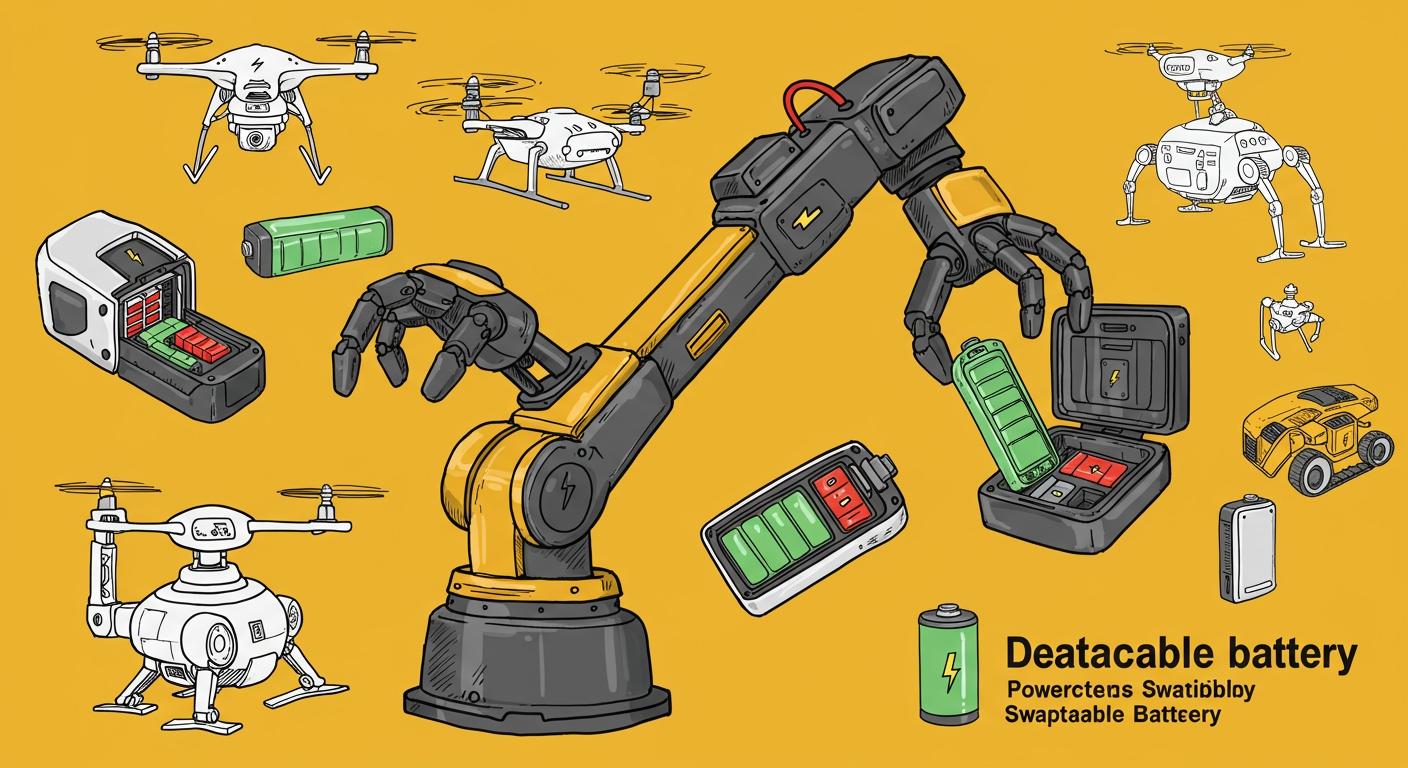

You see modular and swappable batteries changing how robots work in industries around the world. Factories now install more robots than ever before, aiming for nonstop operation and less downtime. The battery swapping market is growing fast, with values expected to reach billions of dollars in the next decade. Modular Batteries give you flexibility and help robots adapt to new tasks. Today, you notice a clear shift toward robot autonomy and modularity, making systems more sustainable and easier to manage.

The battery swapping market is expected to reach $10.24 billion by 2032, growing at a CAGR of over 30%.

Over 4.6 million industrial robots are in use worldwide, showing strong demand for operational efficiency.

Modularity lets robots evolve and stay adaptable for long-term use.

Key Takeaways

Modular batteries enhance robot uptime by allowing quick replacements, minimizing downtime, and boosting productivity in various industries.

Swappable batteries enable continuous operation, with autonomous swapping systems keeping robots running 24/7, crucial for logistics and manufacturing.

Smart battery management systems monitor battery health and performance, helping schedule maintenance and extend the lifespan of robot fleets.

Battery swap stations improve efficiency by allowing rapid battery exchanges, reducing labor costs, and ensuring robots operate at peak performance.

Sustainability is key; recycling and reusing lithium batteries can lower environmental impact, making it essential to choose batteries designed for these practices.

Part 1: Role of Modular Batteries

1.1 Uptime & Efficiency

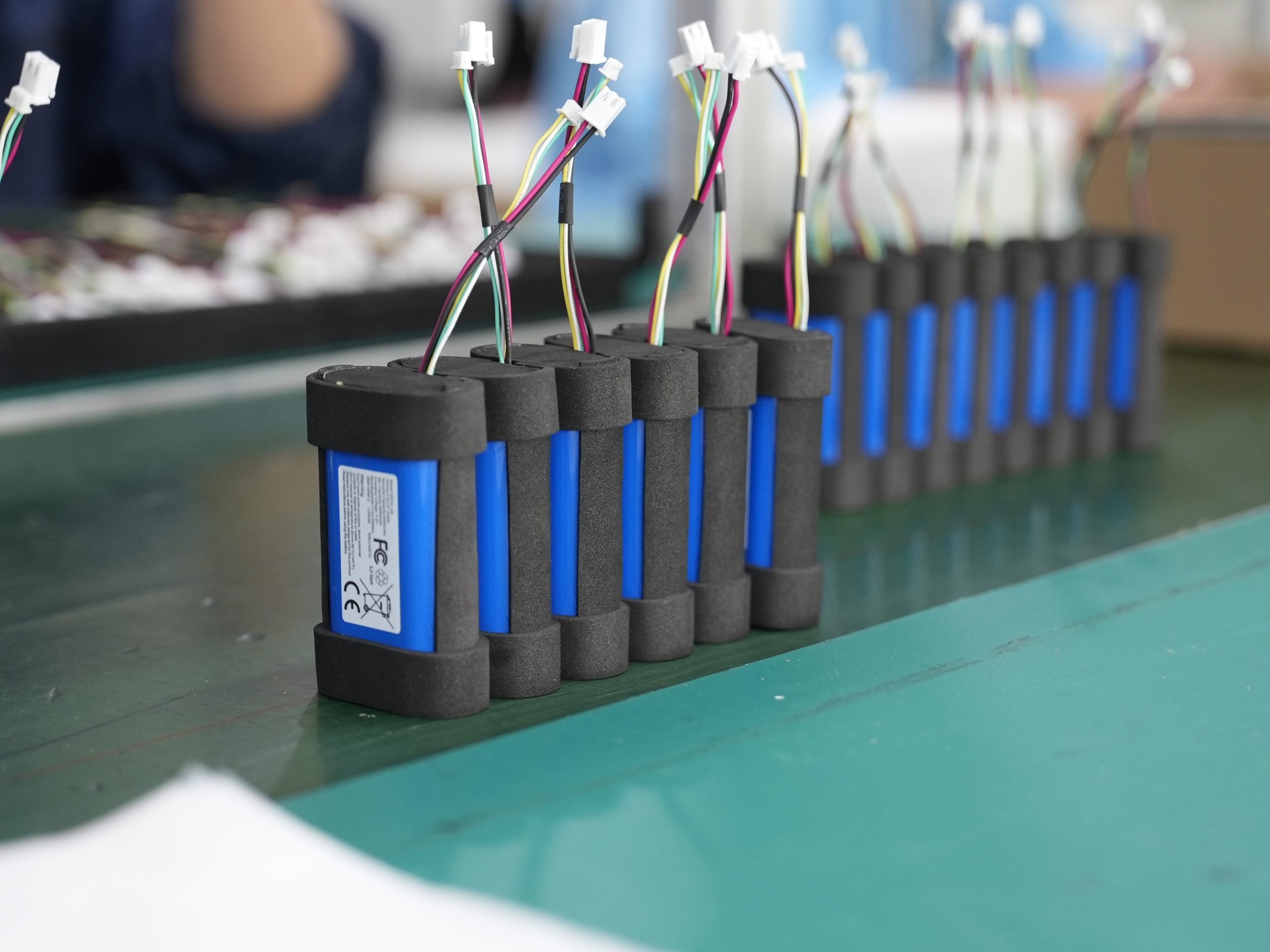

You want your robots to work longer and smarter. Modular batteries help you achieve this goal by allowing quick replacement and minimizing downtime. When you use modular batteries, you can swap out depleted packs in seconds, keeping your robot fleet running without long charging breaks. Modern modular battery systems use intelligent Battery Management Systems (BMS) to monitor safety and performance. These systems support high current and varying loads, which is essential for robots in high-duty cycles. You notice that high-quality modular batteries directly improve operational duration and load-carrying capacity, boosting productivity in industrial settings.

Tip: Modular batteries with advanced BMS technology help you maintain safe and efficient operation, even during demanding tasks.

Here is a comparison of efficiency improvements you can expect when you deploy modular batteries in your robotics operations:

Improvement Type | Description |

|---|---|

Enhanced Safety | The modular platform uses non-physical safety devices to maintain operator safety during operations. |

Reduced Downtime | Optimized solutions minimize downtime during the startup period. |

Increased Throughput | The palletizing system outperforms performance requirements, solving productivity challenges. |

Better Operator Training | Operators learn quickly due to the intuitive interface, improving operational efficiency. |

Maintenance Capabilities | Maintenance personnel gain better visibility into downtime events, aiding in quicker resolutions. |

You see these benefits across many sectors, including medical, security systems, infrastructure, and industrial automation. For example, LiFePO4 Lithium battery packs offer high cycle life and stable platform voltage, making them ideal for robots that require consistent uptime. NMC Lithium battery packs provide higher energy density, supporting longer operation between swaps.

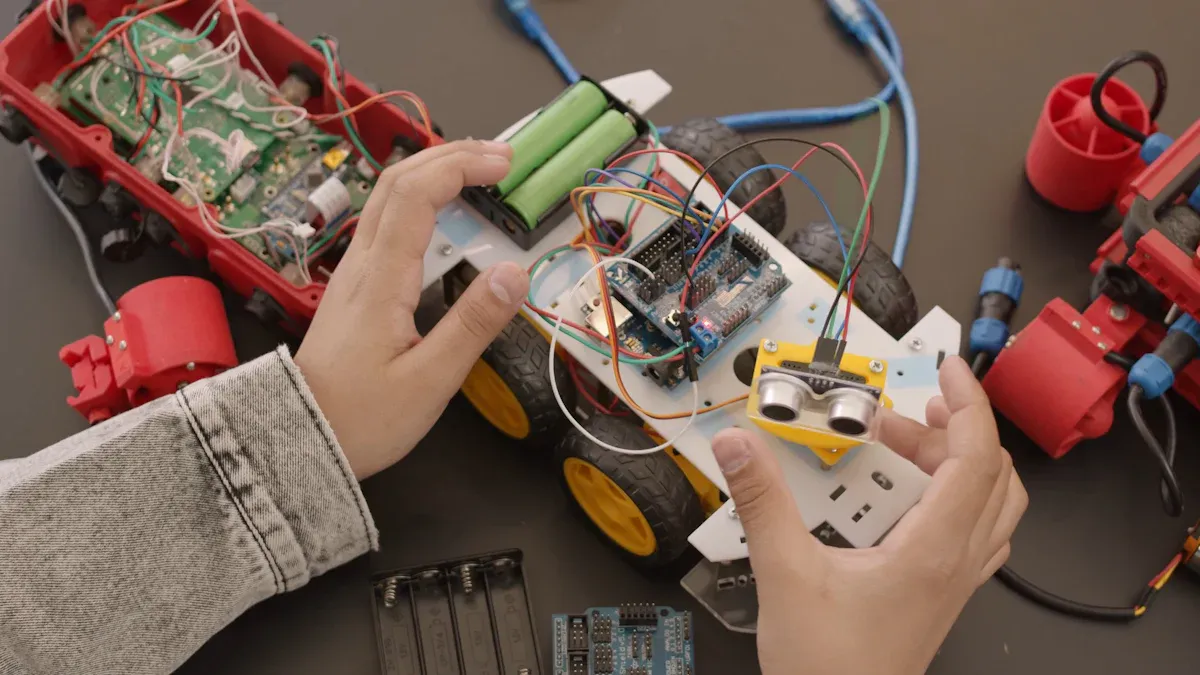

1.2 Flexibility & Deployment

You need robots that adapt to changing tasks and environments. Modular batteries give you the flexibility to customize power solutions for different applications. In warehouse fleets, you can design custom lithium battery packs to fit the internal geometry of each robot, optimizing performance without sacrificing functionality. This modularity allows easy replacement and expansion, which is crucial when you scale your robotic platforms.

A large battery manufacturer automated the transfer of metallic plates in a hazardous environment using a modular robotic platform. This solution improved safety and efficiency, showing how modular batteries address specific operational challenges. You can deploy modular batteries in robots, security systems, and transportation infrastructure, where tailored power solutions are essential.

Note: Modular batteries support various lithium chemistries, such as LiFePO4, NMC, LCO, and LMO Lithium batteries. Each chemistry offers unique advantages in energy density, cycle life, and platform voltage. You can select the best option for your robot based on your operational needs.

You also benefit from swappable batteries in scenarios where continuous operation is critical. Modular batteries make it easy to upgrade or replace packs as technology advances, keeping your robots future-ready.

Part 2: Swappable Batteries in Robotics

2.1 Autonomous Swapping

You want your robots to operate around the clock without human intervention. Autonomous battery swapping makes this possible. Robots like the Walker S2 use advanced battery technologies to detect low battery levels and navigate to swap stations automatically. This process keeps your operations running 24/7, which is essential in logistics, manufacturing, and infrastructure sectors.

Autonomous swapping systems rely on precise control and communication protocols. These protocols allow robots to manage battery swaps quickly and safely. The system uses a hybrid architecture that combines centralized planning with independent execution. This means your robot can adapt to changing conditions and maintain high battery performance even in dynamic environments.

To ensure safety and reliability, you must follow strict technical standards. The table below summarizes the key requirements for autonomous battery swapping in robotics platforms:

Standard | Description |

|---|---|

IEC 60695 | Assesses fire hazards in electrotechnical products. |

UL 94 | Measures flammability of plastic materials exposed to flame. |

IEC 62933 | Focuses on safety aspects in battery energy storage systems. |

UL 1973 | Outlines safety specs for insulation materials in battery modules. |

IEC 62619 | Ensures safety of lithium-ion cells in battery energy storage. |

UL 9540 | Comprehensive standard for electrical isolation and fire protection. |

You also need robust electrical isolation and modular mechanical design. These features allow easy integration of swappable batteries into different robotic systems. Advanced power management strategies ensure continuous operation during swaps, which is critical for maintaining battery performance and uptime.

When you compare battery recovery strategies, autonomous swapping stands out. The following table shows how battery swapping impacts throughput time and annual costs compared to other methods:

Battery Recovery Strategy | Performance Impact (Throughput Time) | Annual Cost Comparison |

|---|---|---|

Battery Swapping | Generally higher cost unless battery costs are low | |

Inductive Charging | Best performance in throughput | Cost sensitive to robot price |

Plug-in Charging | Lower performance compared to swapping | Generally lower cost |

You see that battery swapping improves throughput and supports continuous operation. This advantage is especially important in sectors where downtime leads to significant losses, such as industrial automation and medical robotics.

Tip: Use modular LiFePO4 Lithium battery packs or NMC Lithium battery packs for autonomous swapping systems. These chemistries offer high cycle life and stable platform voltage, which are essential for reliable robot battery technology.

2.2 Battery Swap Stations

You need efficient infrastructure to support autonomous battery swapping. Battery swap stations provide a dedicated location where robots can exchange depleted batteries for fully charged ones. These stations use advanced battery technologies to handle multiple battery types, including LiFePO4 Lithium battery, NMC Lithium battery, LCO Lithium battery, and LMO Lithium battery packs.

The global market for robot battery swap docks is growing rapidly. Analysts project a compound annual growth rate of 17.3% from 2025 to 2033. By the end of this period, the market size could reach approximately USD 2,370 million. This growth reflects the increasing adoption of autonomous robots in industrial, medical, and infrastructure applications.

Battery swap stations offer several key benefits:

Reduce downtime by enabling quick battery exchanges.

Support multiple robot models and lithium battery chemistries.

Improve battery performance by maintaining optimal charge cycles.

Enhance safety with built-in fire protection and electrical isolation.

You can deploy swap stations in warehouses, hospitals, and transportation hubs. These stations help you scale your robot fleet without increasing labor costs. They also ensure that your robots always operate with batteries at peak performance, which extends the lifespan of your lithium battery packs.

Note: When you select a battery swap station, check for compliance with safety standards such as UL 9540 and IEC 62933. These standards guarantee safe operation and protect your investment in advanced battery technologies.

By integrating battery swap stations into your operations, you unlock the full potential of robot battery technology. You gain continuous uptime, improved battery performance, and the flexibility to adapt to new tasks and environments.

Part 3: Innovations & Management

3.1 Smart Battery Systems

You rely on smart battery systems to keep your robot fleets running efficiently and safely. These systems use advanced battery management systems (BMS) to monitor every aspect of your lithium battery packs, including LiFePO4 Lithium battery and NMC Lithium battery chemistries. In industrial and medical robotics, smart BMS technology tracks the state of charge (SOC) and state of health (SOH) for each battery. This data helps you schedule maintenance before failures occur, which supports both uptime and sustainability.

Here is how smart battery systems contribute to predictive maintenance:

Feature | Contribution to Predictive Maintenance |

|---|---|

State of Charge (SOC) | Estimates battery life and schedules maintenance. |

State of Health (SOH) | Monitors battery condition to predict failures. |

Real-time diagnostics | Provides immediate alerts for potential issues. |

Communication protocols | Enables remote monitoring and analysis. |

Thermal management | Prevents overheating, improving battery safety. |

Cell balancing | Ensures uniform performance, extending lifespan. |

You benefit from remote monitoring, which alerts you before a failure disrupts your operations. This approach reduces emergency repairs and increases the lifespan of your robot fleet. In sectors like security systems and infrastructure, you see fewer interruptions and lower maintenance costs.

Tip: Use smart BMS with automatic logging and AI analysis to identify issues early and schedule proactive maintenance.

3.2 Predictive Energy Management

You want your robots to complete tasks efficiently while maximizing battery life. Predictive energy management tools, such as EPICC and AI-driven systems, help you achieve this goal. These tools collect data from delivery ecosystems, including GPS and traffic APIs, to optimize route planning for delivery robots in industrial and infrastructure settings.

Tool Name | Description | Key Features |

|---|---|---|

EPICC | Energy Prediction for Intelligent Command and Control | Route planning, dynamic mission updates, fuel consumption prediction, anomaly detection |

AI-driven predictive maintenance systems | Uses AI for maintenance predictions | Enhances operational readiness and energy efficiency |

You follow a process that starts with data collection and cleaning, then moves to feature engineering and pattern recognition. Predictive models simulate future conditions and forecast delays. The route optimization engine determines the best delivery sequence, and real-time reoptimization adjusts routes as conditions change. Performance feedback helps you retrain models for better accuracy.

You support sustainability by reducing unnecessary energy use and extending battery life. Predictive energy management also improves battery safety by preventing overuse and overheating. In medical and industrial robots, this means more reliable service and lower operational costs.

Part 4: Challenges & Solutions

4.1 Safety & Reliability

You face several safety and reliability challenges when you deploy modular and swappable batteries in your robot fleets. High current draws and harsh environments can accelerate battery aging, especially in industrial and medical robots. Inaccurate state of charge readings may cause unexpected shutdowns, affecting critical operations in security systems and infrastructure. Uneven cell balancing can reduce capacity and lead to premature failures. Overheating from high-power actuators poses risks to both performance and safety. You must also prevent fires caused by overcharging or short circuits.

Here is a table showing common reliability issues and how advanced battery management systems (BMS) address them:

Challenge | Problem Description | BMS Solution |

|---|---|---|

Battery Degradation Over Time | Aging from large current draws and environmental stress | Monitors state of health and suggests better charging techniques |

Inaccurate State of Charge | Unexpected shutdowns due to poor estimation | Combines voltage and coulomb counting for accuracy |

Uneven Cell Balancing | Premature failure and reduced capacity | Uses active or passive balancing to equalize voltage |

Overheating | Heat from actuators affects performance | Initiates power throttling or cooling with temperature sensors |

Safety Risks | Fires from overcharging or short circuits | Immediate disconnect and real-time problem identification |

Tip: Always select lithium battery packs with robust BMS features for your robot platforms to ensure safe and reliable operation.

4.2 Scalability & Integration

You want to scale your robot fleet and integrate new battery technologies without excessive costs. Modular systems often require higher initial investment because you need multiple components and operational expertise. However, these systems offer scalability and customization, which help you optimize capital efficiency over time. Integrated systems may seem simpler and cheaper at first, but they can lead to higher maintenance costs as your fleet grows.

Consider these points when comparing integration costs:

Modular systems reduce long-term expenses through scalability.

Centralized systems may have lower initial costs but higher maintenance over time.

Integrated systems offer operational simplicity but require higher upfront investment.

Modular systems allow competitive procurement and customization, but you need skilled operators.

You can deploy modular LiFePO4 Lithium battery, NMC Lithium battery, LCO Lithium battery, and LMO Lithium battery packs in various robots for medical, industrial, and infrastructure applications. This flexibility supports rapid expansion and adaptation to new tasks.

4.3 Sustainability

You must address the environmental impact of lithium battery packs throughout their lifecycle. Battery production and disposal can harm the environment, so you need sustainable recycling and reuse practices. Recycling batteries reduces the footprint from manufacturing and disposal. Robotics companies use automation and AI to improve battery recycling, sorting, and disassembly. For example, robotic systems can efficiently recover batteries from laptops, supporting circularity and economic viability. Design for Disassembly Toolchains streamline the process, making it easier to recover valuable materials.

Recycling and reuse of batteries lower environmental impact.

Sustainable disposal practices are essential for battery swapping technology.

Automation and AI improve recycling accuracy and safety.

Robotic disassembly systems increase recovery rates and support sustainability.

You can learn more about sustainable battery practices here.

For information on conflict minerals, visit this statement.

Note: Choose lithium battery packs designed for recycling and reuse to support your sustainability goals in medical, security, infrastructure, and industrial robots.

Part 5: Future Trends

5.1 Market Outlook

You see the market for modular and swappable batteries in robotics changing quickly. By 2035, you will notice an AI-driven, interoperable swapping network supporting autonomous mobile robots across industrial, medical, and infrastructure sectors. Urban delivery fleets and shared mobility services drive growth, especially as electric vehicles become more common. Battery conversion stations will use AI to improve deployment and solve cost challenges. Governments in emerging economies now provide financial support for pilot projects and subsidies for EV infrastructure, recognizing the value of autonomous battery swap methods.

Manufacturers invest in research and development to create efficient and eco-friendly LiFePO4 Lithium battery, NMC Lithium battery, LCO Lithium battery, and LMO Lithium battery packs. You see a strong demand for battery management systems that optimize battery efficiency and monitor performance. Fast-charging solutions help minimize downtime for autonomous mobile robots in continuous operation. Sustainability remains a key focus, with recyclable and energy-efficient batteries gaining attention. The rise of collaborative robots increases the need for long-lasting batteries and reliable robot power solutions.

Note: For more on sustainability and responsible sourcing, review our approach to sustainability and conflict minerals statement.

5.2 Industry Standards

You benefit from industry standards that support interoperability between different robotics platforms. Standardization lets you integrate new autonomous mobile robots from various manufacturers into your existing fleet. You manage robots from different vendors as a single fleet, which improves operational efficiency. Initiatives like VDA5050 and Mass Robotics 2.0 create cross-vendor integration protocols, making autonomous battery swap and robot power solutions easier to deploy.

Here is a table with expert recommendations for robotics integrators and OEMs considering modular battery adoption:

Recommendation | Description |

|---|---|

Demand for modular systems | Modular and swappable battery systems support longer operational cycles for autonomous mobile robots. |

Smart battery management | Integrate smart battery management systems to enhance monitoring, maintenance, and safety. |

Wireless charging | Adopt wireless charging to reduce downtime and enable autonomous mobile robots to recharge themselves. |

Quick battery swapping | Use modular systems for fast battery swaps, minimizing interruptions and supporting scalable fleets. |

Choose high-performance batteries for long cycle life and stable platform voltage.

Consider the costs of high-performance batteries, which may limit use for smaller businesses.

You should select lithium battery packs designed for recycling and reuse to meet sustainability goals in medical, security systems, infrastructure, and industrial robots.

You see modular and swappable batteries transforming robotics by enabling continuous operation and rapid energy replenishment. Swappable batteries allow quick replacements in about 84.2 seconds, much faster than traditional charging.

Battery Type | Charging Time | Impact on Productivity |

|---|---|---|

Lithium-ion | 1-2 hours | Reduces idle time |

LiFePO4 Lithium battery | 1 hour | Increases efficiency |

Industry growth remains strong:

The battery swapping robots market will reach USD 1,428 million by 2033.

Demand rises in medical, industrial, and infrastructure sectors.

Advances in lithium battery chemistry drive adoption.

Standardization supports flexibility, scalability, and safety. You should invest in modular LiFePO4 Lithium battery and NMC Lithium battery systems to future-proof your robotics operations.

FAQ

What benefits do modular and swappable batteries offer for your robot fleet in industrial applications?

You gain continuous operation and fast energy replenishment. Modular batteries let you swap packs quickly, reducing downtime. Swappable systems support your robot fleet in logistics, medical, and infrastructure applications. You improve productivity and adapt to changing tasks with LiFePO4 Lithium battery and NMC Lithium battery packs.

How do lithium battery chemistries impact robot fleet performance in different applications?

You select LiFePO4 Lithium battery for long cycle life (over 2,000 cycles) and stable platform voltage (3.2V). NMC Lithium battery offers higher energy density (200 Wh/kg) for extended operation. LCO Lithium battery and LMO Lithium battery suit specialized applications in security systems and consumer electronics.

What safety features should you look for when deploying lithium battery packs in your robot fleet?

You need advanced battery management systems for your robot fleet. These systems monitor temperature, voltage, and current. You prevent overheating and short circuits in medical and industrial applications. Choose lithium battery packs with real-time diagnostics and cell balancing for reliable operation.

How do battery swap stations improve scalability for your robot fleet in infrastructure applications?

You deploy battery swap stations to support large robot fleet operations. Swap stations enable quick exchanges of LiFePO4 Lithium battery and NMC Lithium battery packs. You reduce labor costs and maintain uptime in transportation and infrastructure applications. Swap stations help you scale your robot fleet efficiently.

What factors influence the selection of lithium battery packs for your robot fleet across different applications?

You consider cycle life, energy density, and platform voltage. LiFePO4 Lithium battery suits medical and industrial robots needing reliability. NMC Lithium battery fits robot fleet applications requiring longer runtime. LCO Lithium battery and LMO Lithium battery serve security systems and consumer electronics.

Tip: Always match lithium battery chemistry to your robot fleet’s specific application needs for optimal performance.