A lithium battery charging cycle refers to the process of fully charging, discharging, and recharging a battery, representing 100% of its capacity. It plays a critical role in industrial applications like grid energy storage and electric trains, where battery health directly impacts performance. Optimizing charging cycles reduces costs by extending battery lifespan and improving reliability.

Key Takeaways

Knowing how lithium battery charging works helps it last longer. Try to keep the battery level between 20% and 80%. This lowers stress and makes the battery last more.

Don’t let the battery drain too much or overcharge it. Doing this can wear it out faster and lower its power. Use systems to watch and manage how the battery is used.

Use smart tools to check charging cycles. Tools like battery management systems and special computer programs can improve how it works and save money.

Part 1: What Is a Lithium Battery Charging Cycle?

1.1 Definition and Components of a Charging Cycle

A lithium battery charging cycle represents the process of using 100% of the battery’s capacity, whether through a single full discharge or multiple partial discharges that cumulatively equal 100%. For example, if you use 70% of the battery’s charge one day and 30% the next, this counts as one complete charging cycle. This concept is crucial for understanding how lithium-ion batteries perform over time.

The components of a charging cycle include:

Charging Phase: The battery is replenished with energy, typically up to 4.2 volts per cell for most lithium-ion batteries. This phase directly impacts the battery’s health and longevity.

Discharging Phase: Energy is drawn from the battery to power devices or systems. The depth of discharge (DoD) significantly influences the number of cycles a battery can complete.

Rest Phase: Between charging and discharging, the battery may remain idle, which also affects its overall performance.

The table below highlights how different charge levels and depths of discharge impact the number of cycles and available energy:

Charge Level (V/cell) | Discharge Cycles | Available Stored Energy |

|---|---|---|

4.30 | 150–250 | 110–115% |

4.25 | 200–350 | 105–110% |

4.20 | 300–500 | 100% |

4.13 | 400–700 | 90% |

4.06 | 600–1,000 | 81% |

4.00 | 850–1,500 | 73% |

3.92 | 1,200–2,000 | 65% |

3.85 | 2,400–4,000 | 60% |

Understanding these components helps you optimize battery performance and extend battery life in industrial applications.

1.2 How Charging Cycles Are Counted in Lithium Battery Packs

Counting charging cycles involves tracking the cumulative energy discharged from the battery until it equals 100% of its capacity. This process can be measured using advanced methodologies such as:

Method | Description |

|---|---|

Coulomb Counting | Monitors the current drawn from the battery and integrates it over time to calculate the total charge delivered. This method expresses the state of charge (SoC) as a percentage of the remaining charge compared to the maximum capacity. |

ECBE Method | Analyzes the discharge curve of each cell after every cycle to determine the maximum deliverable charge capacity (Qd). This method provides a more accurate measure of battery capacity. |

These methods ensure precise monitoring of charging cycles, which is essential for maintaining the efficiency and reliability of lithium-ion battery packs in industrial and commercial settings.

1.3 Common Misunderstandings About Charging Cycles

Several misconceptions about charging cycles can lead to improper battery usage and reduced lifespan. Here are some common misunderstandings clarified:

“You must fully discharge the battery before recharging.”

Lithium-ion batteries do not have a memory effect, so partial charges do not harm them. In fact, shallow discharges and charges (e.g., keeping the battery between 20% and 80%) are better for battery health.“Leaving the battery plugged in after it’s fully charged damages it.”

Modern lithium-ion batteries include built-in mechanisms to stop charging once they reach full capacity. However, storing the battery at 100% charge for extended periods can degrade its lifespan.“Using third-party chargers always harms the battery.”

While low-quality chargers can pose risks, reputable third-party chargers with matching specifications are safe to use.

Misunderstandings like these can lead to unnecessary wear and tear on your battery. By adopting proper charging practices, you can maximize the lifespan and efficiency of your lithium-ion battery packs.

For businesses relying on lithium-ion batteries, understanding these nuances is vital. It ensures optimal performance and reduces operational costs over time.

Part 2: Why Charging Cycles Matter for Lithium Battery Packs

2.1 Impact on Battery Health and Performance

The charging cycle directly influences the health and performance of a lithium-ion battery. Each cycle involves chemical reactions within the battery’s cells, which gradually affect its capacity and efficiency. Over time, these reactions can lead to a decline in battery performance, impacting its ability to store and deliver energy effectively.

Research indicates that single-crystal nickel-rich cathodes can mitigate stresses that typically lead to degradation, thus enhancing the overall performance of lithium battery packs. However, during charge-discharge cycles, nickel-rich cathodes experience significant chemical changes. These changes result in a 10% capacity drop after 100 cycles due to the formation of an oxygen-poor surface layer that traps lithium ions.

The depth of discharge (DoD) plays a critical role in determining how quickly a battery degrades. Batteries subjected to shallow discharges (e.g., 20%-80% usage) tend to last longer than those frequently discharged to near 0%. This is because deep discharges place more strain on the battery’s internal components, accelerating wear and tear.

In industrial applications, such as robotics or infrastructure systems, maintaining optimal battery health is essential. A well-maintained battery ensures consistent performance, reduces downtime, and minimizes replacement costs. By understanding the impact of charging cycles, you can implement strategies to preserve battery health and maximize its operational efficiency.

2.2 Relationship Between Charging Cycles and Battery Lifespan

The number of charging cycles a battery can complete before its capacity significantly diminishes is a key indicator of its lifespan. For lithium-ion batteries, this lifespan is typically measured in terms of the total number of full cycles the battery can endure while retaining at least 80% of its original capacity.

Aspect | Details |

|---|---|

Dataset Size | Over 3 billion data points from 228 commercial NMC/C+SiO lithium-ion cells aged for more than a year. |

Focus | Investigates calendar and cyclic aging under various operating conditions. |

Measurement Frequency | Measurement logs with two-second resolution. |

Applications | Modeling battery degradation, optimizing operating strategies, and testing algorithms. |

Aging Mechanisms | Includes both calendar aging (SEI growth) and cyclic aging (lithium plating). |

Dependencies | Aging mechanisms depend on SoC, temperature, charging rate, and age of the cell. |

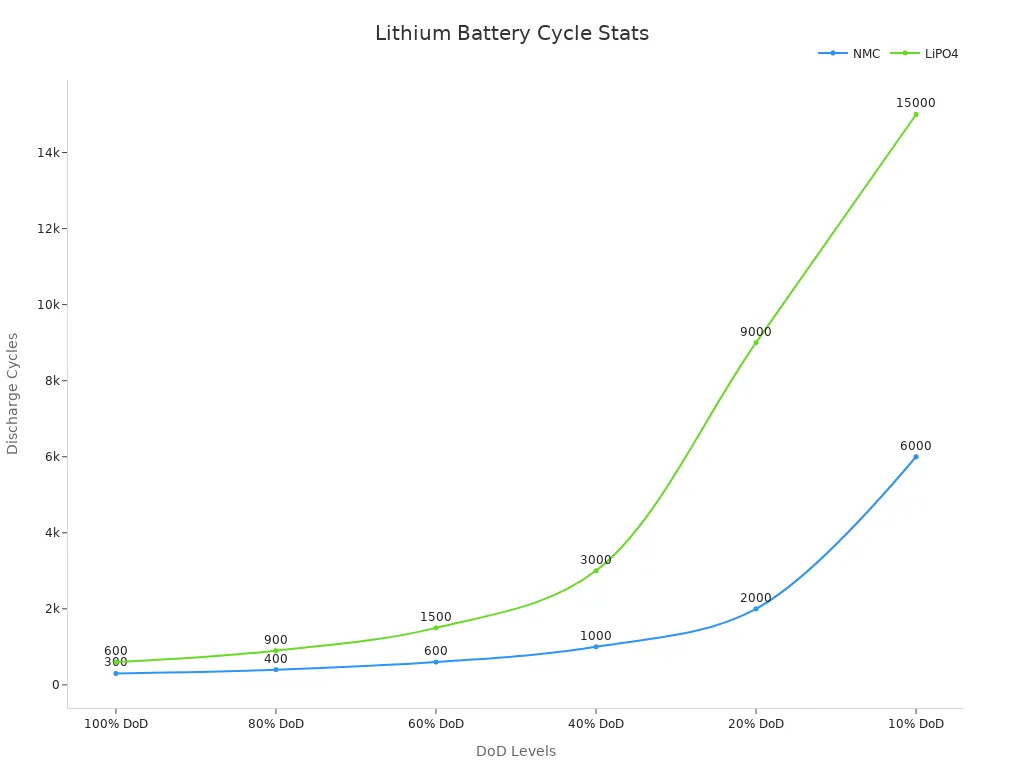

The table above highlights the factors influencing battery aging. Cyclic aging, caused by repeated charging and discharging, is one of the primary contributors to capacity loss. For example, NMC lithium batteries typically offer 1,000-2,000 cycles, while LiFePO4 batteries can achieve 2,000-5,000 cycles due to their superior chemical stability.

Tesla’s new 4680 cylindrical batteries, which utilize a cathode with 80% nickel, demonstrate improved electrochemical performance. This improvement is attributed to the nickel-rich layer that facilitates lithium ion flow, reducing degradation during charging cycles. Such advancements underscore the importance of material innovation in extending battery life.

To maximize the lifespan of your lithium-ion battery packs, you should adopt best practices such as avoiding deep discharges, maintaining moderate temperatures, and using appropriate charging equipment. These measures not only prolong battery life but also enhance the sustainability of your operations by reducing waste and resource consumption.

For businesses relying on lithium-ion batteries, understanding the relationship between charging cycles and battery lifespan is crucial. It enables you to optimize usage patterns, reduce operational costs, and ensure reliable performance across various applications.

Learn more about sustainability in battery solutions here.

Part 3: Tips for Optimizing Lithium Battery Charging Cycles

3.1 Factors Affecting Charging Cycle Efficiency in Battery Packs

Several factors influence the efficiency of a lithium battery charging cycle. Temperature plays a critical role. High temperatures accelerate chemical reactions within the battery, leading to faster aging and reduced battery capacity. Conversely, low temperatures can increase internal resistance, affecting energy transfer. Maintaining a controlled temperature environment ensures optimal performance.

Charge and discharge currents also impact efficiency. Higher discharge rates increase internal stress, causing faster capacity decay. For example, tests on Sony 18650 batteries revealed capacity losses of 9.5%, 13.2%, and 16.9% as discharge rates increased. Depth of discharge (DoD) is another key factor. While deeper discharges provide better energy efficiency, they can strain internal components, accelerating wear.

The table below summarizes these factors and their quantitative impacts:

Factor | Description | Quantitative Evidence |

|---|---|---|

Temperature | Affects battery performance; high temperatures can accelerate aging and capacity decay. | High temperature increases SEI membrane growth and intra-battery resistance. |

Charge and Discharge Current | Higher discharge multiples lead to increased capacity decay and resistance. | Capacity decay of 9.5%, 13.2%, and 16.9% with increasing discharge multiples. |

Discharge Depth | Impacts battery health; deeper discharges can lead to better energy efficiency before significant capacity decay. | Similar decay rates until 85% capacity, with deeper modes performing better. |

Understanding these factors helps you optimize charging cycles and extend battery life.

3.2 Best Practices for Charging Industrial Lithium Battery Packs

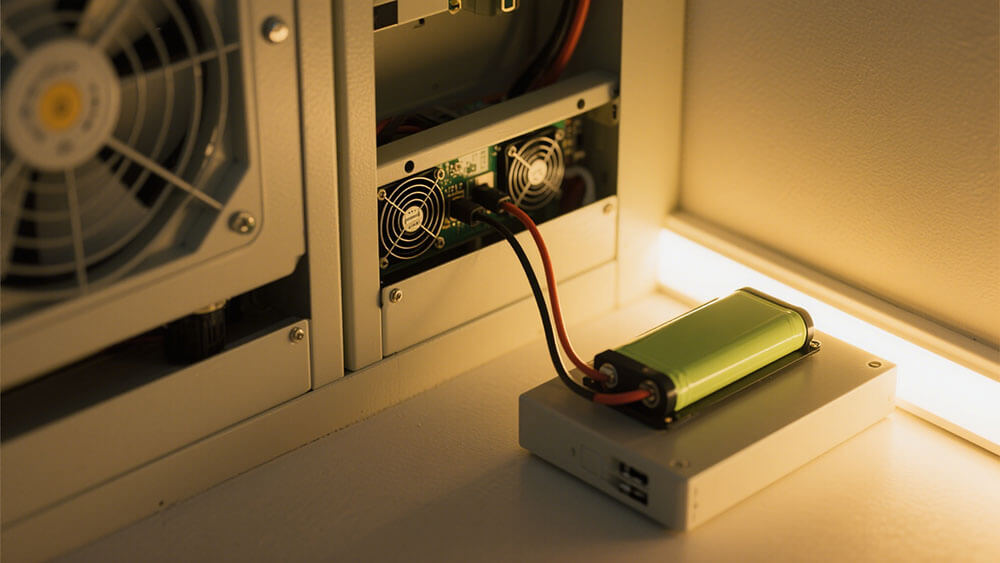

Adopting best practices ensures efficient charging and prolongs battery life. Use chargers tailored to the specific requirements of your lithium-ion battery packs. This prevents overvoltage or undervoltage issues that can degrade battery health. Regularly monitor battery performance to identify potential issues early. Implement temperature-controlled charging environments to avoid inefficiencies and safety risks.

Safety features in charging infrastructure are essential for industrial applications. These include overcurrent protection and thermal management systems. By following these practices, you can enhance the reliability and longevity of your lithium-ion battery packs.

3.3 Avoiding Overcharging and Deep Discharging in Business Operations

Overcharging and deep discharging significantly impact battery performance. Excessive voltage during overcharging stresses the battery, accelerating degradation. Deep discharges strain internal components, causing heat buildup and capacity loss. Higher Depth of Discharge (DoD) correlates with faster degradation due to increased stress.

To prevent these issues, maintain battery usage within a 20%-80% range. This reduces strain and extends battery life. For industrial operations, integrating battery management systems (BMS) ensures precise monitoring and control, minimizing risks associated with overcharging or deep discharging.

3.4 Monitoring and Managing Charging Cycles with Advanced Tools

Advanced tools simplify the monitoring and management of charging cycles. Artificial Neural Networks (ANNs) predict battery metrics, optimizing performance in applications like electric vehicles. Accurate State of Charge (SoC) estimation ensures efficient energy usage and prevents overcharging.

The table below highlights datasets that support advanced monitoring:

Dataset Name | Key Features |

|---|---|

Automotive Li-ion Cell Usage Dataset | Includes voltage, current, conducted charge, SOC, and time for realistic driving cycles. |

Fast-Charging Optimization Dataset | Utilizes 224 different fast-charging protocols and records internal resistance during charging. |

Cycle Life Prediction Dataset | Contains data from 135 cells cycled to end of life for cycle life prediction modeling. |

These tools enable precise tracking of charging cycles, helping you optimize battery performance and reduce operational costs.

Understanding lithium battery charging cycles is essential for businesses aiming to optimize battery life and operational efficiency. Charging habits, such as avoiding complete discharge or overcharging, significantly influence battery health and longevity. Research shows that charging beyond 80% state of charge can reduce battery lifespan, while fast charging generates excess heat, accelerating wear.

To enhance battery reliability and reduce costs, adopt strategies tailored to your operations. Use scenario-specific charging methods, monitor charging progress in real-time, and perform periodic maintenance to balance cells and manage temperatures. Industry studies validate these practices, demonstrating improved energy efficiency, reduced costs, and enhanced grid resilience through advanced optimization techniques like machine learning and genetic algorithms.

FAQ

1. What is the ideal charging range for lithium batteries?

Keep the battery between 20% and 80% charge. This range minimizes stress on internal components and extends battery lifespan.

2. Does fast charging harm lithium batteries?

Frequent fast charging generates excess heat, accelerating wear. Use regular charging methods for daily operations to preserve battery health.

3. How can you monitor charging cycles effectively?

Use battery management systems (BMS) or advanced tools like artificial neural networks (ANNs) to track cycles and optimize performance.

For customized solutions tailored to your needs, explore Large Power’s custom battery solutions.