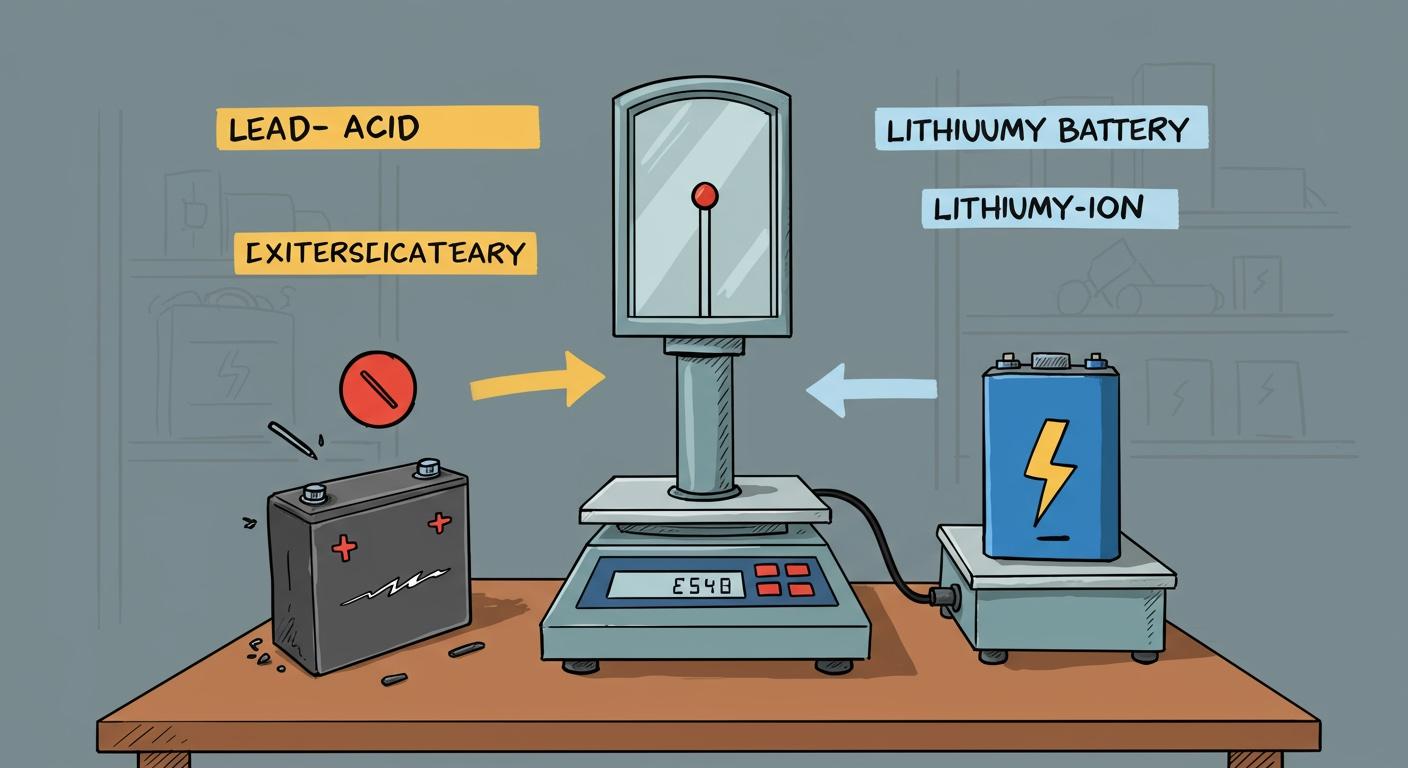

You now see commercial weighing scales favor li-ion batteries for clear business advantages. Lithium weighing machine batteries deliver longer lifespan, faster charging, and higher energy density. These benefits cut operational costs and boost reliability.

Lithium-based solutions now power 40% of new weighing scale integrations.

Businesses report fewer delays, reduced maintenance, and faster battery charging.

Improvement Type | Description |

|---|---|

Enhanced Lifespan | Lithium-ion batteries can last up to 10 years, far outpacing lead-acid battery options. |

Reduced Maintenance | Lithium weighing machine batteries require zero maintenance, saving time and money. |

Key Takeaways

Lithium-ion batteries last longer, with a lifespan of 5 to 10 years, reducing the need for frequent replacements.

Fast charging capabilities allow lithium-ion batteries to recharge in just 1 to 2 hours, minimizing downtime during operations.

Lithium-ion batteries require no maintenance, saving time and money compared to lead-acid batteries that need regular upkeep.

Higher energy density in lithium-ion batteries means lighter and smaller battery packs, improving portability and design flexibility.

Switching to lithium-ion batteries can lower overall operational costs due to their efficiency and longer lifespan.

Part1: Performance

1.1 Energy Density

You need batteries that deliver maximum power in a compact form. Lithium weighing machine batteries offer much higher energy density than lead-acid batteries. This means you can use smaller, lighter battery packs without sacrificing runtime or reliability.

Battery Chemistry | Energy Density (Wh/kg) | Typical Application Sectors |

|---|---|---|

LiFePO4 | 90-160 | Industrial, Infrastructure |

NMC | 150-220 | Medical, Robotics, Security |

LCO | 150-200 | Consumer Electronics |

LMO | 100-150 | Industrial, Security |

LTO | 70-80 | Medical, Infrastructure |

Lead-acid | 30-50 | Industrial, Infrastructure |

Higher energy density in lithium weighing machine batteries lets you power advanced weighing systems in medical, robotics, and industrial sectors. You can reduce the size and weight of your weighing machine battery, which improves portability and design flexibility.

1.2 Charging Speed

Fast charging is essential for commercial weighing operations. Lithium weighing machine batteries charge much faster than lead-acid batteries. You can recharge a lithium-ion battery in just 1 to 2 hours, while lead-acid batteries often require about 8 hours and a cooldown period.

Battery Type | Charging Time | Additional Notes |

|---|---|---|

Lithium-ion | 1 to 2 hours | Supports opportunity charging |

Lead-acid | About 8 hours | Requires cooldown period after charging |

Charging efficiency directly impacts your productivity. With lithium weighing machine batteries, you can run multiple shifts without swapping batteries or waiting for long recharge cycles.

Feature | Lithium-Ion Batteries | Lead Acid Batteries |

|---|---|---|

Charging Time | 1 to 2 hours | 8 hours |

Cool Down Time | N/A | 8 hours |

Safe Discharge Level | 20% | 30% |

Number of Batteries Needed | 1 per weighing unit | 2 or 3 per weighing unit |

Operational Shifts | 2 or 3 shifts | 1 shift |

You can support continuous weighing operations in industrial, medical, and security sectors with lithium weighing machine batteries. Faster charging means less downtime and fewer weighing machine battery replacements.

1.3 Self-Discharge

Battery self-discharge affects reliability and operational costs. Lithium-ion batteries exhibit a much lower self-discharge rate than lead-acid batteries. You can store lithium weighing machine batteries for extended periods without losing significant charge. Lead-acid batteries lose charge quickly when not in use, which can disrupt weighing schedules and require frequent recharging.

Lower self-discharge in lithium weighing machine batteries ensures your weighing equipment stays ready for use, even after long periods of inactivity. This reliability is critical for medical, infrastructure, and industrial weighing applications.

Battery management systems play a key role in optimizing performance and charging efficiency.

You gain higher performance, faster charging, and better reliability with lithium weighing machine batteries. These advantages help you maintain consistent weighing operations and reduce total cost of ownership.

Part2: Lifespan and Maintenance

2.1 Longevity of Li-ion Batteries

You want your weighing operations to run smoothly for years. Lithium weighing machine batteries offer a much longer lifespan than traditional lead-acid battery options. Most lithium-ion battery packs last between 5 and 10 years, depending on usage and chemistry. Lead-acid batteries often require replacement every 2 to 3 years, especially in high-demand environments like industrial or medical weighing.

Battery Chemistry | Typical Lifespan (Years) | Application Sectors |

|---|---|---|

LiFePO4 | 8-10 | Industrial, Infrastructure |

NMC | 6-8 | Medical, Robotics, Security |

LCO | 5-7 | Consumer Electronics |

LMO | 5-7 | Industrial, Security |

LTO | 10+ | Medical, Infrastructure |

Lead-acid | 2-3 | Industrial, Infrastructure |

Longer lifespan means fewer weighing machine battery replacements and less disruption to your business. You can rely on lithium weighing machine batteries to support continuous weighing in critical sectors such as medical and security.

2.2 Maintenance Needs

You save time and money when you choose lithium weighing machine batteries. Maintenance requirements for lead-acid batteries are high. You need to water them after charging, perform equalization charging weekly, and clean terminals often. Lithium-ion batteries eliminate these tasks.

Maintenance Task | Lead-acid Batteries | Lithium-ion Batteries |

|---|---|---|

Watering | Needed after charging | Not needed |

Equalization Charging | Every week | Not needed |

Cleaning Terminals | Often | Not needed |

Labor Time | High | Very little |

Downtime | Happens a lot | Rare |

No periodic maintenance is required for lithium weighing machine batteries. This reduces operational expenses and keeps your weighing equipment available for use. You can focus on your business instead of battery upkeep.

Evidence | Explanation |

|---|---|

No periodic maintenance is required | This indicates that commercial weighing scale owners can save on maintenance costs, leading to lower operational expenses over time. |

Tip: Battery management systems help you monitor lithium weighing machine batteries and further reduce maintenance needs.

2.3 Reliability Over Time

You need reliable weighing equipment for accurate results. Lithium weighing machine batteries maintain stable performance throughout their lifespan. Lead-acid batteries lose capacity quickly and may cause erratic readings or unexpected downtime.

Battery Usage Scenario | Recommended Replacement Frequency |

|---|---|

Frequent power cuts | Once a year |

Rare battery use | Once every two years |

Battery lifespan affects the scale’s ability to function during power interruptions.

Regular maintenance ensures accurate readings.

Non-functional batteries can lead to erratic weight readings.

You can trust lithium weighing machine batteries to deliver consistent weighing performance in industrial, medical, and security sectors. Reliable batteries keep your weighing operations running and protect your business from costly interruptions.

Reliable lithium weighing machine batteries help you avoid downtime and maintain accurate weighing results. You gain peace of mind and better control over your operations.

Part3: Cost and Value

3.1 Initial vs. Lifetime Cost

You want to maximize your investment in weighing equipment. The initial purchase price of a lithium weighing machine battery may seem higher than a lead-acid battery, but the lifetime cost tells a different story. Lithium weighing machine batteries deliver more value over time because you replace them less often and spend less on maintenance.

Battery Type | Initial Purchase Cost | Estimated Lifetime Cost |

|---|---|---|

Lead-Acid AGM | 78,000€ | 0.42€ / usable kWh |

Lithium-Ion | 23,000€ | 0.15€ / usable kWh |

You save money with lithium weighing machine batteries because they last longer and require fewer replacements. You also benefit from higher energy efficiency and lower operating costs. Li-ion batteries support over 3,500 charging cycles, while lead-acid batteries offer only about 1,000 cycles. You avoid frequent battery purchases and reduce your total cost of ownership.

Tip: Battery management systems help you track battery health and optimize performance, further lowering your costs.

3.2 Downtime Reduction

Downtime can disrupt your weighing operations and lead to lost revenue. Lithium weighing machine batteries minimize downtime by charging faster and requiring less maintenance. You keep your weighing equipment running smoothly and avoid delays.

Lithium weighing machine batteries charge at 96% efficiency, while lead-acid batteries reach only 75%.

You can use partial and fast charging with lithium weighing machine batteries, which keeps your weighing machines available for multiple shifts.

Maintenance tasks like water refills and corrosion checks are not needed for lithium weighing machine batteries.

You spend less time waiting for batteries to charge and more time getting accurate weight readings.

Feature | Lithium-Ion Batteries | Lead-Acid Batteries |

|---|---|---|

Charging Cycles | 3,500+ | 1,000 |

Charging Time | 1-2 hours | 6-8 hours |

Maintenance Needs | Minimal | High |

Downtime | Rare | Frequent |

You improve reliability and efficiency in medical, industrial, and security sectors by choosing lithium weighing machine batteries. You get consistent weighing performance and reduce interruptions. You also support sustainability goals by using batteries with longer lifespan and lower energy consumption. Learn more about sustainability in battery technology here.

Part4: Practical Benefits

4.1 Accuracy and Consistency

You rely on accurate weight readings for every transaction and process. Li-ion batteries deliver stable voltage throughout their lifespan, which helps your weighing equipment maintain precise measurements. Lead-acid battery options often show voltage drops as they discharge, which can cause errors in weighing results. Lithium weighing machine batteries support consistent performance, so you get reliable data for inventory, billing, and compliance. In medical and industrial sectors, accurate weight readings protect your business from costly mistakes and ensure you meet regulatory standards.

Tip: Stable battery output reduces calibration needs and helps you maintain high-quality weighing operations.

4.2 Portability and Design

You want weighing equipment that fits your workspace and moves easily. Li-ion batteries offer high energy density, so you can use smaller and lighter battery packs. This makes your weighing machines easier to transport and install. You can place weighing units in tight spaces or move them between locations without heavy lifting. Lightweight battery design supports mobile weighing in medical, robotics, and security applications. You improve workflow and reduce physical strain for your team.

Compact battery packs allow flexible placement.

Lightweight design supports mobile weighing tasks.

Easy transport increases operational efficiency.

4.3 Application Flexibility

You need weighing solutions that work in many environments. Battery flexibility lets you operate weighing equipment in locations without mains power. Lithium weighing machine batteries adapt to mobile and outdoor applications, so you can use your scales in warehouses, clinics, or remote sites. Rechargeable batteries allow continuous operation when connected to power, which keeps your weighing machines running during long shifts.

Benefit of Battery Flexibility | Description |

|---|---|

Wider Range of Use | Enables operation in locations without mains power |

Adaptability | Suitable for mobile and outdoor applications |

Continuous Operation | Rechargeable batteries allow uninterrupted use |

You support weighing in medical, industrial, and infrastructure sectors with flexible battery options. Li-ion batteries help you meet changing business needs and expand your weighing operations to new locations. You gain reliable performance and reduce downtime, which improves your bottom line.

Part5: Transition Tips

5.1 Choosing Li-ion Batteries

You want to select the right battery for your commercial weighing equipment. Start by reviewing your operational needs. Consider the voltage and capacity requirements for your weighing machines. Li-ion battery packs come in several chemistries, such as LiFePO4, NMC, and LTO. Each type offers unique benefits for industrial, medical, and security sectors. LiFePO4 batteries provide long lifespan and stable performance, making them ideal for infrastructure and industrial weighing. NMC batteries deliver high energy density, which suits robotics and medical applications. LTO batteries excel in environments that demand rapid charging and long cycle life.

Tip: Always check the manufacturer’s specifications for compatibility with your weighing equipment. Reliable suppliers provide technical data sheets for each battery chemistry.

You should also evaluate the battery management system. This system monitors battery health and ensures safe operation. Real-time data helps you maintain consistent performance across battery batches, which is critical in demanding environments. Consistent battery performance reduces inefficiencies and prevents failures in applications like rail transport or continuous industrial weighing.

5.2 Upgrading from Lead-Acid

When you upgrade your weighing equipment from lead-acid to lithium-ion batteries, follow a structured process to ensure a smooth transition. Use the steps below to guide your upgrade:

System Assessment: Match the new lithium battery’s voltage and capacity to your old lead-acid battery. Measure the battery compartment for fit and check all connectors.

Charger Compatibility: Verify that your charger supports lithium batteries. Using the wrong charger can damage the battery or reduce its lifespan.

Upgrades Needed: Upgrade the charger and battery tray. Secure the battery properly. Add counterweights if necessary to maintain balance in your weighing machine.

Businesses often face challenges during this transition. You may notice variability in battery performance across different batches. This can lead to inefficiencies or failures, especially in sectors where weighing equipment runs constantly. You need real-time data to monitor battery health and performance. A robust battery management system helps you address these challenges and maintain reliable weighing operations.

Note: Work with experienced technicians when upgrading your weighing equipment. Proper installation ensures safety and maximizes the benefits of lithium-ion battery technology.

You see why businesses now choose lithium-ion battery packs for commercial weighing needs. These battery solutions deliver superior performance, longer lifespan, and lower total cost. You reduce downtime and maintenance with every weighing operation. Reliable battery technology keeps your weighing equipment accurate and ready. Consider upgrading your weighing systems to lithium-ion battery packs for better efficiency and long-term value.

FAQ

What makes Li-ion batteries better for commercial weighing scales than lead-acid batteries?

You get higher energy density, faster charging, and longer lifespan with Li-ion battery packs. These features help your business reduce downtime and maintenance. Li-ion batteries also support more shifts and deliver stable performance in medical, industrial, and security weighing applications.

Do Li-ion weighing machine batteries produce emissions during use?

You benefit from no emissions during normal operation of Li-ion battery packs. This helps your business meet environmental standards and supports clean energy goals. Unlike some older technologies, you avoid harmful emissions in your workplace.

How do Li-ion batteries help reduce operational costs?

You save money over time because Li-ion batteries last longer and need less maintenance. You avoid frequent replacements and reduce labor costs. Lower emissions also mean fewer regulatory concerns for your business in industrial and infrastructure sectors.

Can I upgrade my existing weighing equipment from lead-acid batteries to Li-ion?

You can upgrade most commercial weighing scales from lead-acid batteries to Li-ion packs. Check voltage and size compatibility first. Upgrading helps you achieve better performance, longer runtime, and lower emissions in your daily operations.

Are Li-ion batteries safe for use in sensitive environments like hospitals?

You can use Li-ion battery packs safely in hospitals and medical labs. They have advanced safety features and produce no emissions during use. This makes them ideal for sensitive environments where clean air and reliability matter.