You can often succeed at reviving dead batteries with practical reconditioning methods. Many B2B clients see benefits when they make dead batteries work, especially with lithium battery packs. Batteries lose charge from age, improper use, or environmental factors. Reconditioning helps you make dead batteries work and extend battery life through maintenance and simple household hacks.

Key Takeaways

Regular cleaning, proper charging, and safe storage can extend battery life and help revive dead batteries safely.

Avoid risky methods like freezing or physical manipulation for lithium batteries; use smart chargers and monitor battery health closely.

Always watch for signs of damage like swelling or leaks and recycle damaged batteries properly to protect people and the environment.

Reviving Dead Batteries

Causes of Battery Failure

You often see batteries fail due to several common reasons.

Overcharging can cause overheating, which damages lithium battery packs.

Using the wrong charger or charging in extreme heat speeds up battery degradation.

Letting batteries discharge completely shortens their lifespan.

Physical damage, such as drops or stress, leads to internal faults.

Battery Management Systems (BMS) help prevent overcharge, over-discharge, and overheating.

Mechanical failures, like deformation or welding faults, increase resistance and cause connection issues.

Chemical changes, such as lithium dendrite formation, can create short circuits and make reviving dead batteries difficult.

You should always look for signs like swelling, leaks, or overheating before trying reconditioning.

Battery Capacity Retention

Battery capacity retention describes how much charge a battery can hold after many cycles. For lithium-ion batteries, industry standards say a battery reaches its cycle life when it drops to 80% of its original capacity. The cycle life depends on the depth of discharge. For example, an NMC 18650 cell may last 500 cycles at 80% depth of discharge, but up to 2,500 cycles at 20%. High discharge rates and extreme temperatures speed up capacity loss. In B2B settings like Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial, you need to monitor battery health closely to plan reconditioning and replacement.

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Typical Cycle Life |

|---|---|---|---|

lithium-ion | 3.6–3.7 V | 150–250 | 500–2,000 |

LiFePO4 | 3.2 V | 90–160 | 2,000–5,000 |

lithium-polymer/LiPo | 3.7 V | 100–200 | 300–1,000 |

Lithium Battery Pack Considerations

Reviving dead batteries with simple reconditioning techniques is more complex for lithium battery packs than for other types. Each cell may need individual attention, and cells often differ in age and quality. If a cell has internal shorts or dendrite growth, reconditioning may not work. Specialized chargers with revive functions can sometimes help, but you must use proper equipment and follow safety steps. In B2B applications, always prioritize safety and use a BMS to monitor battery status. Attempting to revive batteries with severe damage or zero voltage is rarely successful and can be risky.

Step-by-Step Guide to Battery Reconditioning

Reconditioning batteries can help you make dead batteries work and extend their useful life, especially in B2B settings like Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial applications. This battery reconditioning guide gives you a step-by-step guide to battery reconditioning, focusing on lithium battery packs and rechargeable batteries. You will learn practical ways to make dead batteries work, how to recharge batteries, and when to use each method.

Cleaning and Maintenance

Proper cleaning and maintenance are the foundation of any battery reconditioning guide. You can prevent many battery failures by following these steps:

Wear protective gloves and safety glasses before handling batteries.

Inspect the battery for cracks, swelling, leaks, or corrosion. Remove and dispose of leaking batteries safely.

Clean the terminals:

Mix baking soda with distilled white vinegar or lemon juice to create a cleaning paste.

Dip a cotton swab in the paste and gently clean the battery contact points.

Use an old toothbrush for hard-to-reach areas.

Wipe the area with a paper towel and let it dry completely.

Store batteries at about 50% charge in a cool, dry place. Avoid high temperatures and moisture.

Recharge batteries before they drop below 25% to prevent deep discharge damage.

Use the correct charger for your battery type. Chargers rated at about 1/4 of the battery capacity ensure safe, slow charging.

Avoid overcharging and do not leave batteries charging overnight.

Monitor battery performance and replace batteries that no longer hold a charge.

Tip: Regular cleaning and gentle use help you make dead batteries work longer and reduce downtime in B2B operations.

Aluminum Foil Hack

The aluminum foil hack is a quick fix for batteries with worn-out terminals or minor contact issues. This method does not restore chemical capacity but can help you make dead batteries work in a pinch.

Steps:

Cut a small piece of aluminum foil.

Fold it to match the size of the battery terminal.

Place the foil between the battery terminal and the device contact point.

Insert the battery and check if the device powers on.

Expected Results:

This hack may restore temporary contact and allow the device to function. It works best for low-drain devices and is not recommended for critical B2B equipment.

Note: Do not use this method for lithium battery packs in high-value B2B applications. It may cause overheating or short circuits.

Physical Manipulation

Physical manipulation techniques are common in reconditioning car batteries, especially lead-acid types. For lithium battery packs, you must use extreme caution.

Common Methods:

High voltage charging to break down sulfation (for lead-acid batteries).

Flushing and replacing electrolyte.

Pressing battery case ends to release trapped gas bubbles.

Limitations and Safety:

These methods offer only short-term results and often restore partial capacity.

Physical manipulation of lithium battery packs can cause internal short circuits, fire, or explosion. Damaging the BMS or protection circuits increases risk.

For lithium-ion, LiFePO4, or lithium-polymer/LiPo batteries, avoid physical manipulation. Instead, use diagnostic tools to check cell balance and voltage.

⚠️ Warning: Never attempt to physically manipulate lithium battery packs. The risks outweigh the benefits, especially in B2B environments.

Freezing Method

Some people try to recharge batteries in the freezer, hoping to revive dead cells. This method originated with older chemistries like NiCd or NiMH, not lithium-ion.

Steps (Not Recommended for Lithium-Ion):

Place the battery in an airtight bag.

Freeze for 24 hours.

Thaw at room temperature for 8 hours.

Attempt to recharge with a smart charger.

Scientific Basis and Effectiveness:

Freezing lithium-ion batteries can cause electrolyte contraction, internal damage, and increased risk of short circuits. No scientific evidence supports this method for lithium battery packs. You may see a temporary response, but true capacity is not restored. Freezing can make dead batteries work for a short time, but it often leads to permanent damage.

Condition or Scenario | Recommended Action |

|---|---|

Battery has warmed and charges normally | Recharge slowly with a smart charger; monitor closely |

Charger blinks or refuses to start | Try a different charger |

Voltage reads 0V | Attempt gentle trickle charge |

Battery swells, heats up, or smells odd | Replace immediately; do not reuse |

Do not recharge batteries in the freezer if you use lithium-ion, LiFePO4, or lithium-polymer/LiPo batteries. Use smart chargers with low-voltage recovery instead. For more on battery freezing myths, see Nature.

Safety and Disposal

Safety is critical in every battery reconditioning guide. Always follow these steps to protect yourself and the environment:

Discharge lithium battery packs slowly using a low current load in a sand-filled container.

Isolate damaged or bulging batteries in a sand bucket.

Tape or insulate battery terminals before storage or transport.

Never use saltwater dunking for disposal; it can give false readings and does not neutralize all risks.

Recycle batteries at certified facilities. Improper disposal can cause chemical leaks, landfill fires, and environmental pollution.

Lithium batteries contain toxic metals like cobalt, copper, and nickel. These can contaminate soil and water if not handled properly.

Monitor for signs of permanent damage: swelling, leaks, chemical odors, or failure to hold charge. Replace and recycle these batteries immediately.

Note: About 98% of lithium-ion batteries end up in landfills, causing fires and pollution. Always recycle to protect your business and the environment.

Table: Expected Results and Limitations of Reconditioning Methods

Method | Expected Results | Limitations |

|---|---|---|

Cleaning & Maintenance | Improved contact, longer battery life | Does not restore lost chemical capacity |

Aluminum Foil Hack | Temporary device function | Not suitable for high-drain or critical devices |

Physical Manipulation | Short-term revival (lead-acid only) | Unsafe for lithium packs; limited long-term benefit |

Freezing Method | Rare, short-lived response (non-lithium) | Damages lithium batteries; not recommended |

Software/BMS Reset | Restores balance, fixes software errors | Only works for imbalance, not chemical degradation |

Reminder: The best ways to make dead batteries work involve regular maintenance, proper charging, and safe disposal. Reconditioning car batteries and lithium battery packs requires patience, the right tools, and a focus on safety.

Reconditioning Old Batteries

Maintenance Tips

You can extend the lifespan of lithium battery packs in Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial applications by following proven battery maintenance tips. Reconditioning old batteries starts with controlling temperature. Keep batteries in cool, dry places, ideally between 68°F and 77°F. Store batteries at a partial charge, around 40%-60%, and avoid full charges or deep discharges. Use manufacturer-approved chargers and limit fast charging to reduce stress. Recharge batteries every three months during storage to counteract self-discharge. Clean battery terminals regularly to maintain charging efficiency. Monitor battery health indicators such as internal resistance and capacity. Advanced BMS systems help you track voltage, temperature, and charge cycles, preventing overcharge and overheating. Tailor maintenance routines to your device type. For example, electric vehicles use cooling systems and BMS, while laptops benefit from software updates and moderate charging. Keep detailed records of battery performance to refine your reconditioning strategy.

🛠️ Regular reconditioning and maintenance can extend battery life by up to six years, saving costs and supporting sustainability. For more on sustainability and conflict minerals, see Nature.

Practice | Benefit |

|---|---|

Temperature control | Slows aging, extends lifespan |

Partial charge storage | Reduces stress |

Routine health monitoring | Prevents failures |

Advanced BMS | Enables predictive maintenance |

Quality chargers | Maintains integrity |

When to Dispose

You must recognize signs a battery can be reconditioned and when disposal is necessary. Swelling, cracking, bulging, or misalignment of the battery or device case means you should not attempt reconditioning. Excessive heat, unpleasant odors, or unusual sounds during charging signal immediate removal and disposal. Sudden loss of charge capacity also indicates end-of-life. In B2B settings, always follow EPA and state guidelines for safe collection, storage, and recycling. Consider second-life reuse for batteries that no longer meet original performance but remain safe for stationary energy storage. End-of-life lithium-ion batteries are hazardous waste and require certified recycling. Employee training and proper labeling support safe handling. Reconditioning old batteries supports a circular economy, reduces hazardous waste, and conserves resources.

⚠️ If you see any warning signs, remove the battery from service and recycle it through certified programs. Never recharge or reuse damaged batteries.

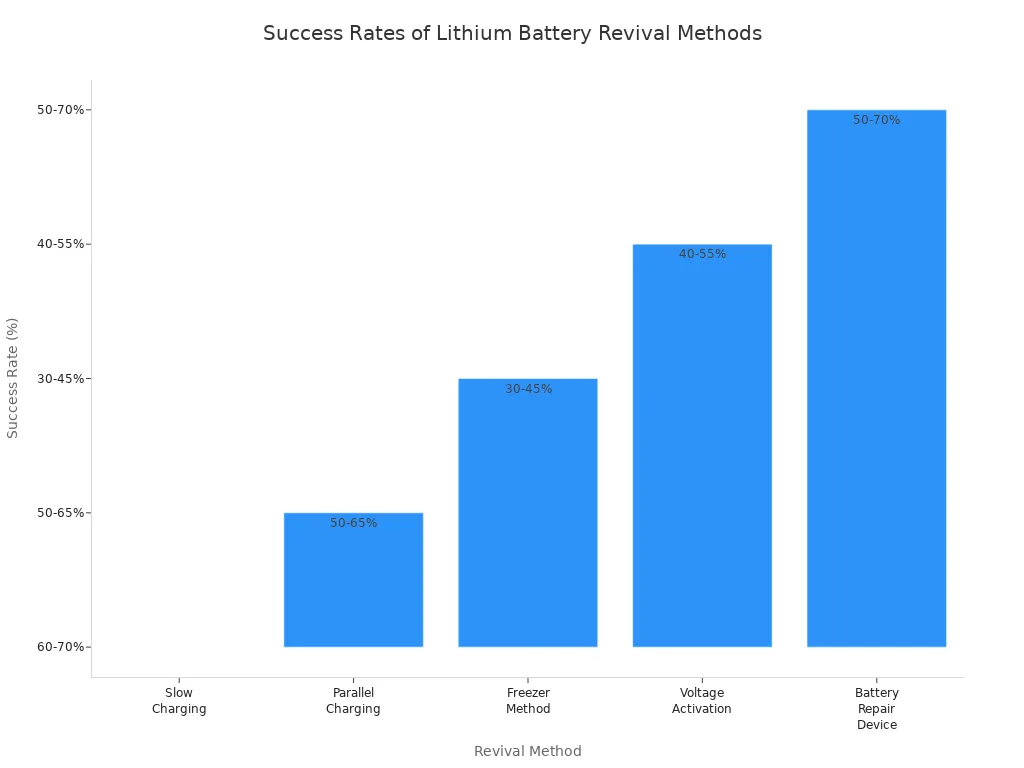

You can achieve cost savings and support sustainability by choosing reconditioning for lithium battery packs in Medical, Robotics, Security, Infrastructure, Consumer Electronics, and Industrial applications. The most effective methods include slow charging, parallel charging, and voltage activation. See the chart below for success rates:

Method | Complexity | Success Rate | Cost |

|---|---|---|---|

Slow Charging | Low | 60-70% | $0-$50 |

Parallel Charging | High | 50-65% | $100-$300 |

Voltage Activation | Medium | 40-55% | $50-$200 |

Always use reconditioning when batteries show no swelling or leakage. Dispose of damaged batteries using environmentally-friendly practice. Responsible battery maintenance protects the environment. For custom battery consultation, contact Large Power.

FAQ

What is the safest way to start reconditioning lithium battery packs in B2B applications?

You should use a smart charger with a revive function. Always monitor the process. Large Power recommends following all safety guidelines for lithium battery packs.

Can reconditioning extend the life of lithium battery packs in Industrial or Medical devices?

Yes. Reconditioning helps you restore some capacity and delay replacement. For best results, follow maintenance routines for Industrial and Medical battery packs.

How do I know if a battery is beyond reconditioning and needs disposal?

If you see swelling, leaks, or strong odors, do not attempt reconditioning. Remove the battery and recycle it. For custom battery solution, contact Large Power.