You face unprecedented pressure to understand and implement the EU battery regulations. Non-compliance can remove your batteries from the EU market, threaten your reputation, and expose you to strict penalties. The regulation covers lithium battery packs at every stage. You must act quickly to secure compliance, protect your business, and unlock new opportunities.

Failure to meet environmental and recycled content targets will result in significant financial losses and trade barriers for manufacturers, especially in the EU.

Explore the Interpretation of the EU Battery Regulations to strengthen your competitive position.

Key Takeaways

Understand and comply with the EU battery regulations to avoid penalties and keep your products in the market. Focus on sustainability, safety, labeling, and digital battery passports to meet all requirements.

Adopt circular economy practices by designing batteries for easy replacement, using recycled materials, and meeting strict collection and recycling targets. This approach reduces environmental impact and supports long-term business success.

Use digital tools and strong supplier partnerships to improve data management, traceability, and compliance. Early action on these fronts can give your business a competitive edge in the evolving EU energy market.

Part 1: Interpretation of the EU Battery Regulations

1.1 Scope and Coverage

You need a clear interpretation of the EU battery regulations to navigate compliance and seize new opportunities in the energy sector. The EU Battery Regulation 2023/1542 sets a unified legal framework for all batteries placed on the EU market, with a strong focus on lithium battery packs used in medical, robotics, security, infrastructure, consumer electronics, and industrial applications. This new batteries regulation aims to harmonize standards, drive sustainability, and support the European Green Deal.

Key objectives of the regulation include:

Strengthening the EU internal market by regulating battery products, processes, and waste management.

Promoting a circular economy by encouraging reuse, recycling, and responsible battery production.

Reducing environmental and social impacts throughout the battery lifecycle.

The scope of the new batteries regulation covers nearly all battery types except those for military, space, or nuclear use. You must pay special attention to lithium battery packs, as they fall under several categories depending on their application and weight. The regulation applies to:

Battery Category | Key Characteristics |

|---|---|

Portable battery | Sealed, ≤5 kg, not classified as other types |

Starting, Lighting, Ignition (SLI) | Used for vehicle ignition, lighting, or starting; auxiliary or backup for vehicles/mechanical transport |

Light Means of Transport (LMT) | Sealed, ≤25 kg, powers L-type vehicles (e-bikes, scooters), not classified as EV batteries |

Industrial battery | Designed for industrial use, >5 kg, not LMT/SLI/EV |

Electric Vehicle (EV) battery | Used for hybrid or battery electric vehicle traction, for L-type vehicles >25 kg |

Lithium battery packs are included in these categories, especially as portable, EV, or industrial batteries. The regulation covers both rechargeable and non-rechargeable batteries, as well as cells, modules, and complete battery systems.

You must also comply with mandatory requirements for sustainability, safety, labeling, due diligence, waste management, and the digital battery passport. These requirements ensure transparency and traceability across the entire battery value chain.

1.2 Circular Economy Goals

The interpretation of the EU battery regulations reveals a strong commitment to the circular economy and sustainability. The regulation covers the entire lifecycle of batteries, from raw material extraction to end-of-life recycling and repurposing. You must design and produce batteries that meet strict performance, durability, and labeling standards, including QR codes and digital passports for traceability.

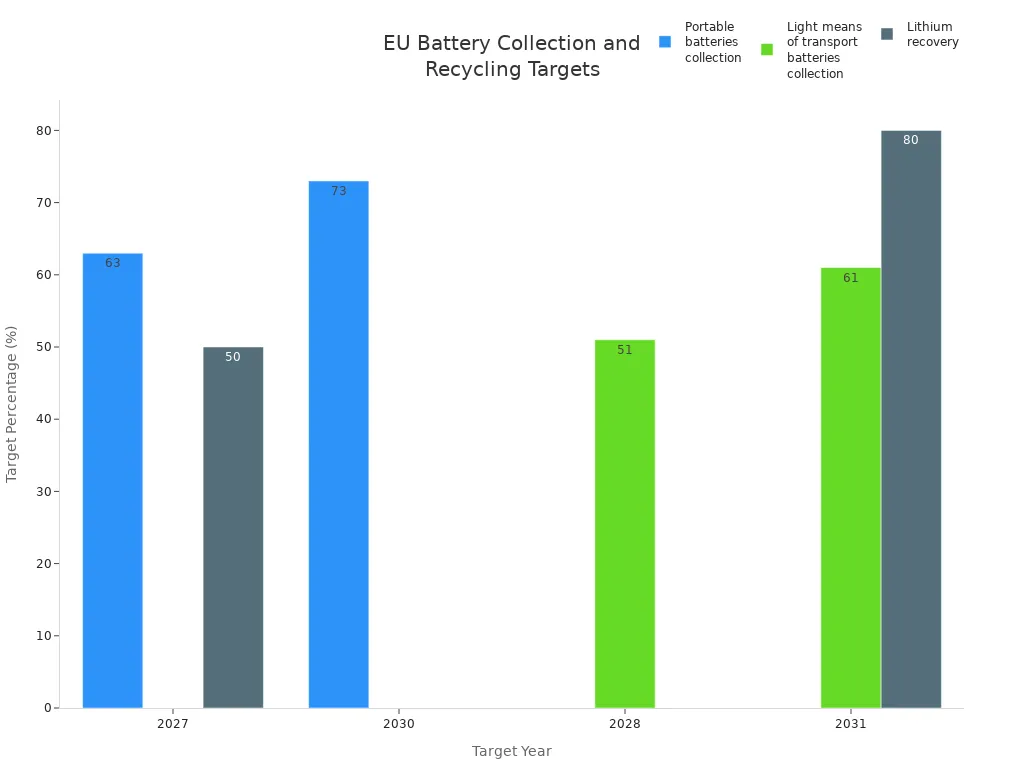

The regulation sets ambitious recycling targets and efficient take-back systems for waste batteries. For example, you must achieve a 63% collection rate for portable batteries by 2027 and 73% by 2030. For light means of transport batteries, the targets are 51% by 2028 and 61% by 2031.

You must also meet minimum recycled content levels for critical materials such as cobalt, lead, lithium, and nickel. This supports the circular economy by reducing reliance on virgin resources and minimizing environmental impact.

The regulation enforces extended producer responsibility, holding you accountable for the environmental impacts of your batteries throughout their lifecycle.

You need to implement supply chain due diligence to ensure ethical sourcing of battery materials. For more on conflict minerals, see our conflict minerals statement.

The new batteries regulation encourages you to adopt low-carbon technologies and responsible recycling practices. This aligns with the European Green Deal and the EU Circular Economy Action Plan, making sustainable battery production the norm.

The regulation also introduces digital solutions such as the battery passport, which enhances transparency and supports circular business models. You can leverage these tools to differentiate your products and demonstrate compliance to customers and regulators.

If you want to learn more about how to integrate sustainability into your battery production and supply chain, visit Our Approach to Sustainability.

The interpretation of the EU battery regulations shows that you must adapt your operations to meet new requirements for energy efficiency, recycling, and circularity. By doing so, you not only comply with the law but also position your business as a leader in the evolving energy market. For customized consulting on compliance and competitive strategy, explore our custom battery solutions.

Part 2: Regulatory Requirements

2.1 Battery Passport Regulations

You must comply with the latest battery passport regulations if you manufacture or supply lithium battery packs for the EU market. The regulation requires a digital battery passport for each battery above 2 kWh, including those used in industrial, light means of transport (LMT), and electric vehicle (EV) applications. This passport serves as a digital record, accessible via a QR code, and contains over 90 mandatory data attributes.

The DIN DKE SPEC 99100 standard guides you on the required data, which includes:

1. Unique identification and QR code for each battery. 2. Accurate, up-to-date information maintained by all responsible parties. 3. Proven origin of materials for supply chain transparency. 4. Carbon footprint data covering all lifecycle stages. 5. Circularity information, such as safety instructions for recyclers and spare parts availability. 6. Performance data, including capacity, estimated lifetime, and efficiency ratios.

Mandatory Requirement | Description |

|---|---|

Unique Identification | Each battery must have a unique serial number visibly marked on it. |

Basic Characteristics | Includes production date, battery type and model, chemical composition, and intended use. |

Performance and Durability | Information on battery performance throughout its lifecycle, updated by repair or repurposing parties. |

Digital Accessibility | Battery passport must be an electronic record accessible via QR code. |

Lifecycle Data Updates | Data must be updated throughout the battery’s lifecycle, including repair, refurbishment, and recycling. |

Applicability | Applies to industrial, LMT, and EV batteries above 2 kWh, effective from 18 February 2027. |

Comprehensive Data | Includes materials, components, carbon footprint, and lifecycle information. |

The battery passport regulations support traceability, transparency, and compliance with battery recycling regulations. You can use the passport to demonstrate responsible sourcing, report on recycled content, and manage end-of-life processes. The European Commission maintains a central registry to verify authenticity and compliance, while you control access to sensitive data. This approach helps you meet regulatory requirements and build trust with partners and customers.

Tip: Start preparing your data management systems now to ensure a smooth transition before the 2027 deadline.

2.2 Labeling and QR Codes

Labeling and QR code requirements form a critical part of the regulation. From August 2026, you must label all batteries with essential information, and from February 2027, you must add a QR code that links to the digital battery passport for industrial, LMT, and EV batteries above 2 kWh.

The QR code provides instant access to detailed battery-specific information, including material composition, hazardous substances, recycled content, carbon footprint, expected lifetime, usable temperature ranges, and safety instructions.

The QR code must be visible, indelible, and permanently attached to the battery or its packaging.

The CE marking, product ID, company details, manufacturing date, weight, capacity, and chemistry must appear on the label.

You must also display the separate collection symbol and chemical symbols for hazardous materials.

Requirement Category | Details |

|---|---|

CE Marking | Permanently attached to battery/packaging and documents; affixed before sale/use; may include risk pictograms |

General Label Information | Product ID, company ID, manufacturing date, weight, capacity, chemistry, hazardous substances |

Separate Collection Symbol | Max 5×5 cm; covers ≥3% of largest battery side or ≥1.5% of cylindrical cell surface; printed above chemical symbol |

QR Code Requirements | LMT, industrial (>2 kWh), EV batteries: link to digital battery passport; others: access to general info |

Carbon Footprint Labeling | Required on EV, LMT, and rechargeable industrial batteries >2 kWh; must be obvious, readable, permanent |

Additional Labeling | Rechargeable portable, LMT, SLI batteries: label capacity; non-rechargeable: label “non-rechargeable” |

QR codes improve traceability and compliance by providing a standardized, accessible method for all stakeholders to verify battery information. You can use blockchain technology to enhance data security and integrity. This system supports the entire battery lifecycle, from raw material sourcing to recycling, and helps you meet the EU’s strict requirements.

Note: The QR code and labeling requirements apply to all batteries, but the digital battery passport is mandatory only for industrial, LMT, and EV batteries above 2 kWh.

2.3 Recycled Content

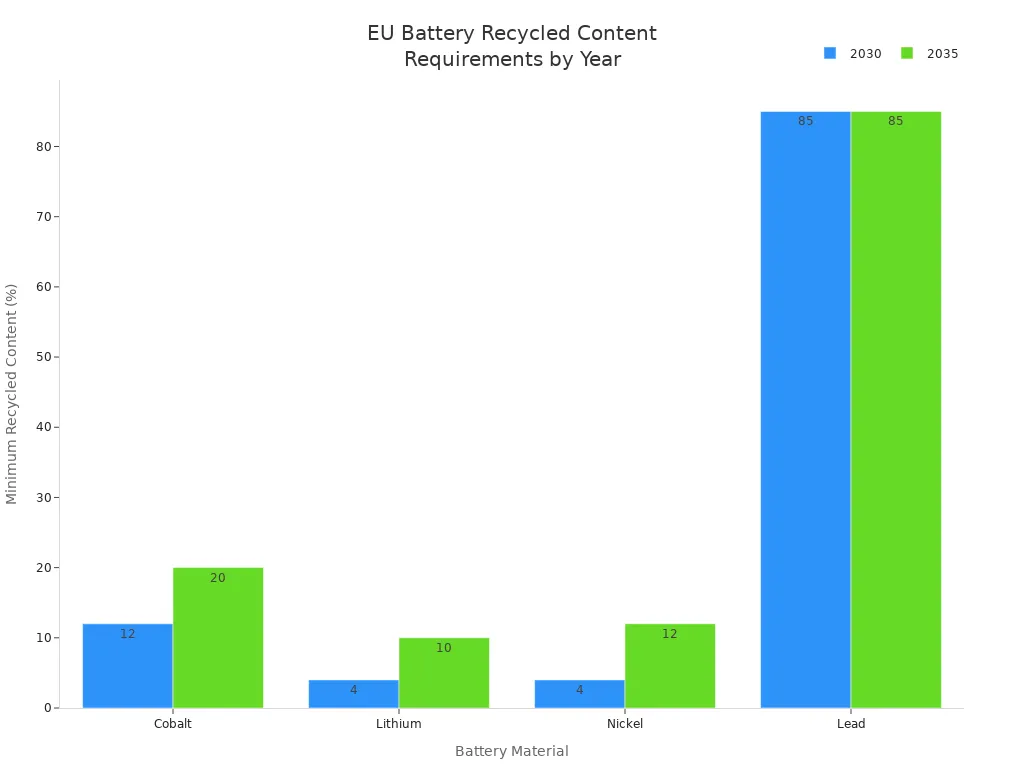

The regulation sets ambitious minimum recycled content requirements for batteries. You must ensure that your lithium battery packs contain a specific percentage of recycled cobalt, lead, lithium, and nickel. These targets increase over time, pushing you to adopt sustainable sourcing and manufacturing practices.

Battery Material | Minimum Recycled Content 2030 (%) | Minimum Recycled Content 2035 (%) |

|---|---|---|

Cobalt | 12 | 20 |

Lithium | 4 | 10 |

Nickel | 4 | 12 |

Lead | 85 | 85 |

Recycled content requirements drive a shift toward domestic sourcing of critical battery metals, reducing logistics and CO2 emissions. Using recycled metals can lower emissions by up to 40% for lithium, 10% for nickel, and 8% for cobalt compared to virgin materials. You must adapt your battery designs and supply chains to integrate recycled materials and support circularity. Extended Producer Responsibility policies require you to ensure batteries are recycled at end-of-life, influencing your manufacturing processes.

For more on sustainable battery production, see Our Approach to Sustainability.

2.4 Collection and Recycling Targets

The EU regulation introduces strict collection and recycling targets for batteries. You must achieve these targets to remain compliant and support the circular economy.

Target Category | Target Year | Target Percentage |

|---|---|---|

Collection of waste portable batteries | 2027 | 63% |

Collection of waste portable batteries | 2030 | 73% |

Collection of waste batteries from light means of transport | 2028 | 51% |

Collection of waste batteries from light means of transport | 2031 | 61% |

Lithium recovery from waste batteries | 2027 | 50% |

Lithium recovery from waste batteries | 2031 | 80% |

The regulation expands the scope to include more battery types and introduces material-specific recovery targets for lithium, cobalt, and nickel. You must implement efficient take-back systems and recycling processes to meet these goals. The approach shifts from basic recycling participation to a lifecycle and circular economy model, emphasizing producer responsibility, safety standards, and traceability.

Efficient battery recycling supports compliance and reduces your environmental impact. For more on battery recycling regulations, review the latest updates from the European Commission.

2.5 Replaceable Battery

The regulation requires that portable batteries in devices must be safely removable and replaceable by the end user using commercially available tools. This requirement applies from February 2027 and aims to improve repairability, extend product life, and support recycling.

Devices must operate with both original and compatible batteries.

Spare batteries must be available at a reasonable price for at least five years after the last unit is placed on the market.

Instructions and safety information on battery use, removal, and replacement must be provided and permanently available online.

Some exceptions exist for products used in wet environments, certain medical devices, and devices where power continuity is critical.

These requirements directly influence the physical design and assembly of lithium battery packs. You must design for easy access and replacement, support third-party repairers, and ensure safety and compliance. Modular, standardized, and sustainable battery designs will help you meet both regulatory and market demands.

Part 3: Challenges and Solutions

3.1 Data and Reporting

You face complex data and reporting challenges as you work to comply with the EU battery regulations. Managing information across the entire lifecycle of batteries requires robust systems and clear coordination with supply chain partners. The table below highlights the main obstacles:

Challenge Category | Description |

|---|---|

Supply Chain Transparency | Enhanced coordination needed with all partners to meet strict requirements. |

Data Complexity | Over 90 regulatory articles require detailed data across the battery lifecycle. |

Compliance Costs | High costs for data management and regulatory reporting. |

Material Shortages | Limited raw materials impact both production and compliance. |

Technical Standards | Evolving standards create uncertainty in compliance efforts. |

Tools and Platforms | Need for advanced tools to manage chemical data, carbon footprint, and reporting. |

Reporting and Assessment | Streamlined tools and proactive assessments are essential for regulatory navigation. |

Centralized document management systems, such as those from CHEMTREC, help you consolidate lithium battery compliance data. Digital solutions like BMIS and UL’s incident reporting database support real-time monitoring and transparent reporting. These tools enable you to track batteries, improve safety, and meet EU requirements for energy storage and recycling.

3.2 Cost Management

Cost management is critical as you adapt to new EU regulations for batteries in the energy sector. You can control expenses by investing in integrated ERP systems that centralize compliance, automate documentation, and track supplier performance. Consider these strategies:

Use ERP platforms for real-time monitoring and early risk detection.

Centralize data collection to simplify audits and inspections.

Automate compliance reporting to reduce manual errors.

Train staff regularly on regulatory updates.

Benchmark costs against industry peers and adjust pricing as needed.

Embrace energy efficiency and sustainability initiatives to lower operational costs.

Outsource non-core activities to scale efficiently.

A culture of continuous improvement and preventive maintenance helps you avoid downtime and extend the life of batteries, especially in demanding energy applications.

3.3 Supplier Engagement

Strong supplier engagement ensures you meet EU battery regulation standards and maintain energy supply chain resilience. Follow these steps:

Conduct a gap analysis to identify compliance shortfalls.

Build a detailed plan for phased regulatory obligations.

Audit suppliers and provide targeted training on compliance.

Communicate clear goals and expectations to all partners.

Use technology platforms for data intelligence and risk management.

Collaborate with legal and regulatory experts for due diligence.

Proactive engagement, long-term partnerships, and regular audits improve transparency and accountability. Training and incentives help suppliers align with your sustainability and energy goals. Technologies like blockchain and AI enhance traceability, supporting compliance for batteries in Medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Part 4: EU Battery Strategy

4.1 Market Impact

You operate in a rapidly changing energy market shaped by the EU battery strategy. The regulation introduces strict requirements for sustainability, safety, and circular economy, directly affecting lithium battery pack manufacturers. You must adapt to new rules that cover every vehicle segment, from electric vehicle production to industrial and consumer electronics. The regulation mandates consumer-removable batteries by 2027, which challenges your product design and may increase costs. You face the need to create EU-specific variants, which can fragment the market and slow the energy transition.

The EU battery strategy aims to harmonize the legal framework for all battery types, supporting the energy transition and reducing reliance on non-EU raw materials. This approach increases complexity and compliance costs, especially for companies producing batteries for vehicles and energy storage. You must navigate overlapping regulations and prepare for extensive documentation, which can impact your ability to innovate and compete in the European market.

Note: The regulation’s focus on circularity may paradoxically increase electronic waste if not managed carefully, as more DIY battery replacements could reduce recycling efficiency.

4.2 Competitive Advantage

You can turn the EU battery strategy into a competitive advantage by acting early. Proactive compliance gives you access to advanced, sustainability-focused markets and positions your brand as an ESG leader. Early adoption of the Digital Battery Passport streamlines supply chain management and ensures responsible sourcing for every vehicle and energy application.

You improve operational efficiency by embedding traceability and real-time data capture at every stage of production.

Upgrading workflows for compliance future-proofs your business against evolving energy transition demands.

The strategy drives innovation in modular, repairable, and recyclable lithium battery packs, extending their value across multiple energy cycles.

You reduce long-term costs by automating data collection and lifecycle planning, which supports second-life battery applications in energy storage and vehicle fleets. By aligning with the EU battery strategy, you build resilience and unlock new opportunities in the global energy transition.

You gain a competitive edge by prioritizing compliance and continuous improvement in lithium battery pack operations. Assess your readiness, update your processes, and leverage digital tools. For complex regulatory challenges, seek expert guidance through our customized consulting services. Stay proactive to lead in the evolving EU market.

FAQ

1. What is the digital battery passport, and how does it affect lithium battery pack compliance?

The digital battery passport stores essential data for each lithium battery pack. You use it to prove compliance, track lifecycle, and support recycling.

2. How do the EU regulations impact lithium battery pack design for industrial applications?

You must design lithium battery packs for easy replacement, clear labeling, and traceability. These steps ensure compliance and support sustainability in industrial sectors.

3. Where can I get expert guidance on EU battery regulation compliance for my business?

You can contact Large Power for custom battery consulting. Our team helps you navigate compliance, optimize supply chains, and maintain your competitive edge.