Reliable batteries keep your Power Inspection Device running in harsh winter conditions. Cold temperatures slow chemical reactions in lithium-ion cells like LiFePO4, NMC, LCO, LMO, and LTO, causing reduced power delivery and efficiency. You may notice batteries losing significant capacity below freezing, leading to poor performance in industrial settings, robotics, and security systems. When the environment gets colder, batteries struggle even more, and extreme cold can cause irreversible damage.

Key Takeaways

Cold temperatures slow down chemical reactions in lithium-ion batteries, reducing their efficiency and capacity. Monitor battery performance closely in low temperatures.

Avoid charging lithium-ion batteries below freezing to prevent lithium plating, which can cause permanent damage. Always pre-warm batteries before charging.

Select the right battery chemistry for cold weather applications. LiFePO4 and LTO chemistries offer better performance and longer cycle life in low temperatures.

Implement effective battery management practices, such as using insulation and pre-warming techniques, to extend battery life and maintain efficiency.

Innovations like self-heating batteries and advanced battery management systems enhance performance in cold environments, ensuring reliable operation for critical devices.

Part1: Low Temperature Batteries: Performance Challenges

1.1 Chemical Reaction Slowdown

You face a major challenge when using lithium-ion batteries in cold environments. The rate of chemical reactions inside the cell slows down as the temperature drops. This slowdown affects both the anode and cathode, making it harder for ions to move and reducing battery performance. The Arrhenius equation shows that reaction rates increase with temperature, so colder conditions mean less kinetic energy and slower reactions. You see this effect in many sectors, including robotics, medical devices, and industrial infrastructure.

Note: Accurate temperature measurement helps you manage lithium-ion batteries more effectively in low temperature batteries.

Here is a summary of the main factors that contribute to chemical reaction slowdown:

Ionic conductivity drops sharply at low temperatures, which limits how well the battery can deliver power.

Charge transfer impedance rises, making it harder for lithium ions to move between electrodes.

Ion transport kinetics slow down, reducing overall efficiency.

Factor | Description |

|---|---|

Ionic Conductivity | Decreases significantly at low temperatures, leading to reduced performance. |

Charge Transfer Impedance | Increases with lower temperatures, affecting Li+ desolvation and diffusion. |

Ion Transport Kinetics | Slows down considerably, impacting overall battery efficiency. |

1.2 Increased Internal Resistance

You notice that low temperature batteries show much higher internal resistance. When lithium-ion batteries operate below freezing, the solid electrolyte interphase (SEI) becomes more resistive. This change makes it harder for the battery to charge and discharge efficiently. Research shows that internal resistance can increase over seven times when the temperature drops from 50˚C to −25˚C. This dramatic rise leads to slower charging times and reduced power output.

Low temperatures increase internal resistance in all battery types.

For lithium-ion batteries, this means you get less usable energy and slower response.

In lead-acid batteries, internal resistance can rise by about 50% from +30°C to -18°C.

⚡ Tip: If you use lithium-ion batteries in industrial or security systems, always monitor internal resistance to avoid unexpected downtime.

1.3 Capacity Reduction Below Freezing

You experience significant capacity loss in lithium-ion batteries when temperatures fall below 10°C. The ionic conductivity of the electrolyte drops, which means the battery cannot hold or deliver as much energy. At extremely low temperatures, lithium plating and dendrite formation can occur during charging, causing permanent damage and capacity loss. Standard lithium-ion batteries can operate down to -40°C, but you see major performance drops below freezing.

Reduced capacity and energy density limit how long your devices can run.

Irreversible lithium plating can cause short-circuits and shorten battery life.

Performance decreases as temperature drops, especially in industrial and medical applications.

Here is a comparison of common lithium-ion battery chemistries used in low temperature batteries:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Applications |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000+ | Industrial, robotics, infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Medical, consumer electronics |

LCO | 3.6 | 150-200 | 500-1000 | Security systems, consumer devices |

LMO | 3.7 | 100-150 | 700-1500 | Industrial, grid storage |

LTO | 2.4 | 70-80 | 7000+ | Medical, robotics, infrastructure |

You should select the right lithium-ion chemistry for your battery packs based on your operating environment and application needs. Low temperature batteries with LTO chemistry offer excellent cycle life and cold weather performance, while NMC and LiFePO4 provide higher energy density for longer runtime.

Part2: Power Inspection Device: Cold Weather Risks

2.1 Decreased Runtime and Reliability

You rely on your power inspection device to deliver consistent performance, but cold weather batteries often struggle in low temperatures. When you operate lithium-ion batteries in cold conditions, resistance increases and the movement of lithium ions slows down. This change leads to shorter runtime and less reliable operation. Think of the battery as a river—cold temperatures slow the flow of energy, making your device less efficient. You may notice longer charging times and reduced power output, especially in industrial, robotics, and security systems.

Cold weather batteries show increased resistance, which slows lithium-ion movement.

Performance drops, and charging takes longer.

The flow of energy inside the battery slows, just like a river in winter.

2.2 Avoid Charging Below Freezing

You must avoid charging below freezing to protect lithium-ion batteries. Charging at temperatures below 0°C can cause lithium ions to form metallic lithium on the anode. This process creates dendrites, which can puncture the separator and lead to internal short circuits. These risks include thermal runaway, overheating, and even fires or explosions. You also see significant capacity loss, with cells losing over 35% of their nominal capacity after only 132 cycles. Manufacturers recommend strict guidelines for charging cold-resistant batteries:

Battery Type | Charge Temperature (°F) | Discharge Temperature (°F) | Additional Guidelines |

|---|---|---|---|

Lithium-ion | 32°F to 113°F | -4°F to 140°F | No charging below freezing; fast charge at 41°F, lower rate below this temperature. |

Lead-acid | -4°F to 122°F | -4°F to 122°F | Smart charger recommended; charge at 0.3C or less below freezing. |

Nickel-based | 32°F to 113°F | -4°F to 149°F | Reduce charge current to 0.1C below freezing; fast charging requires thermal management. |

You should always follow these guidelines to maintain battery efficiency and safety.

2.3 Material Aging and Leakage

Repeated exposure to low temperatures accelerates material aging in lithium-ion batteries. You see reduced diffusion rates for lithium ions, which increases polarization and causes faster capacity fade. Charging in cold weather can prevent lithium ions from fully intercalating into the anode, leaving deposits that cannot be reused. This process decreases battery capacity and efficiency. Over time, cold-resistant batteries experience more heat generation due to polarization, which can lead to further degradation if you use them in high-temperature conditions later. You must keep batteries warm and pre-warm batteries before use to reduce these risks and extend cycle life.

Low temperatures speed up aging and capacity loss.

Lithium-ion batteries may leak or degrade faster after repeated cold exposure.

Cold-resistant batteries last longer when you manage temperature and charging practices.

Part3: Efficiency Strategies for Cold Weather Batteries

3.1 Pre-Warming and Insulation

You can improve the performance of lithium-ion batteries in cold environments by using pre-warming techniques and proper insulation. Preheating methods fall into two categories: external and internal heating. External heating uses devices like heating pads or warm air blowers. These methods are simple but take longer and waste more energy. Internal heating uses built-in heating elements or self-heating batteries. These solutions heat up faster and work more efficiently, but you must monitor safety closely.

Insulation plays a key role in keeping batteries at optimal temperatures. When you insulate battery packs, you reduce the risk of thermal runaway, which can cause overheating and fires. Insulation helps maintain ideal operating temperatures, boosting battery performance and extending lifespan. You also save energy because insulation controls heat dissipation, which can lower operating costs for your business.

External heating: Simple setup, longer heating time, higher energy loss.

Internal heating: Faster, more efficient, higher safety risk.

Insulation: Enhances safety, improves performance, increases efficiency.

If you manage lithium-ion batteries in robotics, medical devices, or industrial infrastructure, you should combine pre-warming and insulation for best results.

3.2 Choosing Cold-Resistant Models

Selecting the right battery model is critical for reliable operation in cold weather. Cold-resistant batteries, such as AGM types, offer several advantages over standard lithium-ion batteries. These models deliver better performance in low temperatures, with less capacity reduction. You benefit from lower internal resistance, which means faster charging and steady power output. AGM batteries also resist vibration and physical stress, making them ideal for rugged environments like industrial sites or mobile medical equipment.

When you choose lithium-ion batteries for power inspection devices, consider the chemistry. LiFePO4 and LTO chemistries provide excellent cycle life and cold weather stability. NMC and LMO offer higher energy density for longer runtime in security systems and consumer electronics. Always match the battery chemistry to your application and environment.

Enhanced cold weather performance: AGM batteries maintain capacity in low temperatures.

Lower internal resistance: Faster charging and consistent power output.

Durability and vibration resistance: Robust design for industrial and medical use.

You should evaluate battery specifications and test performance in real-world conditions before deploying new battery packs.

3.3 Battery Management Practices

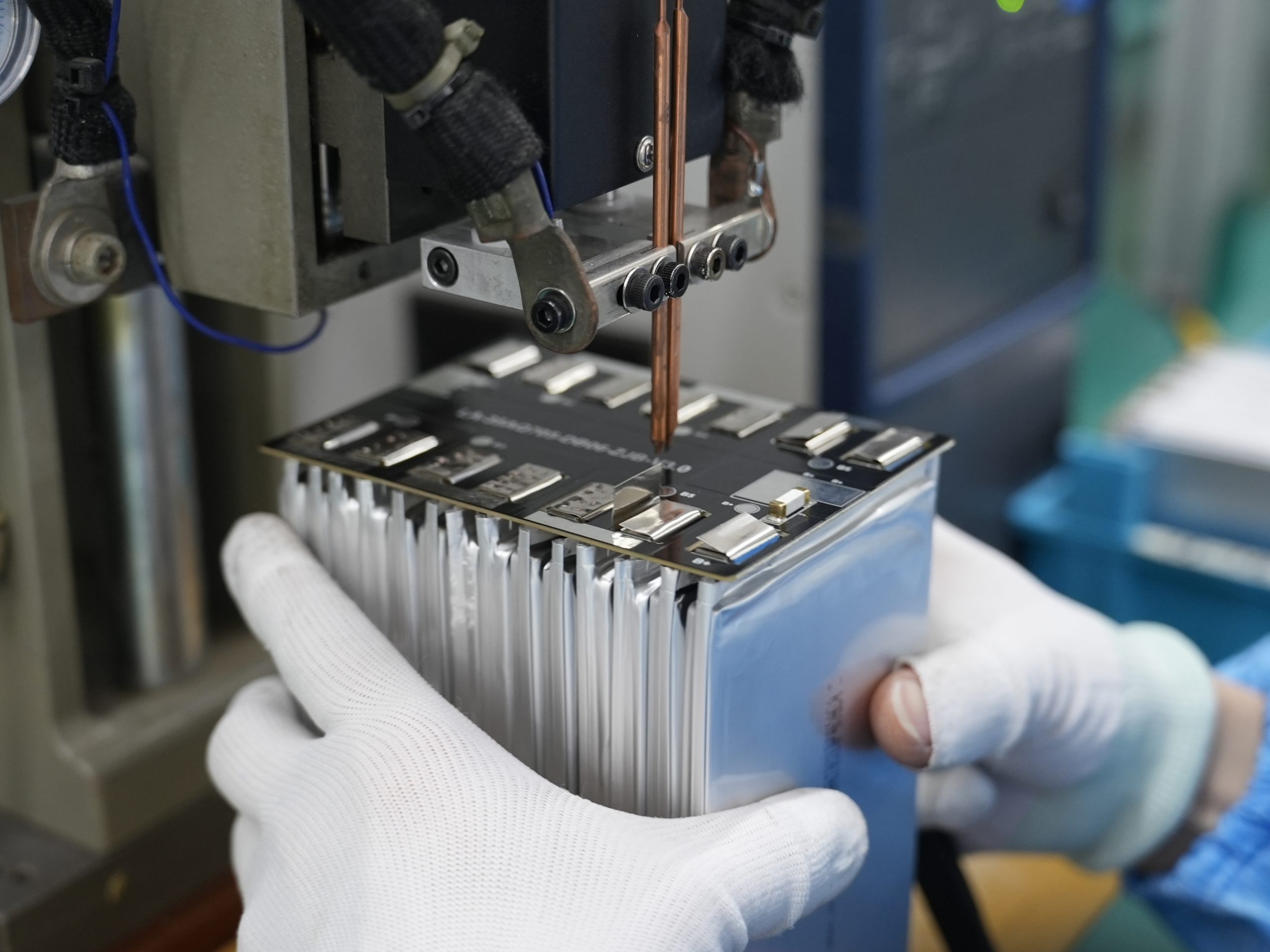

Effective battery management extends the life and reliability of lithium-ion batteries in cold environments. You should implement a battery management system (BMS) to monitor temperature and activate heating elements when needed. Modern lithium UPS systems use BMS with self-heating features, ensuring reliable operation in cold weather. These systems outperform traditional VRLA banks, which lack self-heating capabilities.

Active heating solutions, such as heaters or heating films, help raise battery temperature before charging. This practice prevents lithium plating, which can damage batteries and reduce capacity. You must store batteries in controlled environments, keeping warehouse temperatures around 20±5°C (68±9°F). Avoid exposing batteries to extreme cold below -13°F (-25°C) or heat above 149°F (65°C).

🔗 For more details on battery management systems and protection circuit modules, visit the BMS and PCM page.

Use BMS to monitor and control battery temperature.

Activate heating elements in cold conditions.

Store batteries at recommended temperatures.

Prevent lithium plating by pre-warming before charging.

You can apply these practices to lithium-ion batteries in industrial, medical, robotics, and security applications. Proper management ensures consistent performance and extends battery life, even in harsh winter conditions.

Part4: Innovations in Low Temperature Batteries

4.1 Self-Heating Battery Technology

You can rely on self-heating technology to keep lithium-ion batteries efficient in cold environments. These batteries automatically heat themselves when the temperature drops, maintaining optimal performance. You see this innovation in lithium battery packs for industrial, medical, and robotics applications. Self-heating LiFePO4 batteries maintain over 80% capacity even at temperatures as low as -20°C. Internal heating mechanisms help keep the battery within the best operating temperature range, reducing the risk of thermal runaway and capacity loss. This technology helps you protect lithium-ion batteries and ensures battery safety during extreme temperatures.

Self-heating batteries activate in cold environments to maintain performance.

LiFePO4 batteries retain over 80% capacity at -20°C.

Internal heating mitigates the effects of cold and prevents runaway.

4.2 Advanced Battery Management Systems

You benefit from advanced battery management systems (BMS) that optimize lithium-ion batteries for cold weather. These systems use new electrolyte formulations to lower the freezing point and maintain ionic conductivity. Thermal stability enhancers and high-conductivity materials improve lithium-ion movement, reducing internal resistance. Active thermal management systems pre-heat batteries, which is crucial for electric vehicles and industrial machinery. Phase change materials regulate temperature by absorbing and releasing heat. Insulation and enclosure designs minimize heat loss, keeping batteries safe from runaway and extending operational life.

Aspect | Description |

|---|---|

Internal Heating Mechanism | Incorporates a heating element to warm the battery, improving performance in low temperatures. |

Material Optimization | Optimizes materials for stability in extreme temperatures, enhancing safety and efficiency. |

Operational Range | Expands operational temperature range to -50 to 75 C, allowing use in previously infeasible applications. |

Reduced External Systems | Eliminates the need for external thermal management, reducing costs and maintenance requirements. |

You can read more about sustainability in battery innovations on our sustainability page.

4.3 Application in Power Inspection Devices

You see these innovations applied in power inspection device batteries across many industries. In aerospace, all-solid-state lithium-ion batteries work in vacuum and extreme temperature variations. Medical equipment like pacemakers uses compact, safe lithium-ion batteries. Industrial machinery, including semiconductor manufacturing and aerospace equipment, relies on lithium-ion batteries that function in extreme temperatures and prevent runaway. These advancements help you maintain battery safety and reliability in harsh environments.

Application Area | Description |

|---|---|

Aerospace Industry | All-solid-state batteries are suitable for the vacuum and temperature variations in space. |

Medical Equipment | Used in devices like pacemakers, offering safety and compact design. |

Industrial Machinery | Applicable in semiconductor manufacturing and aerospace equipment, functioning in extreme conditions. |

If you want to learn more about responsible sourcing and conflict minerals, visit our conflict minerals statement.

You face unique challenges when using batteries in cold weather. Low temperatures reduce capacity, increase internal resistance, and shorten runtime for power inspection devices. Recent innovations help you overcome these issues.

Lithium batteries now operate from -70°C to 80°C, maintaining over 60% discharge capacity at -50°C.

Advanced battery management systems optimize charging for batteries in cold conditions.

You should select batteries with LiFePO4, NMC, LCO, LMO, or LTO chemistries for industrial, medical, and security applications.

For best results, always pre-warm batteries, use insulation, and monitor battery packs with smart systems.

FAQ

What happens to lithium battery packs in cold weather?

You see lithium battery packs lose capacity and efficiency in cold weather. The chemical reactions slow down, and internal resistance rises. Devices in industrial, medical, and security systems may run for shorter periods. You must monitor battery temperature to maintain reliable operation in cold environments.

Can I safely charge batteries in cold temperatures?

You should avoid charging lithium battery packs below freezing. Charging in cold can cause lithium plating, leading to permanent damage or safety risks. Always pre-warm batteries before charging in cold weather applications, especially for vehicles, robotics, and infrastructure systems.

Which lithium battery chemistry works best for cold weather?

You get the best cold weather performance from LTO and LiFePO4 chemistries. These types offer stable operation and long cycle life in cold environments. NMC and LMO provide higher energy density for electric vehicles and consumer electronics, but may lose more capacity in low temperatures.

How do I extend battery life in cold weather applications?

You can extend battery life by using insulation, pre-warming, and advanced battery management systems. Store batteries at recommended temperatures. Activate heating elements before charging. These practices help you maintain efficiency in industrial, medical, and security devices during cold weather.

Are self-heating batteries suitable for electric vehicles in cold climates?

You benefit from self-heating lithium battery packs in electric vehicles. These batteries automatically warm up in cold weather, improving charging safety and runtime. Self-heating technology supports reliable operation for applications used in infrastructure, robotics, and consumer electronics sectors.