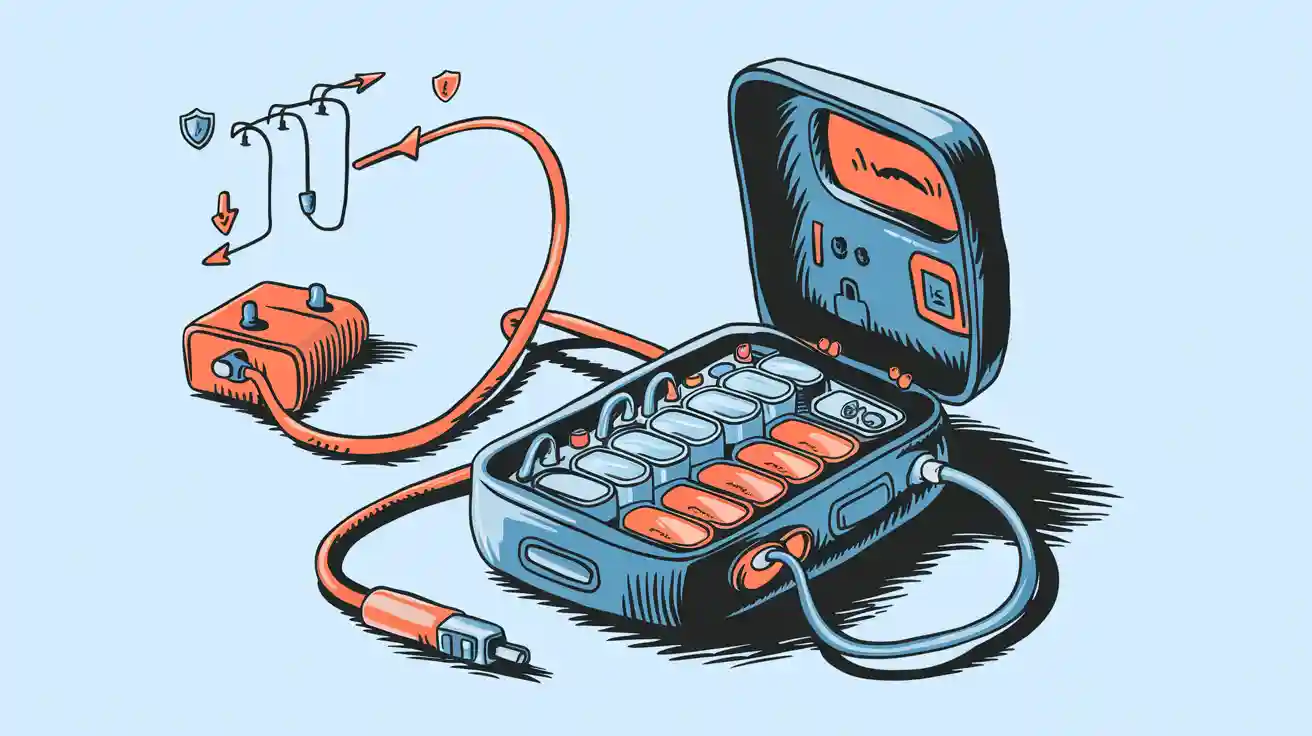

Infusion Pump Battery Design plays a critical role in delivering a continuous power supply to medical devices. Hospitals and clinics trust these systems as a reliable power source during patient care. Advanced battery management systems monitor and regulate medical-grade lithium battery packs, ensuring safety and performance. Power failure can threaten patient outcomes, so healthcare providers demand robust backup solutions that eliminate risk.

Key Takeaways

Infusion pumps need reliable power to deliver medication without interruptions, especially during emergencies.

Lithium battery packs are preferred for their high energy density and long lifespan, ensuring continuous operation.

Backup systems and battery management are crucial to prevent power failures that can harm patient safety.

Healthcare facilities should prioritize rechargeable batteries to reduce waste and lower operational costs.

Regular maintenance and testing of battery systems are essential to ensure reliable performance and compliance with safety standards.

Part 1: Power Supply Needs

1.1 Continuous Operation

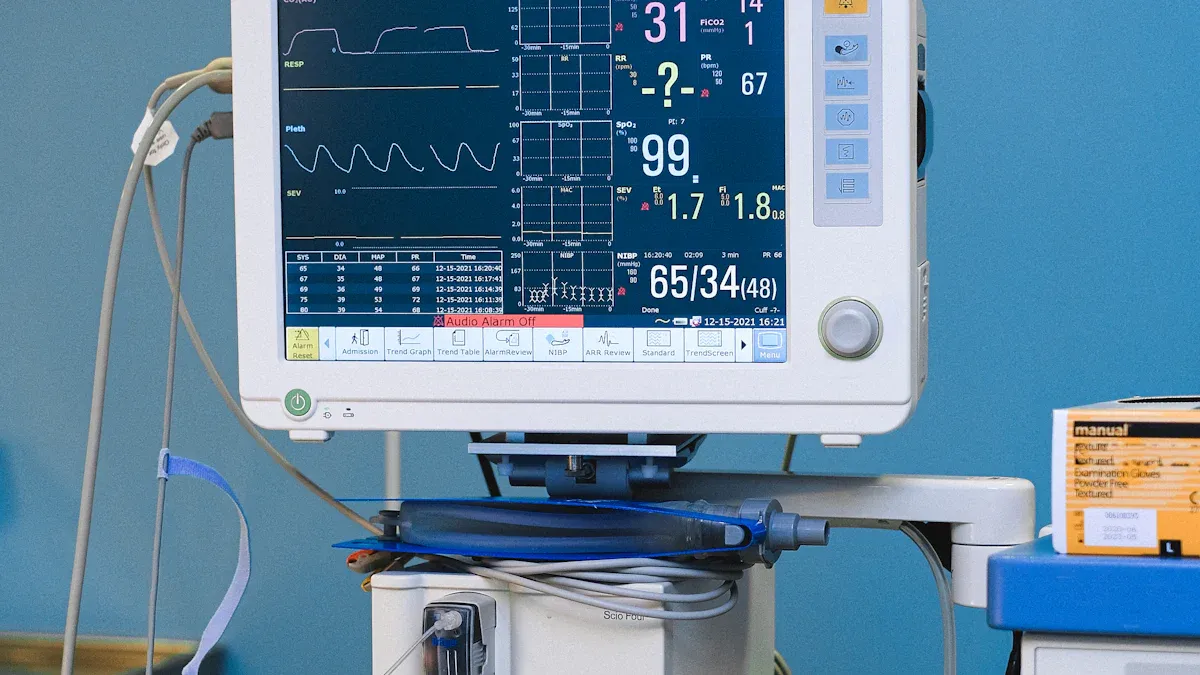

Infusion pumps in hospitals and clinics must deliver medication without interruption. Medical teams rely on these devices to function during procedures and emergencies. Lithium battery packs provide consistent voltage and current, supporting continuous operation even when power outages occur. Modern infusion pumps can run for eight to ten hours on a single battery pack at full speed. Designers use switch-mode voltage regulators to manage power efficiently and extend battery life. Portability remains essential, so the size and weight of the power supply must fit the needs of mobile healthcare environments. In critical care, uninterrupted therapy is vital, and lithium battery packs help prevent risks associated with power outages.

1.2 Power Failure Risks

Power outages pose serious threats to patient safety and device reliability. When an infusion pump loses power, therapy can stop suddenly. The consequences range from unexpected shutdowns to loss of communication between components. Excessive battery discharge may damage the battery and interrupt therapy. The following table outlines documented clinical consequences of power outages in infusion pump operation:

Clinical Consequence | Description |

|---|---|

Unexpected Shutdown | Device ceases operation without warning, leading to loss of therapy. |

Loss of Communication | Incorrect voltage can disrupt communication between components, causing therapy loss. |

Excessive Battery Discharge | Can damage batteries and interrupt therapy. |

Infection | Occurs frequently due to product component failure. |

Overdose | Can lead to serious adverse effects such as respiratory depression or death. |

Underdose | Results in delay or interruption of therapy, potentially causing serious injury or death. |

Interruption of Therapy | Main hazard from unexpected shutdowns, leading to serious injuries. |

Equipment Faults | Includes sensor failure, pump door breakdown, and occlusion, contributing to power failure risks. |

Medical-grade lithium battery packs reduce the risk of power outages by providing reliable backup power. Healthcare facilities must address power outages with robust battery management systems and backup solutions.

1.3 Regulatory Standards

Regulatory standards ensure infusion pumps remain safe and effective during power outages. The FDA requires rigorous testing and quality assurance for all battery components. International standards from the International Electrotechnical Commission (IEC) specify requirements for battery performance, safety, and reliability. Devices must meet UL® and IEC safety requirements, preventing electrical shocks, short circuits, and overvoltage conditions. Portability and efficiency remain critical, especially in environments where power outages can disrupt patient care. Compliance with these standards protects patients and supports continuous operation, even during unexpected power outages.

Part 2: Infusion Pump Battery Design

2.1 Lithium Battery Technologies

Infusion pump battery design relies heavily on advanced lithium battery chemistries. Lithium-ion (NMC), lithium iron phosphate (LiFePO4), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), and lithium titanate (LTO) each offer unique benefits for medical applications. These chemistries deliver high energy density, long cycle life, and stable platform voltage, making them ideal for infusion pumps that require continuous and reliable power.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

NMC | 3.6–3.7 | 150–220 | 1000–2000 |

LiFePO4 | 3.2–3.3 | 90–160 | 2000–7000 |

LCO | 3.7 | 150–200 | 500–1000 |

LMO | 3.7 | 100–150 | 300–700 |

LTO | 2.3 | 70–80 | 7000–20000 |

Lithium-ion and lithium-polymer batteries stand out in infusion pump battery design due to their lightweight construction and high energy output. For example, the PS-1000 PCA infusion pump can operate for up to five days without a recharge under certain conditions. This extended runtime reduces the need for frequent maintenance and supports uninterrupted therapy.

Lithium-ion batteries typically achieve 700–950 cycles, while nickel-metal hydride (NiMH) batteries range from 500–800 cycles.

Under optimal conditions, lithium batteries can reach tens of thousands of cycles, making them suitable for devices that require frequent charging.

Strict temperature management is necessary for lithium batteries to prevent thermal runaway, but their performance and longevity outweigh these challenges in controlled medical environments.

Lithium battery packs also find applications in robotics, security systems, infrastructure, consumer electronics, and industrial sectors. Their adaptability and reliability make them a preferred choice for infusion pump battery design in healthcare.

2.2 Disposable vs. Rechargeable Batteries

Infusion pump battery design must balance the use of disposable and rechargeable batteries. Disposable batteries, such as those used in the MiniMed™ 780G insulin pump, offer convenience and immediate replacement. However, they pose environmental risks. Incineration of disposable batteries releases toxic gases and heavy metals, contaminating groundwater and harming public health.

Rechargeable batteries, like those in Medtronic Guardian transmitters, last up to one year and require charging only once a week. This approach significantly reduces battery waste and supports sustainable practices in healthcare. Hospitals and clinics prefer rechargeable lithium battery packs for infusion pumps because they lower operational costs and minimize environmental impact.

Tip: Healthcare facilities should prioritize rechargeable battery solutions to support sustainability goals and reduce hazardous waste.

In some cases, infusion pumps operate on AC power with a rechargeable backup battery. This configuration ensures continuous operation during power interruptions. Deep cycle batteries play a crucial role in these systems. They provide long-lasting, consistent energy and maintain stable power output even with frequent discharge and recharge cycles. This reliability is essential for life-saving devices that must operate without interruption.

2.3 Selection Criteria

Healthcare facilities evaluate several criteria when selecting batteries for infusion pump battery design. The following table compares lithium-ion and NiMH batteries based on key performance metrics:

Criteria | Lithium-Ion Batteries | NiMH Batteries |

|---|---|---|

Energy Density | Up to 250 Wh/kg | Around 100 Wh/kg |

Weight | Approximately 30% lighter than NiMH | Heavier than lithium-ion |

Longevity | Over 500 cycles at 80% capacity | Fewer cycles |

Regulatory Compliance | Must meet FDA and IEC standards | Must meet IEC standards |

Facilities also consider:

Compliance with ANSI/AAMI ES 60601-1 for medical electrical equipment.

IEC 60086-4 and IEC 60086-5 for primary cell batteries.

UL2054 for household and commercial batteries.

FDA requirements for lithium batteries.

Deep cycle batteries enhance the reliability of infusion pump battery design. They deliver stable power over extended periods and withstand frequent charge-discharge cycles. This makes them indispensable in medical settings where continuous infusion is critical.

Infusion pump battery design must address energy density, weight, longevity, and regulatory compliance. By selecting the right lithium battery chemistry and configuration, healthcare providers ensure safe, reliable, and efficient infusion therapy for patients.

Part 3: Design Strategies and Backup Systems

3.1 Battery Management Systems (BMS)

Battery management systems play a vital role in ensuring the safety and efficiency of battery backup in infusion pumps. These intelligent systems monitor voltage, current, and temperature in real time. They prevent overcharging, deep discharge, and overheating, which can damage lithium battery packs and compromise patient safety. A reliable BMS extends battery life and maintains consistent performance, even in demanding clinical environments.

Modern BMS solutions use advanced algorithms to balance cells within lithium battery packs. This balancing ensures each cell operates within safe limits, reducing the risk of failure. Medical device manufacturers often select BMS platforms that support remote diagnostics and predictive maintenance. These features help healthcare facilities identify potential issues before they lead to downtime.

For more information on BMS and protection circuit modules, visit this resource.

Note: A reliable BMS is essential for battery backup power systems in infusion pumps, robotics, security systems, and industrial applications. It provides the foundation for safe and continuous operation.

3.2 Redundancy and Backup Power

Redundancy forms the backbone of reliable battery backup in medical devices. Infusion pumps often integrate secondary batteries to ensure continuous operation during unexpected power events. When the primary battery fails or depletes, the system automatically switches to the backup battery. This seamless transition prevents therapy interruptions and protects patient safety.

Manufacturers design battery backup power systems with multiple layers of protection. Alarm systems alert clinical staff to low battery levels or switchover events. These alarms provide time for intervention before therapy is disrupted. Automatic switchover mechanisms eliminate manual intervention, reducing the risk of human error.

Backup systems in infusion pumps must meet strict regulatory standards. They undergo rigorous testing to verify performance under various conditions. Reliable battery backup ensures that infusion pumps deliver medication without interruption, even during power outages or equipment faults.

Tip: Hospitals should regularly test backup systems and maintain detailed records. This practice supports compliance and ensures reliable operation during emergencies.

3.3 UPS and External Options

Uninterruptible power supply (UPS) systems provide an additional layer of protection for infusion pumps and other critical medical devices. Healthcare facilities integrate UPS systems with battery backup to maintain continuous operation during power failures. Several design considerations help ensure reliable performance:

Regulatory compliance remains essential for patient safety and operational reliability.

Modular UPS systems enhance scalability and localized redundancy, supporting continuous operation.

Selecting the right battery type and understanding its maintenance requirements is vital, as batteries often represent the weakest link in UPS systems.

Battery backup power systems in UPS configurations often use lithium iron phosphate (LiFePO4) or lithium-ion (NMC) chemistries. These batteries deliver high energy density, long cycle life, and stable platform voltage. For example, LiFePO4 batteries offer a platform voltage of 3.2–3.3 V, energy density of 90–160 Wh/kg, and cycle life of 2,000–7,000 cycles. These characteristics make them ideal for reliable backup power in healthcare, infrastructure, and industrial sectors.

External battery backup options, such as portable battery packs, support mobile infusion pumps in ambulatory care and emergency response. These solutions provide reliable power when access to AC outlets is limited. Facilities often deploy battery backup power systems in robotics, security systems, and consumer electronics, where continuous operation is critical.

Alert: Regular maintenance and timely replacement of batteries in UPS and external backup systems are crucial. Neglecting battery health can compromise the reliability of backup power and put patient safety at risk.

Part 4: Reliability and Best Practices

4.1 Safety and Compliance

Manufacturers of life-sustaining medical equipment must adhere to strict safety standards and regulatory protocols. The FDA, IEC, and UL require comprehensive testing for lithium battery packs used in infusion pumps. These standards ensure uninterrupted power and emergency power during critical care. Testing protocols include electrical safety, thermal management, and performance under stress. Facilities must document compliance to meet audit requirements and maintain certifications. Companies also address conflict minerals in their supply chain, supporting ethical sourcing. For more information, see the conflict minerals statement.

4.2 Maintenance Tips

Preventive maintenance ensures uninterrupted care and reliable medical grade battery backup. Healthcare teams follow a structured approach:

Conduct regular safety checks to confirm all critical features operate correctly.

Document maintenance activities to track equipment condition and compliance.

Train staff to recognize malfunctions and use devices properly.

Replace worn-out parts before failures occur.

Test pump mechanisms and flow sensors for accurate medication delivery.

Calibrate control panels and user interfaces to prevent errors.

Maintain alarm systems for patient safety.

Clean and sanitize components to reduce health risks.

Inspect tubing and connections for leaks or blockages.

These steps help maintain stable battery and power supply, supporting uninterrupted power for life-sustaining medical equipment.

Tip: Regular maintenance of lithium battery packs reduces downtime and extends device lifespan.

4.3 Innovations

Recent innovations in lithium battery packs drive improvements in medical grade battery backup and emergency power systems. Manufacturers now use advanced chemistries such as lithium iron phosphate (LiFePO4) and lithium-ion (NMC) to achieve higher energy density, longer cycle life, and stable platform voltage. These batteries support uninterrupted care in hospitals, robotics, security systems, and industrial applications. Smart battery management systems enable predictive maintenance and remote diagnostics, reducing the risk of unexpected failures. Companies also focus on sustainability by adopting eco-friendly materials and recycling programs. Learn more about sustainable practices in battery design here.

Infusion pump battery design and backup systems deliver continuous, safe operation in clinical environments. Advanced battery fail-safe systems and integrated sensors protect against power loss and infusion complications:

Battery fail-safe systems provide backup power during outages, ensuring uninterrupted medication delivery.

Sensors detect air and pressure changes, preventing infusion risks.

Lithium battery technologies offer key advantages:

Benefit | Description |

|---|---|

High Energy Density | Compact energy storage fits medical devices and robotics. |

Long Lifespan | Fewer replacements reduce maintenance in healthcare and industry. |

Reliable Power Supply | Consistent operation supports patient safety and critical infrastructure. |

Compact Size | Enables innovative designs in medical and security systems. |

Adopting best practices and staying informed on battery innovations ensures reliable, compliant performance across sectors.

FAQ

What makes lithium battery packs ideal for medical equipment?

Lithium battery packs deliver high energy density, long cycle life, and stable platform voltage. Medical equipment in hospitals and clinics relies on these batteries for uninterrupted operation. Designers select lithium iron phosphate, lithium-ion, and lithium cobalt oxide chemistries for their reliability in medical equipment and other critical sectors.

How do battery management systems improve safety in medical equipment?

Battery management systems monitor voltage, current, and temperature in real time. Medical equipment benefits from these systems because they prevent overcharging and overheating. Hospitals use battery management systems to extend battery life and maintain safe operation in infusion pumps and other medical equipment.

Why do hospitals prefer rechargeable lithium battery packs for medical equipment?

Hospitals choose rechargeable lithium battery packs for medical equipment due to lower operational costs and reduced environmental impact. Medical equipment with rechargeable batteries requires less frequent replacement. Clinics and healthcare facilities also benefit from sustainable practices when using lithium battery packs in medical equipment.

What regulatory standards apply to lithium battery packs in medical equipment?

Medical equipment must comply with FDA, IEC, and UL standards. Lithium battery packs undergo rigorous testing for electrical safety, thermal management, and performance. Hospitals document compliance to maintain certifications. Regulatory standards protect patients and ensure medical equipment operates safely with lithium battery packs.

Can lithium battery packs support medical equipment in other industries?

Lithium battery packs power medical equipment in hospitals and clinics. These batteries also support robotics, security systems, infrastructure, consumer electronics, and industrial sectors. Medical equipment designers rely on lithium battery packs for reliable energy storage and continuous operation in diverse application scenarios.