diagnostics with each engine start sequence.

These three operational controls form the foundation for doubling battery service life while reducing maintenance requirements across equipment fleets.

Battery Selection Criteria for Heavy Equipment Applications

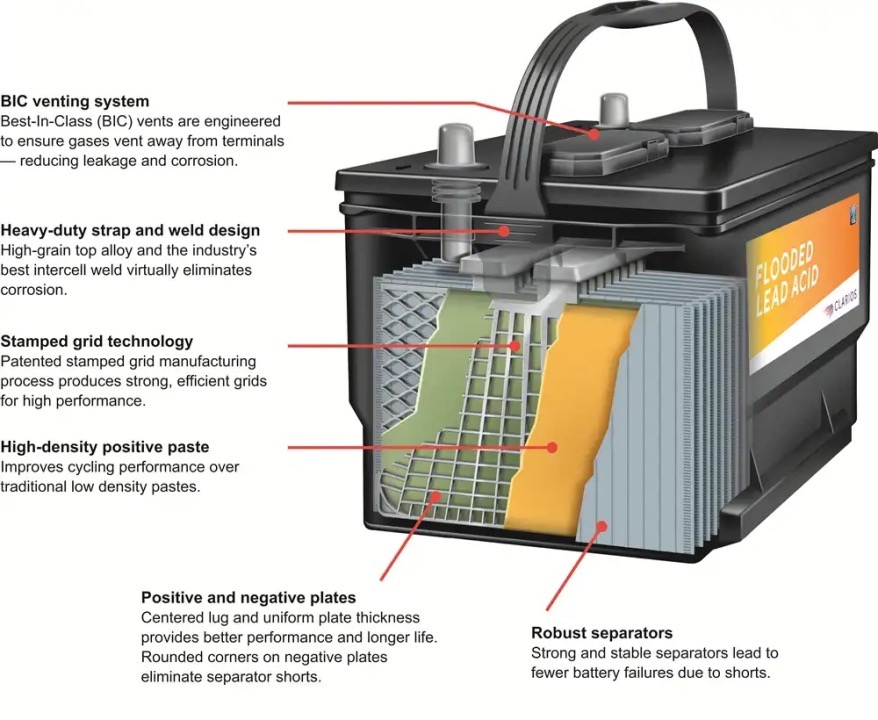

Image Source: Brava Batteries

Image Source: Brava Batteries

Battery selection for heavy equipment requires matching electrochemical characteristics to specific operational parameters. The selection process determines performance capabilities, maintenance protocols, and total cost of ownership across the equipment lifecycle.

Power Requirements and Chemistry Selection

Equipment power demands dictate appropriate battery chemistry selection. Lead-acid batteries provide cost-effective solutions for standard applications, requiring regular electrolyte maintenance protocols. Lithium-ion chemistry delivers 3,500-5,000 charge cycles compared to approximately 500 cycles for lead-acid alternatives. The extended cycle life justifies higher initial investment for high-demand applications with frequent charge-discharge patterns.

Battery Chemistry Comparison Analysis

Each battery technology offers distinct operational characteristics:

- Flooded Lead-Acid: Cost-effective with high instantaneous power output, requires periodic electrolyte level maintenance and ventilation considerations

- AGM Batteries: Sealed construction eliminates maintenance requirements, provides superior vibration resistance and faster charge acceptance rates

- Gel Electrolyte: Temperature-stable performance with minimal maintenance demands, limited by lower power density and extended charge times

AGM technology commands higher procurement costs but eliminates maintenance labor while extending operational lifespan.

Physical Specifications and Fitment Parameters

BCI Group Size classifications define battery dimensions, terminal configurations, and electrical specifications. Heavy equipment applications typically utilize Group 24, 27, 29, 30, and 31 classifications. Physical fitment verification requires confirming length, width, and height dimensions against equipment battery compartment specifications. Cold cranking amps (CCA) and reserve capacity ratings must meet or exceed manufacturer requirements to ensure reliable starting performance.

Advanced Charging and Maintenance Technology for Equipment Battery Management

“Lead-acid batteries need frequent watering, corrosion checks, and regular cleaning. Facilities without dedicated battery maintenance staff may struggle to perform these tasks consistently.” — Leoch Lithium Editorial Team, Battery technology experts, Leoch Lithium

Battery maintenance technology for heavy equipment has advanced considerably, offering operators sophisticated tools for maximizing battery performance while controlling replacement costs. These technological solutions address the complex charging requirements and monitoring needs of modern equipment fleets.

Smart Battery Maintainer Technology

Smart battery maintainers provide regulated, low-amperage charging that compensates for self-discharge during storage periods. These devices incorporate voltage-sensing circuits that detect full charge conditions and automatically terminate charging current, preventing overcharge damage. Heavy equipment battery maintainers are engineered for continuous connection over extended periods, unlike consumer electronics chargers. Equipment with seasonal operation patterns or intermittent deployment schedules particularly benefit from these maintenance charging systems.

Solar Power Integration for Remote Operations

Solar charging systems have become viable solutions for equipment batteries at remote worksites where grid power is unavailable. Flexible photovoltaic panels designed for equipment applications mount directly to machine cab structures, maintaining functionality under impact conditions up to 51mph. Solar charging systems require specialized charge controllers that regulate current flow from photovoltaic arrays, optimizing charge efficiency while preventing battery damage from uncontrolled charging. Connected fleet operations utilizing solar charging report 23% improved financial performance compared to conventional charging approaches.

Real-Time Battery Monitoring Systems

Real-time monitoring technology represents a significant advancement in equipment battery management. Data acquisition systems continuously measure voltage, current flow, and cell temperature—the primary parameters determining battery service life. IoT-enabled monitoring platforms store operational data locally and transmit information to cloud-based servers for analysis and predictive maintenance scheduling. Mobile applications provide immediate access to battery status information, enabling proactive maintenance decisions and enhancing operational safety through predictive failure detection. Standardized monitoring approaches facilitate rapid deployment across multiple equipment sites while reducing the frequency of manual maintenance inspections.

Conclusion

Heavy equipment battery management directly impacts operational efficiency and cost control across fleet operations. The strategies presented in this guide demonstrate proven methods for doubling battery lifespan while eliminating expensive downtime incidents. Operational practices—controlled cranking protocols, auxiliary load management during idle periods, and continuous voltage monitoring—establish the foundation for extended battery performance.

Battery chemistry selection matched to specific equipment requirements determines long-term operational outcomes. Flooded lead-acid batteries provide cost-effective solutions for standard applications, while AGM and lithium-ion chemistries deliver superior performance under extreme operating conditions despite higher initial capital requirements.

Smart maintenance technologies have fundamentally changed power system management approaches. Intelligent battery maintainers, solar charging capabilities for remote installations, and IoT-enabled monitoring platforms provide real-time visibility into battery health parameters. These systems enable predictive maintenance strategies that prevent failures before they occur, eliminating costly no-start incidents.

The economic impact remains significant—a single battery failure costs between $900-$1,700 in lost productivity, excluding contract penalties and reputation consequences. Comprehensive battery management practices represent high-return maintenance investments for equipment managers seeking operational optimization.

Custom battery solutions tailored to specific operational profiles continue gaining importance as equipment electrification advances. Partnerships with experienced battery manufacturers who understand operational demands will prove essential for optimizing power system performance. Properly specified and maintained battery systems determine whether equipment delivers profitable uptime or remains idle, consuming resources without generating productivity.

For any heavy equipment battery request, you can contact Large Power, a leading custom battery pack manufacturer.

Key Takeaways

Proper battery management can dramatically reduce operational costs and prevent the $900-$1,700 expense of each no-start incident while doubling equipment battery lifespan.

- Avoid over-cranking during startups– Limit cranking attempts to 5-10 seconds with cooling periods to prevent heat buildup and premature battery failure.

- Turn off auxiliary loads when idle– Power cab electronics and accessories separately from starter batteries to eliminate unnecessary deep discharge cycles.

- Choose the right battery chemistry– AGM batteries offer 3-10 times longer cycle life than flooded batteries, offsetting higher costs through reduced maintenance.

- Implement smart charging systems– Use intelligent maintainers and IoT monitoring to prevent overcharging while tracking voltage, current, and temperature in real-time.

- Monitor battery voltage continuously– Install onboard systems that provide early failure warnings and perform automatic starting system tests with each engine start.

These proven strategies transform battery management from reactive maintenance to proactive fleet optimization, ensuring maximum uptime while minimizing replacement costs across your heavy equipment operations.

FAQs

Q1. How can I extend the life of my heavy equipment battery? To extend your heavy equipment battery life, avoid over-cranking during startups, turn off auxiliary loads when idle, and use smart charging systems. Regular maintenance, proper storage, and monitoring battery voltage are also crucial for maximizing lifespan.

Q2. What type of battery is best for heavy equipment? The best battery type depends on your specific equipment needs. AGM batteries offer longer cycle life and reduced maintenance compared to flooded lead-acid batteries, making them suitable for many heavy equipment applications. However, lithium-ion batteries provide the longest lifespan and best performance in high-demand situations.

Q3. How often should heavy equipment batteries be replaced? With proper care and maintenance, heavy equipment batteries can last several years. However, the exact replacement frequency depends on usage patterns, environmental conditions, and battery type. Regular monitoring and maintenance can help you identify when a battery is nearing the end of its useful life.

Q4. What are the benefits of using a smart battery maintainer for heavy equipment? Smart battery maintainers provide consistent, low-power charging that prevents overcharging and compensates for natural energy loss during storage. They can significantly extend battery life, especially for equipment with irregular usage patterns, and help prevent costly no-start situations.

Q5. How do solar charging options benefit heavy equipment batteries in remote locations? Solar charging solutions are ideal for remote worksites without reliable power infrastructure. They can be mounted directly on equipment, provide continuous charging to prevent battery depletion, and help eliminate downtime due to dead batteries. This technology is particularly useful for construction and mining operations in isolated areas.