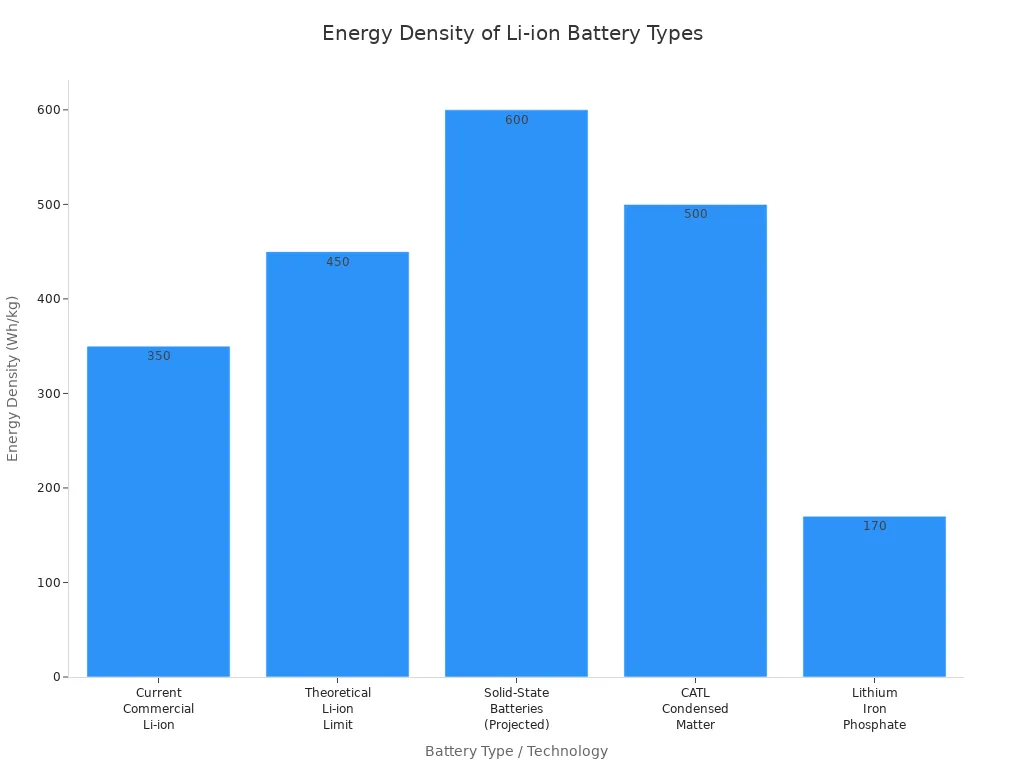

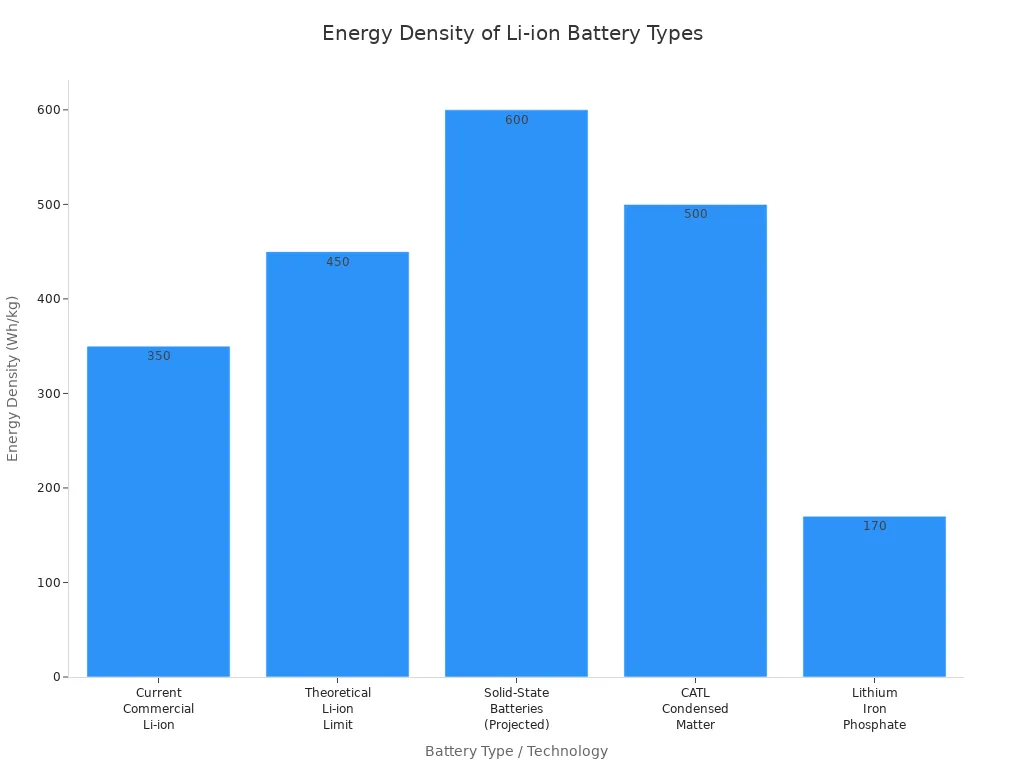

You encounter lithium-ion battery weight and density as key factors when designing battery packs for electric vehicles, electronics, or industrial systems. Higher energy density means you can store more power in less weight, which improves efficiency and range. For example, recent advances have pushed typical lithium-ion battery energy density to around 350 Wh/kg, allowing lighter packs for longer runtimes.

Battery Type / Technology | Energy Density (Wh/kg) | Notes / Weight Implications |

|---|---|---|

Current Commercial Li-ion Batteries | ~350 Wh/kg | Typical gravimetric energy density for current lithium-ion cells used in EVs and consumer electronics. |

Theoretical Li-ion Limit | 400-500 Wh/kg | Upper theoretical limit; approaching this is challenging due to safety and cycle life issues. |

Solid-State Batteries (Projected) | 500-700 Wh/kg | Expected to nearly double current densities, improving range and safety; potential future commercial tech. |

Tesla 4680 Cells | Not explicitly stated | Expected 5x increase in energy capacity and 16% range boost; implies higher energy density and efficiency. |

CATL Condensed Matter Battery | 500 Wh/kg | Latest commercial advancement enabling longer-range EVs and electric aircraft; significant weight savings. |

Nickel-Rich Cathodes (NCM 811) | +10-20% over NMC | Improves energy density by increasing nickel content, enhancing energy per unit weight. |

Lithium Iron Phosphate (LFP) | 160-180 Wh/kg | Lower energy density (~30% less than nickel-based) but longer cycle life (4000+ cycles), used in >50% of EVs in China. |

Full EV Battery Pack | ~30-40% less than cells | Due to packaging, cooling, wiring, and casing, effective pack energy density is lower than cell-level values. |

Lithium-ion battery weight and density influence your choice of materials and technologies, whether you build batteries for medical devices, robotics, or infrastructure. You optimize performance by balancing these factors for each application.

Key Takeaways

Higher energy density means storing more power with less weight, which improves battery performance and efficiency in electric vehicles, medical devices, and robotics.

Choosing the right lithium-ion battery chemistry, like NMC for lightweight needs or LiFePO4 for safety and long life, helps balance weight, energy, and application requirements.

You can estimate battery weight by dividing the battery’s energy capacity by its specific energy density and adding extra weight for packaging, ensuring accurate design and better battery selection.

Part 1: Lithium-ion Battery Weight and Density

1.1 Definitions

You need to understand the core concepts behind lithium-ion battery weight and density to make informed decisions in battery pack design. Industry organizations, define energy density as the ratio of a battery’s energy to its weight or volume. This metric is sometimes called power density, but in most technical contexts, energy density is the standard term. When you see gravimetric energy density, it refers specifically to the amount of energy stored per unit weight, usually measured in watt-hours per kilogram (Wh/kg).

Manufacturers use these definitions in technical datasheets. They measure energy density in Wh/kg, which tells you how much energy a lithium ion battery can store for every kilogram of weight. This value directly affects how long your device or vehicle can run before needing a recharge. Datasheets also specify the conditions under which they measure energy density, such as discharge rate, temperature, and cut-off voltage. Think of energy density like the size of a water bottle: a larger bottle holds more water, just as a battery with higher energy density stores more energy for the same weight.

You will also encounter volumetric energy density, which measures energy per unit volume (Wh/L). However, gravimetric energy density is more important when weight is a critical factor, such as in electric vehicles, drones, or portable medical devices. In these cases, lithium-ion battery weight and density determine how much energy you can carry without adding unnecessary mass.

Term | Definition | Typical Units |

|---|---|---|

Gravimetric Energy Density | Energy stored per unit weight | Wh/kg |

Volumetric Energy Density | Energy stored per unit volume | Wh/L |

Battery Weight | Total mass of the battery, including cells, casing, and electronics | kg or g |

Lithium-ion Battery Density | General term for either gravimetric or volumetric energy density | Wh/kg or Wh/L |

Note: Always check the measurement conditions in datasheets to ensure you compare batteries accurately.

1.2 Importance for Battery Packs

Lithium-ion battery weight and density play a central role in the performance and efficiency of battery packs across many industries. When you design battery packs for electric vehicles, robotics, or industrial systems, you must balance the need for high energy density with safety, cost, and operational requirements.

A higher energy density allows you to store more energy in a smaller, lighter battery. This advantage is crucial for electric vehicles, where battery weight directly impacts driving range, acceleration, and handling. For example, a lighter battery lowers the vehicle’s center of gravity, which improves stability and reduces rollover risk. In the medical sector, lightweight lithium-ion batteries enable portable devices that patients can carry comfortably. Robotics and security systems also benefit from reduced battery weight, as it allows for more agile movement and longer operational times.

You will notice that lithium-ion battery weight and density affect not only performance but also cost and efficiency. In industrial and commercial settings, reducing battery weight can lower the total cost by enabling smaller, less expensive battery packs that still meet power requirements. However, using lightweight materials like aluminum or carbon fiber may increase manufacturing costs. You must weigh these trade-offs carefully during the design process.

Recent advances in lithium-ion battery technology have pushed gravimetric energy density to new heights. Researchers in China have developed lithium-ion batteries with energy densities exceeding 600 Wh/kg, which is double the current best commercial batteries. This breakthrough means you can achieve longer driving ranges and improved performance in electric vehicles without increasing battery weight. However, as you increase battery size to meet higher power demands, you may encounter diminishing returns. Heavier batteries can reduce efficiency and handling, especially in larger vehicles like SUVs.

Part 2: Battery Weight Factors

2.1 Size and Chemistry

You influence battery weight by selecting the right size and chemistry for your application. The physical dimensions of a lithium ion battery cell, such as electrode thickness and particle size, directly affect its energy density and overall weight. Thicker electrodes can increase capacity at low discharge rates, but may reduce performance at high rates. Smaller particle sizes improve capacity and thermal management, which helps you achieve better energy density and lighter batteries.

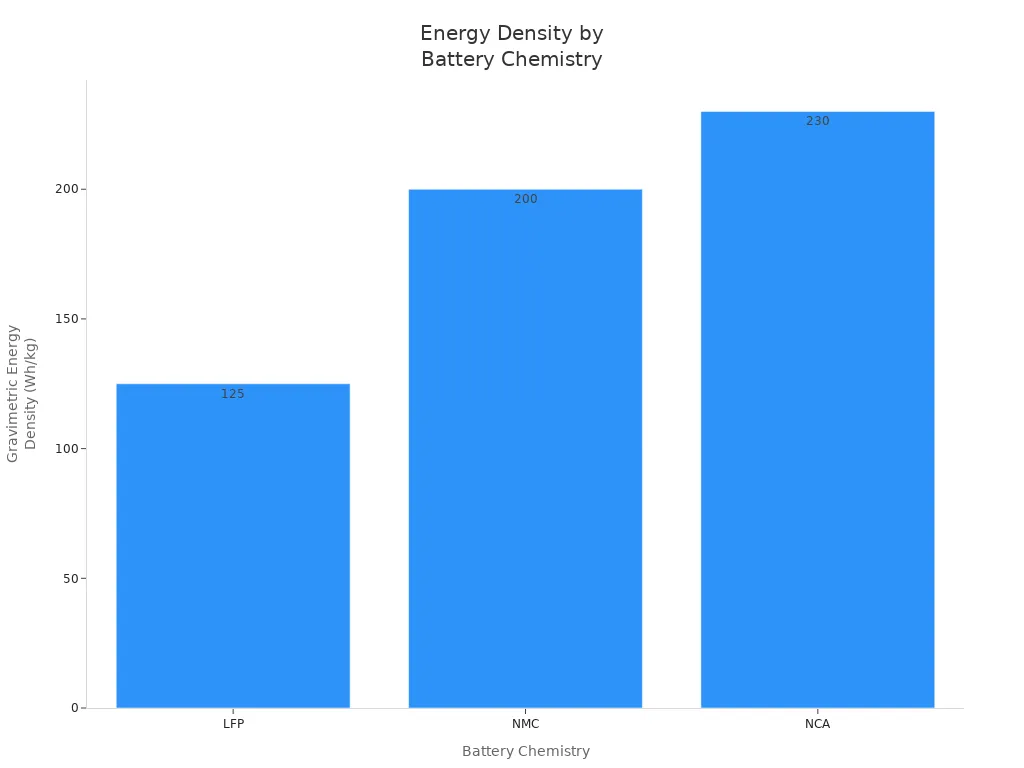

Manufacturers use different lithium ion battery chemistries to optimize weight and energy density. For example, LiFePO4 batteries offer 90-160 Wh/kg gravimetric energy density and 300-350 Wh/L volumetric energy density. These batteries are heavier for the same capacity but provide excellent safety and long cycle life, making them ideal for industrial and infrastructure systems. NMC batteries deliver 150-250 Wh/kg and 500-700 Wh/L, resulting in lighter and more compact designs. NCA batteries reach 200-260 Wh/kg, supporting high-performance electric vehicles and robotics.

Battery Chemistry | Gravimetric Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) | Weight Characteristics | Notes |

|---|---|---|---|---|

LiFePO4 | 90-160 | 300-350 | Heavier for same capacity | Safer, longer cycle life |

NMC | 150-250 | 500-700 | Lighter, compact | High energy density |

NCA | 200-260 | N/A | Lightweight | Very high energy density |

You should match lithium ion battery chemistry and cell size to your sector’s needs. For medical devices and consumer electronics, prioritize lightweight NMC or NCA cells. For industrial or security systems, LiFePO4 batteries provide reliability and safety.

2.2 Energy Content

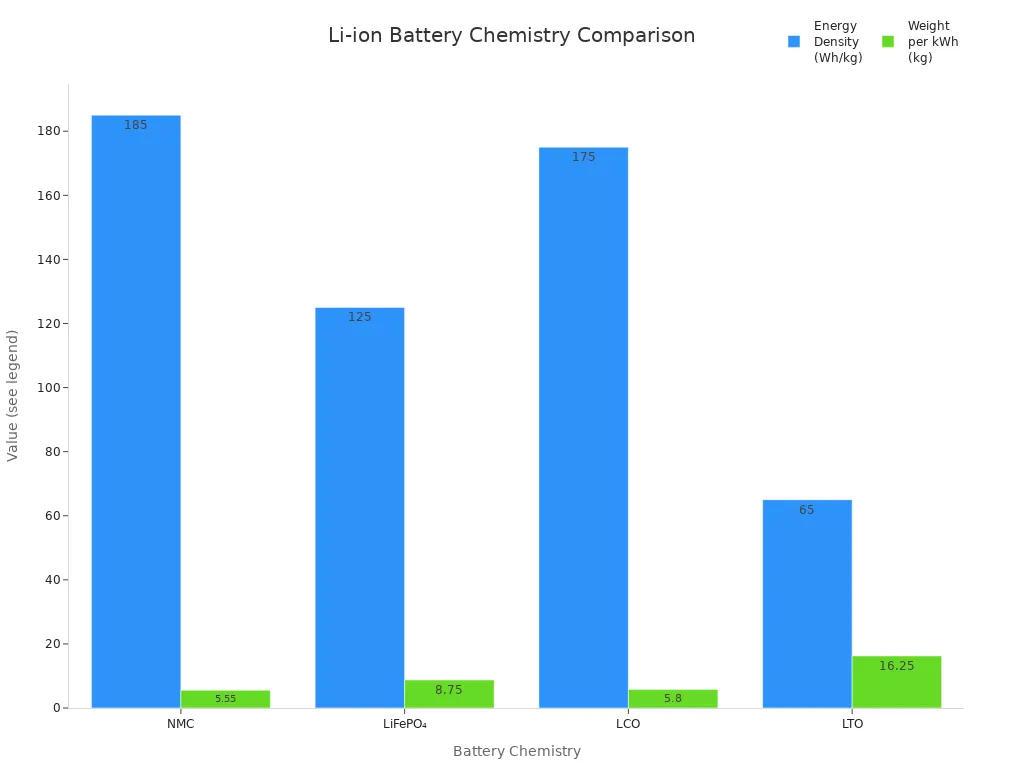

You determine battery weight by calculating the total energy content required for your device or system. The relationship between energy content and weight depends on the energy density of the lithium ion battery chemistry you select. Higher energy density means you can store more energy with less weight, which is critical for portable electronics, robotics, and electric vehicles.

For example, LTO batteries have an energy density of 50-80 Wh/kg, resulting in heavier batteries for the same energy content. LiFePO4 batteries balance weight and energy, making them suitable for industrial equipment and infrastructure. NMC and LCO batteries offer 150-220 Wh/kg, enabling lighter batteries for medical devices and consumer electronics.

Lithium-Ion Battery Chemistry | Energy Density (Wh/kg) | Implication on Weight and Energy Content |

|---|---|---|

LTO | 50-80 | Heavier batteries for same energy content |

LiFePO4 | 90-160 | Balanced weight and energy, reliable and safe |

LCO | 150-200 | Lightweight, ideal for portable electronics |

NMC | 150-220 | Enables lighter batteries for same energy |

You maximize battery performance by choosing high energy density lithium ion battery chemistries for weight-sensitive applications. Always consider safety and cycle life when selecting batteries for robotics, medical, or security systems.

Part 3: Battery Weight Calculation

3.1 Weight per Watt-hour

You need to estimate lithium ion battery weight accurately when designing battery packs for electric vehicles, consumer electronics, or industrial systems. The most reliable method uses the formula:

Battery Weight (kg) = Battery Capacity (Ah) × Nominal Voltage (V) / Energy Density (Wh/kg)

This formula allows you to calculate the weight of a lithium ion battery by combining its capacity, voltage, and the specific energy density of the chosen chemistry. For example, LiFePO4 batteries typically offer 95-120 Wh/kg, while NMC batteries provide 115-150 Wh/kg. You can use a lithium ion battery weight calculator to simplify this process, especially when comparing chemistries for robotics or medical devices.

Tip: Always check the energy density value for your selected lithium ion battery chemistry. This ensures your calculation matches real-world performance.

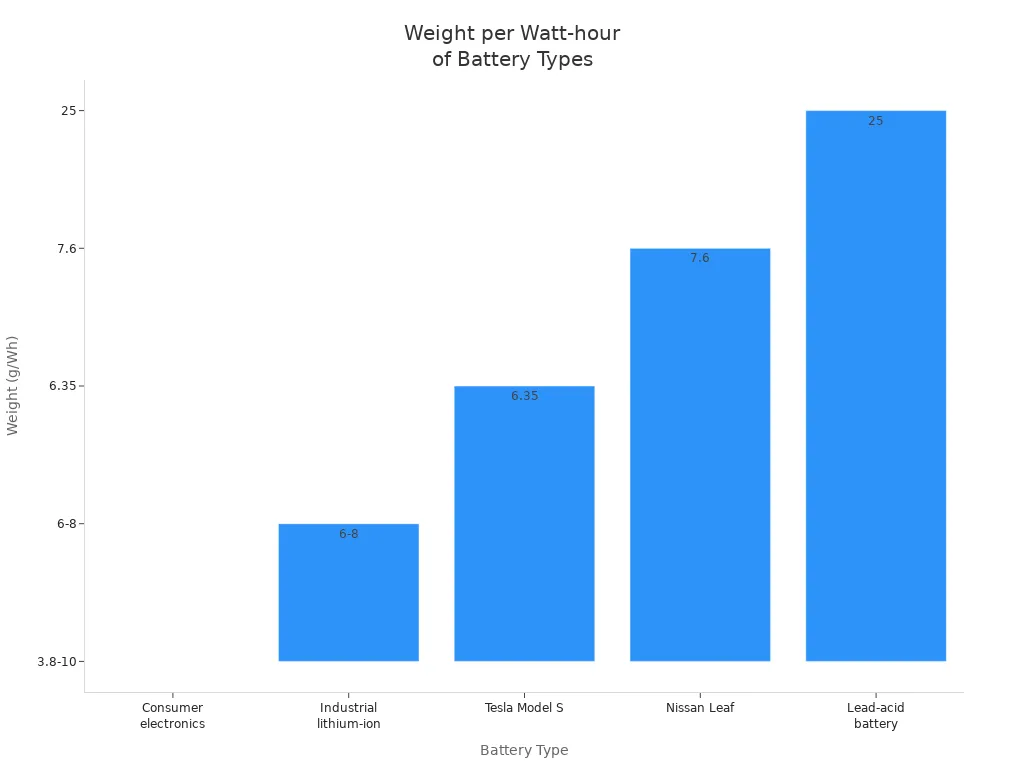

The weight per watt-hour varies by application. Consumer electronics batteries usually range from 3.8 to 10 grams per watt-hour, while industrial lithium ion batteries for electric vehicles weigh about 6 to 8 grams per watt-hour. This difference reflects the design priorities for each sector.

Application Sector | Typical Energy Density (Wh/kg) | Weight per Watt-hour (g/Wh) | Example Device |

|---|---|---|---|

Consumer Electronics | 100 – 265 | 3.8 – 10 | Laptop, smartphone |

Industrial (EV, Storage) | 100 – 265 | 6 – 8 | Electric vehicle, power station |

Lead-acid (reference) | ~40 | ~25 | Backup power, infrastructure |

You can see that lithium ion battery weight is much lower than traditional lead-acid batteries, which is why you prefer lithium ion technology for portable and high-performance applications.

3.2 Estimation Methods

You can estimate lithium ion battery weight for any application using a step-by-step approach. This method works for medical devices, robotics, security systems, infrastructure, and consumer electronics.

Determine Battery Capacity

Find the battery capacity in amp-hours (Ah) or watt-hours (Wh). Manufacturers list this in product specifications. For example, a laptop battery may have a capacity of 7800 mAh at 11.1 V.Identify Specific Energy

Check the specific energy (Wh/kg) for your lithium ion battery chemistry. Use the following values:LiFePO4: 95-120 Wh/kg

NMC: 115-150 Wh/kg

LCO: 140-175 Wh/kg

LMO: 115-145 Wh/kg

LTO: 50-80 Wh/kg

Calculate Battery Weight

Use the formula:Weight (kg) = Capacity (Wh) / Specific Energy (Wh/kg)You can also use a lithium ion battery weight calculator for quick results.

Consider Structural Components

Add extra weight for casing, separators, and packaging. These components can increase total battery weight by 30-40% in electric vehicle packs.

Note: Always include structural components in your calculation for accurate results, especially in industrial and infrastructure applications.

Example Calculations

You can apply these steps to real-world scenarios:

Laptop Battery

A rugged laptop uses a lithium ion battery with 7800 mAh capacity at 11.1 V.Capacity: 7800 mAh × 11.1 V = 86.58 Wh

Chemistry: LMO (120 Wh/kg)

Weight: 86.58 Wh / 120 Wh/kg ≈ 0.72 kg

Electric Vehicle Battery

The Tesla Model S battery pack has 85 kWh capacity.Capacity: 85,000 Wh

Weight: 85,000 Wh / 13.4 Wh/kg ≈ 6.35 kg/kWh (actual pack weight: 540 kg)

Portable Power Station

A power station with 2 kWh capacity uses NMC cells (150 Wh/kg).Capacity: 2,000 Wh

Weight: 2,000 Wh / 150 Wh/kg ≈ 13.3 kg

Medical Device Battery

A medical device uses a lithium ion battery with 2.5 Ah at 3.7 V.Capacity: 2.5 Ah × 3.7 V = 9.25 Wh

Chemistry: LCO (175 Wh/kg)

Weight: 9.25 Wh / 175 Wh/kg ≈ 0.053 kg (53 grams)

Application | Chemistry | Capacity (Wh) | Specific Energy (Wh/kg) | Estimated Weight (kg) |

|---|---|---|---|---|

Laptop | LMO | 86.58 | 120 | 0.72 |

Tesla Model S (EV) | NMC | 85,000 | 134 | 635 |

Portable Power Station | NMC | 2,000 | 150 | 13.3 |

Medical Device | LCO | 9.25 | 175 | 0.053 |

You can use these examples to guide your own calculations. A lithium ion battery weight calculator helps you compare options quickly, ensuring you select the best battery for your application.

Pro Tip: For robotics and security systems, prioritize chemistries with higher specific energy to minimize battery weight and maximize operational time.

Part 4: Lithium Ion Battery Energy Density

4.1 Specific vs. Volumetric Density

You encounter two main types of energy density when evaluating lithium-ion batteries: specific energy density and volumetric energy density. Specific energy density measures the energy stored per unit mass (Wh/kg), while volumetric energy density refers to energy stored per unit volume (Wh/L). You see specific energy density benefit from lithium’s low atomic mass, which allows more energy storage per weight. Volumetric energy density depends on how tightly you pack electrodes and electrolyte inside the cell.

Aspect | Specific Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) |

|---|---|---|

Definition | Energy stored per unit mass | Energy stored per unit volume |

Influencing Factors | Lithium’s light weight and small atomic size | Electrode design, porosity, packing density |

Example from Li–S Batteries | High sulfur utilization improves specific energy | High electrode porosity reduces volumetric energy density |

Practical Values | Cell-specific energy improved significantly | Volumetric energy density often below 400 Wh/L in many cases |

Design Strategies | Focus on increasing sulfur content and utilization | Use of dense, low tortuosity electrodes and optimized electrolyte permeability |

Challenges | Maintaining high sulfur loading without loss of capacity | Reducing electrode porosity to increase volumetric density without sacrificing performance |

Recent research shows that specific energy density is driven by the intrinsic capacity of electrode materials and lithium’s lightness. Volumetric energy density is shaped by cell structure, electrode porosity, and inactive components. You often see nanostructured anodes boost specific energy density but lower volumetric energy density due to low tap density. You must balance these metrics for applications in medical devices, robotics, and consumer electronics.

Specific energy density benefits from lithium’s small size.

High-capacity electrodes like graphite and silicon increase specific energy density.

Volumetric energy density relies on efficient packing and low porosity.

Solid electrolytes can raise volumetric energy density.

Tip: You should prioritize specific energy density for portable devices and volumetric energy density for space-constrained systems such as robotics or infrastructure.

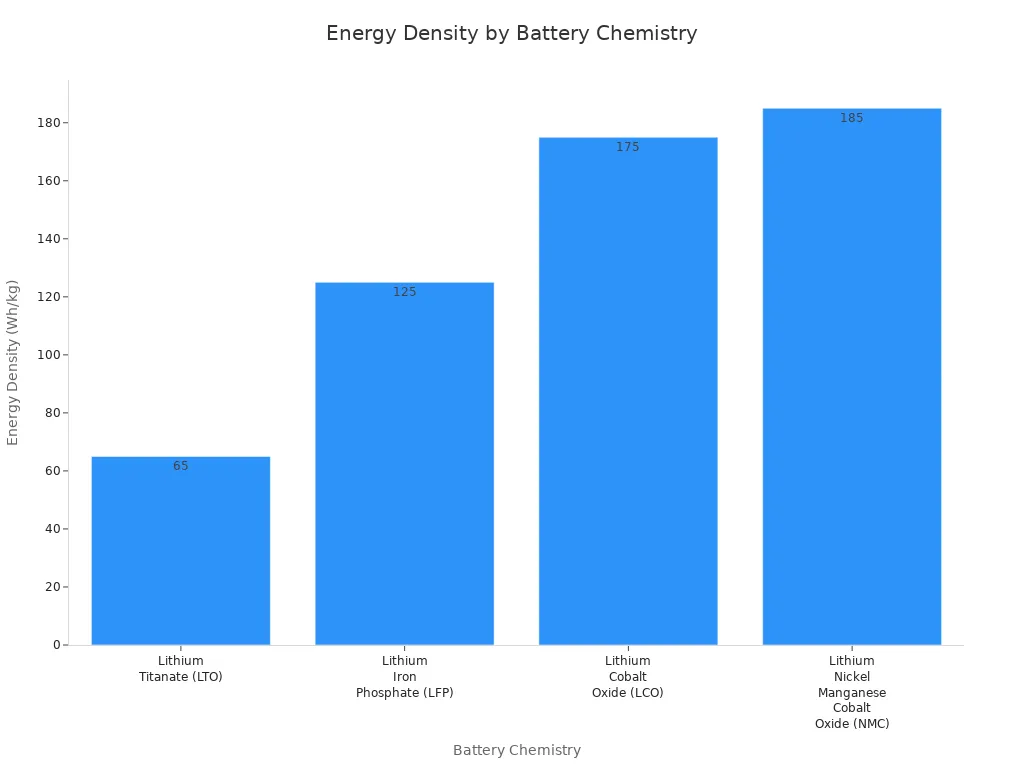

4.2 Chemistry Comparisons

You select lithium-ion battery chemistry based on the required energy density, weight, and application. NMC batteries deliver high energy density (150–220 Wh/kg), platform voltage of 3.7 V, and cycle life of 1000–2000 cycles. These batteries suit electric vehicles and robotics, where high energy density and low weight improve range and agility. LiFePO4 offers lower energy density (90–160 Wh/kg), platform voltage of 3.2 V, and cycle life exceeding 4000 cycles. You choose LiFePO4 for industrial and infrastructure systems needing safety and long life.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Weight per kWh (kg) | Application Examples |

|---|---|---|---|---|---|

NMC | 3.7 | 150–220 | 1000–2000 | 4.5–6.6 | EVs, robotics, consumer electronics |

LiFePO4 | 3.2 | 90–160 | 4000+ | 6.5–11 | Industrial, infrastructure, security |

LCO | 3.7 | 150–200 | 500–1000 | 5–6.6 | Medical, consumer electronics |

LMO | 3.7 | 115–145 | 1000–2000 | 6.9–8.7 | Security, industrial |

LTO | 2.4 | 50–80 | 7000+ | 12.5–20 | Grid storage, infrastructure |

You notice that high energy density chemistries like NMC and LCO reduce battery weight and maximize range for electric vehicles and portable electronics. Low energy density chemistries such as LiFePO4 and LTO provide safety and long cycle life, which you value in industrial and infrastructure sectors.

You must weigh trade-offs between energy density, power density, safety, and cost. Nickel-rich cathodes in NMC batteries boost energy density and extend EV driving range. Manganese and cobalt improve safety and thermal stability. You optimize battery selection by matching chemistry to your sector’s needs, whether for medical devices, robotics, security systems, or industrial infrastructure.

Part 5: Battery Pack Weight Breakdown

5.1 Cell Components

You need to understand how each cell contributes to the total weight of a lithium-ion battery pack. The cell contains several key parts: anode, cathode, separator, and electrolyte. Each part plays a specific role in storing and transferring energy. The cathode usually makes up the largest portion of the cell’s mass, followed by the electrolyte, anode, and separator. The table below shows a typical mass percentage breakdown for these components:

Component | Typical Mass Percentage of Total Battery Pack Weight |

|---|---|

Anode | 5-10% |

Cathode | 20-25% |

Electrolyte | 10-15% |

Separator | 3-5% |

You see that the cathode and electrolyte together account for a significant share of the total weight. When you select a lithium ion cell for medical, robotics, or security system applications, you must consider how each component affects both performance and safety. The separator, though light, is critical for safety by preventing short circuits between the anode and cathode.

5.2 Pack Structure

You must also account for the weight added by the pack structure and auxiliary systems. In commercial battery packs, the cells often make up about 60% of the total weight. The remaining 40% comes from the enclosure, Battery Management System (BMS), cooling system, and wiring. For example, the Mitsubishi Outlander PHEV battery pack weighs 175 kg, with the cells alone at 105.6 kg. The enclosure provides mechanical support, protects against dust and water, and resists corrosion. The BMS manages cell safety and performance, while the cooling system keeps the cells within safe temperature ranges.

Manufacturers use several strategies to optimize pack weight and maximize energy density:

They use Cell-to-Pack (CTP) designs to eliminate intermediate modules, increasing volume utilization.

Large module designs reduce structural mass per cell and improve connection strength.

Direct integration of cells, like BYD’s blade battery, increases specific energy and lowers production costs.

Lightweight materials such as aluminum-magnesium alloys and composites reduce enclosure weight.

Advanced simulation tools help vary material thickness, reinforcing load-bearing parts and thinning others.

You benefit from these innovations by getting battery packs that deliver more energy with less weight, while maintaining safety and reliability for industrial, infrastructure, and consumer electronics applications.

You drive innovation by balancing lithium-ion battery weight and energy density. Advances like silicon anodes and self-standing electrodes boost energy density for NMC and LiFePO4, supporting lighter, safer packs. For B2B projects, prioritize chemistry, regulatory compliance, and lifecycle cost. Apply these insights to optimize battery selection in your next design.

FAQ

1. What factors most influence lithium-ion battery weight and density?

You control lithium-ion battery weight and density by selecting chemistry, cell design, and capacity. NMC and LCO cells offer high energy density for robotics and consumer electronics.

2. How do you estimate lithium ion battery weight for your application?

You use a lithium ion battery weight calculator. Enter capacity and energy density. For medical devices, choose LCO cells with 150–200 Wh/kg for lightweight, safe batteries.

3. Why does battery energy density matter in industrial and infrastructure sectors?

You maximize efficiency and reduce battery weight by choosing high energy density lithium-ion batteries. NMC and LiFePO4 chemistries deliver reliable performance for transportation and security systems.