You face increasing pressure to ensure safety and reliability in medical infusion pumps. Traditional battery issues—such as false alarms, depleted power, and data errors—pose significant risks. Recent lithium advancements deliver longer battery life, predictable performance, and real-time data monitoring. These innovations drive rapid adoption across healthcare device manufacturing.

Safety Incident Type | Description |

|---|---|

False Alarms | Devices issuing alarms that do not correspond to actual issues, leading to unnecessary interventions. |

Unanticipated Depleted Battery Alarms | Alarms indicating battery depletion that were not expected, potentially leading to device failure. |

Abnormal Circuit Board Behavior | Malfunctions in the circuit board that can disrupt normal operation of the pump. |

Interruptions in Medication Delivery | Failures that prevent the continuous delivery of medication, posing risks to patient care. |

Malfunctioning Communication Networks | Issues affecting the communication between devices, which can lead to errors in medication delivery. |

Inaccurate Dosage Information Displays | Incorrect displays of dosage information that can lead to medication errors. |

Class I Recalls | Severe recalls indicating significant risk of serious harm or death associated with device use. |

Key Takeaways

Lithium batteries enhance safety in medical infusion pumps by preventing overheating and short-circuits, ensuring reliable operation.

Choosing lithium battery solutions improves patient outcomes by providing consistent power, reducing device failures, and enhancing data accuracy.

Adopting advanced lithium battery technology supports sustainability by minimizing waste and lowering environmental impact in healthcare.

Part 1: Battery Safety and Reliability in Medical Infusion Pumps

1.1 Overheating and Short-Circuit Prevention

You need to prioritize safety when selecting batteries for medical infusion pumps. Overheating and short-circuit incidents can cause severe device failures, risking patient safety and disrupting healthcare operations. The main causes of these incidents often relate to internal damage or contamination:

The final warning relates to three issues associated with the potential for thermal damage in affected pumps. First, reports of damage to the circuit board within the housing of a rechargeable battery pack may cause the melting of the plastic housing. Second, damage to the wireless communication module circuit board may also lead to melting of its plastic housing. Third, damaged or dislodged battery separators or foreign material in the battery compartment can create an electrical short condition between the battery contacts. These issues can lead to overheating and short-circuit incidents.

To address these risks, you should consider advanced lithium battery solutions that incorporate multiple safety features. The following table summarizes the most effective safety mechanisms found in modern lithium battery packs for healthcare applications:

Safety Feature | Function |

|---|---|

Battery Management Systems (BMS) | Anticipate failures before they occur, ensuring safety. |

Solid-State Lithium-Ion Technology | Safer and more stable, almost eliminating the chance of thermal runaway. |

Heat-Resistant Electrolytes | Can withstand higher temperatures, reducing the risk of overheating. |

Protection Circuits | Prevent overcharging, over-discharging, and short circuits, ensuring safe operation. |

Thermal Cutoffs | Monitor temperature thresholds and halt current flow when limits are reached, preventing overheating. |

Pressure Relief Mechanisms | Safely vent pressure during internal explosions, protecting surrounding equipment and personnel. |

You will also find that the choice of battery packaging plays a critical role in safety. Aluminum-plastic flexible packaging, now standard in many lithium metal batteries, offers a significant advantage over traditional metal packaging:

Feature | Aluminum-Plastic Packaging | Metal Packaging |

|---|---|---|

Risk of Explosion | Low (bulges only) | High (prone to explosion) |

Response to Safety Hazards | Bulging | Explosion |

This packaging reduces the risk of catastrophic failure, as it tends to bulge rather than explode under stress. You can rely on this design to enhance the excellent safety performance of lithium battery packs in medical infusion pumps.

When you evaluate battery chemistry for medical infusion pumps, you must consider platform voltage, energy density, and cycle life. The table below compares the most common lithium battery chemistries used in healthcare applications:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1,000 |

NMC | 3.7 | 150-220 | 1,000-2,000 |

LiFePO4 | 3.2 | 90-160 | 2,000-5,000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 5,000-10,000 |

Solid-State | 3.7 | 250-300 | 2,000-10,000 |

Lithium Metal | 3.7 | 300-500 | 500-1,000 |

You can see that lithium metal batteries and solid-state lithium-ion batteries offer higher energy density and longer cycle life, making them ideal for critical medical infusion pumps.

1.2 Consistent Power and Long Life

You depend on consistent power delivery and long operational life for reliable performance in medical infusion pumps. Lithium battery chemistry ensures stable voltage and minimizes the risk of sudden power loss. This stability is crucial for maintaining accurate data and uninterrupted medication delivery.

Lithium batteries maintain output around 3.7V nominal across more than 90% of charge.

You benefit from consistent performance in various medical monitors.

This prevents diagnostic drift or sensor error, ensuring accurate data for clinical decisions.

Lithium-ion batteries function through electrochemical reactions, where lithium ions transfer between the anode and cathode, generating electricity. This process is crucial for maintaining a stable power output in medical devices like infusion pumps.

A Battery Management System (BMS) monitors voltage, current, and temperature. It ensures stable operation and efficiency. This is vital for safety in clinical environments.

When you compare operational lifespan, lithium batteries, especially rechargeable lithium-ion and lithium metal batteries, outperform other battery types:

Lithium batteries, particularly rechargeable lithium-ion, are ideal for frequently used medical devices like infusion pumps due to their longer life and stable voltage.

In contrast, alkaline batteries are less reliable for critical applications despite being cheaper.

The lifespan of medical devices varies significantly; for instance, implantable devices like pacemakers can last 5-10 years, while portable devices such as insulin pumps typically last 1-3 years.

You also gain environmental benefits by choosing lithium battery solutions. Rechargeable lithium batteries reduce waste by replacing hundreds of disposable batteries and have a much lower global warming impact after multiple cycles.

Battery Type | Environmental Impact |

|---|---|

Lithium (Rechargeable) | Reduces waste by replacing 100-1,000 disposables, 28 times less global warming impact after 50 cycles |

Disposable | Contributes significantly to landfill issues |

Healthcare providers evaluate the reliability of lithium battery-powered infusion pumps through a comprehensive approach:

Component | Description |

|---|---|

Risk Assessments | Identifying potential hazards associated with lithium battery use in clinical settings. |

Compliance with Safety Standards | Ensuring adherence to established safety regulations and guidelines for battery-powered devices. |

Ongoing Staff Training | Providing continuous education to staff on the safe use and management of infusion pumps. |

Preventive Maintenance | Regular inspections and maintenance of devices to ensure functionality and safety. |

Incident Response Framework | Establishing protocols for documenting and responding to incidents involving battery failures. |

Regulatory Guidelines | Following evolving standards set by accreditation bodies to ensure safety and compliance. |

You can reduce maintenance costs and improve device uptime by leveraging the long life and reliability of lithium metal batteries. This approach supports better patient outcomes and operational efficiency in healthcare environments.

Tip: When you select lithium battery solutions for medical infusion pumps, you not only improve safety and performance but also contribute to sustainability and regulatory compliance. Explore more about medical battery solutions and sustainability for your next procurement cycle.

Part 2: Compliance, Patient Outcomes, and Portable Medical Devices

2.1 Meeting Medical Device Safety Standards

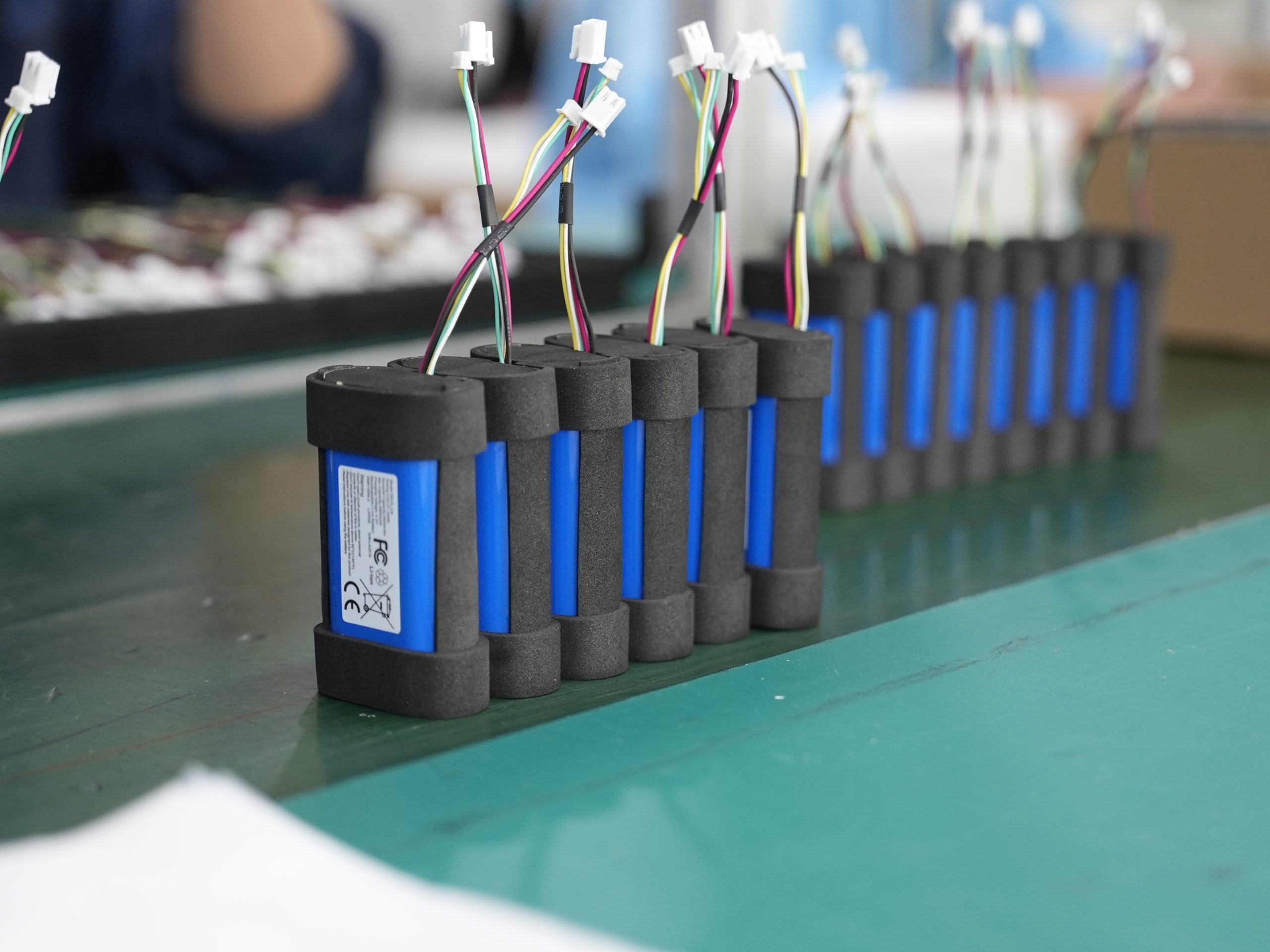

You must meet strict safety and performance standards when designing medical infusion pumps. Lithium battery solutions help you achieve compliance with evolving regulations. These batteries support reliable operation and simplify certification for your devices. Battery management systems, thermal cutoffs, and advanced chemistries like LiFePO4, NMC, and LCO ensure your products pass rigorous tests. You can also apply these standards to robotics, security, infrastructure, consumer electronics, and industrial sectors, which all demand high reliability. Learn more about application scenarios.

Feature | Lithium-ion Batteries | NiMH Batteries |

|---|---|---|

Energy Density | High energy density allows for compact design | Lower energy density |

Self-Discharge Rate | Low self-discharge, retains charge longer | Higher self-discharge rate |

Temperature Sensitivity | Sensitive to temperature fluctuations | Less sensitive |

Suitability for Medical Use | Ideal for portable devices like infusion pumps | Less suitable for portable devices |

2.2 Impact on Patient Safety and Clinical Results

You improve patient safety and clinical outcomes by choosing lithium battery-powered medical infusion pumps. These batteries deliver stable power, which reduces the risk of device failure and data loss. You gain confidence in your equipment and can focus on patient care. The following table highlights real-world results from healthcare settings:

Evidence Description | Outcome |

|---|---|

Standardized training and vendor collaboration | 97% auto-programming success, drug library override rates dropped from 26% to 7%, zero adverse infusion-related events |

Integration with electronic medical records | 27% decrease in infusion medication events, drug library compliance >95%, low-alert override rate <5% |

Retrospective review of pump data | Average drug library compliance of 96%, 2% of infusion time in alarms state, 92% reduction in overrides |

You see fewer adverse events and more accurate data, which leads to better patient outcomes and higher healthcare provider confidence.

2.3 Lithium Battery Trends in Portable Medical Devices

You witness the rapid expansion of the portable medical devices market, driven by lithium battery technology. Lithium-ion batteries now hold over 50% of the global market share for medical batteries. Their high energy density, ranging from 150 to 250 Wh/kg, supports compact and lightweight device designs. The market for lithium batteries in medical devices was valued at 4,580 million USD in 2024 and is projected to reach 10.8 billion USD by 2035, with a compound annual growth rate of 8.1%. This growth reflects the increasing demand for reliable power in medical device design and other sectors. You benefit from this trend by adopting advanced battery solutions that ensure data integrity, device uptime, and patient safety.

Note: The rapid expansion of the portable medical devices market creates new opportunities for innovation and improved patient care. You can leverage lithium battery advancements to stay ahead in a competitive landscape.

Part 3: Technology Innovations in Medical Infusion Pump Batteries

3.1 Energy Efficiency and Compact Design

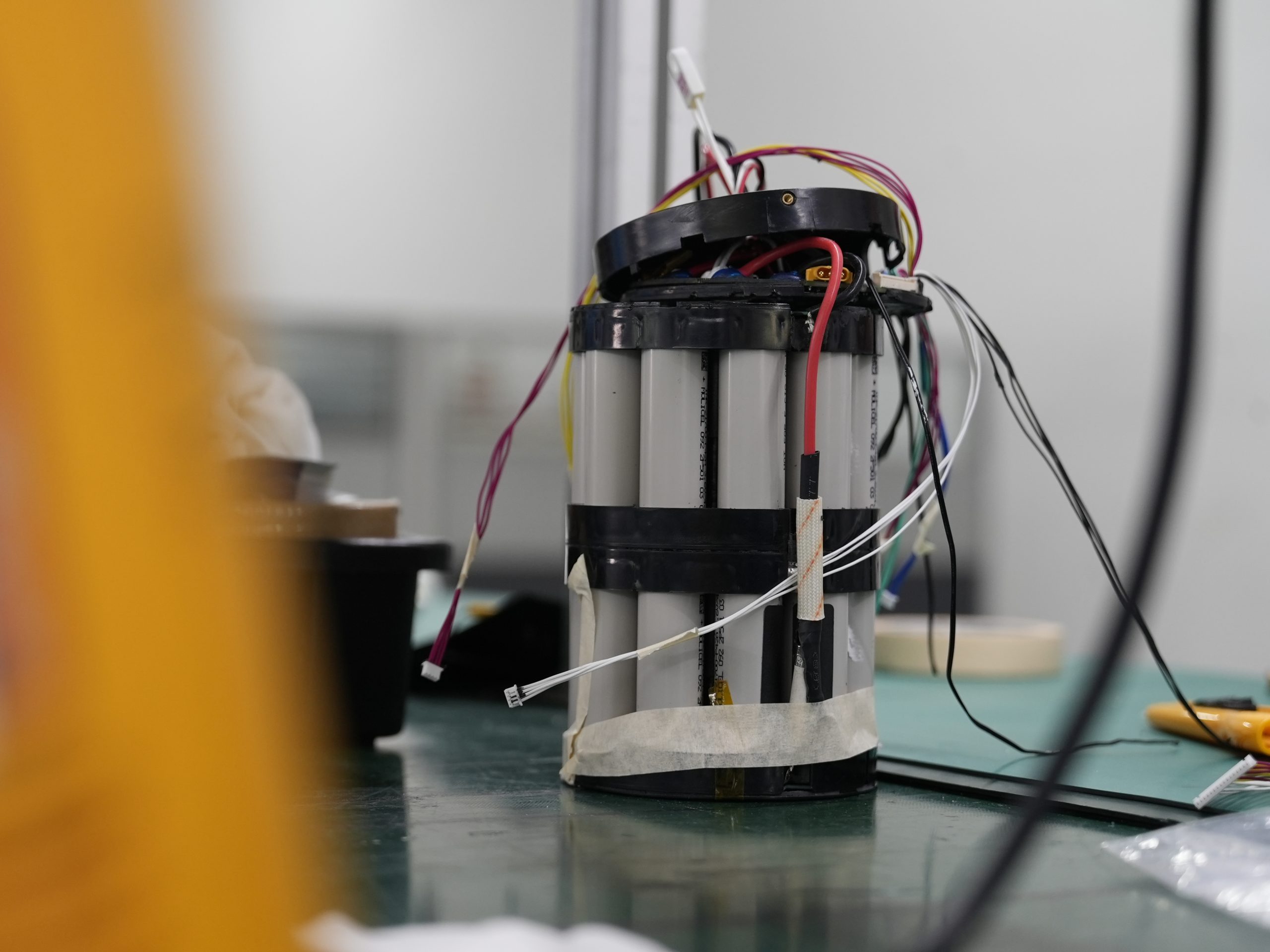

You see rapid advancements in battery technology driving the evolution of portable medical devices. Manufacturers now focus on enhancing battery life and reducing size, which improves the efficiency of infusion pumps. You benefit from lithium batteries that deliver higher energy density, enabling longer operation on a single charge. These batteries are more reliable and compact than older technologies, and their quick charging capabilities increase usability in clinical environments.

You can rely on lithium battery packs to support long operation times, which is essential for mobile healthcare.

Advanced lithium-ion batteries (learn more) offer faster charging and enhanced safety features, improving performance.

The compact design of these batteries allows for smaller, lighter infusion pumps, which is crucial for portability in healthcare settings.

Lithium-polymer (learn more) and LiFePO4 (learn more) batteries enable continuous operation, minimizing maintenance for clinical staff.

You can expect infusion pumps to operate for eight to ten hours on a single charge at full speed. This reliability ensures effective performance in various clinical environments.

Battery Type | Energy Density (Wh/kg) | Typical Cycle Life (cycles) | Platform Voltage (V) |

|---|---|---|---|

Lithium-ion | 150-220 | 1,000-2,000 | 3.7 |

LiFePO4 | 90-160 | 2,000-5,000 | 3.2 |

Lithium-polymer | 150-200 | 500-1,000 | 3.7 |

Solid-state | 250-300 | 2,000-10,000 | 3.7 |

3.2 Integration with Smart Monitoring Systems

You gain a competitive edge by integrating smart monitoring systems with lithium battery-powered infusion pumps. Recent innovations in implantable energy storage devices, including lithium batteries, support continuous health monitoring and treatment. These systems use wireless charging and energy harvesting, which enhance the functionality of portable medical devices.

Smart monitoring systems provide several features that improve safety and performance:

Feature | Description |

|---|---|

Cascading Capability | Integrates with bedside infusion workstations for comprehensive management. |

Large Display Screen | 3.5-inch full-color LCD for clear visuals and easy monitoring. |

Intelligent Battery | High-capacity lithium-ion battery with real-time monitoring for uninterrupted infusion. |

Wireless Connectivity | WiFi support for remote monitoring and information sharing with central workstations. |

Safe Infusion | Multi-CPU control with independent alarms ensures safe infusion practices. |

Smart Medication Administration | Drug library and DERS system adjust rates based on orders, enhancing patient safety. |

Precision Infusion | External drip sensor connection for closed-loop precision infusion, improving accuracy. |

You can use battery management systems (learn more) to monitor voltage, current, and temperature in real time. This technology ensures uninterrupted operation and supports remote monitoring, which is vital for modern healthcare environments. These innovations in lithium battery packs set new standards for safety, reliability, and efficiency in portable medical devices.

You gain safer, more reliable infusion pumps by adopting advanced lithium battery solutions. Over the past decade, lithium-ion and lithium-polymer technologies have boosted device efficiency by 20%. Industry experts recommend custom battery solutions, strict compliance, and collaboration with trusted suppliers. Future trends include longer life, miniaturization, and enhanced patient safety.

FAQ

What advantages do lithium battery packs offer for medical infusion pumps compared to NiMH batteries?

Feature | NiMH Batteries | |

|---|---|---|

Energy Density | 150–300 Wh/kg | 60–120 Wh/kg |

1,000–10,000 cycles | 500–1,000 cycles | |

Platform Voltage | 2.4–3.7 V | 1.2 V |

How does Large Power support custom lithium battery solutions for B2B medical device manufacturers?

You receive tailored lithium battery pack designs, compliance support, and technical consultation. Request a custom battery consultation. Large Power ensures safety and performance for your application.

Which lithium battery chemistries best suit medical, robotics, and industrial applications?

You benefit from LiFePO4, NMC, and LCO chemistries. These offer high safety, long cycle life, and stable voltage. They meet strict requirements in medical, robotics, and industrial sectors.