You measure state-of-charge in lithium battery packs using estimation methods like voltage/OCV, coulomb counting, impedance, mechanical, model-based, and machine learning. State-of-charge accuracy matters because errors below 2.16‰ in advanced systems prevent overcharging, extend battery life, and support reliable battery management system operation. Modern battery monitoring combines real-time sensing with machine learning, delivering robust lithium battery state of charge control. Accurate state-of-charge tracking ensures safer operation and supports applications from industrial to medical and infrastructure sectors. Measure state-of-charge of lithium batteries with the right soc estimation methods to optimize performance and safety.

Key Takeaways

Choose the right SoC measurement method based on your battery’s use, balancing accuracy and simplicity for best performance and safety.

Combine methods like voltage, coulomb counting, impedance, and machine learning to improve accuracy and adapt to changing conditions.

Regular calibration and advanced monitoring help maintain precise SoC tracking, extending battery life and ensuring reliable operation.

Part 1: SoC Measurement Methods

Accurately measuring state of charge in lithium battery packs is essential for safety, performance, and operational efficiency. You need to select the right soc estimation method to measure state-of-charge of lithium batteries in your application. Below, you will find a comprehensive overview of the main approaches used in the industry.

1.1 Voltage and OCV Methods

The open circuit voltage method is one of the most direct ways to measure state-of-charge of lithium batteries. You measure the battery’s terminal voltage after it rests, allowing the voltage to stabilize. This voltage correlates with the lithium battery state of charge, especially in chemistries like LCO, NMC, and LiFePO4. The open circuit voltage method is simple, cost-effective, and suitable for real-time soc estimation in battery management systems.

Recent research, such as the study “Development of low complexity open circuit voltage model for state of charge estimation with novel curve modification technique,” confirms the effectiveness of this approach. The study demonstrates that a polynomial OCV model, modified for battery aging, achieves root mean square errors below 0.01885 across the full soc estimation range. Another study highlights the adaptability of OCV models under varying temperatures, making them practical for electric vehicles and industrial battery packs.

Tip: The open circuit voltage method works best when you can allow the battery to rest, such as during scheduled maintenance or in stationary energy storage. However, it becomes less accurate under dynamic load conditions due to voltage hysteresis and polarization effects.

You should consider voltage and OCV methods for applications where simplicity, low computational load, and real-time monitoring are priorities. These methods are widely used in industrial, infrastructure, and consumer electronics battery packs.

1.2 Coulomb Counting

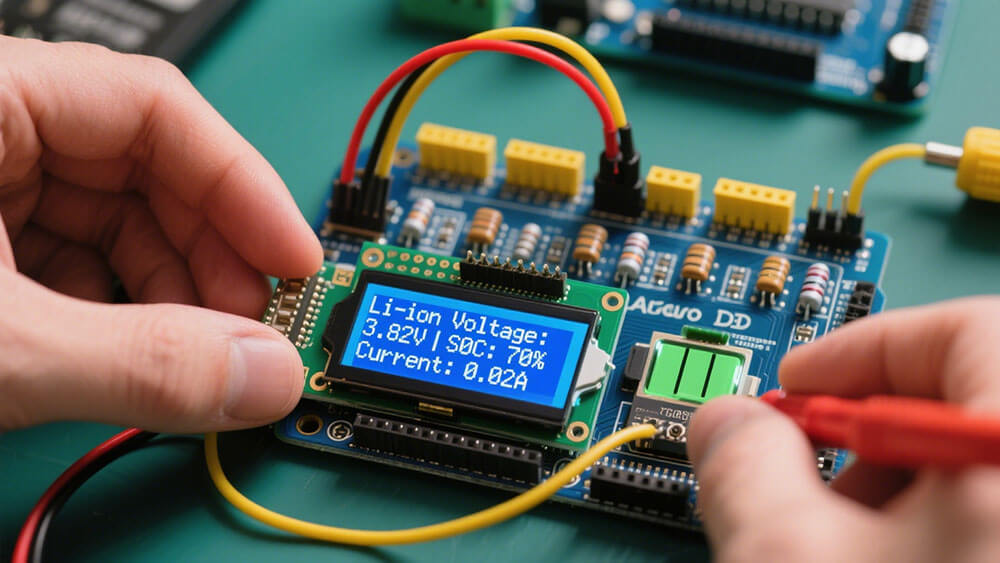

Coulomb counting, also known as the ampere-hour integral method, estimates state-of-charge by integrating the current flowing into and out of the battery over time. You start with a known initial state of charge and track every charge and discharge event. This method is straightforward and easy to implement in battery management systems.

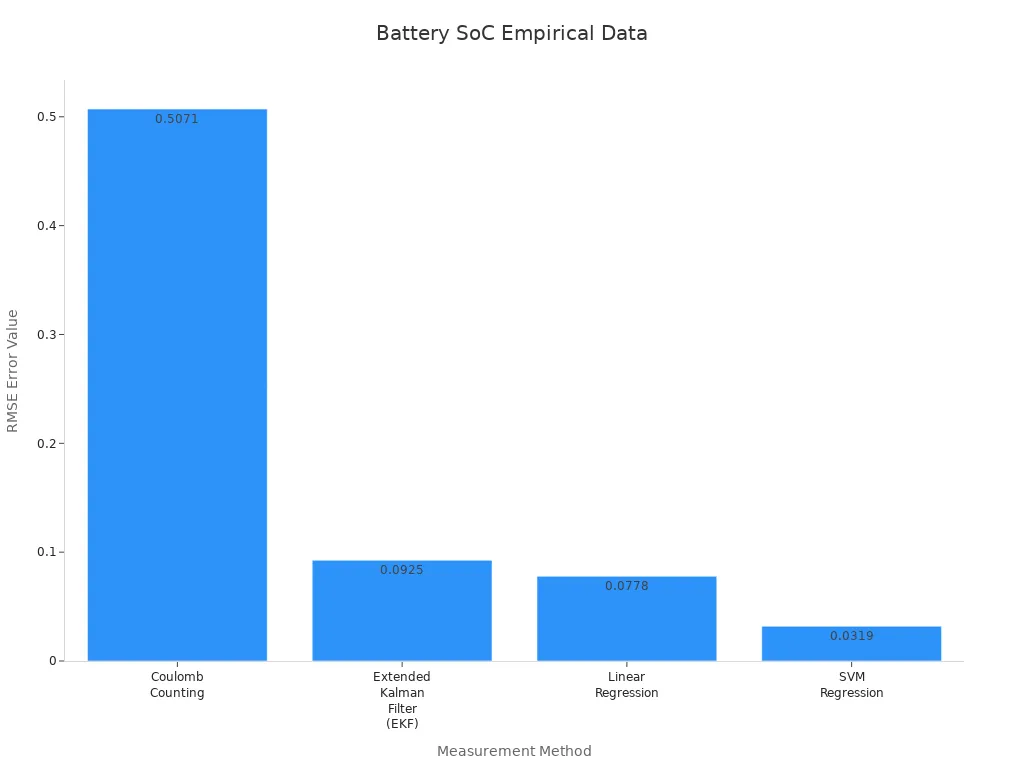

However, empirical studies show that coulomb counting suffers from cumulative errors due to sensor noise, current measurement inaccuracies, and uncertainties in battery capacity. The table below summarizes the accuracy of coulomb counting compared to other soc estimation techniques:

Method | RMSE | MSE | MAE | Notes |

|---|---|---|---|---|

Coulomb Counting | 0.5071 | 0.2572 | 0.4571 | Highest errors due to cumulative sensor noise, measurement inaccuracies, and integration errors. |

Extended Kalman Filter (EKF) | 0.0925 | N/A | N/A | Improved accuracy via model-based dynamic correction; requires detailed system modeling. |

Linear Regression | 0.0778 | N/A | N/A | Better than EKF but limited by SOC nonlinearity. |

SVM Regression | 0.0319 | N/A | N/A | Lowest errors by modeling complex correlations; higher computational cost. |

You will find that coulomb counting is best suited for applications where you can frequently reset the state of charge, such as in consumer electronics or medical devices. For large lithium battery packs in industrial or infrastructure settings, you should combine coulomb counting with other soc estimation methods to correct for drift and maintain accuracy.

1.3 Impedance and Mechanical Methods

Impedance measurement, especially impedance spectroscopy, provides a powerful way to measure state-of-charge of lithium batteries. You apply a small AC signal to the battery and analyze the response to determine internal resistance and other electrochemical properties. Impedance spectroscopy is sensitive to changes in lithium battery state of charge, battery aging, and temperature.

Statistical analyses show that impedance-based soc estimation methods achieve accuracy rates above 90% across different battery types and temperatures. These methods are robust and can detect subtle changes in battery health, making them valuable for critical infrastructure, security systems, and industrial applications. Impedance measurement is especially useful for monitoring large lithium-ion battery packs where reliability is paramount.

Mechanical methods, such as measuring battery expansion, strain, or acoustic emissions, offer non-destructive, in-situ soc estimation. These techniques complement traditional voltage and current measurements, improving overall accuracy. Mechanical sensors can be integrated into battery modules for real-time monitoring, but you must consider cost, complexity, and sensor calibration.

Note: Impedance measurement and impedance spectroscopy require specialized equipment and expertise. You should use these methods when you need high accuracy and detailed insight into battery health, such as in transportation infrastructure or advanced robotics.

1.4 Model-Based and Machine Learning

Model-based soc estimation uses mathematical models, such as equivalent circuit models or electrochemical models, to predict the lithium battery state of charge based on voltage, current, and temperature data. Advanced filtering algorithms, like the Extended Kalman Filter, improve accuracy by dynamically correcting for measurement errors and battery nonlinearities.

Machine learning approaches, including neural networks and deep learning, have revolutionized soc estimation. You can train these models on large datasets from real-world lithium-ion battery packs to capture complex relationships between input signals and state of charge. Case studies confirm that machine learning methods, such as RNARX-LSA and LSTM, achieve root mean square errors below 1%, outperforming traditional model-based and open circuit voltage method approaches.

The RNARX-LSA method consistently delivers RMSE below 1% across different temperatures, aging cycles, and discharge rates.

MLP and LSTM neural networks maintain high accuracy even with limited training data, making them robust for diverse applications.

Machine learning models adapt to nonlinear battery behavior and temperature fluctuations, providing reliable soc estimation for electric vehicles, grid storage, and large-scale industrial battery packs.

You should consider model-based and machine learning methods when you require the highest accuracy, adaptability, and real-time performance. These techniques are ideal for battery management systems in electric vehicles, renewable energy storage, and mission-critical infrastructure.

Part 2: Method Comparison and Selection

2.1 Accuracy and Practicality

When you evaluate soc estimation methods for lithium battery state of charge, you must balance accuracy with real-world practicality. Coulomb counting delivers accurate state-of-charge readings in the short term, but sensor drift and initial calibration errors can cause long-term inaccuracies. Open-circuit voltage methods offer simplicity, but temperature and battery aging can affect results. Advanced approaches, such as Kalman filtering and machine learning, provide robust and precise soc estimation. For example, hybrid algorithms using Kalman filters and neural networks have achieved root mean square errors below 0.5% across dynamic test cycles, supporting both high accuracy and real-time battery monitoring. These methods adapt well to changing temperatures and battery chemistries, making them suitable for industrial, infrastructure, and electric vehicle applications.

2.2 Pros and Cons

You can compare the main soc estimation methods for lithium battery state of charge using the table below:

SoC Measurement Method | Pros | Cons | Typical Applications |

|---|---|---|---|

Open-Circuit Voltage (OCV) | Simple, non-invasive | Needs rest period, affected by aging | Standby systems, ESS, UPS |

Coulomb Counting | Real-time, high short-term accuracy | Cumulative errors, needs calibration | Consumer electronics, medical devices |

Electrochemical Impedance Spectroscopy (EIS) | Detailed health insights, detects capacity fade | Complex, expensive, not real-time | Aerospace, grid-scale storage |

Model-Based (Kalman Filters) | High accuracy, adapts to conditions | Computationally intensive, complex | Electric vehicles, robotics |

Hybrid Approaches | Combines strengths, robust | Increased system complexity | Electric vehicles, industrial |

Tip: Hybrid soc estimation methods often deliver the most reliable lithium battery state of charge results for demanding applications.

2.3 Choosing the Right Method

You should select a soc estimation method based on your application’s requirements for lithium battery state of charge. For stationary energy storage or backup systems, open-circuit voltage methods may suffice. In consumer electronics or medical devices, coulomb counting offers real-time tracking but requires regular calibration. For electric vehicles, robotics, and industrial battery packs, model-based or hybrid soc estimation ensures accurate state of charge under dynamic conditions. If you need to optimize battery performance and safety, consider integrating advanced algorithms and real-time battery monitoring. For custom solutions tailored to your lithium-ion battery packs, consult with our OEM/ODM experts.

You improve battery management and safety by selecting SoC methods that fit your lithium battery pack’s operational needs. Each method offers trade-offs in accuracy and complexity. As shown below, SoC estimation accuracy drops as load increases, so combining advanced techniques ensures reliable performance:

Load (%) | MSE | MAE | R² |

|---|---|---|---|

0 | 0.002636 | 0.999419 | |

10 | 0.000473 | 0.017283 | 0.997079 |

20 | 0.002061 | 0.033809 | 0.987262 |

FAQ

1. How often should you calibrate SoC estimation systems in lithium battery packs?

You should calibrate SoC estimation systems at least every six months. Frequent calibration ensures accuracy, especially in industrial or infrastructure applications with high reliability requirements.

2. What factors most affect SoC measurement accuracy in lithium battery packs?

Key factors include temperature fluctuations, battery aging, sensor precision, and load variability. You can improve accuracy by combining multiple estimation methods and using advanced battery management systems.

3. Why choose Large Power for custom lithium battery pack SoC solutions?

Large Power provides tailored SoC solutions for industrial, medical, and infrastructure applications. You receive expert support and advanced technology. Request a custom consultation today.