You optimize battery life for dynamic blood glucose monitoring devices by using smart power management, lithium polymer batteries, adaptive controls, and regular maintenance.

Smart power management reduces energy waste.

Lithium polymer batteries deliver reliable performance.

Adaptive controls adjust device activity.

Regular maintenance ensures consistent operation.

Key Takeaways

Implement smart power management techniques to reduce energy waste and extend battery life in glucose monitoring devices.

Choose lithium polymer batteries for their high energy density and safety features, ensuring reliable performance in medical applications.

Regularly monitor battery health and follow recommended charging practices to maximize lifespan and maintain device reliability.

Part1: Battery Life Optimization

1.1 Key Strategies

You can extend battery life in dynamic blood glucose monitoring devices by implementing several proven strategies. These approaches ensure continuous glucose monitoring remains reliable and efficient for medical professionals and patients.

Select low quiescent current devices to minimize energy drain during idle periods.

Integrate efficient battery management solutions that combine multiple power functions in compact designs.

Activate low-power modes, such as ‘ship mode’, to preserve battery life during storage and transport.

Use advanced battery technologies, including lithium polymer batteries, for stable performance and long cycle life.

Employ adaptive battery controls to adjust device activity based on real-time needs.

Tip: Regularly review your device’s battery management protocols. This practice helps you identify inefficiencies and optimize battery life for continuous glucose monitoring.

Strategy | Description |

|---|---|

Adaptive Power Management | Disconnects battery from voltage regulator when not needed, saving power. |

Selective Component Disabling | Disables components based on battery conditions to reduce energy waste. |

Self-Powered Sensor Architectures | Uses glucose sensor as a power source during sleep mode, extending battery life. |

Intelligent Data Scheduling | Employs FIFO buffers and low-power sleep states to minimize power usage. |

You should prioritize these strategies to achieve power consumption optimization and maintain device reliability. Medical wearables with robust battery management systems deliver consistent performance and reduce downtime, which is essential for patient safety and operational efficiency.

1.2 Smart Power Management

Smart power management plays a vital role in optimizing battery life for continuous glucose monitoring devices. You can leverage low-power chips and adaptive battery controls to maximize operational time without sacrificing accuracy.

Low-power chips, such as those in the Balletto family of microcontrollers, use autonomous intelligent power management systems. These systems manage subsystems and peripherals by turning off unused components and adjusting clock speeds according to workload. This approach results in very low sleep currents and minimal active power consumption.

You can also implement dynamic voltage and frequency scaling (DVFS) and low-power sleep modes. These techniques allow your device to operate efficiently on small batteries, which is crucial for continuous glucose monitoring in medical environments.

Note: Devices with advanced battery management and smart power management systems meet international safety standards like IEC 60601-1. These standards protect patients and ensure uninterrupted operation in clinical settings.

Technique | Description |

|---|---|

Safety Compliance | Ensures power supplies meet international safety standards to protect patients. |

Reliability | Power supplies are engineered for longevity and incorporate fail-safes for uninterrupted operation. |

Noise Minimization | Minimizes audible noise and electromagnetic interference for clear signal transmission. |

Precision Control | Delivers stable voltage and current for accurate glucose readings. |

Adaptability | Offers configurability and scalability for various medical applications. |

Space-Saving Designs | Compact power supplies maximize space efficiency in medical environments. |

Effective Thermal Management | Reduces heat generation to maintain stable operation and prevent equipment failure. |

You should select components and design systems that support these smart power management techniques. This approach enhances battery life, improves device reliability, and elevates the user experience for both healthcare providers and patients relying on continuous glucose monitoring.

Part2: Continuous Glucose Monitoring Devices

2.1 Lithium Polymer Batteries

You rely on lithium polymer batteries to power continuous glucose monitoring devices in medical environments. These batteries offer high energy density, which allows you to design compact devices that deliver stable power for extended periods. You benefit from multiple safety features, including built-in protection circuits, which minimize risks in critical medical applications. Advances in lithium polymer technology provide longer battery life and faster charging, reducing downtime and maintenance for healthcare teams.

You see lithium polymer batteries used in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Their suitability for wearables comes from their lightweight design and ability to support continuous glucose monitoring without frequent charging. Disposable lithium polymer batteries typically last between 6 months and a year, depending on usage. Rechargeable models can support several hundred to 2,000 tests per charge, ensuring reliable operation for patient monitoring.

Battery Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

Lithium Polymer (LiPo) | 3.7 V | 150-200 | 300-500 | Medical, Robotics, Security, Consumer |

Lithium Iron Phosphate | 3.2 V | 90-120 | 2000+ | Infrastructure, Industrial |

Lithium Nickel Manganese Cobalt Oxide | 3.7 V | 150-220 | 500-1000 | Medical, Consumer Electronics |

Tip: Choose lithium polymer batteries for continuous glucose monitoring devices when you need a balance of safety, energy density, and compact form factor.

2.2 Battery Gauging Systems

You improve device reliability by integrating advanced battery gauging systems into continuous glucose monitoring solutions. On-board fuel gauges use precision analog-to-digital conversion technology, providing high accuracy with error correction and temperature compensation. The Smart LiB fuel gauge measures the relative state of charge with 2.8% accuracy, even under unstable conditions. You can monitor battery voltage and temperature using the HG-CVR method, which enhances prediction of battery depletion.

You benefit from fuel gauges like the LC709203F, which operate at low current (15 µA) and save PCB space. These systems do not require a fully charged battery for calibration, allowing accurate calculations even at partial charge. Accurate battery gauging ensures uninterrupted continuous glucose monitoring, reduces user burden, and supports patient-centered device design.

Gauging Technology | Accuracy | Power Consumption | Calibration Needs | Key Features |

|---|---|---|---|---|

Smart LiB Fuel Gauge | 2.8% | Low | Not required | Error correction, temp compensation |

HG-CVR | High | Moderate | Required | Voltage/temp monitoring |

LC709203F | High | 15 µA | Not required | Compact, low power |

🩺 You enhance user adherence and satisfaction by minimizing device obtrusiveness and reducing maintenance tasks through reliable battery gauging.

Part3: Power Management in Medical Wearables

3.1 Active and Standby Modes

You manage battery life in medical wearables by optimizing transitions between active and standby modes. Devices consume much less power in standby, which extends operational time and reduces maintenance. For example, Excelon F-RAM uses only 0.35 mA in standby, compared to 21 mA in active mode. Async SRAM draws 20 mA in standby and 35 mA in active mode. The table below highlights these differences:

Memory Type | Active Current (mA) | Standby Current (mA) | Energy Consumption (mW/Sec) |

|---|---|---|---|

Async SRAM | 35 | 20 | 90.75 |

Excelon F-RAM | 21 | 0.35 | 35.23 |

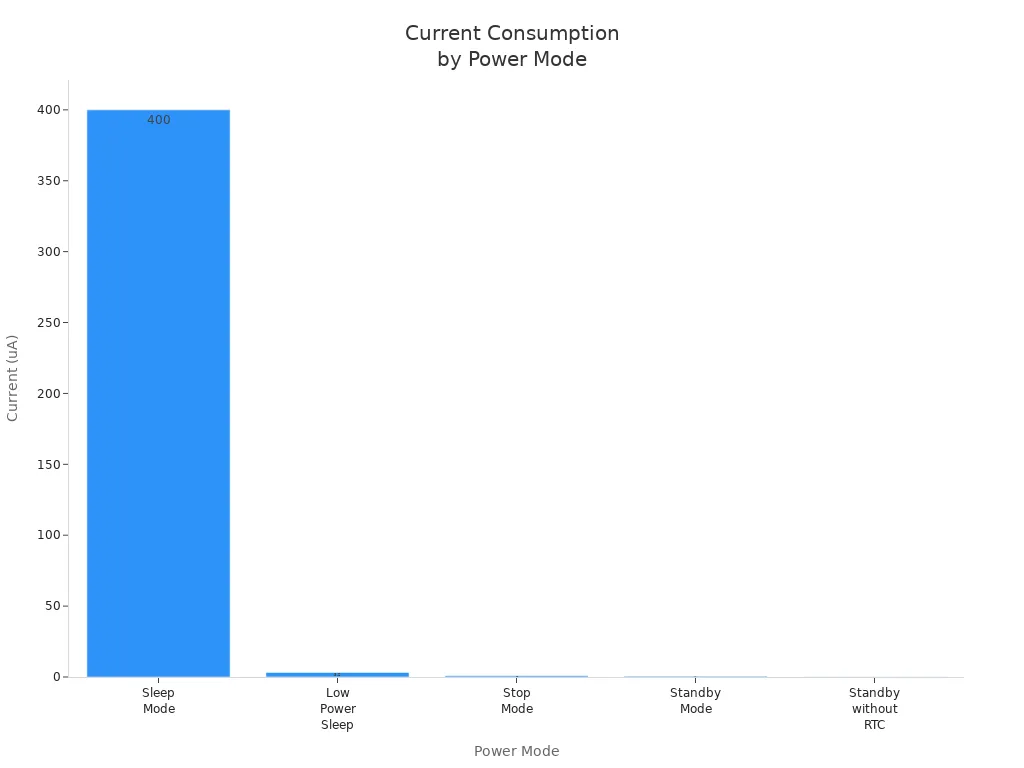

You can further reduce power consumption by using advanced sleep and stop modes. Manufacturers design adaptive power management systems that switch between modes based on device activity. The chart below shows current consumption for different power modes:

Tip: You should select memory and processor components that support ultra-low standby currents. This strategy maximizes battery life and ensures reliable performance in medical environments.

3.2 Load Switching

You optimize power management in medical wearables by implementing effective load switching technologies. DC/DC converters deliver high efficiency and maintain compliance with medical noise limits. Battery management units provide accurate charge estimation and control, supporting rechargeable lithium polymer battery packs in continuous glucose monitoring devices. Modular DC/DC converters offer compact solutions and simplify compliance testing for medical standards.

Technology Type | Description |

|---|---|

DC/DC Converters | High-efficiency switching power supplies that manage power for medical devices, ensuring compliance with noise limits. |

Battery Management Units | Integrated solutions that provide accurate charge estimation and power management for rechargeable batteries. |

Modular DC/DC Converters | Compact solutions with pre-certification for medical standards, simplifying compliance testing. |

You should integrate these technologies to achieve robust power management and extend battery life in medical wearables. This approach supports reliable operation in medical, robotics, and consumer electronics sectors.

Part4: Advanced Battery Management

4.1 Adaptive Controls

You strengthen battery management in wearable medical devices by using adaptive controls. These systems monitor device activity and adjust power usage in real time. You see adaptive observer methods estimate system variables and insulin delivery needs. Lyapunov direct methods help maintain system stability. Simulation results confirm that adaptive controls track blood glucose levels effectively.

Method | Description |

|---|---|

Adaptive Observer | Estimates state variables and system parameters to adjust insulin delivery. |

Lyapunov Direct Method | Establishes overall stability of the adaptive control system. |

Simulation Results | Verifies effectiveness in tracking blood glucose levels. |

You benefit from adaptive model predictive control (MPC), which uses dynamic glucose setpoints and insulin dosing. These controls handle disturbances from meals and physical activity. Effectiveness is tested with in silico subjects using glucose-insulin-physiological simulators.

Method | Description |

|---|---|

Adaptive MPC | Incorporates dynamic trajectories for glucose setpoint and insulin dosing. |

Robustness | Handles disturbances from unannounced meals and physical activities. |

Effectiveness | Tested with in silico subjects in a glucose-insulin-physiological simulator. |

You improve health outcomes with adaptive controls. Continuous glucose monitors reduce HbA1c by over 1% in diabetes patients. Patient engagement rises by 15% when you pair medical wearables with coaching. Remote monitoring lowers hospital admissions by 30% for heart failure patients.

4.2 Energy Harvesting

You extend battery life in wearable medical devices by integrating energy harvesting technologies. These solutions capture ambient energy and convert it into electrical power, supporting battery management and reducing reliance on frequent charging. You find several energy harvesting methods in blood glucose monitoring devices:

Piezoelectric

Solar

Thermal

Triboelectric

Electromagnetic

You translate health goals into daily actions with real-time feedback from medical wearables. Patients report better medication adherence and lifestyle changes. Remote patient monitoring through wearables leads to lower healthcare costs and less strain on medical infrastructure.

Part5: Maintenance for Wearable Medical Devices

5.1 Charging Practices

You maximize battery lifespan in wearable medical devices by following industry-recommended charging practices. Lithium polymer battery packs power most continuous glucose monitoring systems in medical, robotics, and security sectors. You protect battery health by managing temperature. Avoid exposing devices to extreme heat or cold, as both can shorten battery life. You maintain optimal charge levels by keeping batteries between 20% and 80%. Deep discharges and overcharging accelerate degradation. You use manufacturer-approved charging accessories to control charging speed and minimize heat buildup.

Avoid extreme temperatures during charging and storage.

Maintain battery charge between 20% and 80%.

Tip: You extend battery cycle life and reduce maintenance costs by following these charging guidelines. The International Diabetes Federation and the American Diabetes Association recommend regular device checks and proper charging routines for medical wearables.

5.2 Battery Health Monitoring

You ensure reliable operation of wearable medical devices by monitoring battery health regularly. Schedule battery checks at set intervals to detect early signs of wear or capacity loss. Use built-in battery management systems to track charge cycles and voltage levels. You replace lithium polymer battery packs when capacity drops below 80% of the original rating. Document maintenance activities to comply with regulatory standards and support device traceability.

Maintenance Task | Frequency | Purpose |

|---|---|---|

Battery Capacity Check | Monthly | Identify degradation early |

Voltage Level Monitoring | Weekly | Prevent unexpected shutdowns |

Cycle Count Review | Plan timely battery replacement |

🩺 You improve patient safety and device reliability by adopting proactive battery health monitoring. Health organizations recommend routine maintenance to ensure uninterrupted operation in clinical and industrial environments.

You achieve reliable device performance by adopting advanced battery management solutions, such as IBMS, which offer real-time monitoring, predictive data processing, and enhanced user engagement.

You improve device reliability in medical, robotics, and security sectors.

You maximize operational uptime with regular maintenance and smart controls.

Adopting these best practices ensures your lithium battery packs deliver consistent results in demanding environments.

FAQ

What is the recommended cycle life for lithium polymer battery packs in medical wearables?

You should expect lithium polymer battery packs to deliver 300–500 cycles. This range ensures reliable performance for continuous glucose monitoring in medical, device applications.

How do self-powered sensor architectures impact battery life in glucose monitoring devices?

You benefit from self-powered sensor architectures because they allow glucose sensors to generate power during sleep mode. This approach extends battery life and reduces maintenance requirements.

Why is accurate battery gauging important for continuous glucose monitoring devices?

You rely on precise battery gauging to prevent unexpected shutdowns. Accurate monitoring supports uninterrupted operation in medical, industrial, and robotics sectors.