Lithium-ion battery shelf life typically ranges from two to four years, with most batteries lasting between 600 and 1,000 cycles before performance drops. You depend on battery shelf life to maintain reliable operations in sectors like medical devices, robotics, and industrial automation. If you handle battery packs improperly, you risk safety hazards, reduced efficiency, and unexpected costs. Proper storage, such as keeping batteries at moderate temperatures and charge levels, preserves capacity and prevents early failure. When you compare primary and secondary batteries, you find that secondary batteries require more careful shelf life management. You need to focus on best practices for handling secondary batteries to extend their lifespan and ensure your battery inventory stays ready for critical applications.

Keep batteries cool and dry.

Monitor battery charge and voltage regularly.

Rotate battery stock using FIFO principles.

Separate battery types to avoid cross-contamination.

Inspect battery packs for signs of damage or leakage.

Key Takeaways

Lithium-ion batteries usually last 2 to 4 years or 600 to 1,000 charge cycles before their performance drops.

Store batteries in cool, dry places at about 30–50% charge to slow down aging and prevent damage.

Avoid fully charging or fully discharging batteries during storage to extend their lifespan.

Regularly inspect batteries for damage, swelling, or leaks and recharge them every few months to keep them healthy.

Use battery management systems to monitor battery health and follow best handling and storage practices to ensure safety and reliability.

Part 1: Lithium-Ion Battery Shelf Life

1.1 Typical Lifespan

You need to understand two key terms when managing lithium rechargeable batteries: shelf life and cycle life.

Cycle life refers to the number of full charge-discharge cycles a battery can complete before its capacity drops below 80% of its original value. This metric shows how many times you can use and recharge a battery before it becomes unreliable.

Shelf life measures how long you can store a battery without significant loss of performance or capacity. Storage conditions, such as temperature and state of charge, play a major role in determining shelf life.

Manufacturers report that most lithium-ion batteries in consumer electronics, like smartphones, last between 300 and 500 cycles. This usually equals about one year or more of daily use under ideal conditions. In contrast, lithium iron phosphate (LFP) batteries, which you often find in home energy storage and industrial backup systems, can last 8 to 15 years and endure 3,000 to 5,000 cycles before losing 20–30% of their original capacity. The actual lifespan depends on how often you cycle the battery, the temperature, and how deeply you discharge it.

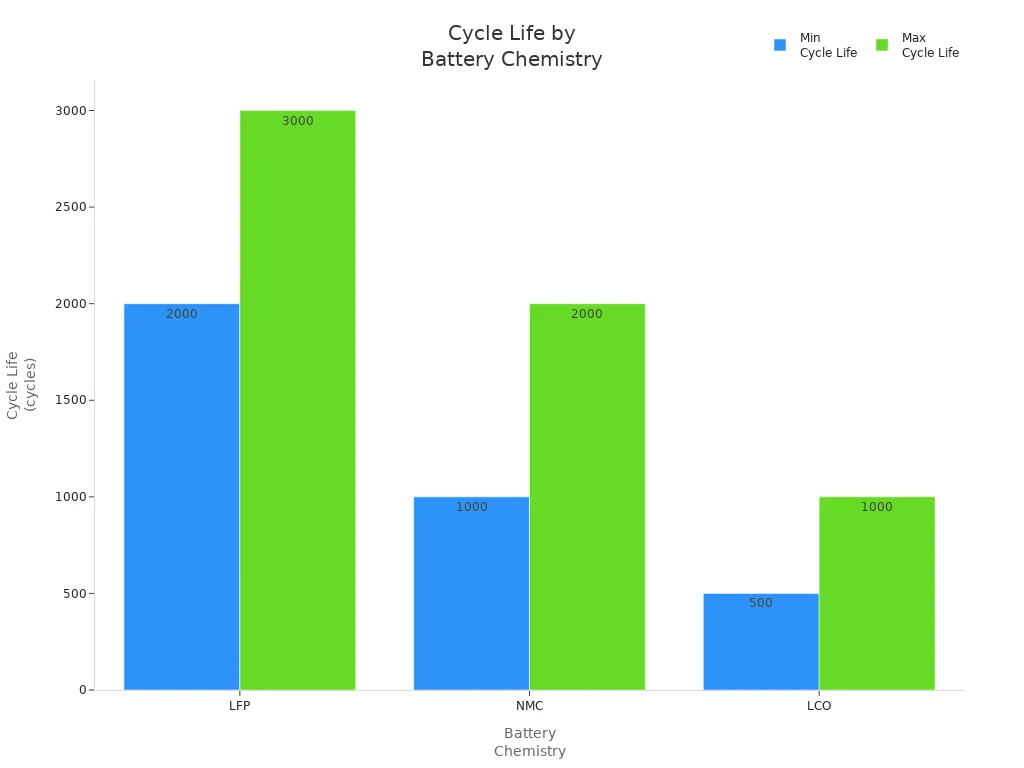

The chemistry of secondary batteries directly affects their longevity. For example, lithium cobalt oxide (LCO) batteries have a shorter lifespan, typically under 1,000 cycles, and are sensitive to high charge and discharge rates. Nickel manganese cobalt oxide (NMC) batteries offer a moderate cycle life of 1,000 to 2,000 cycles and balance energy density with stability. LFP batteries stand out for their long cycle life, excellent thermal stability, and high durability, making them ideal for stationary energy storage and industrial applications.

Chemistry | Typical Cycle Life (cycles) | Key Lifespan Characteristics |

|---|---|---|

LFP | 2,000 – 3,000+ | Longest cycle life, high durability, excellent thermal stability, ideal for stationary energy storage |

NMC | 1,000 – 2,000 | Moderate cycle life, higher energy density, balanced power and lifespan |

LCO | Under 1,000 | Shortest lifespan, less thermally stable, safety concerns, used in portable electronics |

You should select the right chemistry for your application. For example, medical devices and robotics often require batteries with high reliability and long shelf life, while consumer electronics may prioritize energy density over longevity.

1.2 Expiration and Self-Discharge

Lithium-ion battery shelf life does not only depend on how often you use the battery. Even when you store secondary batteries, they slowly lose capacity over time. This process is called self-discharge. Several factors cause expiration and self-discharge in lithium rechargeable batteries:

Electrode material degradation, including irreversible reactions and damage to the graphite structure.

Electrolyte effects, such as corrosion, dissolution of electrode materials, and formation of passivation layers.

Impurities and manufacturing defects, which can cause internal micro-short circuits.

Storage conditions, especially high temperature and high state of charge, which accelerate self-discharge.

Bonding failure between active substances and collectors, leading to capacity loss.

Tip: Always store secondary batteries in a cool, dry place and avoid keeping them fully charged for long periods. This practice slows down self-discharge and extends battery shelf life.

As batteries age, you will notice several impacts on performance:

Capacity loss and permanent reduction in charge storage.

Increased internal resistance, which reduces power output and efficiency.

Internal short circuits, leading to thermal instability and safety hazards.

Gas formation inside cells, causing swelling, leakage, and potential toxic exposure.

Accelerated degradation and shortened cycle life, resulting in more frequent replacements.

Device malfunctions due to unexpected power failures and reduced standby time.

Safety risks in high-drain applications, including overheating and fire hazards.

Environmental risks from improper disposal of degraded batteries.

For businesses that rely on battery packs in critical applications—such as backup power for infrastructure, medical equipment, or industrial automation—battery shelf life is essential. You may store batteries for months or even years before use. If you do not manage storage conditions, you risk deploying batteries that have already lost significant capacity. This can lead to unexpected downtime, safety incidents, and increased replacement costs.

You should implement inventory management practices, such as first-in, first-out (FIFO), to ensure you use older batteries before newer stock. Regularly monitor battery voltage and inspect for signs of degradation. By understanding and managing lithium-ion battery shelf life, you protect your investment and maintain reliable operations across all your business applications.

Part 2: Factors Affecting Battery Longevity

2.1 Chemistry and Components

The chemistry and internal components of a battery play a critical role in its longevity. You should select battery chemistries that match your application needs. For example, lithium iron phosphate (LFP) batteries offer high chemical stability and long cycle life, making them ideal for industrial and infrastructure backup systems. The choice of cathode and anode materials directly affects degradation rates. Cathode materials like lithium cobalt oxide (LCO) degrade faster at high temperatures, while LFP provides better resistance to structural changes. Anode materials, especially carbon-based types, can suffer from lithium plating and solid electrolyte interphase (SEI) growth, which reduce battery life.

Component/Material | Role in Battery Longevity |

|---|---|

Lithium Iron Phosphate (LiFePO4) | Provides chemical stability, structural integrity, and contributes to long cycle life and safety. |

Carbon Additive | Enhances electrode conductivity, improving battery efficiency and performance. |

Metal Conductive Agent (Copper) | Facilitates efficient electron transfer, critical for optimal battery function. |

Separator | Acts as a physical barrier preventing short circuits while allowing lithium ion transport, crucial for safety and lifespan. |

Electrolyte | Enables ion movement between electrodes; stable composition is essential for maintaining performance and cycle life. |

Cathode and Anode Materials | Influence energy density, charging rates, and cycle life, directly affecting battery longevity. |

Additives | Improve conductivity, stability, and safety, reducing degradation and extending battery life. |

Coating Materials | Protect electrodes from side reactions, enhancing structural integrity and lifespan. |

Packaging Materials | Protect battery from external damage, maintaining performance over time. |

2.2 Storage Temperature

You must control storage temperature to maximize battery longevity. High storage temperature accelerates chemical reactions inside secondary batteries, leading to faster capacity loss. For example, when storage temperature rises from 25°C to 55°C, the rate of capacity loss can triple. Manufacturers recommend storing batteries between -20°C and 25°C, with an ideal point near 15°C. In medical and robotics applications, maintaining proper storage temperature ensures batteries remain reliable and safe for critical use.

Tip: Always store batteries in cool, dry, and well-ventilated areas to slow down degradation.

2.3 Charge Level

The charge level during storage has a direct impact on the health of secondary batteries. Storing batteries at high charge levels increases SEI layer growth on the anode, which leads to capacity fade. You should store batteries at a 40–60% charge level for best results. Avoid keeping batteries fully charged or fully discharged for long periods. This practice helps preserve battery longevity and reduces the risk of sudden failure in security or industrial systems.

2.4 Handling and Packaging

Proper handling and packaging protect secondary batteries from physical and chemical damage. You should inspect batteries for damage, insulate terminals, and use protective materials to prevent short circuits. Packaging must meet international standards, such as UN 38.3, and include correct labeling for safe transport and storage. Inadequate handling can lead to fires, leaks, or hazardous exposure, as seen in past industrial accidents. By following best practices, you reduce risks and extend the service life of your battery inventory.

Part 3: Battery Types Compared

3.1 Primary vs. Secondary

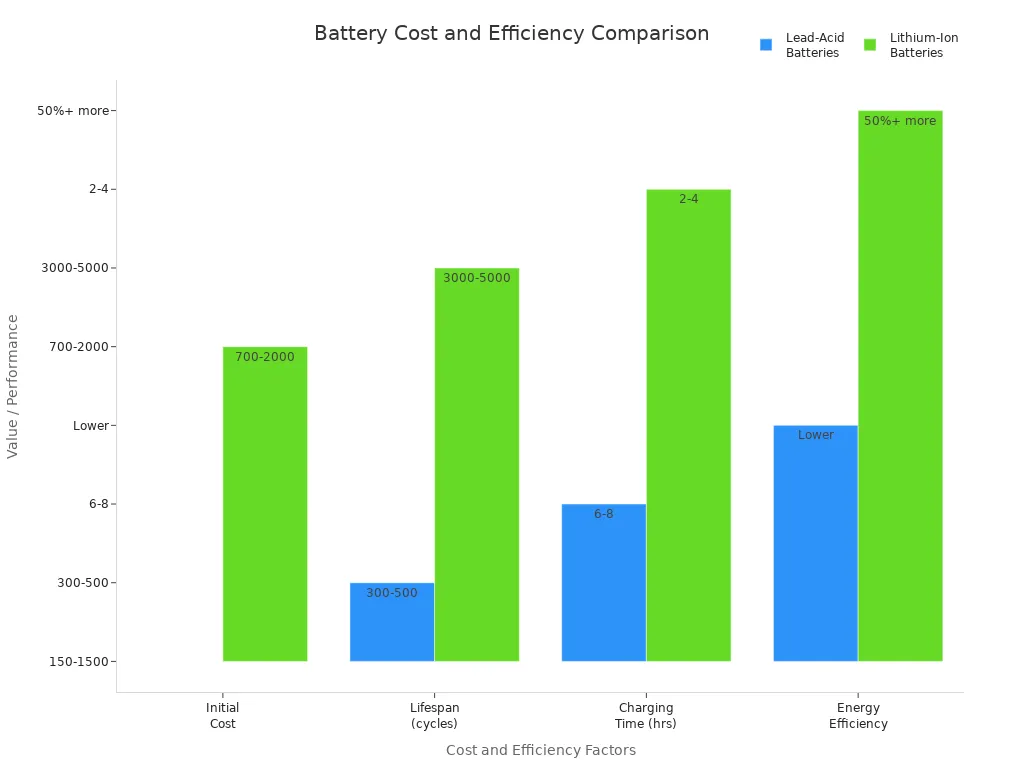

You encounter two main categories in the battery market: primary and secondary batteries. Primary batteries, such as alkaline or lithium metal cells, provide single-use power. You cannot recharge these batteries. They suit low-drain devices like remote controls or emergency flashlights. In contrast, secondary batteries, including lithium-ion and lithium iron phosphate (LFP) chemistries, offer rechargeability and repeated use. You rely on secondary batteries for critical applications in medical devices, robotics, security systems, and industrial automation.

Primary batteries deliver consistent voltage until depletion, then require replacement.

Secondary batteries support hundreds or thousands of charge-discharge cycles, reducing waste and long-term costs.

You can integrate secondary batteries into battery packs with advanced management systems for safety and performance.

Note: Secondary batteries, especially lithium-ion types, require careful management to maximize their usable life and ensure safety in demanding environments.

3.2 Usage and Performance

Your choice between primary and secondary batteries depends on usage patterns and performance needs. Secondary batteries excel in high-drain, frequent-use scenarios. You benefit from their ability to handle repeated cycling and deep discharges. However, usage patterns directly affect battery longevity. For example, you should avoid fully discharging lithium-ion batteries below 25%. Maintaining charge levels between 20% and 80% reduces stress and slows degradation. Shallow discharge cycles (10-15%) work best for daily use in robotics or medical equipment.

Depth of Discharge (DoD) | Approximate Cycle Life | Application Example |

|---|---|---|

80% | ~3,000 cycles | Industrial backup, EVs |

50% | ~6,000 cycles | Medical devices, security systems |

10-15% | 10,000+ cycles | Robotics, daily-use electronics |

State of health (SOH) and internal resistance are key performance metrics for secondary batteries. As batteries age, you see reduced capacity, increased resistance, and possible swelling. You should use battery management systems (BMS) to monitor these metrics and predict end-of-life based on real-world usage, not just fixed thresholds. This approach helps you maximize the practical longevity of your battery packs.

Battery longevity depends on specific use cases, not just fixed SOH thresholds.

BMS data (current, voltage, temperature) enables individualized, data-driven end-of-life predictions.

Cycling patterns and current rates in second-life applications, such as renewable energy storage, strongly influence battery longevity.

3.3 Pack Management

Effective pack management extends the usable life of secondary batteries in your operations. You should maintain battery charge between 20% and 80% to avoid chemical stress. Avoid full discharges and overcharging, which cause permanent damage. Store batteries at about 50% state of charge in cool, dry environments to maximize lifespan. Control operating temperature within recommended ranges (about -7°C to 35°C) to prevent accelerated aging and safety risks.

You should use advanced BMS for real-time monitoring of voltage, current, temperature, and state of charge. These systems enable cell balancing and predictive maintenance. Regular health checks, including monitoring internal resistance and capacity, help you detect early signs of degradation. Use manufacturer-recommended chargers and limit frequent fast charging to preserve battery capacity and cycle life.

Temperature management is critical. Stable, moderate temperatures can extend battery life by up to 15%.

Store batteries partially charged and recharge every few months during long storage.

Tailor management strategies to your application. For example, EVs benefit from advanced BMS and cooling systems, while consumer electronics require moderate charge levels and avoiding full discharges.

Tip: A quality BMS provides overcharge, over-discharge, and short-circuit protection. It also enables real-time monitoring and predictive maintenance, directly contributing to the longevity and safety of your battery packs.

Part 4: Storage and Handling

4.1 Ideal Conditions

You must maintain optimal storage conditions to maximize the shelf life and safety of every lithium battery pack. Industry guidelines recommend storing batteries at 30–40% state-of-charge (SOC) to reduce stress and volatility. For long-term storage, keep the battery in a cool, dry, and well-ventilated area. The ideal temperature is around 59°F (15°C), and you should avoid temperatures below -13°F (-25°C) or above 149°F (65°C). High humidity can cause corrosion and internal damage, so always select a location with low moisture. Store each battery upright and separated to prevent short circuits and pressure buildup. For medical, robotics, and industrial applications, these practices ensure your battery packs remain reliable and ready for deployment.

Storage Aspect | Recommended Condition |

|---|---|

Temperature | 59°F (15°C) ideal; avoid extremes below -13°F or above 149°F |

Humidity | Low humidity; avoid moisture to prevent corrosion |

Ventilation | Well-ventilated area to dissipate heat and gases |

Charge Level (SOC) | 30–40% for long-term storage |

Positioning | Upright, separated, and secured to prevent damage |

Tip: Always use original packaging or approved battery cases for storage and transport to minimize risk.

4.2 Monitoring and Safety

You need to monitor each battery pack during storage to detect early signs of degradation or safety risks. Advanced monitoring technologies, such as Fiber Bragg Grating sensors, track temperature, strain, and pressure in real time. These systems provide early warnings for overheating, swelling, or gas release, which are critical for infrastructure and security applications. Regularly inspect batteries for damage, swelling, or leaks. Use a battery management system (BMS) to monitor state-of-charge and temperature, preventing overcharge, deep discharge, and thermal runaway. Adhere to safety standards like NFPA 855 and the International Fire Code. Always ensure proper ventilation to prevent hazardous gas accumulation.

Store batteries away from ignition sources and direct sunlight.

Discard damaged or swollen batteries following local regulations.

Equip storage areas with fire suppression systems and emergency response plans.

4.3 Buying and Using

When purchasing lithium battery packs, select chemistries like lithium iron phosphate (LiFePO4) for safety and long cycle life. Ensure the battery matches your system’s voltage and capacity requirements. Choose batteries with built-in safety features, such as overcharge, over-discharge, and short-circuit protection. Verify compliance with certifications like UL1642 and IEC62133. For commercial and industrial use, buy from reputable suppliers who offer technical support and traceability. During use, avoid deep discharges below 20% SOC and prolonged full charges. Recharge batteries in moderate temperature environments and avoid fast charging unless the battery is designed for it. Monitor self-discharge rates and recharge periodically during storage to maintain capacity.

Note: Proper storage, monitoring, and usage practices extend battery life, reduce replacement costs, and ensure safe operation in all application scenarios.

You need to understand lithium-ion battery shelf life to keep your business running smoothly. When you store each battery in a cool, dry place and keep it at the right charge, you extend its lifespan and reduce costs. Proper battery handling means fewer replacements, less downtime, and safer operations in medical, robotics, security, and industrial settings. Regular battery monitoring and following best practices help you avoid costly incidents and maintain efficiency.

Store each battery at 30–50% charge in ventilated, dry areas.

Inspect and recharge every few months to prevent deep discharge.

Use certified chargers and avoid physical damage to any battery.

By making battery care a priority, you improve productivity and protect your investment across all applications.

FAQ

How do you determine when a lithium battery pack needs replacement?

You monitor battery performance using a battery management system. If you see reduced capacity, increased charging time, or swelling, you should replace the battery. Regular voltage checks help you avoid unexpected failures in medical, robotics, or industrial applications.

What is the best way to store lithium battery packs for long periods?

You store each battery at 30–40% charge in a cool, dry, and ventilated area. Avoid direct sunlight and high humidity. For infrastructure or security systems, periodic inspections and recharging every few months maintain battery health.

Can you use lithium battery packs in extreme temperatures?

You should avoid exposing any battery to extreme heat or cold. High temperatures accelerate degradation, while freezing conditions reduce capacity. For robotics and medical devices, keep battery packs within manufacturer-recommended temperature ranges to ensure safety and reliability.

How often should you inspect battery packs in storage?

You inspect each battery pack every one to three months. Look for signs of swelling, leakage, or voltage drop. In industrial and consumer electronics applications, regular inspections prevent safety risks and extend battery life.

What certifications should you look for when buying lithium battery packs?

You select battery packs certified to UL1642 and IEC62133 standards. These certifications confirm safety and quality. For medical, security, and industrial use, choose batteries from reputable suppliers who provide technical support and traceability.