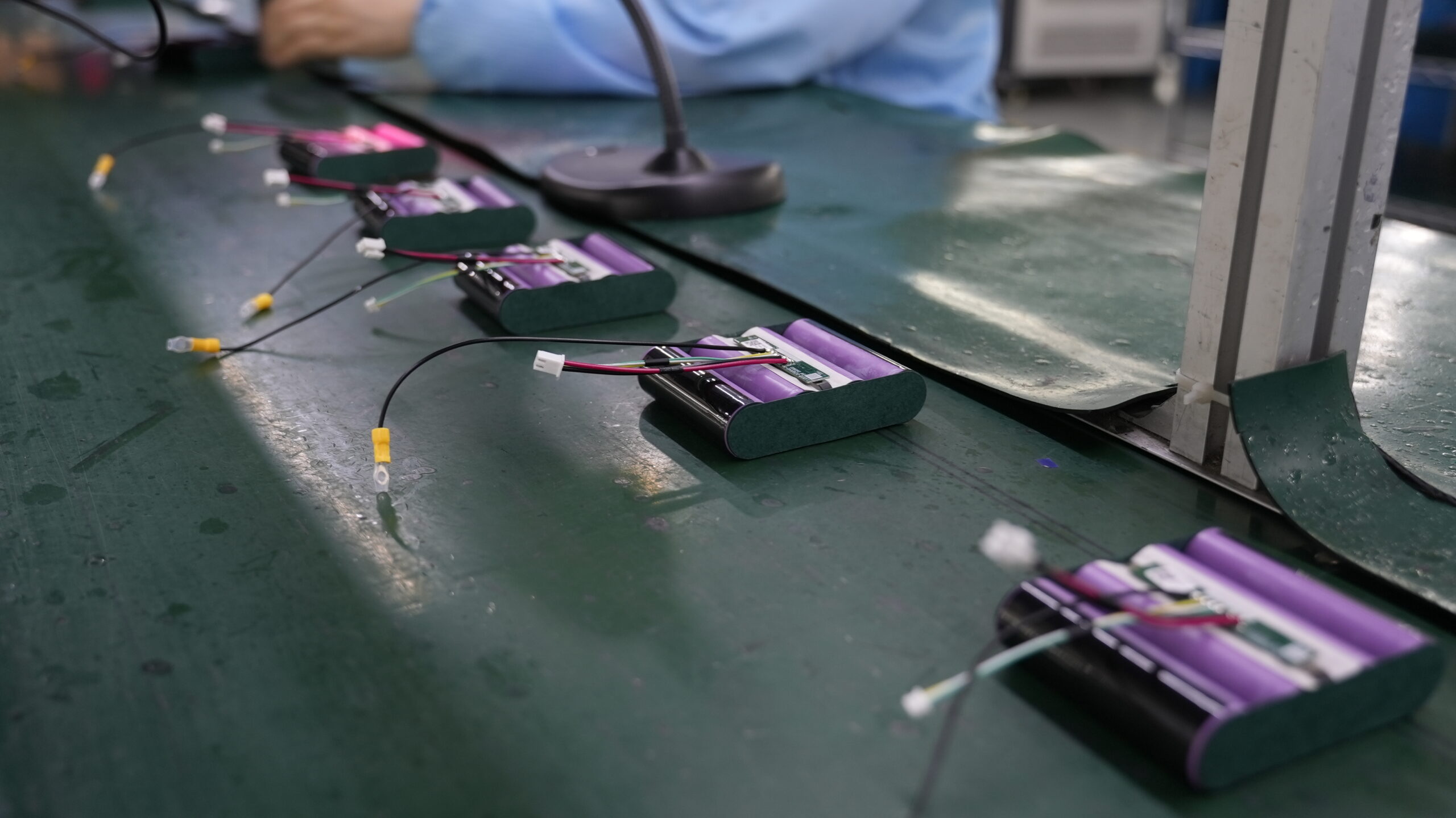

You may encounter lithium-ion battery zero voltage after recharging, which can disrupt your operations and damage assets. In B2B environments, lithium-ion battery zero voltage often results from short circuits, faulty chargers, or battery aging.

Zero voltage failures in lithium-ion batteries can cause:

Fires and catastrophic loss

Multi-million dollar asset damage

Higher battery replacement costs

Business continuity risks

Ignoring a dead lithium-ion battery or poor management shortens battery life and increases costs. Careful attention to lithium-ion battery zero voltage ensures safer, longer-lasting battery performance.

Key Takeaways

Zero voltage in lithium-ion batteries often results from short circuits, faulty chargers, battery aging, or the battery entering hibernation mode to protect itself.

Diagnose zero voltage by checking battery voltage, BMS status, and carefully attempting safe revival methods like slow charging or boost charging if no physical damage exists.

Prevent zero voltage by regularly monitoring battery health, using proper chargers, avoiding deep discharges, and following safe storage and handling practices.

Causes of Lithium-ion Battery Zero Voltage

Short Circuits

You may encounter a sudden zero voltage in a lithium-ion battery due to a short circuit. This issue often results from manufacturing defects, physical damage, or wiring failures. In deep overdischarge, the anode’s copper dissolves and migrates, causing internal short circuits. As the internal resistance drops, the battery voltage falls rapidly to zero. This process generates intense heat and can trigger thermal runaway, posing risks in critical applications like medical devices, robotics, and security systems. Once a short circuit occurs, you cannot revive the battery; immediate replacement is necessary to maintain safety and operational continuity.

Faulty Chargers

A faulty charger can cause lithium-ion battery zero voltage by failing to terminate charging properly or by delivering incorrect voltage or current. Common charger faults include continuous constant voltage charging, excessive spot welding current, and lack of cutoff mechanisms. These faults lead to lithium plating, electrolyte decomposition, and internal short circuits. In industrial and infrastructure settings, using a mismatched or damaged charger can result in dead batteries and unexpected downtime. Always use chargers that match your battery specifications and ensure your battery management system (BMS) is functioning correctly.

Hibernation Mode

Lithium-ion batteries feature a built-in BMS that disconnects the battery when voltage drops below a safe threshold, entering hibernation mode. In this state, you may measure zero voltage externally, but the battery retains some internal charge. Hibernation protects against overdischarge and extends battery life in consumer electronics and security systems. You can often revive a hibernating battery by applying a small charge current to reactivate the BMS. If the battery does not recover, replacement is required.

Trigger Condition | Description |

|---|---|

Low Voltage (Undervoltage) | Battery voltage falls below cutoff due to deep discharge or storage. |

Overcharge | Voltage exceeds upper limit, activating protection. |

Overcurrent | Sudden current surge triggers protection. |

Overtemperature | Temperature rises above safe threshold. |

Long Inactivity | Extended storage triggers sleep mode. |

Safety Faults | Short circuits or extreme conditions cause BMS shutdown. |

Lithium-ion Aging

Aging is a gradual process that reduces lithium-ion battery capacity and performance. Over 8 to 10 years or 3,000 to 5,000 cycles, you will notice faster voltage drops and diminished runtime. Aging can indirectly cause zero voltage if you leave batteries discharged or store them improperly. In industrial and consumer applications, aged batteries may become dead and fail to recover even after charging. Replace batteries showing rapid voltage loss or persistent zero voltage to avoid operational risks.

Tip: Regularly monitor battery health and follow best practices for charging and storage to prevent lithium-ion battery zero voltage incidents.

Zero Voltage: Diagnosis & Solutions

Identifying the Cause

You need a systematic approach to diagnose zero voltage in a lithium-ion battery pack. Start by measuring the battery voltage. If you see a zero reading, do not assume the cells are dead. Many times, the battery management system (BMS) has activated protection mode.

Follow these steps to pinpoint the cause:

Measure the battery voltage using a calibrated multimeter.

Check the BMS status. A tripped or failed BMS often causes zero voltage. Review the BMS indicator lights or connect to diagnostic software if available.

Attempt to wake up the BMS. Briefly place the battery on a charger for about 0.1 seconds. This can reset the protection circuit.

Try a safe BMS jump start. Short the B- and P- connections on the BMS for a moment. This may reactivate the circuit without harming the battery.

Inspect for BMS failure. If the BMS remains unresponsive, it may require repair or replacement.

Re-measure the voltage after any intervention to confirm restoration.

Note: Zero voltage often results from BMS protection, not actual cell failure. Proper diagnosis prevents unnecessary replacement and reduces downtime in industrial, medical, and security applications.

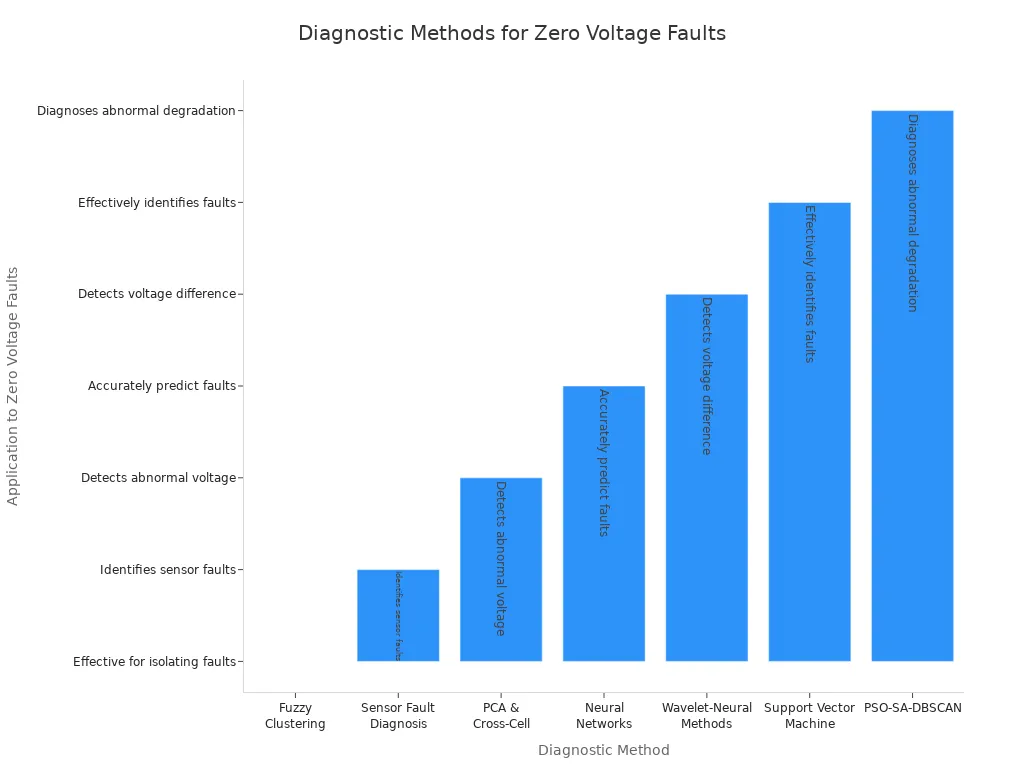

You can use advanced diagnostic tools to improve accuracy. The table below compares common diagnostic approaches for lithium-ion battery zero voltage:

Diagnostic Approach | Description | Advantages | Limitations | Relevance to Zero Voltage Diagnosis |

|---|---|---|---|---|

Knowledge-Based | Uses historical and empirical rules for fault diagnosis | Simple implementation | Needs extensive fault data | Detects known fault patterns causing zero voltage |

Model-Based | Establishes physical battery models and compares parameters | Accurate parameter estimation | Complex modeling required | Detects deviations causing zero voltage |

Data-Driven | Uses algorithms like PCA, LSTM, SVM on battery data | Adaptable, no physical model needed | Needs large datasets | Highly effective for zero voltage faults |

You can also apply methods such as fuzzy clustering, sensor fault diagnosis, neural networks, and wavelet-neural analysis. These techniques monitor voltage abnormalities and synchronize voltage variations across cells, which is critical for identifying zero voltage in lithium-ion battery packs.

Revival Methods

If you confirm that the lithium-ion battery is not physically damaged and the BMS is in hibernation mode, you can attempt safe revival. Always inspect the battery for swelling, cracks, or leaks before proceeding.

Follow these proven revival methods:

Slow Charging: Use a low-output charger (such as a USB charger at 0.5 amps or less). Charge the battery for 6-8 hours, checking voltage periodically. Once the voltage reaches about 3.0V, switch to a regular charger.

Boost Charging: Connect the dead battery terminals to a healthy lithium-ion battery of the same voltage for 1-2 minutes. This can raise the voltage above 2.5V, allowing normal charging.

Controlled Charging: Use a variable DC power supply set to 4.2V and a low current (about 100mA). Gradually increase current as voltage rises. Switch to a standard charger when the battery reaches 3.7V.

Freezing Method: As a last resort, seal the battery in a plastic bag, freeze for 24 hours, then allow it to warm to room temperature before slow charging.

Software Recalibration: For batteries with management software, run a calibration or reset process to correct charge level readings.

⚠️ Safety Alert: Never attempt to revive batteries that are swollen, leaking, or overheating. These batteries pose fire and explosion risks. Always use a charger with a “repair mode” or low current setting. For complex packs like those in laptops, consult professionals.

When to Replace

You must know when to stop revival attempts and replace the lithium-ion battery. Use the following criteria to guide your decision:

Criterion | Indicator/Threshold | Implication for Replacement or Revival |

|---|---|---|

Capacity | 80-100% (lower for less critical use) | Below threshold suggests replacement or limited use |

Internal Resistance | Low until end of life; high indicates anomalies | High resistance signals possible corrosion or damage |

Self-Discharge Rate | Voltage loss within ±5mV per cell over 24 hours | Stable voltage supports revival; instability suggests failure |

Programmed End-of-Life Signals | Fixed cycle count, calendar date, max error on SMBus | Indicates battery should be replaced |

Communication Faults | Inability to communicate digitally | May require cell salvage; pack replacement recommended |

Physical Condition | Swelling, leakage, or damage | Immediate replacement recommended |

Replace the battery if you see swelling, leakage, or severe physical degradation.

If revival attempts fail or the battery cannot hold a charge, replacement is necessary.

Use only chargers designed for lithium-ion batteries during revival.

Advanced revival techniques, such as balance charging or jump-starting, require caution due to lithium-ion sensitivity.

Tip: Attempting to revive irreparably damaged batteries can cause fire, toxic gas release, and environmental contamination. Always recycle dead batteries at certified facilities.

Maintenance Tips

You can prevent lithium-ion battery zero voltage by following best practices for maintenance and management:

Regularly monitor each cell’s voltage, current, and temperature using a robust BMS. Learn more about BMS technology (insert internal link).

Store batteries at 40-60% state of charge in a cool, dry place to minimize aging.

Use only chargers that match the battery chemistry and voltage specifications (e.g., NMC, LFP, LCO).

Schedule periodic capacity and resistance checks, especially in critical applications like medical, robotics, and security systems.

Avoid deep discharges and overcharging. The BMS should enforce safe operating limits.

For industrial and infrastructure deployments, implement cross-cell monitoring and data-driven diagnostics to detect early signs of zero voltage.

Train staff on safe handling, inspection, and disposal procedures. Always use personal protective equipment when handling damaged batteries.

Follow industry standards such as IEC 62133, UN/DOT 38.3, and UL 2580 for safe handling, transport, and disposal.

Note: Lithium-ion batteries are classified as hazardous waste. Always tape contacts and send batteries to approved recycling centers. Never dispose of batteries in regular trash.

By following these steps, you can extend battery life, reduce downtime, and ensure safety across all application scenarios.

You face zero voltage in lithium-ion battery packs due to several main causes:

Failure to charge on time or using a faulty charger leads to performance loss and zero voltage.

Battery aging causes rapid voltage drop and failure.

Short circuits create dead cells and zero voltage.

Lithium-ion batteries may enter hibernation mode below 2 volts. Sometimes you can recover them, but zero voltage often means permanent damage.

Revival attempts may restore some voltage, but full capacity rarely returns. Replacement is usually the best solution.

Accurate diagnosis of lithium-ion battery health helps you optimize operations, extend battery life, and reduce costs. You improve safety and reliability by identifying issues early. Regular maintenance and proper charging practices keep your lithium-ion battery packs performing at their best.

FAQ

What causes lithium-ion battery packs to enter hibernation mode?

Your battery pack enters hibernation mode when voltage drops below the BMS cutoff threshold. This protects cells from deep discharge and extends overall battery life.

How do you safely revive a lithium-ion battery pack showing zero voltage?

You can use a low-current charger or a controlled boost charge. Always inspect for physical damage before attempting revival. Replace the battery if swelling or leakage appears.

Which lithium-ion chemistry offers the longest cycle life for B2B applications?

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LFP | 3.2V | 90-160 | 3,000–5,000 |

NMC | 3.7V | 150-220 | 1,000–2,000 |

LCO | 3.7V | 150-200 | 500–1,000 |

LFP chemistry provides the longest cycle life and stable performance for B2B battery packs.