ISO 13485 sets a rigorous standard for quality and safety in medical battery manufacturing, driving excellence in lithium battery pack production for healthcare applications. Manufacturers achieve compliance to assure healthcare providers of reliable, safe power sources. The standard strengthens risk management and streamlines process efficiency, supporting regulatory approval.

Battery failures cause 1.42% of medical device recalls, highlighting the need for robust quality systems.

Adopting ISO 13485 reduces recalls, improves reliability, and expands market opportunities for medical, robotics, and industrial sectors.

Key Takeaways

ISO 13485 ensures high quality and safety in medical battery manufacturing, reducing the risk of recalls.

Implementing strict documentation and traceability helps manufacturers comply with regulations and improve product reliability.

Continuous improvement practices foster innovation and enhance the safety of lithium battery packs in critical applications.

Effective supplier management and qualification are essential for maintaining quality and reliability in battery production.

ISO 13485 certification opens doors to global markets, boosting business growth and customer trust.

Part1: ISO 13485 in Medical Battery Manufacturing

1.1 Overview of ISO 13485

ISO 13485 stands as the global benchmark for quality management systems in medical device manufacturing. The standard addresses the unique challenges of medical battery manufacturing, especially for lithium battery packs used in critical medical applications. Manufacturers must implement robust procedures to ensure safety and performance. ISO 13485 standards require strict documentation, full traceability, and adherence to cleanliness protocols. These requirements apply to Class 2A, 2B, and 3 medical products, where reliability and patient safety remain paramount.

Note: Lithium battery packs, including lithium iron phosphate (LiFePO4), lithium cobalt oxide (LiCoO2), and lithium nickel manganese cobalt oxide (NMC), serve diverse roles in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Each chemistry offers distinct advantages in energy density, cycle life, and safety profile.

Lithium Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Profile | Typical Applications |

|---|---|---|---|---|

Lithium Iron Phosphate | 90-160 | 2000+ | High thermal stability | Medical, robotics, infrastructure |

Lithium Cobalt Oxide | 150-200 | 500-1000 | Moderate | Consumer electronics, medical |

Lithium NMC | 150-220 | 1000-2000 | Good | Industrial, security, medical |

ISO 13485 differs from general quality standards such as ISO 9001. It targets regulatory requirements and risk management specific to medical device oems and battery manufacturing. The standard mandates comprehensive documentation and process validation, ensuring safe and effective products for healthcare environments.

1.2 Importance for Medical Battery Producers

Medical battery producers face increasing pressure to deliver reliable power sources for life-critical devices. ISO 13485 certification provides a structured framework for quality management, driving higher product quality and safety. Manufacturers must validate every step in the production process, maintain detailed records, and implement stringent controls to meet regulatory requirements.

Key requirements for medical battery manufacturing include:

Comprehensive documentation practices to support audits and regulatory compliance.

Full traceability from raw materials to finished lithium battery packs.

Adherence to cleanliness and cross-contamination protocols.

Validation and testing at every stage of manufacturing.

These practices reduce the risk of product recalls and lawsuits. They also promote continual improvement and employee engagement. Medical device oems benefit from enhanced reliability and safety, which strengthens their reputation in the market.

Tip: Producers should establish partnerships with certified body suppliers and maintain a conflict minerals statement to support ethical sourcing and regulatory compliance. Read more about conflict minerals statement

1.3 Regulatory Compliance and Market Access

ISO 13485 certification opens doors to global markets by aligning with regulatory requirements in major regions. Regulatory bodies recognize the standard as a prerequisite for medical device manufacturing and battery manufacturing.

Region | Regulatory Body | Requirement |

|---|---|---|

EU | MDR 2017/745 | ISO 13485:2016 certification for medical device manufacturers and related entities |

USA | FDA | Proposed rule to harmonize QSR with ISO 13485, making it mandatory |

Japan | MHLW MO 169 | Compliance with ISO 13485:2016 and additional QMS requirements |

Malaysia | Medical Device Act (Act 737) | ISO 13485 compliance required for manufacturers |

Singapore | Health Products (Medical Device) Regulations 2010 | ISO 13485-compliant QMS required |

Australia | Therapeutic Goods (Conformity Assessment Standard for Quality Management Systems) Order 2019 | ISO 13485:2016 as the conformity assessment standard |

ISO 13485 provides a framework for regulatory compliance, ensuring manufacturers deliver safe and effective products. The standard aligns with FDA regulations and supports participation in the Medical Device Single Audit Program (MDSAP), reducing audit frequency and optimizing resources. Certified body recognition streamlines approval processes and accelerates market entry for medical battery producers.

Manufacturers in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors rely on ISO 13485 to meet regulatory requirements and deliver products that meet the highest standards of safety and performance.

Part2: Quality Management Systems

2.1 Core QMS Elements under ISO 13485

A robust quality management system forms the backbone of medical battery manufacturing. ISO 13485 outlines essential elements that guide manufacturers in producing lithium battery packs for medical devices, robotics, security, infrastructure, consumer electronics, and industrial sectors. The following table summarizes these core elements and their descriptions:

Core Element | Description |

|---|---|

Management Responsibility | Top management’s commitment drives the effectiveness of the QMS, ensuring resources and focus on quality improvement. |

Customer Focus | Understanding and responding to both direct customers and patients’ needs ensures the safety and performance of medical devices. |

Risk-Based Decision Making | Decisions consider the unique risks associated with medical devices, focusing on the probability and severity of potential harm. |

Document Everything | Comprehensive documentation of processes and records maintains an effective QMS, ensuring compliance and traceability. |

Improvement is Essential | Continuous improvement adapts to regulatory changes and enhances process and product quality, fostering employee engagement. |

Manufacturers use these elements to achieve consistent product quality. The table below shows how each QMS element contributes to reliability in lithium battery pack production:

QMS Element | Contribution to Product Quality |

|---|---|

Quality Policy | Establishes management’s commitment to quality, guiding QMS implementation. |

Organizational Structure | Ensures clear responsibilities and authority, facilitating effective oversight of quality processes. |

Management Review | Assesses QMS effectiveness, ensuring alignment with quality objectives. |

Design Controls | Systematically controls design processes to meet user needs and specifications, crucial for product reliability. |

Document Control | Maintains accuracy and availability of documents, essential for compliance and traceability. |

Production and Process Controls | Monitors production processes to ensure conformity to specifications, directly impacting product quality. |

Purchasing Controls | Ensures that suppliers meet quality standards, affecting the quality of materials used in production. |

Corrective and Preventive Actions | Addresses non-conformities and prevents recurrence, maintaining consistent quality over time. |

Record Keeping | Comprehensive documentation supports traceability and accountability, vital for regulatory compliance. |

2.2 Process Control in Battery Assembly

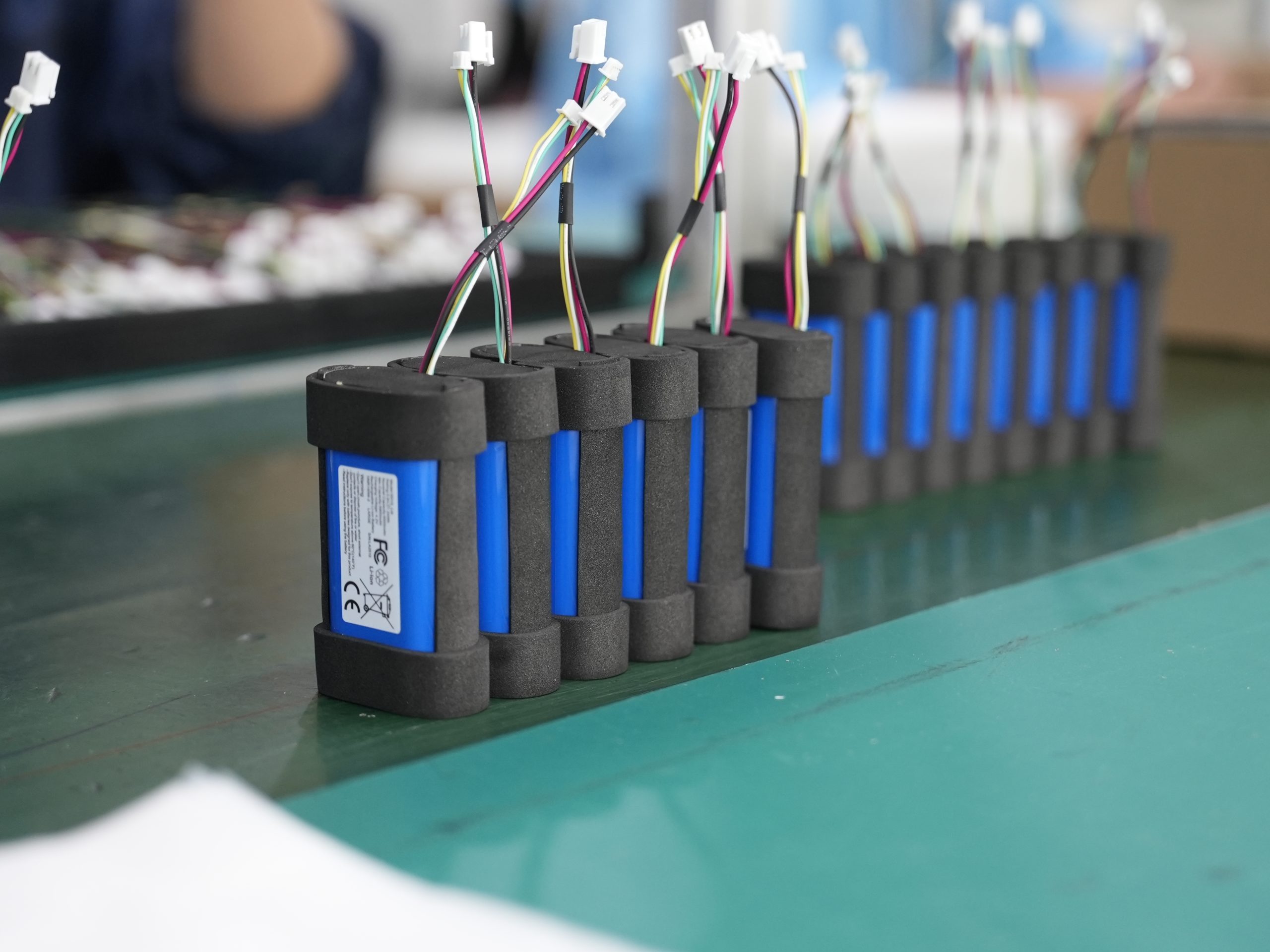

Process control ensures that every lithium battery pack meets strict specifications. Manufacturers implement standardized procedures for lithium iron phosphate (LiFePO4), lithium cobalt oxide (LiCoO2), and lithium nickel manganese cobalt oxide (NMC) chemistries. These controls include automated assembly, real-time monitoring, and rigorous testing. Battery management systems (BMS) play a critical role in maintaining safety and performance. Manufacturers reference internal BMS protocols to optimize charge cycles and prevent thermal runaway.

Tip: Automated inspection systems detect defects early, reducing the risk of nonconforming products entering the market.

Process control supports traceability and compliance, especially in medical devices where reliability is essential. Manufacturers document each step, from cell selection to final assembly, ensuring every pack meets regulatory standards.

2.3 Continuous Improvement Practices

Continuous improvement drives innovation and quality in medical battery manufacturing. Manufacturers measure effectiveness by monitoring QMS results, reporting quality metrics, and controlling nonconforming products. Audits identify areas for improvement, while corrective and preventive actions address root causes.

Monitoring QMS results

Reporting quality metrics

Controlling nonconforming products

Identifying improvement areas through audits

Implementing corrective and preventive actions

These practices foster a culture of engagement and accountability. Manufacturers adapt quickly to regulatory changes and technological advancements, ensuring lithium battery packs remain safe and reliable across all application scenarios.

Part3: Supplier and Component Traceability

3.1 Supplier Qualification

Supplier qualification forms the foundation of quality in medical battery manufacturing. Manufacturers select suppliers based on strict criteria to ensure every lithium battery pack meets the standard for safety and reliability in medical devices and other critical applications. The following table outlines key criteria for supplier qualification under iso 13485:

Criteria | Description |

|---|---|

Quality Management Systems | Suppliers must operate robust quality management systems that comply with iso 13485. |

Safety and Reliability | Components must support safe and reliable operation in medical and industrial environments. |

Thorough Supplier Evaluation | Manufacturers conduct comprehensive evaluations of supplier capabilities and controls. |

Timely Delivery | Suppliers must meet delivery targets to prevent disruptions in manufacturing. |

Traceability of Components | Suppliers must maintain full traceability for all components used in lithium battery packs. |

Manufacturers also investigate supplier quality controls and require certification to iso 9001, iso 13485, or QSR/GMP. Quality in yields quality out, so rigorous supplier selection directly impacts the reliability of lithium iron phosphate, lithium cobalt oxide, and lithium NMC battery packs.

Health Canada, Japan’s MHLW, South Africa’s SAHPRA, and Australia’s TGA all require detailed records of supplier qualifications and risk evaluations to ensure compliance with local regulations.

3.2 Traceability in Medical Battery Manufacturing

Traceability enables manufacturers to track every component from raw material to finished lithium battery pack. This process supports rapid identification and isolation of defective products, which is essential for managing recalls and protecting patient safety. Manufacturers use systematic tracking to enhance supply chain transparency and maintain compliance with the standard.

Traceability allows quick response to recalls in medical, robotics, and industrial sectors.

Accurate records ensure all parties can verify the origin and quality of each component.

Manufacturers support ethical sourcing by maintaining a conflict minerals statement.

Application scenarios such as hospital equipment, surgical robots, and industrial automation systems rely on this level of traceability to ensure uninterrupted operation and regulatory compliance.

3.3 Managing Outsourced Processes

Manufacturers often outsource critical processes in lithium battery pack production. To maintain compliance with iso 13485, they implement best practices for supplier management:

Best Practice | Description |

|---|---|

Supplier Selection | Manufacturers communicate requirements clearly to potential partners. |

They assess supplier capabilities before approval. | |

Continuous Monitoring | Ongoing performance reviews ensure suppliers meet obligations. |

Robust Purchasing Process | |

Risk Management | Controls address risks associated with outsourcing critical manufacturing steps. |

Supplier Performance Monitoring | Regular monitoring detects and resolves issues early. |

Manufacturers use quality assurance agreements, supplier audits, and incoming goods inspections to verify compliance. They also collect feedback from stakeholders and use performance indicators to measure the effectiveness of their quality management system. These controls help ensure that outsourced partners uphold the same standards required for safe and reliable lithium battery packs in all application sectors.

Part4: Risk Management and Safety

4.1 Risk Assessment in Battery Design

ISO 13485 places risk management at the core of medical battery manufacturing. Manufacturers use a structured approach to identify, evaluate, and control risks throughout the design and production of lithium battery packs. This process ensures that batteries used in medical devices, robotics, and industrial systems meet the highest safety standards.

A typical risk assessment process under the standard includes:

Hazard Identification: Teams identify hazards such as thermal runaway, electrolyte leakage, or electrical short circuits in lithium iron phosphate, lithium cobalt oxide, and lithium NMC battery packs.

Risk Estimation: Engineers estimate the likelihood and severity of incidents, considering application scenarios like surgical robots or hospital monitoring equipment.

Risk Control Options Analysis: Teams analyze options such as enhanced battery management systems or improved cell balancing.

Implementation of Risk Controls: Manufacturers apply measures like design changes, protective circuitry, or user training.

Verification of Risk Controls: Quality teams verify that controls effectively reduce risks.

Risk assessment reduces the likelihood of battery-related incidents, protecting both patients and equipment in critical environments.

Lithium Chemistry | Key Risks | Mitigation Strategies | Application Scenarios |

|---|---|---|---|

Lithium Iron Phosphate | Overheating, short circuit | High-temp cutoff, robust BMS, flame-retardant casing | Medical devices, robotics, infrastructure |

Lithium Cobalt Oxide | Thermal runaway, venting | Pressure relief valves, cell balancing, monitoring | Consumer electronics, medical |

Lithium NMC | Overcharge, capacity fade | Advanced charge algorithms, cycle tracking, redundancy | Security, industrial, medical |

4.2 Preventive and Corrective Actions

ISO 13485 requires manufacturers to implement both preventive and corrective actions to address potential and actual nonconformities in lithium battery pack production. These actions form the backbone of continuous improvement and compliance.

Preventive Actions | Description |

|---|---|

Material Selection | Choosing safer materials or components for enhanced reliability. |

User Interface | Improving interface clarity for better usability in medical settings. |

Input Checks | Adding checks to prevent incorrect parameter entry. |

Purpose Restriction | Limiting device use to intended applications. |

System Architecture | Modifying design, such as integrating watchdog circuits. |

Employee Qualification | Enhancing staff training and certification. |

Process Improvement | Refining assembly and testing processes. |

Code Reviews | Increasing software review rigor for embedded BMS. |

Software Requirements | Updating review checklists for software. |

Static Code Analysis | Applying new metrics for code quality in battery management. |

Manufacturers also document all actions and justify any lack of response to complaints. They must demonstrate the effectiveness of these actions, which helps reduce nonconformities and improve product safety. Corrective and preventive action (CAPA) processes address existing issues and proactively identify risks. CAPA ensures compliance, prevents recurrence, and drives continuous improvement. By implementing CAPA, organizations enhance safety and reliability, reducing the chance of safety incidents in medical, robotics, and industrial sectors.

For more on sustainable practices in battery manufacturing, see Sustainability in Medical Battery Production.

4.3 Post-Market Surveillance

Post-market surveillance (PMS) is a critical requirement under ISO 13485. Manufacturers must monitor lithium battery packs after release to ensure ongoing safety and performance in real-world conditions. PMS strategies include:

Element | Description |

|---|---|

Applicability | Defines the scope, such as single battery models or entire product families. |

Data Collection | Gathers data from production, field use, and user feedback. |

Frequency | Sets intervals for data review and analysis. |

Processing Methods | Uses statistical tools to analyze trends and detect issues. |

Indicators | Establishes thresholds for triggering investigations or recalls. |

Complaint Handling | Outlines procedures for managing and resolving complaints. |

Investigations | Details steps for investigating field incidents or failures. |

Reporting | Specifies how to report findings to regulators and stakeholders. |

PMS Outputs | Generates reports for internal and external review. |

CAPA and FSCA | Links PMS findings to corrective and preventive actions, including field safety corrective actions. |

PMCF | Conducts post-market clinical follow-up when required. |

Feedback | Provides insights to design and risk management teams for future improvements. |

PMS data influences future design and manufacturing processes for lithium battery packs. Real-world performance data reveals issues not seen during pre-market testing. Safety monitoring identifies risks and adverse events, prompting timely corrective actions. User feedback informs design updates and labeling improvements. Continuous data analysis refines risk assessments, ensuring compliance with the standard. Lessons learned from PMS drive iterative enhancements, supporting innovation and maintaining a competitive edge in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Effective post-market surveillance closes the loop between product performance and ongoing quality improvement, ensuring lithium battery packs remain safe and reliable throughout their lifecycle.

Part5: Documentation and Compliance

5.1 Documentation Requirements

Manufacturers in the lithium battery pack sector must maintain comprehensive documentation to meet the standard for medical devices. Documentation covers every stage, from design and development to production and post-market activities. Teams record technical specifications for lithium iron phosphate, lithium cobalt oxide, and lithium NMC chemistries. They document testing protocols, risk assessments, and validation results for each application scenario, including robotics and industrial automation.

Battery packs produced under an ISO 13485 system must meet the most rigorous standards in design, development, and documentation.

Documentation supports product safety and reliability. It enables manufacturers to demonstrate compliance during regulatory reviews and supports continuous improvement.

5.2 Record Keeping for Traceability

Effective record keeping ensures traceability throughout the lifecycle of lithium battery packs. Manufacturers track each component, from raw material sourcing to final assembly. They maintain records for supplier qualifications, incoming inspections, and process controls. This approach supports rapid identification of issues and efficient recall management in medical, security, and infrastructure applications.

Clear documentation of the relationship between product components ensures all requirements are met throughout the product lifecycle.

Effective quality management and regulatory compliance are facilitated by mapping requirements against development stages, crucial for demonstrating compliance with standards.

Enhanced risk management allows for quick identification of issues related to medical devices, enabling prompt corrective actions.

Effective supply chain management is supported by tracking the movement of components, ensuring product authenticity and efficient recalls.

Meeting regulatory requirements and maintaining high standards of quality and patient safety throughout the product lifecycle.

Manufacturers use digital systems to store and retrieve records, supporting audits and regulatory submissions.

5.3 Preparing for Audits

Audit preparation requires a systematic approach. Teams review documentation for lithium battery pack production, ensuring records are complete and up to date. They verify that all processes align with the standard and regulatory expectations. Manufacturers conduct internal audits to identify gaps and implement corrective actions before external reviews. They organize records by product type, chemistry, and application scenario, making information accessible for auditors.

Tip: Regular internal audits help manufacturers maintain readiness for regulatory inspections and support ongoing compliance.

Audit readiness strengthens market access and builds trust with healthcare providers and partners in robotics, security, and industrial sectors.

Part6: Benefits for Manufacturers and Healthcare Providers

6.1 Enhanced Reliability and Safety

Manufacturers who implement ISO 13485 in medical battery manufacturing achieve higher reliability and safety standards. Lithium battery packs, including lithium iron phosphate, lithium cobalt oxide, and lithium nickel manganese cobalt oxide, deliver consistent performance in medical devices, robotics, and industrial automation. Healthcare providers trust these batteries to power life-critical equipment, reducing the risk of unexpected failures. Companies build credibility by preventing safety incidents and maintaining compliance with strict regulations.

Note: Reliable lithium battery packs support uninterrupted operation in hospital equipment, surgical robots, and security systems.

6.2 Efficiency in Design and Production

ISO 13485 streamlines design and production processes for lithium battery packs. Manufacturers optimize workflows, reduce waste, and improve resource allocation. Teams use standardized procedures to assemble batteries for medical, robotics, and infrastructure applications. Automated inspection and real-time monitoring enhance quality control, allowing rapid identification of defects. Efficient manufacturing supports faster product development and market entry.

Standardized assembly protocols

Automated quality checks

Reduced production delays

Faster regulatory approvals

Organizations foster a culture of continuous improvement, training employees in risk analysis and problem-solving. This approach drives innovation and supports long-term business growth.

6.3 Reduced Recalls and Legal Risks

ISO 13485 helps manufacturers minimize recalls and legal risks. Comprehensive documentation and traceability enable quick response to product issues. Companies protect their reputation by demonstrating dedication to quality and compliance. Healthcare providers benefit from reduced device downtime and improved patient safety.

Benefit | Description |

|---|---|

High credibility of your company | Effective risk prevention strategies minimize reputational damage. |

Great competitive advantage | Adherence to high standards strengthens market position. |

Increased customer satisfaction | Devices meet end-user goals, supporting patient well-being. |

Protection against legal proceedings | Compliance provides evidence of quality standards. |

Boost your business | Positive reputation attracts investors and new projects. |

Manufacturers gain access to new markets and business opportunities. Healthcare providers rely on compliant lithium battery packs for critical operations in medical devices.

Part7: Implementation Challenges

7.1 Common Barriers

Manufacturers face several barriers when implementing ISO 13485 in lithium battery pack production. They often encounter resource constraints, especially in small and mid-sized companies. Teams may lack experience with quality management systems. Integrating new documentation processes can disrupt established workflows. Suppliers sometimes fail to meet traceability requirements. Testing procedures for lithium iron phosphate, lithium cobalt oxide, and lithium nickel manganese cobalt oxide packs may not align with regulatory standards. Companies must also address cultural resistance to change and ensure staff understand the importance of compliance in medical, robotics, and industrial sectors.

Note: Inconsistent testing and incomplete records can lead to audit failures and delayed market access.

7.2 Solutions and Best Practices

Successful organizations use several strategies to overcome these challenges. They invest in staff training and hire quality management experts. Teams standardize testing protocols for all lithium battery chemistries. Digital documentation systems streamline record keeping and support traceability. Companies establish clear supplier qualification criteria and conduct regular audits. Management encourages a culture of continuous improvement. They use feedback from testing and post-market surveillance to refine processes. Collaboration with certified suppliers ensures compliance in medical devices, robotics, and security applications.

Best Practices Table

Practice | Benefit |

|---|---|

Staff Training | Improves understanding of QMS requirements |

Standardized Testing | Ensures consistent product quality |

Digital Documentation | Enhances traceability and audit readiness |

Supplier Audits | Verifies compliance and reliability |

Continuous Improvement | Drives innovation and risk reduction |

7.3 Long-Term Value

Organizations that overcome implementation barriers gain significant long-term value. They achieve higher reliability in lithium battery packs for medical, industrial, and infrastructure sectors. Consistent testing reduces recalls and legal risks. Efficient processes lower production costs and speed up market entry. Companies build strong reputations with healthcare providers and partners in robotics and security. ISO 13485 compliance supports global expansion and fosters innovation. Teams use lessons learned from testing and post-market surveillance to improve future products.

Tip: Continuous investment in quality management and testing delivers lasting benefits for manufacturers and their clients.

ISO 13485 sets the benchmark for quality and safety in lithium battery pack manufacturing across medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Manufacturers gain long-term business growth and innovation by adopting this standard.

Ensures compliance with international regulations

Enhances product safety and reliability

Improves risk management and control

Boosts customer confidence

Increases market access

Manufacturers who treat iso 13485 as a strategic asset strengthen their reputation, reduce recalls, and drive continuous improvement.

FAQ

What makes ISO 13485 essential for lithium battery packs in medical devices?

ISO 13485 ensures lithium battery packs meet strict safety and quality standards. Manufacturers use this standard to reduce risks in medical applications. Compliance supports regulatory approval and builds trust with healthcare providers.

How does ISO 13485 improve traceability in battery manufacturing?

Manufacturers track every component from raw material to finished lithium battery pack. This traceability helps identify issues quickly in medical, security, and infrastructure sectors. Accurate records support efficient recalls and regulatory compliance.

Which lithium chemistries are most common in ISO 13485-certified battery packs?

Manufacturers often use lithium iron phosphate, lithium cobalt oxide, and lithium nickel manganese cobalt oxide chemistries. Each chemistry offers unique benefits for medical, robotics, and industrial applications, such as high thermal stability or long cycle life.

How does ISO 13485 support risk management in battery design?

ISO 13485 requires structured risk assessment for lithium battery packs. Manufacturers identify hazards, estimate risks, and implement controls. This process protects users in medical, consumer electronics, and security sectors from battery failures.

Can ISO 13485 certification help companies enter new markets?

Yes. ISO 13485 certification aligns with global regulations. Manufacturers gain easier access to markets in the EU, USA, Japan, and other regions. This certification demonstrates commitment to quality in medical, robotics, and industrial sectors.