Portable air conditioner battery technology has reached a critical performance threshold where practical cooling applications become feasible. Current units such as RIGID’s portable air conditioner operate on 200W of power input while delivering 500W to 700W (2,387Btu) of cooling capacity. This efficiency ratio represents a substantial engineering achievement for manufacturers developing reliable cooling solutions independent of grid power.

Battery powered portable air conditioners now demonstrate quantifiable performance metrics that address real-world cooling requirements. The EcoFlow Wave 2 delivers 5,100 BTU cooling capacity with an additional 6,100 BTU heating function. The EcoFlow Wave 3 provides 6,100 BTUs of cooling power, representing a 1,000 BTU increase over previous models, while generating 330 cubic meters per hour of airflow. High-performance units can reduce temperature in a 64-square-foot space from 86 degrees to 75 degrees within eight minutes.

Manufacturers face specific technical challenges when designing for cooling applications. The relationship between power consumption, cooling capacity, and operational runtime requires careful optimization to create viable battery power AC units. This guide addresses the technical requirements manufacturers need to understand for portable air conditioner batteries in 2025, covering power specifications, battery configurations from 12V to 48V systems, and measured performance data for custom cooling solutions.custom battery packs

How Battery-Powered Portable Air Conditioners Work

Battery powered portable air conditioners operate through a miniaturized vapor compression refrigeration system designed for mobile applications. These units employ a standard refrigeration cycle where refrigerant absorbs heat through evaporation and releases it through condensation.

Air Cooling Mechanism and Refrigerant Cycle

operated air conditioners execute the refrigeration cycle through four distinct stages. The compressor pressurizes low-temperature, low-pressure refrigerant (commonly R134a or environmentally compliant alternatives such as R290) into high-temperature, high-pressure gas. This compressed gas transfers heat to the surrounding environment through the condenser, cooling and condensing into high-pressure liquid. The liquid refrigerant passes through an expansion valve that reduces both pressure and temperature rapidly. The low-pressure refrigerant then absorbs heat in the evaporator section, vaporizing back to gas to complete the cycle.Portable battery

The refrigerant cooling method provides superior heat transfer efficiency compared to alternative cooling approaches, making it particularly suitable for high-power battery modules. Manufacturers developing custom cooling solutions must understand this cycle because it directly determines power requirements and system efficiency.

Role of Battery in Powering the Compressor and Fan

The compressor represents the primary power consumer in any battery powered air conditioner. Modern portable units have achieved significant miniaturization advances in compressor technology. Current models utilize micro-compressors while delivering 5,280 BTU of cooling power, compared to conventional 8-12 kg compressors found in larger units.weighing as little as 1.8 kg

Battery specifications directly impact system performance for manufacturers designing custom solutions:

| Battery Type | Voltage Range | Typical Applications | Power Consumption |

| Standard | 12V | Small cooling units, camping | 200-350W |

| Medium | 24V | RV, larger portable units | 350-500W |

| High-performance | 48V | Premium portable ACs | 350-500W |

Operating mode significantly affects power consumption. High-performance models draw 350-500W during maximum cooling operation, while sleep modes require only 150-200W. This variation enables manufacturers to optimize battery capacity for specific application requirements.

Differences from Traditional Plug-In AC Units

Battery power AC units incorporate design modifications necessary for energy-constrained operation. Traditional units depend on continuous wall power, while portable battery-operated models must balance cooling performance with energy efficiency constraints.

Compressor technology represents the primary difference. Battery-powered units employ micro-compressors optimized for energy efficiency rather than standard compressors used in conventional systems. These units integrate custom-fitted evaporators, condensers, and ductwork into compact assemblies while maintaining cooling performance.

Battery-powered units typically provide 2,380 BTU to 6,100 BTU cooling capacity, compared to traditional home units that often exceed 10,000 BTU. Battery units focus on applications rather than whole-room temperature control, making them effective for targeted use in spaces of 100-150 square feet.spot cooling

The power-to-cooling ratio is the critical performance metric for manufacturers developing custom battery solutions. Leading models achieve cooling capacity of 500-700W (2,387 BTU) while consuming less than 200W of power input. This efficiency enables , with high-capacity batteries providing 2-7 hours of operation depending on cooling mode.extended runtime on battery power

Types of Batteries Used in Portable AC Units

Battery selection determines the fundamental performance characteristics of portable cooling systems. Manufacturers developing custom battery packs must evaluate chemistry options based on specific application requirements, with battery technology directly influencing runtime, cooling performance, and operational lifespan.

Lithium-ion vs. Lithium Iron Phosphate (LiFePO4)

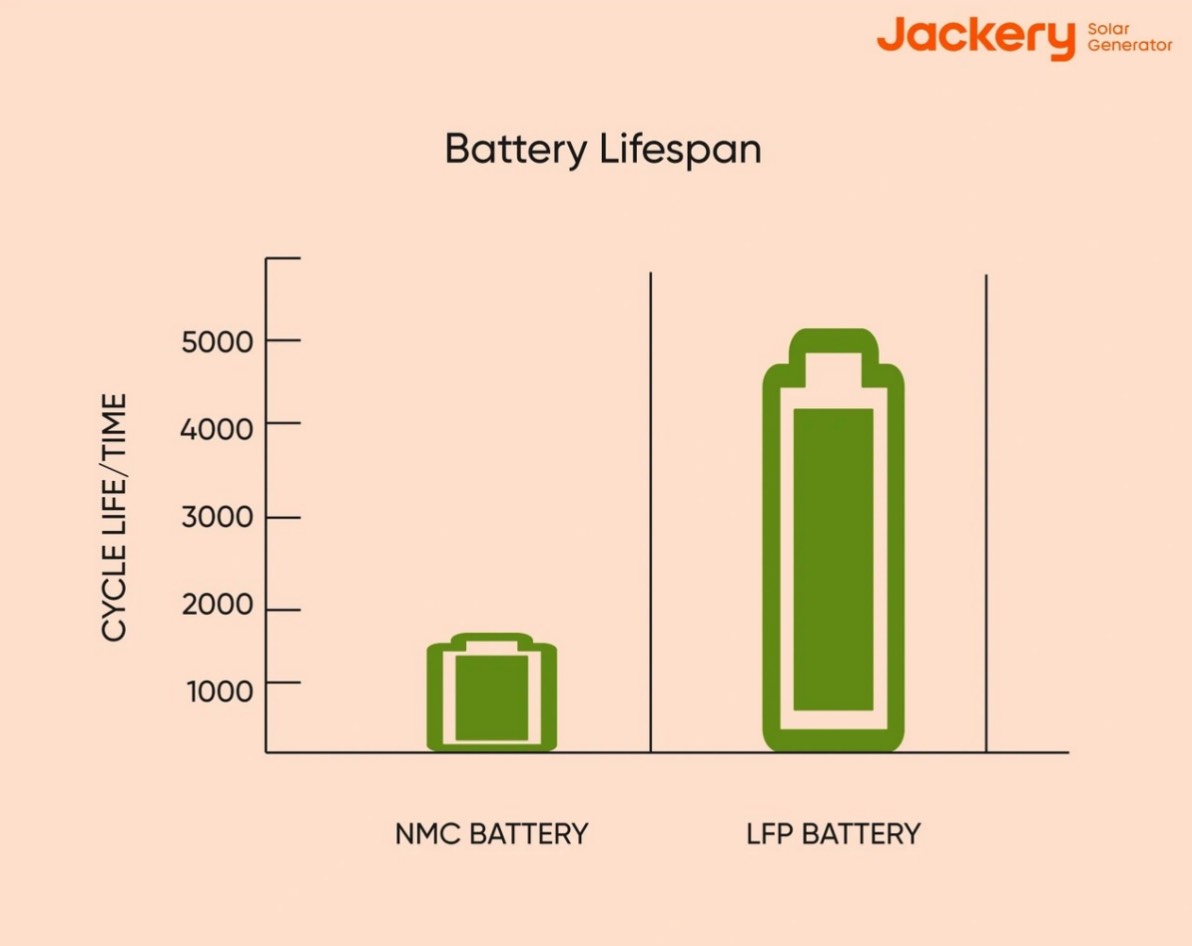

Portable air conditioner battery design centers on two primary electrochemical systems, each optimized for different performance priorities. Traditional lithium-ion batteries deliver compared to LiFePO4 batteries (90-120 Wh/kg), making them suitable for applications with critical weight and space limitations.higher energy density (150-200 Wh/kg)

LiFePO4 batteries have gained acceptance in portable battery operated air conditioners due to specific operational advantages:

| Feature | LiFePO4 | Lithium-ion |

| Safety | Superior thermal stability | Higher risk of thermal runaway |

| Cycle Life | 2,000-6,000 cycles | 500-1,000 cycles |

| Operating Temperature | -4°F to 140°F (-20°C to 60°C) | 32°F to 113°F (0°C to 45°C) |

| Nominal Voltage | 3.2V per cell | 3.6-3.7V per cell |

| Depth of Discharge | Up to 95% | Typically lower |

LiFePO4 batteries require additional space to achieve equivalent energy storage but provide enhanced safety characteristics essential for battery power AC units, particularly those operating in enclosed environments or extreme conditions.

Voltage System Architecture: 12V, 24V, 48V

Battery powered portable air conditioners utilize three standard voltage configurations, each suited to specific power requirements and applications.

12V systems support smaller cooling units and camping applications, though higher amperage requirements increase current draw for equivalent power delivery.

24V configurations balance power output with manageable current requirements, making them effective for RV installations and medium-capacity portable units.

48V systems enable lower current draw while maintaining equivalent power output, resulting in improved efficiency and reduced thermal generation, making them increasingly common in premium portable air conditioner battery designs.

Higher voltage architectures reduce parallel cell connections, simplifying battery management system (BMS) requirements and enhancing overall system reliability for custom solutions.

Battery Capacity and Runtime Analysis

Runtime calculations require precise matching of battery capacity to power consumption patterns. A 100Ah lithium battery powers a 15,000 BTU AC unit for approximately 30-45 minutes, while more efficient units achieve substantially longer operation periods.

depend on three primary factors:Battery capacity requirements

- Cooling capacity (BTU rating)

- Operating mode (full power vs. economy)

- Ambient temperature conditions

High-performance portable units with 48V battery systems achieve the following runtime specifications:

- Maximum cooling (350-500W): 2-3 hours on a single 1022Wh battery

- Economy mode (200-350W): 3-5 hours

- Sleep mode (150-200W): 5-7 hours

Extended runtime can be achieved through parallel battery configurations or modular battery swapping capability. Connecting two 1022Wh batteries doubles maximum cooling mode runtime to 4-6 hours.

Key Performance Metrics to Evaluate

Performance evaluation for portable air conditioner batteries requires assessment across multiple technical parameters that directly impact commercial viability. The selection criteria for manufacturers must account for efficiency ratios, operational constraints, and market positioning factors.

Cooling Capacity (BTU) vs. Power Draw (W)

The efficiency ratio between cooling output and electrical consumption represents the primary performance indicator for battery powered air conditioners. Established market benchmarks demonstrate the following performance levels:

- RIGID’s portable units deliver 500W-700W (2,387 BTU) while consuming less than 200Wcooling capacity

- Zero Breeze Mark 2 provides 2,300 BTU cooling with 240W rated input

- EcoFlow Wave 3 offers 6,100 BTU (1,800W) cooling capacity with 690W AC power draw

Manufacturers should establish a target cooling efficiency ratio of 2.6-3.5 (output watts/input watts) for competitive battery performance. This ratio determines both operational runtime and market differentiation potential.

Custom battery pack specifications must align with predictable power consumption patterns. Portable units with 5,000-8,000 BTU capacity typically require 500-1,000W, while 10,000-12,000 BTU units demand 1,000-1,500W. Battery capacity matching these power requirements ensures optimal system performance.

Runtime on Different Battery Sizes

depend on both battery capacity and unit efficiency characteristics. Quality battery powered portable air conditioners provide the following operational periods:Runtime calculations

| Battery Capacity | Max Cooling | Economy Mode | Sleep Mode |

| 840Wh (24V 35Ah) | 3-4 hours | 4-5 hours | 5+ hours |

| 1,022Wh (typical) | 2-8 hours | 3-5 hours | 6+ hours |

Ambient temperature conditions significantly affect actual runtime performance, with elevated temperatures reducing overall efficiency. Advanced power management systems automatically adjust cooling intensity based on temperature sensors, extending battery life through intelligent load management.

Noise Levels and Thermal Efficiency

Acoustic performance requires careful consideration given the proximity of battery powered air conditioners to end users. Current industry benchmarks establish the following noise parameters:

- 40-50dB in sleep/economy modes

- 50-52dB at maximum cooling

- Under 44dB for premium units (comparable to quiet conversation)

directly impacts both cooling performance and battery longevity. Direct-cooling battery thermal management systems provide superior temperature control compared to conventional cooling methods, maintaining stable operation even under high heat generation conditions.Thermal efficiency

Higher thermal efficiency creates operational advantages by reducing heat rejection while maintaining cooling effectiveness. The Battery Management System (BMS) optimizes the relationship between cooling performance and power consumption through continuous monitoring and adjustment protocols.

Real-world use cases and limitations

The practical deployment of battery powered portable air conditioners extends beyond laboratory specifications, providing cooling solutions where conventional AC units cannot function. For manufacturers developing , understanding these operational environments enables design optimization for specific application requirements.custom battery packs

Camping and RV cooling

Battery power AC units have established utility for outdoor applications and mobile living environments. The Zero Breeze Mark 2 achieves temperature reduction of 25-30 degrees in confined spaces within 10 minutes, making it suitable for tent and recreational vehicle applications. EcoFlow Wave models provide on single battery charges, which addresses overnight comfort requirements in remote locations.5-7 hours of cooling

RV applications typically require units with 2,300-5,100 BTU capacity and compatibility with both 12V and 24V electrical systems. Units designed for camping applications must meet dimensional constraints—optimally under 22″ x 11″ x 15″—and weight limitations under 40 pounds for practical transport between sites.

Emergency backup during power outages

Portable battery operated air conditioners serve as essential cooling solutions during electrical grid failures, particularly for vulnerable populations and critical equipment protection. These units enable rapid deployment to reduce heat stress. Runtime expectations vary based on battery configuration—premium units achieve 8-12 hours of continuous operation when paired with larger capacity power stations.

Custom battery pack designs must accommodate immediate deployment scenarios, requiring quick-charge capabilities and compatibility with multiple power sources including solar panels, car alternators, and standard wall outlets.

Challenges in humid or high-temperature environments

High humidity conditions present significant operational challenges for battery powered air conditioner performance. Continuous operation becomes impossible in environments exceeding 90% relative humidity. This limitation occurs because condensate accumulation exceeds evaporation rates from condenser surfaces.

For manufacturers creating custom battery solutions, addressing this constraint requires specific approaches to condenser design and water management. Electronic expansion valves have demonstrated effectiveness in extending operational time under high-humidity conditions. Manufacturers must implement robust , as battery performance degrades in extreme temperatures, potentially creating operational feedback loops where cooling capacity diminishes when most needed.thermal protection systems

What Manufacturers Should Consider for Custom Battery Packs

Image Source: ResearchGate

Custom battery pack development for portable air conditioner applications requires systematic evaluation of critical design parameters. Manufacturers must address performance requirements, safety standards, and operational constraints to create viable power solutions for cooling systems.

Battery Management System (BMS) Integration

Battery management systems function as the primary control interface for portable air conditioner batteries, monitoring operational parameters to maintain safety thresholds. The BMS tracks individual cell voltages continuously, providing cell balancing functionality essential for maximizing usable capacity across the battery lifecycle. Protection circuits must include overcurrent protection, under-voltage cutoff mechanisms, and short circuit safeguards that activate within milliseconds of detecting hazardous conditions.

BMS design for cooling applications requires specific considerations beyond standard battery applications. Temperature monitoring becomes critical as cooling loads generate significant thermal stress on battery cells during high-demand operations.

Thermal Protection and Safety Features

Thermal management represents a fundamental requirement for custom battery packs in portable cooling applications. operate within defined temperature parameters of -20°C to 60°C, with charging optimized between 0°C and 45°C. Passive cooling methods include heat sinks and heat pipes, while active cooling utilizes forced air or liquid cooling systems based on the specific thermal demands of portable battery operated air conditioners.Lithium-ion cells

The selection between passive and active thermal management depends on power density, operational environment, and cost considerations for the specific cooling application.

Modular Design for Scalability

Modular battery configurations provide advantages for portable air conditioner manufacturers, including thermal runaway containment and enhanced serviceability. This approach allows manufacturers to scale battery capacity by adjusting module quantities to match energy requirements for different portable AC models. Modular designs also support battery swapping capabilities, extending operational utility for field applications.

Charging Options: Solar, Alternator, Wall AC

Multiple charging capabilities increase the practical utility of battery power AC units. Industry specifications recommend including diverse charging methods:

| Charging Method | Power Rating | Full Charge Time |

| AC Wall Power | 700W | 2-3 hours |

| Solar Panels | 400W | 3+ hours |

| Car Alternator | 400-800W | 1-2 hours |

| Car Power Outlet | 100W | 10 hours |

Compliance with Transport and Safety Regulations

Lithium battery transportation requires , which includes altitude simulation, thermal testing, vibration, shock, and additional safety protocols. This certification applies to all lithium battery shipments regardless of size. Any design modification to a certified battery requires complete retesting. Non-compliance with applicable regulations can result in financial penalties or criminal prosecution.UN38.3 certification testing

Manufacturers must incorporate regulatory compliance into the initial design phase rather than treating it as a final step in the development process.

Conclusion

Portable air conditioner battery technology has achieved measurable performance thresholds that establish viability for practical cooling applications. Battery-powered cooling solutions now deliver 5,100-6,100 BTU cooling capacity while maintaining power consumption within acceptable parameters for extended runtime operation.

The selection between lithium-ion and determines fundamental performance characteristics including thermal stability, cycle life, and energy density. LiFePO4 batteries provide superior thermal stability and extended cycle life, while lithium-ion batteries offer higher energy density for weight-critical applications. Application requirements should determine this chemistry selection based on specific operational parameters.LiFePO4 batteries

Battery management system implementation requires careful attention to safety protocols and performance optimization. Effective BMS designs provide real-time monitoring, cell balancing, and protection circuits that maintain operational safety across variable environmental conditions. Thermal protection features enable reliable operation in challenging temperature environments where standard cooling systems fail.

Measured performance data confirms that current battery-powered air conditioners meet operational requirements for camping, recreational vehicle, and emergency backup applications. Humidity limitations above 90% relative humidity present design challenges that require specialized condenser designs and water management systems. Modular battery configurations provide scalability options that address varying capacity requirements across different applications.

offers significant advantages for manufacturers targeting specific cooling applications. Optimized power management, thermal protection systems, and application-specific capacity configurations enable products that meet precise performance requirements rather than generic specifications.Custom battery pack development

The technical evidence supports a definitive conclusion: portable air conditioner batteries deliver effective cooling performance in 2025. Manufacturers who develop matched to specific cooling requirements will establish competitive advantages in applications where traditional AC systems cannot operate effectively. Large Power as leading , established rich experience in portable device battery design. Please contact us if you have any battery inquiry on portable air conditioners.custom battery solutionscustom battery pack supplier and maker

Key Takeaways

Modern battery-powered portable air conditioners have achieved remarkable efficiency breakthroughs, making them genuinely viable cooling solutions for manufacturers and consumers alike.

- Impressive efficiency ratios: Leading units deliver 500-700W cooling capacity while consuming only 200W power input, achieving 2.6-3.5 efficiency ratios.

- LiFePO4 batteries outperform lithium-ion: Superior thermal stability, 2,000-6,000 cycle life, and safer operation make LiFePO4 ideal for portable AC applications.

- Real-world performance delivers: Units can cool 64 sq ft spaces from 86°F to 75°F in 8 minutes with 2-8 hours runtime depending on battery size.

- Custom BMS integration is critical: Proper battery management systems with thermal protection and safety features ensure optimal performance and regulatory compliance.

- Multiple charging options maximize utility: Wall AC, solar, and car alternator charging capabilities make these units practical for camping, RV, and emergency backup scenarios.

The technology has matured significantly, with manufacturers now able to create custom battery solutions that balance cooling performance, runtime, and safety for specific applications ranging from outdoor recreation to emergency preparedness.

FAQs

Q1. How long can a battery-powered portable air conditioner run on a single charge? Runtime varies depending on the unit and battery capacity, but most quality portable ACs can operate for 2-8 hours on maximum cooling mode and up to 5-7 hours on economy or sleep modes with a typical 1,022Wh battery.

Q2. Are battery-powered air conditioners effective for camping and RV use? Yes, modern battery-powered ACs are highly effective for camping and RV use. Some models can cool small spaces by 25-30 degrees in under 10 minutes, making them ideal for tents and recreational vehicles.

Q3. What’s the difference between lithium-ion and LiFePO4 batteries for portable air conditioners? LiFePO4 batteries offer superior thermal stability, longer cycle life (2,000-6,000 cycles), and safer operation compared to lithium-ion. However, lithium-ion batteries have higher energy density, making them more suitable when weight and size are critical factors.

Q4. Can battery-powered air conditioners work in high humidity environments? Battery-powered ACs face challenges in extremely humid environments (90% or higher relative humidity), as condensate accumulates faster than it can evaporate. Some units use electronic expansion valves to extend operational time in high-humidity conditions.

Q5. What charging options are available for portable battery-operated air conditioners? Most portable battery-operated air conditioners offer multiple charging options, including AC wall power (fastest, typically 2-3 hours for a full charge), solar panels, car alternators, and car power outlets. This versatility enhances their utility for various applications.