You can optimize medical cart batteries in your hospital by prioritizing strategic battery management for safety, reliability, and cost-efficiency. Battery replacement and maintenance play a vital role in keeping medical devices operational and supporting patient care.

Effective battery management ensures critical medical equipment functions properly.

Poor battery practices may cause device failures, putting patient safety at risk.

Well-planned battery programs help reduce costs and minimize environmental impact.

Following manufacturer guidelines and adopting data-driven best practices will help you maintain high standards in battery maintenance and replacement.

Key Takeaways

Implement scheduled battery replacements to reduce unexpected failures and enhance patient safety. This proactive approach can lower failure rates from 28% to 7%.

Conduct routine inspections to identify battery wear early. Look for signs like cracks or swelling to ensure reliable equipment performance.

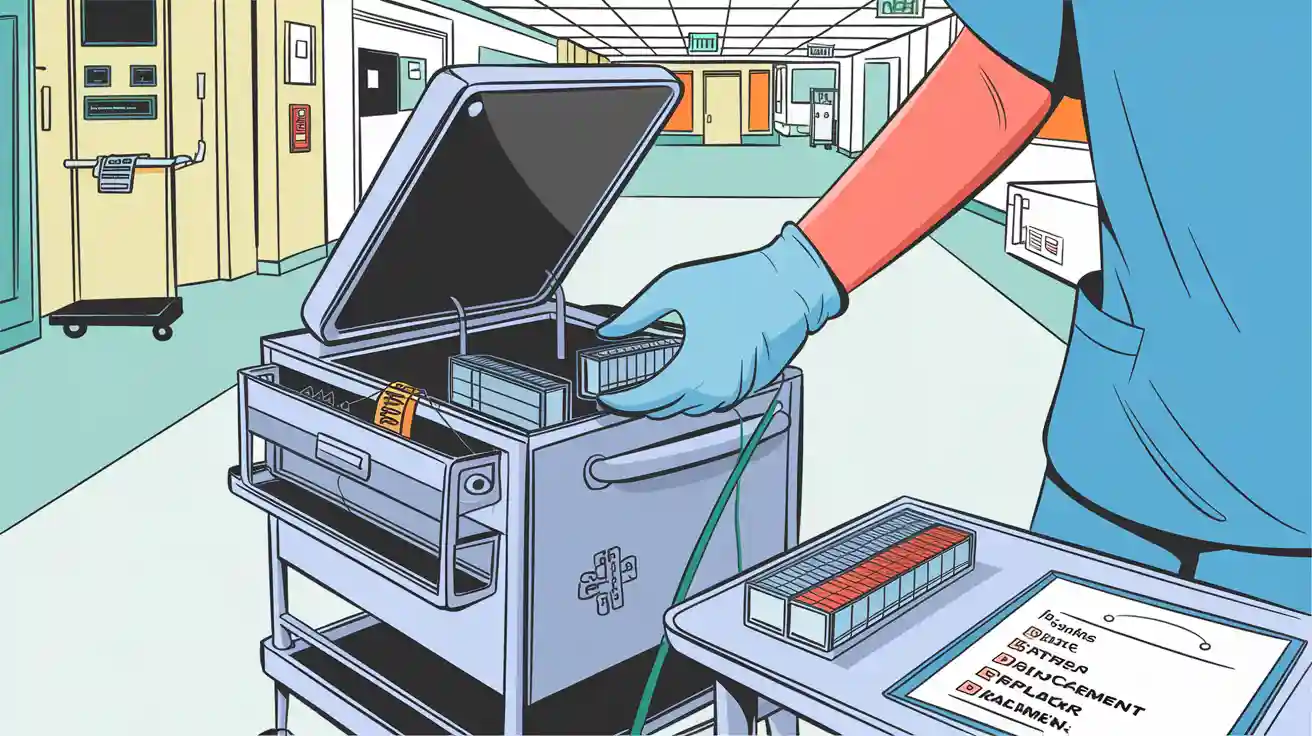

Utilize hot-swappable batteries for uninterrupted patient care. This feature allows quick battery changes without powering down medical devices.

Adopt predictive maintenance strategies using real-time data to anticipate battery issues. This approach minimizes downtime and extends the lifespan of medical devices.

Train staff on proper battery handling and maintenance practices. Ongoing education reduces failure rates and supports safe operations.

Part1: Medical Cart Batteries Replacement

1.1 Scheduled Replacement

You must follow manufacturers’ recommendations for scheduled battery replacement to maintain high standards in hospital equipment. Major manufacturers advise replacing medical cart batteries either annually or every other year, regardless of battery performance. This proactive approach aligns with best practices in battery management and supports patient safety.

Scheduled battery replacement offers clear financial advantages. You will see only a minimal annual cost increase of $5,341, but this strategy reduces the risk of unexpected battery failure from 28% to 7%. By planning ahead, you can prevent up to 93 battery failures between the second and third year. This translates to significant savings in labor and helps avoid potential harm to patients. Unplanned failures cost $80 per battery and $60 in labor, making scheduled maintenance a cost-effective solution.

Regular battery checks are essential. You should inspect batteries for signs of wear, such as cracks, swelling, or bulging. These visual cues indicate that a battery may need replacement before its scheduled interval. By adhering to a maintenance program, you ensure that equipment remains reliable and ready for use.

Tip: Always document battery replacement dates and monitor battery performance to optimize your maintenance program.

1.2 Condition-Based Replacement

Condition-based replacement relies on real-time assessment of battery health. You can use diagnostic tools to evaluate battery performance and decide when to replace batteries based on actual condition rather than a fixed schedule. This strategy helps extend battery life and improves reliability for medical equipment.

Diagnostic Method | Description |

|---|---|

Direct Sensing | Relies on real-time measurements to identify irregularities in battery performance. |

Model-Based Methods | Utilizes mathematical models to predict errors based on deviations from expected battery behavior. |

Data-Driven Methods | Employs statistical or machine learning algorithms to analyze historical and real-time data for error identification and RUL estimation. |

You should prioritize total battery life under clinical duty cycles. Peripheral longevity matters, especially for sensitive medical devices that require consistent power. Charge consistency across shifts and carts ensures that batteries deliver reliable performance throughout their use.

Batteries with longer life cycles reduce the frequency of replacement.

Reliable batteries support critical equipment and minimize downtime.

Consistent charging practices help maintain battery health and backup capability.

Batteries in medical devices must deliver longevity, reliability, and backup capability. These factors directly impact patient outcomes and influence healthcare costs and operational efficiency. You can identify worn or damaged batteries by monitoring charge retention, runtime, and physical condition. If you notice rapid discharge or swelling, replace the battery immediately.

Aftermarket options can provide cost-effective alternatives for battery replacement. You should verify compatibility and quality before integrating aftermarket batteries into your equipment. Always follow manufacturers’ recommendations to maintain safety and performance standards.

1.3 Hot-Swappable Batteries

Hot-swappable batteries offer significant operational advantages for medical cart batteries in hospital settings. You can replace batteries quickly and easily during critical situations, ensuring uninterrupted patient care. This feature eliminates the need for downtime, which is crucial for continuous operations.

Quick, easy battery replacement during emergencies.

Reduced need for downtime, supporting uninterrupted workflows.

No specialized tools or training required for battery swaps.

Enhanced emergency preparedness and backup power availability.

Lower risk of component failure due to simplified battery changes.

Reduced environmental impact through recharging rather than disposal.

Versatility across various medical devices.

Hot-swappable batteries provide continuous power to their connected devices while switching with their backup battery. This means there is no need to power down devices if their primary battery loses charge.

Hot-swappable battery systems eliminate these issues by offering: Continuous Operation: No downtime for charging, ensuring uninterrupted workflows.

You should consider hot-swappable battery systems for equipment that requires constant operation. These systems support battery maintenance by allowing you to swap batteries without interrupting device function. This strategy aligns with best practices in battery management and supports hospital safety standards.

Part2: Battery Maintenance Essentials

2.1 Routine Inspections

You improve operational efficiency and reduce downtime by implementing routine inspections for medical cart batteries. Regular battery maintenance helps you identify early signs of wear, such as cracks, swelling, or bulging. These indicators often signal potential failure and require immediate replacement to maintain safety and equipment standards. You should establish a maintenance program that includes scheduled inspections and diagnostics. Use a ticketing system to document battery failures and resolutions, which ensures quick repairs and keeps equipment in safe working order. Engage technicians for preventive maintenance to support continuous hospital operations.

Tip: Reserve spare functional workstations during repairs to minimize service interruptions and maintain high standards for patient care.

2.2 Cooling and Temperature Control

Temperature management plays a critical role in battery performance and longevity. High temperatures degrade battery health and accelerate internal chemical reactions, leading to capacity loss and quicker deterioration. You must monitor operating temperature to protect medical cart batteries from excessive heat. The recommended temperature range for optimal battery operation is shown below:

Operating Temperature | Range |

|---|---|

Medical Cart Battery | 0°C~35°C |

Maintaining batteries within this range supports reliability and extends service life. You should store batteries in a cool, dry place when not in use. Avoid exposing equipment to direct sunlight or heat sources to prevent premature aging.

2.3 Extending Battery Life

You can extend battery life by following manufacturers’ recommendations for charging and storage. Avoid overcharging and excessive discharge, which can shorten battery lifespan and increase replacement costs. Implement correct charging routines and monitor battery performance regularly. Replace batteries when performance begins to decline to avoid interruptions in service. Proper battery maintenance mitigates the effects of aging and supports continuous equipment operation.

Avoid overcharging and store batteries in a cool, dry place.

Regularly check battery performance and replace old or faulty batteries.

Implement storage guidelines and charging practices.

Avoid excessive discharge to ensure optimal performance.

A comprehensive battery management strategy reduces downtime, minimizes operational costs, and supports hospital safety standards. You maintain reliable medical equipment and improve patient outcomes by prioritizing battery maintenance.

Part3: Battery Management Strategies

Implementing effective battery management strategies in your hospital ensures that medical cart batteries remain reliable and safe. You can follow a step-by-step approach to create a robust maintenance program that supports preventive maintenance and predictive maintenance for all equipment.

3.1 Inventory Tracking

You should start by organizing your inventory using medical storage carts with labeled compartments. This system helps you locate batteries quickly, especially during emergencies. Maintaining an accurate inventory and status of all assets is crucial for fleet management. Modern tracking uses fleet management software to monitor carts remotely. You gain visibility into asset utilization, connectivity, usage frequency, and power levels. These practices help you manage battery replacement schedules and reduce failure rates.

Medical storage carts simplify inventory tracking.

Organized compartments and labeling options enhance efficiency.

Fleet management software provides remote monitoring and asset visibility.

Tracking usage and power levels increases device uptime.

3.2 Staff Training

You must train staff to handle and maintain batteries according to manufacturers’ recommendations. Consistent education reduces battery failure and supports preventive maintenance. Training programs cover lithium battery awareness and safety, focusing on hazards, safe storage, and emergency response.

Training Program | Description | Duration |

|---|---|---|

Required for employees and students handling lithium batteries, covering safe practices and hazards. | N/A | |

Lithium Battery Safety Training | Overview of lithium battery characteristics, hazards, safe storage, and emergency response. | 2 hours |

You should provide ongoing education for staff responsible for battery-powered medical equipment. Develop and adjust your battery management plan as needed. These strategies help you meet safety standards and improve equipment reliability.

Note: Ongoing staff training directly correlates with reduced battery failure rates and improved preventive maintenance outcomes.

3.3 Monitoring Systems

You can use Battery Monitoring Systems (BMS) to track battery health and performance in medical carts. These systems monitor voltage, temperature, current, state of charge, and internal resistance. Real-time visibility allows you to detect issues early and maintain compliance with technical standards. Integrated monitoring systems assess state of charge and state of health, preventing overcharging and over-discharging. You reduce maintenance costs and extend battery life, achieving up to a 30% reduction in total cost of ownership.

BMS provides real-time monitoring and early warnings.

Data-driven insights support predictive maintenance and preventive maintenance.

Integrated systems improve battery management efficiency and reliability.

You should integrate monitoring systems with hospital asset management platforms. Regular performance checks and data analysis help you optimize battery management strategies and meet manufacturers’ recommendations.

Part4: Preventive Maintenance vs Predictive Maintenance

4.1 Preventive Maintenance Overview

You can improve the reliability of your medical cart batteries by implementing preventive maintenance. This approach involves scheduled inspections and servicing at fixed intervals, regardless of battery condition. You follow manufacturers’ recommendations to ensure that equipment remains operational and meets safety standards.

Preventive maintenance reduces the risk of unexpected battery failure. You replace batteries before they reach the end of their life cycle, which helps maintain consistent equipment performance. Hospitals that use preventive strategies experience fewer disruptions and lower overall maintenance costs.

Evidence Type | Description |

|---|---|

Maintenance Strategy | Higher frequency of scheduled maintenance reduces battery failures. |

Reliability Analysis | PVST results showed fewer failed components after preventive maintenance compared to before. |

Cost Management | 67% of maintenance costs for defibrillators were due to battery costs, indicating that better battery management can reduce costs. |

You should establish a maintenance program that includes regular battery checks, documentation, and staff training. This strategy supports compliance with industry standards and helps you avoid costly repairs. Preventive maintenance also extends the lifespan of your equipment and improves patient safety.

Tip: Schedule preventive maintenance based on manufacturers’ recommendations and document each service to track battery performance over time.

4.2 Predictive Maintenance Overview

Predictive maintenance uses real-time battery health data and analytics to determine when servicing is needed. You monitor battery status using IoT technologies and advanced sensors. This approach allows you to anticipate potential issues and address them before they cause equipment failure.

You benefit from predictive maintenance by minimizing unplanned downtime and extending the operational life of your medical devices. Real-time analytics help you identify patterns in battery performance and predict when replacements are necessary. You can allocate resources more efficiently and reduce maintenance expenditures.

Predictive maintenance in hospitals uses IoT technologies to monitor battery health and operational status of medical equipment.

Real-time data analytics help in anticipating and resolving potential issues before they disrupt healthcare services.

This approach minimizes unplanned downtimes and extends the operational lifespan of vital medical devices.

You should invest in predictive maintenance systems if your hospital relies on high-value equipment and advanced lithium battery packs. These systems require an initial investment but offer long-term savings and improved reliability.

Note: Predictive maintenance supports continuous improvement by using battery health data to optimize maintenance strategies.

4.3 Choosing the Right Approach

You must decide between preventive and predictive maintenance based on your hospital’s needs, technology, and resources. Both strategies offer unique advantages for managing medical cart batteries.

Maintenance Approach | Description | When to Use |

|---|---|---|

Preventive Maintenance | Scheduled at fixed intervals, follows manufacturers’ recommendations, reduces risk of failure. | Use for standard equipment and when resources for advanced monitoring are limited. |

Predictive Maintenance | Based on real-time battery health data and analytics, performed as needed, minimizes downtime. | Use for high-value medical devices and advanced lithium battery packs with monitoring capabilities. |

You should consider several factors when choosing your maintenance strategy:

A 2016 FDA study indicated that 50% of hospitals experienced battery or electrical-related issues in the past two years, emphasizing the need for proper battery technology selection and preventive maintenance.

WHO categorized maintenance costs into initial and operating expenditures, with maintenance accounting for 15-60% of healthcare system operations, highlighting the financial impact of maintenance strategies.

Factors such as lack of biomedical engineering, funding, training, and planning were identified as significant issues affecting maintenance practices in hospitals.

Major factors affecting maintenance include inadequate training, lack of documentation, and insufficient management planning.

Maintenance expenditures can consume a significant portion of healthcare budgets, necessitating careful consideration of maintenance strategies.

You should evaluate your hospital’s resources, staff expertise, and equipment requirements before selecting a maintenance program. Preventive maintenance works well for standard medical carts and basic lithium battery packs. Predictive maintenance is ideal for advanced medical devices that require continuous monitoring and high reliability.

Tip: Combine preventive and predictive maintenance for optimal results. Use preventive strategies for routine equipment and predictive systems for critical devices.

Part5: Trends in Medical Cart Battery Management

5.1 New Battery Technologies

You see rapid advancements in lithium battery packs for medical equipment. Manufacturers’ recommendations now favor lithium-ion and lithium iron phosphate chemistries for their superior preventive maintenance and predictive maintenance capabilities. These batteries deliver longer life cycles, faster charging, and increased safety standards. You can power medical carts for 6-10 hours, supporting multiple peripherals and reducing downtime. The table below highlights key improvements:

Improvement Type | Description |

|---|---|

Longer Battery Life | Lithium-ion batteries can power a mobile workstation for 6-10 hours, significantly better than older battery types. |

Faster Charging Times | Advanced lithium-ion cells charge quickly, reducing downtime for medical carts. |

Increased Safety | Lithium iron phosphate batteries are more stable, reducing risks associated with overheating. |

Powering Multiple Peripherals | These batteries can support various devices on the cart, enhancing workflow efficiency. |

You should evaluate battery technologies based on preventive maintenance and predictive maintenance strategies. This approach ensures your equipment meets operational standards and supports continuous patient care.

5.2 AI and Predictive Analytics

You can optimize battery management by integrating AI and predictive analytics into your maintenance program. These technologies use real-time data to monitor battery health, predict failure, and improve performance. You benefit from enhanced preventive maintenance and predictive maintenance, which extend battery life and reduce risks. Consider the following advancements:

AI and machine learning enhance SOC/SOH predictions, reducing failure risks by 20%.

Real-time analytics optimize charging efficiency.

Predictive maintenance extends battery life by 15%.

You should implement battery monitoring systems that leverage AI to meet manufacturers’ recommendations and industry standards. This strategy supports preventive maintenance and predictive maintenance for all medical equipment.

Tip: Use AI-driven battery management to reduce downtime and improve reliability across your medical fleet.

5.3 Future Best Practices

You prepare for future developments by adopting best practices in battery management. Non-powered carts with swappable batteries allow for continuous operation and cost-effective preventive maintenance. Powered carts require extensive modifications and cannot operate while charging, limiting their availability. You should prioritize equipment that supports preventive maintenance and predictive maintenance strategies.

Non-powered carts with swappable batteries enable continuous use and easier preventive maintenance.

Powered carts need more time for battery housing modifications, leading to longer wait times.

Non-powered carts remain available at all times, supporting uninterrupted workflows.

You should review your maintenance program regularly and follow manufacturers’ recommendations to ensure compliance with safety standards. These strategies help you future-proof your battery management and maintain reliable medical equipment.

You can strengthen your hospital’s battery management by following a structured approach. Schedule regular battery checks, use advanced lithium battery packs, and train staff on battery handling. Prioritize safety in every battery replacement to support reliable medical equipment. Monitor battery performance to reduce downtime and control costs. Review your battery strategy often to keep up with new technology and maintain high standards in patient care.

FAQ

What is the recommended cycle life for lithium iron phosphate batteries in medical carts?

You should expect lithium iron phosphate batteries to deliver over 2,000 cycles under standard hospital use. This chemistry offers stable platform voltage and high safety, making it ideal for continuous medical operations.

How do you ensure safe battery disposal in hospital environments?

You must follow EPA and local regulations for lithium battery disposal. Partner with certified recycling vendors to prevent environmental hazards and maintain compliance with healthcare waste management standards.

What maintenance practices extend the lifespan of lithium-ion batteries in medical carts?

You should keep batteries within the 0°C to 35°C operating range. Avoid overcharging and deep discharging. Schedule regular inspections and use battery monitoring systems to track performance and prevent premature failure.

Can you use lithium battery packs in robotic medical devices?

You can deploy lithium battery packs in robotic medical devices for reliable power delivery. Lithium-ion and lithium iron phosphate chemistries support high energy density and long runtime, which are critical for advanced hospital automation.

How do you select the right lithium battery chemistry for medical applications?

You should evaluate platform voltage, energy density, and cycle life. Lithium iron phosphate suits high-safety, long-life needs. Lithium-ion offers higher energy density for devices requiring compact size and extended runtime.