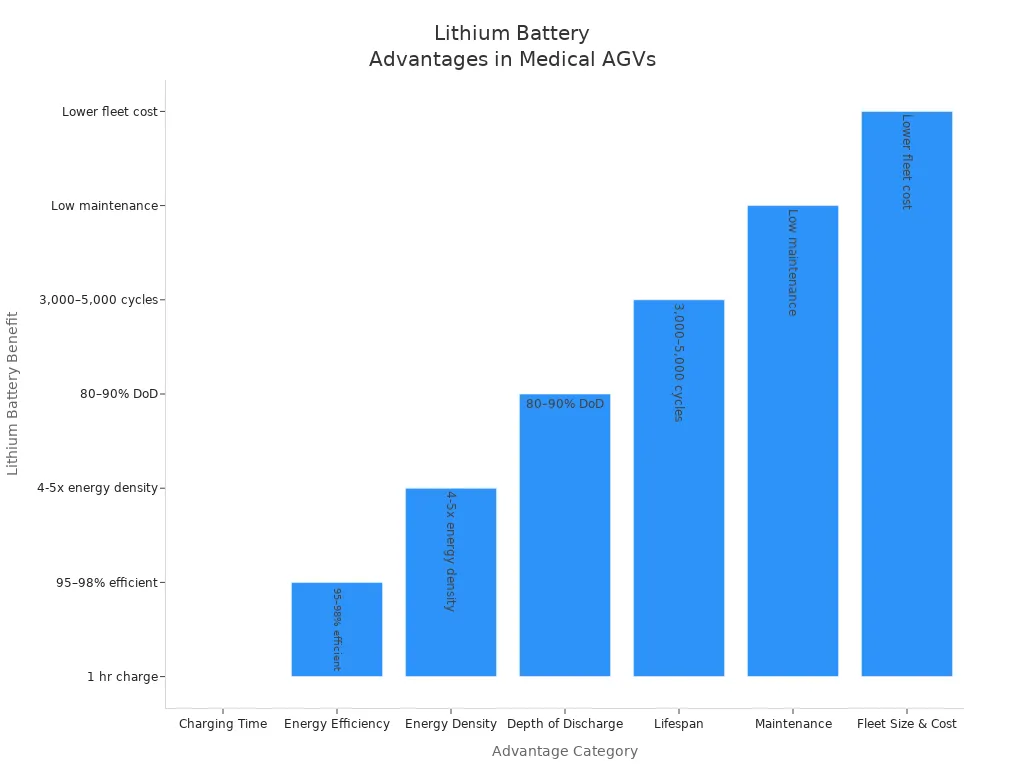

Healthcare facilities increasingly rely on automated guided vehicles for efficient transport of medical supplies, samples, and pharmaceuticals. Lithium batteries for healthcare agvs deliver critical advantages in these demanding environments. Hospitals value fast charging, with lithium batteries reaching full capacity in just one to two hours, which minimizes agvs downtime and keeps healthcare workflows uninterrupted. High energy density makes these batteries lighter and more compact, allowing agvs to maneuver easily in tight hospital corridors. Longer operational lifespans—often exceeding 3,500 cycles—reduce replacement frequency and lower total ownership costs. Maintenance requirements remain minimal, as lithium batteries do not need watering or regular servicing, which supports uninterrupted healthcare operations. Advanced bms provide real-time monitoring, enhancing safety and compliance with strict healthcare standards. The table below summarizes key performance metrics:

Lithium Battery Benefit | Comparison to Lead-Acid/GEL Batteries | |

|---|---|---|

Charging Time | Charges fully in about 1 hour (1C rate), enabling quick recharge during short downtimes | GEL batteries take ~3.3 hours; Lead-acid ~5 hours |

Energy Efficiency | 95–98% efficient; loses ~50 watts per kW charged | Lead-acid/GEL 80–85% efficient; loses 150–200 watts |

Energy Density | 4-5 times higher energy density; lighter weight (~5 kg for 1000 Wh) | Lead-acid battery weighs ~25 kg for same energy |

Depth of Discharge (DoD) | Supports 80–90% DoD without damage, allowing longer use per charge | GEL batteries support 50–60% DoD |

Lifespan (Charge Cycles) | 3,000–5,000+ cycles at 60% DoD, minimal degradation | GEL: 1,000–1,300 cycles; Lead-acid: 400–600 cycles |

Maintenance | Low maintenance; no watering needed; no sulfation or memory effect | Lead-acid requires regular watering and full recharge cycles |

Fleet Size & Cost | Faster charging and longer runtime reduce need for extra vehicles, lowering fleet costs | Slower charging requires 2-3 additional AGVs to maintain operations |

Healthcare agvs benefit from robust bms, which monitor voltage, current, and temperature to prevent safety incidents and ensure compliance. These features make lithium batteries for healthcare agvs the preferred choice for modern medical logistics.

Key Takeaways

Lithium batteries charge quickly, often in just 1 to 2 hours, which keeps healthcare AGVs running with minimal downtime.

These batteries are lightweight and compact, helping AGVs move easily through tight hospital spaces while carrying heavy loads.

Lithium batteries last much longer than traditional batteries, reducing replacement needs and lowering overall costs.

Advanced battery management systems (BMS) monitor battery health in real time, improving safety and ensuring compliance with strict medical standards.

Using lithium batteries in healthcare AGVs boosts efficiency, safety, and reliability, supporting better patient care and smoother hospital operations.

Part 1: Healthcare AGVs Overview

1.1 Role in Medical Facilities

Healthcare agvs have transformed logistics in hospitals and clinics. These automated guided vehicles handle essential transport tasks, reducing the workload for medical staff. They deliver medical supplies, meals, linens, and hazardous waste throughout healthcare environments. By automating these tasks, agvs allow nurses and doctors to focus on patient care. Healthcare agvs use advanced laser-guided navigation systems, moving autonomously without the need for ground infrastructure. They integrate with hospital corridors and elevators, ensuring seamless operation.

Healthcare agvs support several key functions:

Transporting food, medication, sterilized equipment, linens, and waste, including infected materials.

Operating daily, moving between 300 and 2,000 carts depending on facility size.

Using sensors and scanning technologies such as IR sensors, RFID, barcodes, and QR codes for accurate delivery and traceability.

Integrating with hospital infrastructure for safe navigation among staff and patients.

Three main types of healthcare agvs serve different needs:

Platform agvs carry containers with baseplates, such as meals or linens.

Tower agvs offer high visibility for safe movement in busy hospital areas.

Forklift agvs handle bulkier items without baseplates.

Efficient internal logistics, powered by healthcare agvs, help maintain surgical schedules and optimize resource use. These vehicles address staff shortages and rising care demands by automating time-consuming material handling. Healthcare robotics continues to advance, making agvs even more vital in modern medical settings.

1.2 Battery Choice Importance

Battery selection plays a critical role in the reliability and efficiency of healthcare agvs. Lithium battery packs, especially those with advanced bms, have become the preferred choice. High energy density allows healthcare agvs to operate longer without increasing battery size or weight. Fast charging capabilities minimize downtime, supporting continuous 24/7 operation in healthcare environments.

Key factors influencing battery choice for healthcare agvs include:

Energy density, which determines operation duration.

Charging time, affecting vehicle uptime.

Cycle life, impacting how often batteries need replacement.

Safety, ensuring batteries avoid hazards like overheating or leakage.

A robust bms monitors voltage, current, and temperature, preventing overcharging and undercharging. This system extends battery life and enhances safety, which is essential in sensitive healthcare settings. Hospitals often choose lithium battery packs with lithium iron phosphate chemistry for their stability and safety profile. Customized battery solutions optimize power and endurance for specific agvs models, ensuring dependable healthcare operations.

Feature | Impact on Healthcare AGVs Operational Reliability |

|---|---|

Stable, reliable battery performance, reducing unexpected failures. | |

BMS | Monitors and protects battery health, enhancing safety and lifespan. |

Customized battery solutions | Tailored for specific agvs, optimizing power and endurance. |

Lithium Iron Phosphate chemistry | Enhanced safety, reducing overheating risks in healthcare environments. |

High energy density | Longer runtimes, supports heavier loads, improves operational efficiency. |

Extended battery life | Reduces downtime and maintenance, increases agvs availability. |

Quick charging | Minimizes downtime, maximizes uptime for continuous healthcare service. |

Smart energy solutions and advanced bms ensure healthcare agvs deliver reliable performance. Battery choice directly impacts operational reliability, safety, and cost efficiency in healthcare logistics.

Part 2: Lithium Batteries for Healthcare AGVs

2.1 Safety and Compliance

Healthcare AGVs operate in environments where safety and compliance are non-negotiable. Lithium batteries for healthcare AGVs must meet strict safety standards to ensure reliable operation near patients and sensitive equipment. These batteries comply with international medical safety standards such as IEC 62133, UL 2054, ISO 13485, IEC 60601-1, and ISO 10993-1. In the United States, compliance with FDA General Safety and Performance Requirements is mandatory, while European facilities follow the Medical Device Regulation (MDR).

Key safety standards for lithium batteries in healthcare AGVs:

IEC 62133: Ensures safe operation of portable batteries.

UL 2054: Covers household and commercial battery safety.

ISO 13485: Focuses on quality management for medical devices.

IEC 60601-1: Addresses electrical safety in medical environments.

ISO 10993-1: Requires biocompatibility for use near patients.

UN38.3: Regulates safe transportation of lithium batteries.

Manufacturers serialize and trace each battery to prevent counterfeiting and ensure accountability. Lithium batteries for healthcare AGVs include advanced safety features such as overcharge protection, thermal shutdown, and robust battery management systems. These features reduce the risk of overheating, leakage, or electrical faults. The robot battery management system (BMS) monitors voltage, current, and temperature in real time, providing an extra layer of protection. Hospitals rely on these safety protections to maintain uninterrupted care and protect both staff and patients.

2.2 Cost Efficiency

Cost efficiency remains a top priority for healthcare facilities investing in AGVs. While lithium-ion batteries have a higher initial cost than traditional lead-acid batteries, their long-term value far outweighs the upfront expense. Lithium batteries for healthcare AGVs offer a longer service life, often lasting 8 to 10 years or 2,000 to 3,000+ charge cycles. In comparison, lead-acid batteries typically last only 3 to 5 years with 500 to 1,000 cycles.

Aspect | Lead-Acid Batteries | Lithium-Ion Batteries |

|---|---|---|

Cycle Life | 500 to 1,000 cycles | 2,000 to 3,000+ cycles |

Years of Service | 3 to 5 years | 8 to 10 years |

Lithium-ion batteries require no maintenance, reducing labor and operational costs. Their low self-discharge rate ensures AGVs remain ready for use, even after periods of inactivity. The robot battery management system (BMS) extends battery life and minimizes system downtime, further improving cost efficiency. Lithium Iron Phosphate (LFP) batteries, a type of lithium-ion chemistry, provide additional savings due to their lower cost, longer cycle life, and enhanced safety profile. These advantages make lithium batteries for healthcare AGVs the most cost-effective solution for hospitals, clinics, and other medical facilities.

2.3 Performance Benefits

Lithium batteries deliver significant performance improvements for healthcare AGVs. Their high energy density allows AGVs to operate longer between charges and carry heavier loads without increasing battery size or weight. This high energy density also benefits robotics, security systems, infrastructure, consumer electronics, and industrial sectors, where compact and lightweight power sources are essential.

Key performance enhancements with lithium batteries:

Higher energy density for more compact AGV designs.

Extended life cycles, reducing replacement frequency.

Advanced robot battery management system (BMS) for real-time monitoring of state of charge (SoC), depth of discharge (DoD), and state of health (SoH).

Opportunity charging enables partial recharges during short breaks, maximizing AGV uptime.

Minimal maintenance requirements, reducing operational disruptions.

Elimination of hazardous off-gassing and spills, improving workplace safety.

Lithium-ion batteries outperform lead-acid batteries in every major performance metric. They enable healthcare AGVs to complete more deliveries per shift, support 24/7 operations, and adapt quickly to changing hospital needs. The robot battery management system (BMS) optimizes charging and discharging, ensuring maximum efficiency and a long lifespan. These performance benefits extend to other sectors, including robotics and industrial automation, where reliability and uptime are critical.

Hospitals that deploy lithium batteries for healthcare AGVs experience fewer interruptions, lower maintenance costs, and improved patient care. The combination of high energy density, advanced BMS, and robust safety features makes lithium batteries the preferred choice for modern healthcare logistics.

Part 3: LiFePO4 vs. Lithium-Ion

3.1 LiFePO4 Advantages

LiFePO4 batteries deliver outstanding safety and reliability for healthcare AGVs. Their iron phosphate chemistry provides high thermal stability, which reduces the risk of overheating and thermal runaway. Hospitals value this feature because it protects sensitive medical equipment and ensures patient safety. LiFePO4 batteries resist overcharge and over-discharge, offering minimal risk of failure even under demanding conditions. The robust molecular structure makes these batteries non-toxic and environmentally friendly. Healthcare AGVs benefit from long cycle life, typically 2,000–5,000 cycles, which supports continuous operation and reduces replacement costs. The battery management system (BMS) in LiFePO4 battery packs monitors voltage, current, and temperature, further enhancing safety and compliance. These batteries maintain a steady voltage output, ensuring consistent AGV performance in critical medical environments.

LiFePO4 batteries excel in healthcare AGVs due to their superior safety, long lifespan, and chemical stability. The BMS provides real-time protection, making these batteries ideal for medical logistics and equipment movement.

Safety Feature Aspect | LiFePO4 Batteries | Lithium-ion Batteries (Medical Grade) |

|---|---|---|

Thermal Stability | High heat resistance; resistant to thermal runaway | Built-in safety features to prevent overheating |

Overcharge/Over-discharge | Inherently resistant to overcharge and over-discharge | Safety circuits to prevent overcharging and short-circuiting |

Chemical Stability | Chemically stable, non-toxic, non-contaminating | Safe but less chemically stable compared to LiFePO4 |

Lifespan | Longer life cycles (up to 10 times lead-acid) | Long life cycle, but generally shorter than LiFePO4 |

Charging Characteristics | Requires compatible charger; slower charging | Fast charging capability with built-in safety mechanisms |

Environmental Impact | Contains no rare earth metals; eco-friendly | Safe but may contain more complex chemistries |

Application Suitability | Suitable for critical environments like healthcare AGVs due to enhanced safety | Suitable for medical devices needing steady discharge and fast charging |

3.2 Lithium-Ion Benefits

Lithium-ion batteries offer high energy density, which enables healthcare AGVs to use smaller and lighter battery packs. This feature improves mobility and compactness, allowing AGVs to navigate tight hospital corridors and operate in space-constrained environments. Lithium-ion batteries support fast charging, which minimizes downtime and keeps AGVs ready for emergency use. The battery management system (BMS) in lithium-ion battery packs provides electronic protection against overcharging, overheating, and short-circuiting. These batteries adapt to a wide temperature range, making them suitable for various medical, robotics, and industrial applications. Lithium-ion batteries retain capacity well over time and have a low self-discharge rate, ensuring AGVs remain operational even after periods of inactivity.

Key benefits of lithium-ion batteries for healthcare AGVs:

Higher energy density (up to 200 Wh/kg or more)

Lighter weight and smaller size for improved portability

Fast charging capability with BMS protection

Reliable performance in diverse environments

Long cycle life and steady voltage output

The BMS in lithium-ion batteries ensures safe operation, while the compact design supports efficient AGV deployment in healthcare, security systems, and industrial sectors.

3.3 Application Scenarios

Healthcare AGVs require battery solutions that match their operational demands. LiFePO4 batteries are preferred in scenarios where safety and stability are critical. Hospitals use LiFePO4 batteries in AGVs for transporting medical supplies, pharmaceuticals, and hazardous waste. These batteries provide consistent voltage and long cycle life, supporting reliable logistics and reducing maintenance costs. The BMS in LiFePO4 battery packs ensures compliance with medical safety standards.

Lithium-ion batteries power AGVs in environments where compactness and fast charging are essential. Medical facilities deploy lithium-ion battery packs in AGVs for rapid delivery of emergency supplies and equipment. The BMS in these batteries protects against electrical faults, making them suitable for robotics, consumer electronics, and industrial automation.

Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90–120 | 2,000–5,000 |

NMC | 3.7 | 150–220 | 1,000–2,000 |

LCO | 3.7 | 150–200 | 500–1,000 |

LMO | 3.7 | 100–150 | 700–1,500 |

LTO | 2.4 | 70–80 | 7,000–20,000 |

Solid-State | 3.7 | 250–500 | 2,000–10,000 |

Lithium Metal | 3.7 | 350–500 | 500–1,000 |

LiFePO4 batteries suit healthcare AGVs needing maximum safety and reliability.

Lithium-ion batteries fit AGVs requiring compact design and fast charging.

NMC and LCO chemistries serve medical devices and robotics needing high energy density.

LTO batteries offer ultra-long cycle life for industrial AGVs.

Solid-state and lithium metal batteries represent future solutions for advanced medical and security systems.

Selecting the right battery chemistry and BMS ensures healthcare AGVs deliver safe, efficient, and reliable performance across medical, robotics, and industrial sectors.

Part 4: Lithium Batteries Selection Criteria

4.1 Power and Load Needs

Selecting the right lithium batteries for healthcare AGVs starts with a thorough evaluation of power and load requirements. Healthcare AGVs often function as lightweight unit load carriers, which influences the optimal battery size and capacity. Most applications benefit from battery packs under 20 kWh, supporting frequent, short operational cycles. Lithium iron phosphate chemistry remains the preferred choice due to its safety and thermal stability, especially in sensitive healthcare environments. The battery management system, or BMS, plays a crucial role by enabling predictive maintenance and ensuring reliable performance.

Criterion | Explanation |

|---|---|

Healthcare AGVs are often lightweight unit load carriers, influencing battery size and capacity. | |

Battery Capacity | Smaller capacity packs (<20 kWh) suit frequent short operational cycles typical in healthcare. |

Battery Chemistry | |

Charging Methods | Fast or opportunity charging supports high operational uptime required in healthcare environments. |

Operational Environment | Cleanliness and reliability demands necessitate batteries with stable performance and safety. |

Battery Management System | Predictive maintenance capabilities enhance reliability and safety in healthcare AGVs. |

Sustainability | Consideration of end-of-life recycling aligns with healthcare industry sustainability goals. |

Cylindrical lithium-ion batteries offer high energy density and mechanical robustness, making them ideal for AGVs that encounter vibration and varying loads. For light-duty AGVs, lithium iron phosphate batteries deliver high safety, fast charging, and long cycle life. Medium- and heavy-duty AGVs also benefit from this chemistry, which provides reliable discharge rates and thermal stability.

4.2 Charging and Downtime

Charging time and downtime directly impact healthcare AGV efficiency. Lithium-ion batteries typically reach a full charge in about two hours, much faster than traditional lead-acid batteries. Opportunity charging during short breaks allows AGVs to stay operational with minimal downtime. The robot battery management system monitors charging cycles and optimizes schedules, reducing interruptions in material handling. Extended downtime from slow charging or frequent maintenance lowers operational efficiency and increases costs. Advanced scheduling algorithms, supported by the BMS, help predict charging needs and route AGVs efficiently, maximizing throughput and minimizing downtime.

Aspect | Lead-Acid Batteries | Lithium-Ion Batteries |

|---|---|---|

Charging Time | Up to 8 hours plus 8 hours cooling | 2-3 hours, no cooling needed |

Maintenance Requirements | Regular watering, cleaning, equalization | Virtually maintenance-free |

Downtime Impact | Extended downtime due to long charging | Reduced downtime via faster and opportunity charging |

Operational Efficiency | Lower due to frequent and long charging breaks | Higher due to increased AGV availability and throughput |

Case Study Outcome | Increased labor and operational costs | 20% reduction in maintenance labor; 12% throughput increase |

4.3 Safety and Compliance

Safety and compliance remain top priorities in healthcare. Medical-grade lithium-ion batteries must meet strict safety standards, including IEC 60601, ANSI/AAMI ES 60601-1, and UL 2054. These standards ensure patient and staff protection, electrical safety, and risk management. Medical-grade batteries require advanced battery management systems for overcharge and overheat protection, electromagnetic compatibility, and sophisticated thermal management. Production occurs in UL-certified facilities with strict documentation and supply chain oversight, meeting FDA regulations. The robot battery management system provides real-time monitoring, further enhancing safety and compliance. In contrast, commercial-grade batteries focus on operational durability but lack the rigorous protections required in healthcare.

Feature | Medical-Grade Lithium Batteries | Commercial-Grade (Industrial) Lithium Batteries |

|---|---|---|

Regulatory Standards | Must comply with IEC 60601, ANSI/AAMI ES 60601-1, UL2054 | Comply with IEC 62133, UN38.3 |

Safety Mechanisms | Advanced BMS for overcharge and overheat protection | Basic safety features focused on operational safety |

Electromagnetic Compatibility | Mandatory to minimize interference with medical equipment | Generally not required |

Thermal Management | Sophisticated systems to prevent overheating | Designed for tolerance to high temperatures |

Reliability Focus | Prioritized for patient safety and consistent performance | Emphasize durability and environmental resistance |

Production Requirements | UL-certified facilities, strict documentation, FDA compliance | Less stringent requirements |

Tip: Always verify that lithium batteries for healthcare AGVs carry medical-grade certifications and meet all relevant safety standards.

4.4 Cost and ROI

Cost and return on investment drive battery selection for healthcare AGVs. Lithium-ion batteries offer longer lifespan, reduced maintenance needs, and lower total costs compared to lead-acid options. Their fast charging and opportunity charging capabilities minimize downtime, increasing AGV availability and operational efficiency. The robot battery management system reduces maintenance by providing real-time diagnostics and predictive alerts. Healthcare facilities should consider battery lifespan, weight, charging time, discharge characteristics, and maintenance needs. Custom battery designs may offer tailored performance but increase costs and development time, while off-the-shelf solutions provide faster deployment and cost savings.

Facilities should also evaluate sustainability and conflict minerals when selecting lithium batteries. End-of-life recycling supports healthcare sustainability goals (learn more), and responsible sourcing of materials aligns with ethical standards (conflict minerals statement). By prioritizing safety, efficiency, and compliance, healthcare organizations can maximize ROI and ensure reliable AGV performance across medical, robotics, security system, infrastructure, consumer electronics, and industrial sectors.

Healthcare agvs rely on lithium battery packs to deliver unmatched efficiency, safety, and reliability. The right battery chemistry and advanced bms ensure healthcare agvs meet strict operational demands. Hospitals and clinics benefit from high energy density, rapid charging, and long lifespan, which reduce downtime and maintenance. The table below highlights the core advantages:

Key Advantage | Impact on Healthcare AGVs |

|---|---|

High Energy Density | Longer operation, stable voltage |

Fast Charging | Reduced downtime, increased productivity |

Reliability | Consistent performance in healthcare |

Safety Compliance | Meets medical standards, lowers risk |

Long Lifespan | Fewer replacements, lower costs |

Cost Efficiency | Lower total cost of ownership |

Variety of Types | Tailored solutions for diverse needs |

Healthcare agvs in medical, robotics, security system, infrastructure, consumer electronics, and industrial sectors require robust bms for optimal performance. Selecting the right lithium battery type ensures healthcare agvs operate safely and efficiently, supporting the future of healthcare logistics.

FAQ

What makes lithium battery packs ideal for healthcare agvs?

Lithium battery packs provide high energy density and fast charging for agvs. Hospitals use these batteries to keep agvs running longer. The bms monitors battery health, ensuring safety and compliance. These features support reliable logistics in medical, robotics, and security system applications.

How does the bms improve agvs safety in medical environments?

The bms tracks voltage, current, and temperature in real time. This system prevents overcharging and overheating in agvs. Hospitals trust the bms to maintain safe operation. The bms also supports compliance with strict healthcare standards, reducing risks in sensitive environments.

Can agvs with lithium batteries operate in other sectors?

Yes, agvs with lithium battery packs serve robotics, infrastructure, consumer electronics, and industrial sectors. The bms ensures stable performance across different environments. These agvs handle diverse tasks, from moving medical supplies to supporting security systems and industrial automation.

What factors affect the lifespan of lithium batteries in agvs?

The bms manages charging cycles and prevents deep discharges. Proper use of the bms extends battery life in agvs. Environmental conditions, load requirements, and charging habits also impact lifespan. Regular monitoring by the bms helps agvs achieve maximum operational efficiency.

Why do hospitals prefer agvs with advanced bms features?

Hospitals choose agvs with advanced bms for safety and reliability. The bms provides real-time diagnostics and predictive maintenance. This reduces downtime and maintenance costs. The bms also ensures agvs meet medical safety standards, supporting continuous patient care and logistics.