You achieve Long Standby Power for remote diagnostics by selecting advanced lithium battery packs, integrating battery management systems, and using proactive remote monitoring. Cloud-connected UPS and BESS inverters offer real-time tracking, early alerts, and remote management, which improve diagnostics reliability and operational efficiency.

Feature | Benefit |

|---|---|

Remote Monitoring | Real-time UPS status, fewer site visits |

Alerts and Notifications | Early warnings, higher reliability, less downtime |

Mobile App and Web Access | Manage multiple devices remotely, boost efficiency |

Key Takeaways

Choose lithium battery packs for long cycle life and safety. They provide reliable backup power for remote diagnostics.

Implement a Battery Management System (BMS) to optimize battery performance and prevent failures. This ensures safety and extends battery lifespan.

Utilize remote monitoring solutions for real-time insights and predictive maintenance. This reduces downtime and improves operational efficiency.

Part 1: Long Standby Power Needs

1.1 Remote Diagnostics Requirements

You face unique power requirements when deploying remote diagnostics in industrial and utility environments. These systems demand long standby power to ensure continuous monitoring and rapid response. Industrial batteries play a critical role in supporting backup power for remote sensors, controllers, and communication devices. You must select battery systems that deliver reliable backup energy for years, especially in locations where solar or grid access is limited.

Remote monitoring helps you prevent generator failures by detecting issues such as battery faults, fuel quality degradation, and block heater malfunctions.

Most failure-to-start events—up to 90%—result from battery, fuel, or heater problems, as well as ignored alarms. Remote diagnostics can monitor these factors and reduce downtime.

Battery lifespan typically reaches five years, while untreated fuel remains usable for about one year. Regular monitoring extends the life of your backup systems.

You should consider lithium battery packs for their long cycle life and stable energy output. These battery systems support critical infrastructure and industrial applications, providing robust backup power for remote diagnostics.

1.2 Power Challenges

You encounter several power challenges in remote diagnostics, especially in harsh or isolated environments. Many believe remote monitoring systems operate autonomously, but you need strategic planning to avoid outages and ensure reliable backup power.

Extreme weather, such as storms, ice, and high winds, can disrupt solar and backup power systems.

Structural failures in offshore infrastructure often result from harsh conditions, impacting battery systems and inverter performance.

Communication issues may arise, making remote diagnostics and backup installation more complex.

You must address these challenges by choosing advanced battery systems, integrating reliable inverters, and planning for robust solar backup installation. These steps help you maintain long standby power and ensure continuous operation for your remote diagnostics.

Part 2: Battery Selection and Capacity

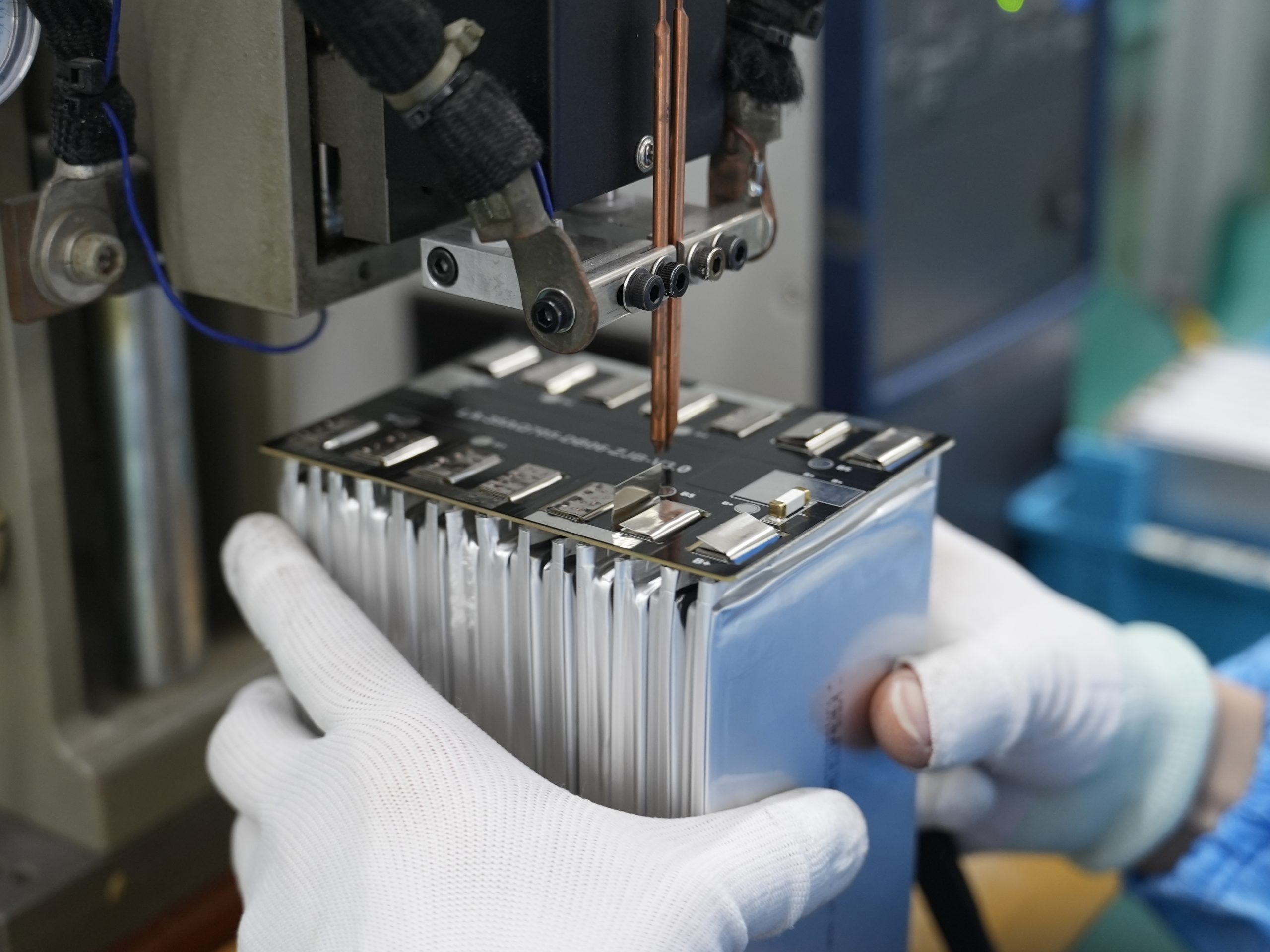

2.1 Lithium Battery Packs

You need to select the right battery chemistry to achieve long standby power for remote diagnostics. Lithium battery packs outperform traditional chemistries in both cycle life and safety. When you compare lithium iron phosphate (LiFePO4) batteries to nickel manganese cobalt (NMC), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium titanate (LTO), solid-state (solid-state), and lithium-polymer (LiPo) batteries, you see clear advantages for industrial and infrastructure applications.

Battery Chemistry | Cycle Life Retention (%) after 500 cycles | Safety | Typical Cycle Life | Application Scenarios |

|---|---|---|---|---|

>99% | High thermal stability, low fire risk | 3,000–10,000 | Industrial, medical, robotics, security, infrastructure | |

NMC | 90.2% | Moderate thermal stability | 1,000–2,300 | Consumer electronics, EVs, backup |

LCO | 80–85% | Lower thermal stability | 500–1,000 | Consumer electronics |

LMO | 85–90% | Moderate stability | 1,000–2,000 | Power tools, medical |

LTO | >99% | Excellent stability | 10,000–20,000 | Grid, heavy-duty, backup |

>99% (projected) | Very high stability | 5,000–10,000 (projected) | Next-gen energy storage solutions | |

80–90% | Moderate stability | 500–1,000 | Wearables, drones |

You benefit from the strong covalent bonds in LFP batteries, which reduce the risk of overheating and fires. LFP batteries also support over 3,000 cycles under most conditions and can exceed 10,000 cycles with optimal energy management systems. This makes them ideal for remote diagnostics, where you need reliable backup and high efficiency.

Tip: For critical infrastructure, always prioritize battery systems with proven safety records and high cycle life. LFP batteries deliver both.

Cloud-connected lithium UPS systems, such as those from SolarEdge, Enphase, and Tesla Powerwall, provide real-time monitoring and remote management. These solutions integrate with energy management systems and inverters to optimize backup power and efficiency. You can monitor battery status, energy consumption, and inverter efficiency from anywhere, reducing site visits and improving operational performance.

2.2 Battery Capacity Sizing

Proper battery capacity sizing ensures your remote diagnostics equipment maintains long standby power and reliable backup. You must analyze your load, backup duration, and energy usage patterns to select the right battery systems. The following table summarizes key sizing methodologies:

Sizing Methodology | Description |

|---|---|

Load analysis | Calculate essential load power consumption |

Duration requirements | Determine desired backup time |

Usage patterns | Consider daily energy consumption |

Solar contribution | Account for daytime solar generation |

Safety margin | Add 20–30% buffer for unexpected loads |

Example Sizing Scenarios | Battery Capacity for Backup Duration |

|---|---|

Basic Essential Loads | 12-hour: 60kWh, 24-hour: 120kWh |

With solar: 40–80kWh depending on season | |

Comfort Loads Included | 12-hour: 96kWh, 24-hour: 192kWh |

With solar: 65–130kWh depending on season |

You should always include a safety margin to account for unexpected power surges or longer backup duration. For installations with solar, you can optimize battery capacity by factoring in daily solar energy generation. This approach improves efficiency and reduces unnecessary oversizing.

Note: Custom consultation with an energy storage solutions provider helps you match battery systems to your specific application, whether in medical, robotics, security, or industrial infrastructure.

2.3 Environmental Considerations

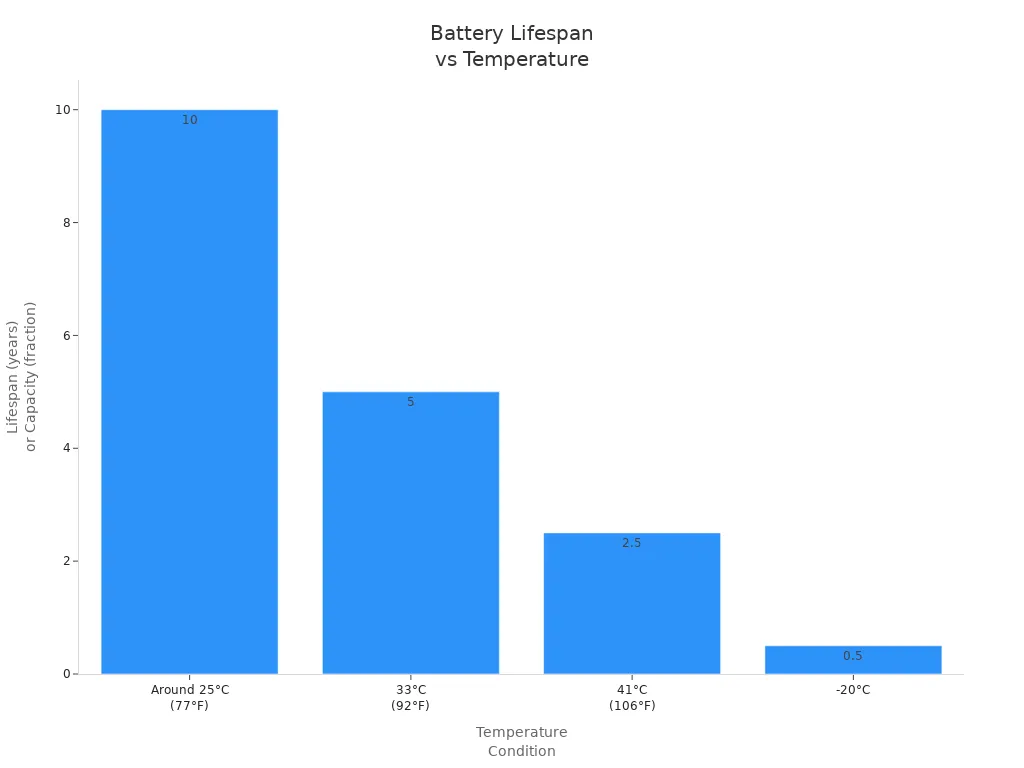

Environmental factors such as temperature and humidity directly impact battery performance, capacity, and lifespan. You must consider these variables during installation and operation to maintain optimal energy storage solutions.

Temperature Condition | Effect on Battery Lifespan or Capacity |

|---|---|

Around 25°C (77°F) | Battery lifespan approximately 10 years; full capacity and optimal performance |

Elevated to 33°C (92°F) | Lifespan reduces to about 5 years due to accelerated chemical degradation |

High heat at 41°C (106°F) | Lifespan further shortens to roughly 2.5 years; increased risk of rust |

Cold temperatures (-20°C) | Battery capacity drops to about 50% of normal; charge efficiency decreases |

Humidity also affects battery systems. High humidity decreases insulation performance and increases the risk of electrical accidents. You should keep humidity below 60%, never exceeding 80%. Use air conditioners with dehumidification, industrial dehumidifiers, and corrosion-resistant coatings to protect your installation.

Select battery systems and components designed for long-term reliability under critical conditions.

Store batteries in cool, dry, and well-ventilated structures.

Ensure installation sites are insulated and protected from extreme temperatures.

Properly size batteries to extend lifespan and maintain backup power.

For sustainability and responsible sourcing, review your supply chain for conflict minerals and prioritize battery systems that meet environmental standards.

By focusing on the right lithium-ion battery technologies, optimizing capacity, and considering environmental impacts, you ensure your remote diagnostics achieve maximum efficiency, reliability, and long standby power.

Part 3: Battery Management System and Monitoring

3.1 Battery Management System Integration

You rely on a battery management system (BMS) to optimize the performance and safety of your lithium battery packs in remote diagnostics. The BMS acts as the central intelligence for your battery systems, ensuring each cell operates within safe parameters. You prevent overheating, overcharging, and short-circuiting, which reduces the risk of fires or explosions. The BMS maximizes battery lifespan by optimizing charge and discharge cycles, extending usable life and maintaining high efficiency for your backup power needs.

Role | Description |

|---|---|

Safety | Prevents overheating, overcharging, and short-circuiting, reducing risks of fires or explosions. |

Maximizing Battery Lifespan | Optimizes charge and discharge cycles to extend the battery’s usable life. |

Efficiency | Ensures the battery operates at peak efficiency for better energy storage and delivery. |

Monitoring and Diagnostics | Provides real-time data on battery health, identifying potential issues early. |

You benefit from functional safety, as the BMS is essential for preventing fires and ensuring user safety in lithium-ion systems. The BMS protects battery cells from aggressive usage, ensuring long-term stability and reliability. You achieve balanced cell charge, which optimizes battery capacity and performance for your backup systems. The BMS continuously monitors all battery cells, collecting data for diagnostics and estimating the state of charge and health of the battery pack. This oversight is crucial for effective remote diagnostics and long standby power.

You deploy lithium battery packs in various application scenarios, including medical, robotics, security, infrastructure, consumer electronics, and industrial environments. You ensure each installation meets the highest standards for safety, capacity, and backup duration.

3.2 Remote Monitoring Solutions

You enhance your battery systems with advanced remote monitoring solutions. These tools provide real-time status updates, predictive maintenance alerts, and operational insights for your backup power installations. You use systems like iPQMS, PowerEye UPS, VIGILANT®, BMS i-com, and BDS-Pro to monitor critical operational parameters and receive instant alerts. You dispatch field service technicians promptly for troubleshooting, minimizing downtime and optimizing performance.

Solution Name | Key Features | Best For |

|---|---|---|

iPQMS Battery Monitoring System | Real-time, high-precision monitoring, predictive analytics, remote access | Data centers, utilities, industrial facilities |

PowerEye UPS Battery Monitoring System | Real-time monitoring, AI-driven analytics, instant alerts | Telecom, healthcare, IT environments |

VIGILANT® Battery Monitoring System | Advanced diagnostics, AI-powered predictive analytics, cloud integration | Large-scale installations |

BMS i-com Battery Monitoring System | Comprehensive battery health data, real-time alerts | Hospitals, financial institutions, industrial plants |

BDS-Pro Battery Cell Voltage Monitoring System | Individual cell voltage monitoring, real-time alarms | Renewable energy systems, large battery banks |

You conduct periodic state-of-health audits to optimize battery performance and capacity. You leverage performance analytics modules to track key battery parameters and gain operational insights for system optimization.

You use cloud-based apps and battery monitors to enable predictive maintenance for your remote diagnostics systems. These platforms offer automated impedance analysis, AI-driven algorithms for interpreting EIS spectra, and early fault detection based on impedance trends. You access cloud-based dashboards for remote battery diagnostics, correlating data with charge cycles, temperature variations, and operational conditions.

3.3 Data Analytics and AI Optimization

You drive optimization of your battery systems and backup power installations with advanced data analytics and AI technology. You analyze energy usage patterns, forecast demand, and allocate resources efficiently. AI-powered platforms continuously monitor your energy systems, providing actionable insights for capacity planning and backup duration optimization.

Benefit | Description |

|---|---|

Cost Savings | AI optimizes energy consumption, reducing costs through better demand forecasting and resource allocation. |

Enhanced Efficiency | Continuous analysis of energy usage patterns leads to improved operations and reduced waste. |

Sustainability | Facilitates integration of renewable energy sources, lowering carbon emissions and environmental impact. |

Improved Reliability | Predictive analytics help anticipate demand fluctuations, ensuring stable energy supply and reducing outages. |

User Engagement | Provides personalized recommendations to encourage energy-saving practices among users. |

Scalability and Flexibility | Easily scalable to meet growing energy needs and adaptable to changes in consumption patterns. |

Data-Driven Insights | Generates insights from data analysis for informed decision-making in energy management strategies. |

Regulatory Compliance | Assists in monitoring energy usage and reporting on sustainability metrics to comply with regulations. |

You integrate BESS inverters to optimize power distribution and enable predictive maintenance. These inverters ensure compliance with grid standards, maintain power quality, and allow real-time monitoring and control. You improve the efficiency and reliability of your remote diagnostics power systems, impacting profitability and operational stability.

You achieve measurable benefits with AI optimization, including cost savings, enhanced efficiency, improved reliability, and sustainability. You generate data-driven insights for informed decision-making and regulatory compliance. You scale your energy systems to meet growing backup capacity needs and adapt to changes in consumption patterns.

You ensure your battery systems deliver long standby power, reliable backup, and optimal capacity for every installation. You maximize performance and efficiency by integrating advanced BMS, remote monitoring, and AI-driven optimization.

For custom consultation on lithium battery packs and energy system optimization, contact your trusted energy storage solutions provider.

Part 4: Maintenance and Reliability

4.1 Regular Health Checks

You maintain long standby power by performing regular health checks on your battery systems. Routine inspections and scheduled testing prevent over two-thirds of telecom network downtime caused by insufficient upkeep. You should:

Monitor individual cell voltage and internal resistance for early fault detection.

Use advanced battery management systems for early warnings and corrective actions.

Conduct monthly inspections to spot rust or loose connections.

Implement real-time monitoring to track key performance indicators and receive instant alerts.

Consistent checks help you assess battery efficiency and longevity. Proactive maintenance strategies extend battery life and reduce costly downtime. In industrial, medical, and infrastructure installations, these practices ensure reliable backup and optimal energy delivery.

4.2 Preventing Failures

You prevent failures by addressing leading causes and using the right technology. Excessive heat, neglecting battery monitoring, and infrequent manual inspections often lead to unexpected downtime and equipment damage. The table below summarizes key risks and solutions:

Leading Causes of Battery Failures | Preventative Measures |

|---|---|

Excessive heat | Continuous battery monitoring |

Neglecting battery monitoring | Implementing Battery Management Systems (BMS) |

Infrequent manual inspections | Ensuring real-time visibility of battery health |

A robust BMS monitors voltage, current, and temperature, protecting against overcharging and deep discharging. This technology ensures thermal management and extends battery life in every backup installation.

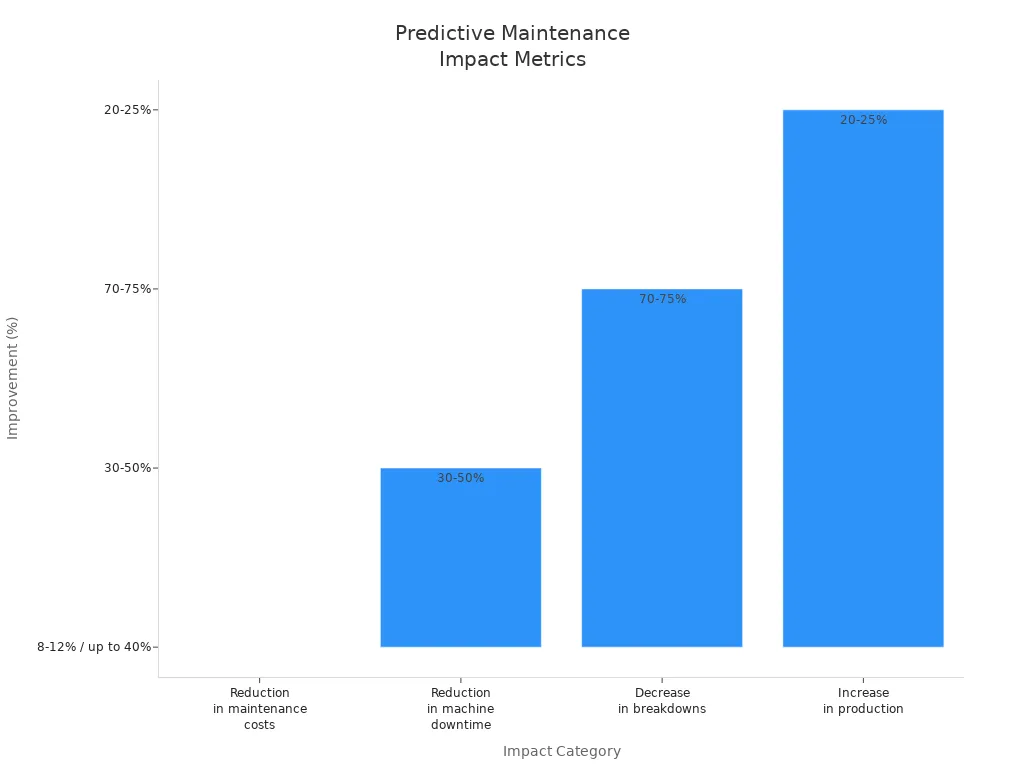

4.3 Predictive Maintenance

You use predictive maintenance to reduce costs and improve reliability in backup power systems. Smart BMS platforms and remote diagnostics use advanced sensors and analytics to forecast failures before they occur. This approach lowers maintenance costs by up to 25% and reduces unplanned downtime by 50%. Companies report a 70% decrease in breakdowns and a 25% increase in production.

You gain real-time insights into battery health, optimize backup duration, and ensure stable power for all installation scenarios, including solar and inverter-based systems. For custom consultation on predictive maintenance technology, contact your energy solutions provider.

You maximize long standby power by choosing lithium battery packs, integrating advanced BMS, and using remote monitoring. Watch for common mistakes:

High battery drain without clear cause

Missing drivers blocking low-power states

USB device and firmware issues

Recent battery trends, such as solid-state and zinc-based chemistries, plus AI-powered analytics, now boost reliability in medical, robotics, and industrial diagnostics. Regulatory standards also shape your battery choices:

Regulatory Standard | Impact on Battery Selection and Management |

|---|---|

IEC 62133 | Ensures safety and performance in batteries used in medical devices. |

UL 2054 | Sets safety requirements for battery systems. |

ISO 13485 | Focuses on quality management systems in medical devices. |

IEC 60601-1 | Addresses the safety and essential performance of medical electrical equipment. |

Adopt these strategies and leverage new technologies to improve reliability and reduce costs across your remote diagnostics operations.

FAQ

What makes whole house battery backup systems ideal for B2B remote diagnostics?

You gain energy independence and system uptime with whole house battery backup systems. These solutions use lithium battery packs for real-time control and reliable backup in industrial, medical, and infrastructure applications.

How do whole house battery backup systems compare to other battery energy storage systems?

System Type | Cycle Life | Safety | Application Scenarios |

|---|---|---|---|

whole house battery backup systems | 3,000–10,000 | High | Medical, robotics, security, infrastructure, industrial |

battery energy storage systems | 1,000–20,000 | High | Grid, heavy-duty, backup |

solar battery backup systems | 3,000–10,000 | High | Renewable, off-grid, infrastructure |

You achieve independence and energy independence with whole house battery backup systems, which deliver stable power and support critical operations.

How can you maximize energy independence and reliability with whole house battery backup systems?

You should select lithium battery packs, integrate advanced management, and use Large Power custom battery solutions. This approach ensures independence and energy independence.

Tip: Whole house battery backup systems support independence, energy independence, and real-time control for B2B operations.