You rely on medical devices to deliver precise and consistent results, even in harsh environments. Low temperatures can drastically reduce battery capacity and increase internal resistance, putting patient safety and device performance at risk. Lithium-ion (Li-ion) chemistries offer high energy density and stable output, making them ideal for medical applications. Consider both technical and regulatory factors when selecting Low-Temperature Battery Solutions. Preheating and thermal management help optimize battery output in critical healthcare settings.

At -18°C (0°F), most batteries deliver only about 50% of their rated capacity.

Specialty Li-ion and NiCd cells show reliability issues in cold conditions.

Key Takeaways

Low temperatures can reduce battery capacity by up to 50%. Choose batteries designed for cold environments to ensure reliable performance.

Always verify the battery’s temperature range and energy density before use. This step helps prevent device failure and ensures patient safety.

Select batteries with strong safety features, such as protection against overcharging and overheating. This enhances the reliability of medical devices.

Consider using preheating solutions to maintain battery performance in cold conditions. This can help avoid voltage drops during critical operations.

Ensure all batteries meet necessary certifications for medical applications. Compliance with standards protects patient safety and device reliability.

Part 1: Low Temperature Challenges

1.1 Battery Performance

You face significant challenges when deploying low temperature batteries in medical devices. At sub-zero temperatures, aqueous batteries (ABs) often fail to deliver adequate discharge capacity and power density. This limitation stems from slower chemical reactions, reduced ion mobility, and increased electrolyte viscosity. For lithium chemistries such as LiFePO4, NMC, LCO, LMO, and LTO, you notice a drop in ionic conductivity below 0°C. The solid electrolyte interphase (SEI) becomes more resistive, which increases internal resistance and reduces cycle life. Physical contraction of internal components further hinders electron transfer, raising the risk of battery failure.

Slower chemical reactions lead to voltage drops.

Prolonged cold exposure can cause irreversible damage, especially during idle periods.

Increased viscosity and resistance reduce charge and discharge efficiency.

Tip: Always verify the platform voltage and energy density for each lithium chemistry before selecting a battery for cold environments. For example, LiFePO4 offers stable cycle life but lower energy density compared to NMC.

1.2 Patient Safety

You must prioritize patient safety when using low temperature batteries in medical devices. Reduced battery output can compromise device reliability, which may affect critical functions such as monitoring or drug delivery. Inconsistent power supply can lead to device shutdowns or inaccurate readings. These risks extend to other sectors, including robotics and security systems, where reliable operation is essential.

Device failure in cold conditions can endanger patient health.

Unpredictable battery behavior may disrupt medical procedures.

1.3 Compliance

You need to ensure compliance with strict regulatory standards when selecting batteries for medical devices operating below 0°C. Medical devices must meet ANSI/AAMI ES 60601-1 for safety and performance. Primary cell batteries require adherence to IEC 60086-4 and IEC 60086-5. UL2054 covers household and commercial batteries. The FDA mandates that lithium batteries come from UL-certified factories and require traceability for failure analysis.

Standard | Application Area |

|---|---|

ANSI/AAMI ES 60601-1 | Medical device safety |

IEC 60086-4/5 | Primary cell batteries |

UL2054 | Household/commercial use |

FDA | Lithium battery traceability |

You protect patients and ensure device reliability by following these standards. Always confirm that your low temperature batteries meet all necessary certifications before integration.

Part 2: Low-Temperature Battery Solutions

When you select low-temperature battery solutions for medical devices, you need to understand the strengths and limitations of each chemistry. The right choice ensures reliable operation in cold environments, supports patient safety, and meets strict industry standards.

2.1 Lithium Primary Chemistries

Lithium primary chemistries, such as LiSOCl₂, TLM, TLI, TL, and TLH, offer excellent performance in extreme cold. You often find these batteries in implantable devices, surgical tools, and cold chain monitoring systems. LiSOCl₂ stands out for its wide operating temperature range and high energy density.

Battery Type | Operating Temperature Range |

|---|---|

LiSOCl₂ | -40 to +85 °C |

Modified LiSOCl₂ | -80 to 125 °C |

LMO | -55 to 85 °C |

LiSOCl₂ batteries can function at temperatures as low as -80 °C and up to 125 °C.

LMO batteries support operation from -55 °C to 85 °C.

You benefit from high capacity retention at low temperatures. For example, at -20 °C, lithium primary chemistries deliver up to 110 mA h g⁻¹ with an average coulombic efficiency of 99.6%. Even at -40 °C, you still get 50 mA h g⁻¹, which supports critical medical applications in harsh environments.

Note: Always match the battery’s temperature range to your device’s requirements to avoid performance loss or device failure.

2.2 Lithium-Ion Variants

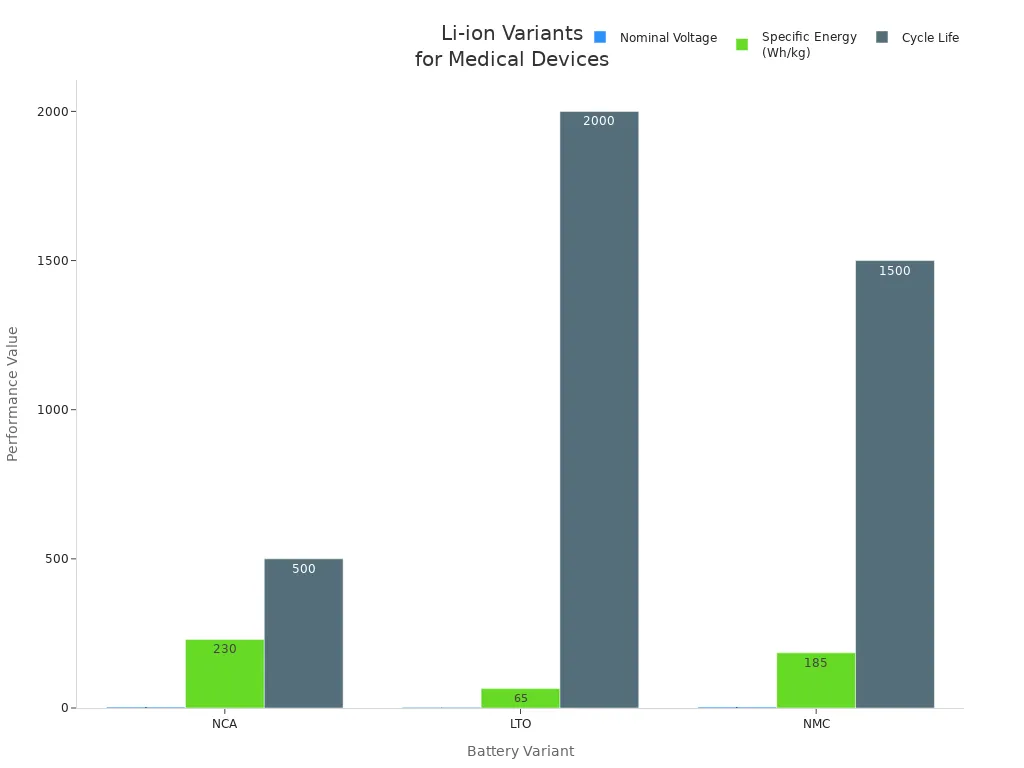

You can choose from several lithium-ion variants for low-temperature battery solutions in medical devices. NCA, LTO, and NMC chemistries each offer unique advantages for different applications.

Variant | Voltage (V) | Specific Energy (Wh/kg) | Charge Rate | Discharge Rate | Cycle Life | Applications |

|---|---|---|---|---|---|---|

NCA | 3.60 (nominal) | 200–260 | 0.7C | 1C | 500 | Medical devices, industrial, electric powertrain |

LTO | 2.40 (nominal) | 65 | Fast charge | 10C | High | Electric powertrains, UPS, solar-powered lighting |

NMC | 3.60–3.70 (nominal) | 150–220 | 0.7–1C | 1C–2C | 1000–2000 | E-bikes, medical devices, EVs, industrial |

NCA batteries provide high energy density, which extends device runtime. LTO batteries excel in fast charging and long cycle life, making them suitable for devices that require frequent recharging. NMC batteries balance energy density and cycle life, supporting a wide range of medical and industrial uses.

2.3 Alternative Chemistries

You may consider alternative chemistries like all-solid-state batteries (ASSBs) for extreme cold. ASSBs use solid-state electrolytes, which resist temperature fluctuations better than liquid electrolytes. These batteries maintain discharge capacities of over 100 mA h g⁻¹ at -60 °C and can operate for more than 200 hours at this temperature. The solid/solid interface in ASSBs lowers charge transfer resistance and speeds up electrochemical reactions, making them more efficient than traditional lithium-ion batteries in subzero conditions.

ASSBs support stable operation in extreme cold.

Solid-state electrolytes improve safety and reliability for medical devices.

2.4 Technology Comparison

You need to compare low-temperature battery solutions based on performance, safety, and customization. The table below summarizes key features for medical applications:

Feature | Benefit |

|---|---|

High energy density (up to 250 Wh/kg) | Longer usage times, fewer battery changes in medical devices |

IP67 compliance | Protection against dust and water, reliable in diverse settings |

High temperature resistance (+130 °C) | Maintains performance in extreme conditions |

Exceptional reliability | Ensures critical medical devices remain operational |

Custom electronic circuits | Tailors performance and safety to specific requirements |

You can also request custom features, such as enhanced safety circuits, to protect against overcharging, overheating, and short circuits. Proven safety standards like UN38.3, UL, and CE ensure your devices meet global certification requirements.

Tip: Customization helps you integrate low-temperature battery solutions seamlessly into your medical devices, improving both safety and performance.

When you evaluate low-temperature battery solutions, always consider the specific needs of your application. Medical devices, robotics, and security systems each demand different performance profiles. By understanding the strengths of each chemistry, you ensure reliable operation and patient safety in any environment. Consult Large Power for custom battery solutions.

Part 3: Selecting Low Temperature Batteries

3.1 Temperature Range

You must start by checking the temperature range for each battery type. Medical devices often operate in environments where temperatures drop below freezing or rise above room temperature. You need batteries that can handle these extremes without losing performance. The table below shows the minimum and maximum operating temperatures for common lithium battery chemistries:

Battery Type | Minimum Temperature | Maximum Temperature |

|---|---|---|

Standard Lithium Batteries | -20°C | 60°C |

Low-Temperature Lithium | -40°C | N/A |

High-Temperature Lithium | N/A | 85°C |

You should match the battery’s temperature range to your device’s requirements. For example, implantable medical devices and cold chain monitoring systems often need low-temperature lithium batteries that work reliably at -40°C. Security systems and robotics may also require batteries that perform well in cold storage or outdoor environments.

Tip: Always confirm the battery’s temperature specifications before integration. This step helps you avoid device failure and ensures patient safety.

3.2 Capacity Retention

You need to evaluate how much energy the battery retains at low temperatures. Capacity retention measures the percentage of original battery capacity available when the device operates in cold conditions. Lithium chemistries like LiSOCl₂ and NMC usually retain more capacity at sub-zero temperatures compared to standard lithium-ion cells.

Medical devices require stable capacity retention to deliver accurate readings and reliable operation.

Industrial and infrastructure applications also benefit from batteries that maintain high capacity in cold climates.

You should request test data from your battery supplier. Look for batteries that retain at least 70% of their rated capacity at the lowest expected operating temperature. This approach helps you maintain device performance and reduce maintenance costs.

3.3 Safety Features

You must prioritize safety features when selecting batteries for medical devices. Safety circuits protect against overcharging, overheating, and short circuits. These features reduce the risk of device malfunction and improve patient safety.

Lithium battery packs for medical use often include built-in protection circuits.

You should look for batteries with IP67-rated enclosures to guard against dust and water.

Custom electronic circuits can enhance safety for robotics, security systems, and industrial equipment.

Alert: Never compromise on safety features. Reliable protection ensures your devices operate safely in all environments.

3.4 Longevity

You need batteries with long cycle life and stable performance over time. Longevity matters for medical devices that require continuous operation, such as implantable monitors and diagnostic equipment. Lithium chemistries like LTO and NMC offer high cycle life, which reduces replacement frequency and lowers total cost of ownership.

Devices in the medical, industrial, and infrastructure sectors benefit from batteries with extended service life.

You should check the manufacturer’s cycle life data and warranty terms.

A battery with high longevity supports uninterrupted patient care and reliable operation in critical systems.

3.5 Certification

You must ensure that every battery meets strict certification standards for medical applications. Certifications confirm that the battery is safe, reliable, and compliant with industry regulations. The following certifications are essential for batteries used in medical devices intended for cold climates:

ANSI/AAMI ES 60601-1: General requirements for safety and performance of medical devices.

IEC 60086-4: Safety of lithium batteries, ensuring safe operation under intended use.

IEC 62133: Safety requirements for secondary lithium cells and batteries.

UL 1642: Safety standard for lithium batteries.

ISO 7176-25: Requirements for batteries and chargers for powered wheelchairs.

You should verify that your battery supplier provides documentation for each certification. This step protects your business from regulatory issues and ensures patient safety.

Note: Certification is not optional. You must comply with all relevant standards before deploying batteries in medical, robotics, security, or industrial devices.

Part 4: Applications and Case Studies

Low-temperature battery solutions play a vital role in many medical and industrial settings. You need reliable power sources for devices that operate in harsh environments. The table below shows common battery types and their operating temperature ranges, helping you select the right option for your application:

Battery Type | Operating Temperature Range |

|---|---|

Lithium Batteries | -20°C to 60°C |

Low-Temperature Lithium Battery | -40°C to 85°C |

Lead-Acid/Nickel-Metal Hydride | Down to -10°C |

4.1 Implantable Devices

You depend on implantable medical devices to function without interruption, even in cold weather applications. Tadiran lithium batteries, for example, power surgical tools and implantable monitors. These batteries maintain stable output at low temperatures, ensuring patient safety during critical procedures. Low-temperature preheating helps these batteries deliver consistent energy, especially when devices are stored or used in cold environments. You can also use advanced battery management systems (BMS) to monitor battery health and extend device life.

4.2 Diagnostic Equipment

Diagnostic equipment often operates in refrigerated labs or outdoor clinics. You need cold weather batteries that retain capacity and provide accurate readings. Large Power’s low temperature batteries perform well in extreme cold, supporting portable ultrasound machines and blood analyzers. Low-temperature preheating and low-temperature heating both improve battery efficiency, reducing downtime and maintenance. These solutions also benefit robotics and security systems that require reliable power in cold storage or field conditions.

Tip: Use low-temperature lithium batteries with built-in BMS for enhanced safety and performance in diagnostic devices.

4.3 Cold Chain Monitoring

You must preserve biological samples and vaccines during transport. Cold chain monitoring systems rely on low-temperature lithium batteries to power sensors and data loggers. Tadiran batteries support long-term operation in subzero environments, making them ideal for logistics and infrastructure. Low-temperature preheating ensures batteries activate quickly, while low-temperature heating maintains optimal performance throughout the journey. Cold weather batteries also support industrial and consumer electronics that require stable operation in freezing conditions.

By choosing the right battery technology, you protect sensitive materials and maintain compliance with industry standards.

Part 5: Low-Temperature Preheating & Integration

5.1 Preheating Solutions

You need to ensure that batteries in medical devices reach optimal temperatures before operation in sub-zero environments. Preheating solutions help maintain performance and extend battery life. The table below outlines common preheating strategies:

Preheating Strategy | Description | Advantages | Disadvantages |

|---|---|---|---|

External Convective Heating | Uses air to warm the battery externally. | Simple implementation | May be less effective in extreme cold |

External Conductive Heating | Transfers heat through direct contact with a warm surface. | Efficient heat transfer | Requires physical contact |

Internal Heating Solutions | Incorporates heating elements within the battery. | Directly warms the battery | More complex design |

Integrated heating films can preheat batteries to safe operating temperatures before charging. Smart battery management systems (BMS) monitor temperature and adjust charging parameters, which enhances safety and extends battery lifespan. In medical applications, these solutions help prevent voltage drops and ensure reliable device operation.

Tip: Preheating systems can raise battery temperature to 20 °C, even in freezing conditions, and maintain it above 10 °C for several hours.

5.2 Thermal Management

Thermal management is essential for the safety and longevity of lithium-ion batteries in medical devices. Active thermal control reduces the risk of thermal runaway and ensures consistent cell performance. Efficient thermal management extends battery lifespan and improves reliability. Some systems use liquid cooling or phase change materials to absorb excess heat and prevent dangerous temperature spikes.

Technology | Description |

|---|---|

Active Thermal Control | Maintains stable cell temperature, reduces aging, and lowers maintenance costs |

Efficient Thermal Management | Enhances safety, extends lifespan, and improves overall performance |

Liquid Cooling/NEPCMs | Absorbs excess heat, prevents overheating during abnormal conditions |

You can also use advanced crystallization systems to boost discharge capacity at low temperatures, which increases overall device performance.

5.3 Maintenance

Proper maintenance protocols keep your lithium-ion batteries reliable in low-temperature medical environments. Follow these best practices:

Charge or discharge batteries to about 50% before storage.

Recharge to 50% at least every six months.

Remove batteries and store them separately from devices.

Store at 5 °C to 20 °C (41 °F to 68 °F).

Check charge status after six months; do not leave unused for long periods.

You should select high-quality lithium-ion batteries designed for cold weather. Choose battery technology engineered for extreme cold to maintain device functionality. For new device designs, develop advanced lithium-based batteries that address kinetic barriers and use specialized electrolyte systems for better low-temperature performance.

Note: Regular testing and maintenance help you avoid unexpected failures and ensure compliance with medical safety standards.

You can achieve reliable performance in medical devices by choosing lithium chemistries like LiSOCl₂, NMC, and LTO. Preheating and thermal management keep batteries efficient in cold environments. When you work closely with battery suppliers, you gain access to advanced safety features and rigorous testing protocols. The table below shows key supplier collaboration benefits:

Feature | Description |

|---|---|

Operating Temperature | Charging: 0°C to 45°C, Discharging: -20°C to 60°C |

Safety Features | Over-voltage, over-discharge, and over-current protection |

Testing Protocols | Low-temperature burn-in, drop, shock, and penetration tests |

You should always verify certifications and match battery specs to your device’s needs. Regularly review new technologies and maintain open communication with suppliers. This approach helps you deliver safe, reliable solutions for medical, robotics, and industrial applications.

FAQ

What makes LiSOCl₂ batteries suitable for medical devices in cold environments?

LiSOCl₂ batteries deliver stable voltage and high energy density at low temperatures. You can use them in implantable monitors, surgical tools, and cold chain sensors. Their wide operating range ensures reliable performance in sub-zero medical and industrial settings.

How do you improve lithium battery pack performance in freezing conditions?

You can use preheating systems or integrated heating films. These solutions raise battery temperature before operation. Battery management systems (BMS) also help by monitoring and adjusting charging parameters. This approach keeps medical and industrial devices running smoothly in cold climates.

Which certifications should you check for lithium battery packs in medical applications?

You should verify ANSI/AAMI ES 60601-1, IEC 60086-4, IEC 62133, and UL 1642 certifications. These standards confirm safety and reliability for lithium battery packs in medical, robotics, and security systems. Always request documentation from your supplier.

Can you customize lithium battery packs for unique medical device requirements?

Yes. You can request custom battery packs with specific chemistries, safety circuits, and enclosures. Suppliers often design packs for specialized medical, infrastructure, or industrial uses. Customization ensures the battery meets your device’s exact needs.

What is the typical lifespan of LTO and NMC lithium battery packs in medical equipment?

LTO battery packs offer high cycle life, often exceeding 5,000 cycles. NMC packs provide a balance of energy density and longevity, usually lasting 1,000–2,000 cycles. You benefit from fewer replacements and lower maintenance in medical and industrial applications.