Predicting battery lifespan for a lithium-ion battery in handheld devices remains challenging. You face variability due to chemistry and usage patterns. The table below shows how cycling profiles and random current loads influence degradation and battery lifespan in lithium-ion battery packs:

Aspect | Details |

|---|---|

Dataset | NASA Randomized Battery Usage dataset focusing on LCO chemistry. |

Cycling Profiles | Dynamic cycling profiles mimic operational variability. |

Impact on Battery Lifespan | Usage patterns significantly affect lifetime and degradation. |

You can adopt strategies such as predictive diagnostics, battery management systems, and Fast Charging Technologies to maximize performance and reliability. Routine maintenance and early-stage prediction help you reduce downtime and extend the lifespan of your lithium-ion battery packs.

Key Takeaways

Understanding factors like temperature, depth of discharge, and charging patterns is crucial for maximizing lithium-ion battery lifespan.

Implementing predictive maintenance and battery management systems can significantly reduce downtime and extend battery life in handheld devices.

Adopting best practices for charge and discharge routines, such as avoiding full cycles and maintaining optimal charge levels, enhances battery performance.

Part1: Battery Lifespan Prediction

1.1 Influencing Factors

You face a complex challenge when predicting battery lifespan for lithium-ion battery packs in handheld devices. Battery lifespan acts as a random variable, shaped by many factors that interact in unpredictable ways. In B2B applications—such as medical, robotics, security, and industrial applications—understanding these influences is critical for planning and reliability.

Battery chemistry

Temperature

Charge and discharge voltage

Current

State of charge

Battery management systems

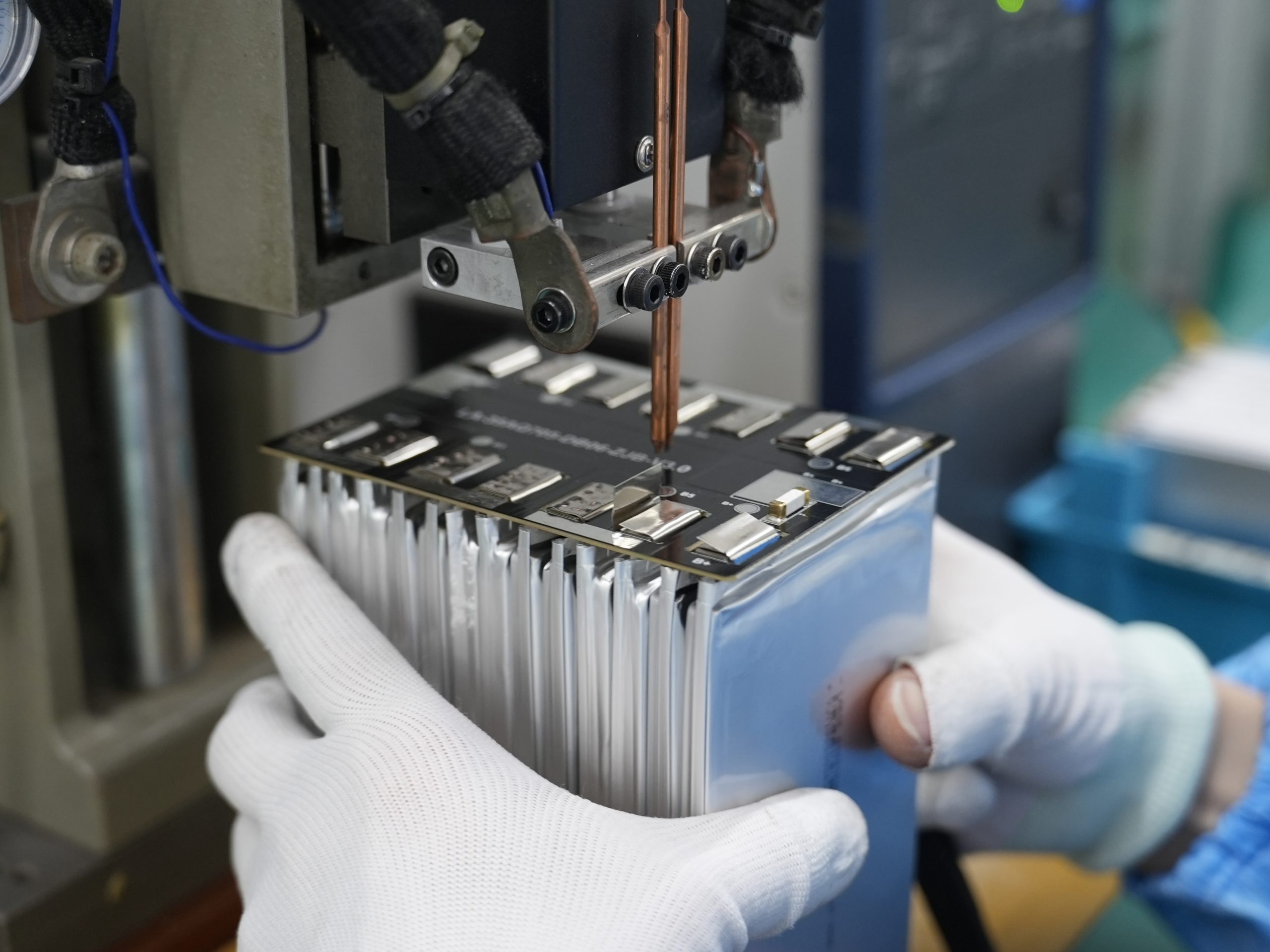

Manufacturing quality

Battery design

Use cases

Recycling

Regulatory factors

You must pay close attention to several primary drivers of battery lifespan:

Depth of Discharge (DoD): Keeping DoD between 20% and 80% helps maximize longevity.

Temperature: Both high and low temperatures accelerate battery degradation.

Charging Patterns: Rapid charging increases stress and shortens cycle life.

Quality of Battery Components: High-quality materials extend battery lifespan.

Battery Management System (BMS): A robust BMS ensures optimal operation and longevity.

Usage Patterns and Cycling: Frequent and intense use reduces cycle life.

Tip: Effective temperature management and controlled charging routines can significantly slow battery degradation and extend battery lifespan in your lithium-ion battery packs.

The table below summarizes how operational factors impact battery degradation:

Factor | Impact on Battery Degradation |

|---|---|

Temperature | Significant impact on discharge capacity and aging law |

Usage Cycles | Divided into calendar aging and cycle aging |

State-of-Charge (SOC) | Affects degradation modeling |

Depth of Discharge (DoD) | Influences aging rates |

Solid Electrolyte Interphase (SEI) | Growth affects battery life |

1.2 Chemistry Variability

Lithium battery chemistry plays a central role in determining battery lifespan, cycle life, and overall performance. You must select the right chemistry for your application—whether in medical devices, robotics, or industrial handhelds—to balance longevity, safety, and energy density.

The most common lithium-ion chemistries for handheld device batteries include LiFePO4, Nickel Manganese Cobalt (NMC), and Nickel Cobalt Aluminum Oxide (NCA). Each chemistry offers unique advantages and trade-offs:

Chemistry Type | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (to 80% capacity) | Typical Lifespan |

|---|---|---|---|---|

3.2 | 90-160 | 3,000-7,000 | 15-20 years | |

NMC | 3.7 | 150-220 | 2,000-4,000 | N/A |

NCA | 3.6 | 200-260 | 1,500-2,500 | N/A |

LCO | 3.7 | 150-200 | 500-1,000 | 2-3 years |

LMO | 3.7 | 100-150 | 300-700 | 1-3 years |

LTO | 2.4 | 70-80 | 7,000-20,000 | 15-25 years |

3.2-3.8 | 250-500 | 5,000-10,000 | 10-20 years | |

3.7 | 100-200 | 300-1,000 | 2-3 years |

You should match the lithium battery chemistry to your operational needs. For example, LiFePO4 offers high cycle life and safety, making it ideal for medical and industrial handhelds. NMC and NCA provide higher energy density, which suits robotics and security devices where weight and size matter.

1.3 Prediction Models

You can leverage advanced prediction models to estimate the remaining useful life (RUL) of lithium-ion battery packs. Accurate RUL estimation enables you to plan maintenance, reduce downtime, and optimize asset utilization across your organization.

Modern approaches include:

Statistical models such as Kalman filtering and particle filtering, which model battery degradation probabilistically.

Machine learning techniques like support vector machines, random forests, and XGBoost, which use hand-crafted features for RUL prediction.

Deep learning models, including LSTM networks and Transformer models, which capture temporal dependencies and global features in battery lifespan data.

The table below compares these model types:

Model Type | Description |

|---|---|

Statistical Models | Approaches like Kalman filtering and particle filtering that model battery degradation probabilistically. |

Machine Learning | Techniques such as support vector machines, random forests, and XGBoost that utilize hand-crafted features for RUL prediction. |

Deep Learning | Models like LSTM networks and Transformer models that excel in capturing temporal dependencies and global features respectively. |

You can also use DLinear, which employs two linear layers to capture both trend and seasonality in battery lifespan data. DLinear offers a simpler structure than LSTM or Transformer models and effectively models both decreasing and periodic increasing trends.

Note: Studies using datasets from over 120 lithium-ion battery packs show that early-stage prediction methods can achieve high accuracy. For example, mean absolute error (MAE) can reach as low as 0.0058, with a coefficient of determination (R²) of 0.9839. These results demonstrate that you can rely on early prediction to inform maintenance planning and reduce operational risks.

By integrating prediction models with your battery management systems, you gain actionable insights into battery lifespan and can schedule proactive maintenance. This approach supports continuous improvement in reliability and cost control for your lithium-ion battery packs.

Part2: Battery Performance Optimization

2.1 Charge/Discharge Routines

You can optimize battery performance in your lithium battery packs by managing charge and discharge cycles with precision. In medical, robotics, and industrial applications, tracking each cycle helps you avoid unnecessary full charges and discharges. Adopting partial cycles and keeping batteries within the optimal charge range reduces chemical stress and extends battery lifespan. The following table summarizes best practices for charge and discharge routines:

Best Practice | Description |

|---|---|

Manage Charging Cycles | Track and control each charge/discharge event to avoid unnecessary full cycles. |

Adopt Partial Cycles | Use partial charges and discharges to reduce wear and extend battery lifespan. |

Charge to 80% | Limit charging to about 80% to lower cell stress and slow down capacity loss. |

Avoid Deep Discharge | Keep battery levels above 25% to prevent damage and maintain long-term performance. |

Keeping batteries between 25% and 80% charge can achieve up to four times more cycles. Avoiding full discharges minimizes battery wear and supports reliable operation in security and infrastructure devices.

2.2 Fast Charging Technologies

Fast charging technologies have transformed how you manage lithium battery packs in consumer electronics and industrial handhelds. These technologies use a two-phase process: bulk charging with high current, followed by topping-off with lower current to prevent overheating. While fast charging technologies reduce downtime, they generate heat and can accelerate battery degradation. You must implement effective thermal management strategies to maintain safety and cycle life.

“Fast charging protocols can significantly affect battery cycle life and safety, particularly through mechanisms like thermal runaway and lithium plating. Effective thermal management is essential during fast charging.”

“High state of charge levels and deep depth of discharge can enhance energy utilization, but they also pose risks to cycle life and safety. Understanding degradation mechanisms helps you optimize SOC-DOD combinations for improved performance and longevity during fast charging technologies.”

2.3 Depth of Discharge

Depth of discharge (DoD) plays a critical role in battery performance and longevity. Operating lithium battery packs at shallow discharge levels minimizes strain and extends battery life. The table below compares the impact of different DoD levels:

Depth of Discharge (DoD) | Capacity Retention After 1000 Cycles | Capacity Loss by Cycle 400 |

|---|---|---|

50% | 92% | 40% |

100% | 67% | 40% |

You should maintain DoD between 70% and 90% for lithium-ion and LiFePO4 batteries in medical and robotics fleets. This approach balances usable capacity and cycle life, supporting long-term reliability in industrial and security applications.

Tip: Set device alerts for 20% and 80% charge levels, schedule regular charging breaks, and rotate devices to avoid overusing a single battery pack.

Part3: Battery Health Monitoring

3.1 Battery Management Systems

You rely on battery management systems to maintain the performance and safety of lithium battery packs in your remote monitoring devices. These systems play a central role in battery health monitoring by providing real-time monitoring of voltage, current, and temperature. You gain several advantages when you implement advanced battery management systems in your medical, robotics, or industrial fleets:

You ensure optimal charging and discharging, which extends battery life.

You prevent overcharging and over-discharging, two factors that can quickly reduce battery lifespan.

You balance cell voltages and receive real-time feedback on battery health and performance.

Battery management systems also deliver critical diagnostics. They reveal the state-of-charge and state-of-health, which helps you make informed decisions about device deployment. When your remote monitoring devices operate in harsh environments, the system prompts caution or service if it detects high temperature or cell imbalance. You receive end-of-life notifications when capacity falls below your set threshold, allowing you to plan replacements before failures occur.

Tip: Battery management systems provide essential safety and longevity features for lithium-ion batteries.

You also benefit from compliance with regulatory standards, which is crucial in medical and security applications. By monitoring key parameters and implementing safety mechanisms, you reduce the risk of power loss and ensure uninterrupted operation of your remote monitoring devices.

3.2 Predictive Maintenance

Predictive maintenance transforms how you manage battery health in remote monitoring devices across industrial, infrastructure, and security sectors. You use real-time monitoring data to anticipate failures and schedule service before issues disrupt operations. This approach reduces downtime by 30-50% and extends machine life by 20-40%. You experience fewer unexpected breakdowns, which leads to higher productivity and operational efficiency.

You can implement predictive maintenance by integrating battery diagnostics with your battery management systems. These systems analyze trends in voltage, temperature, and state-of-health. When they detect anomalies, you receive alerts to investigate or replace affected lithium battery packs. This proactive strategy supports sustainability by minimizing waste and maximizing the usable life of each battery. For more on responsible sourcing and sustainability, see our conflict minerals policy.

Predictive maintenance empowers you to make data-driven decisions. You optimize maintenance schedules and reduce costs by focusing on actual battery health rather than fixed intervals.

In medical and robotics applications, predictive maintenance ensures that remote monitoring devices remain operational during critical tasks. In infrastructure and security, you avoid costly service interruptions and maintain compliance with industry standards.

3.3 Health Assessment Metrics

You depend on accurate health assessment metrics to guide your maintenance and replacement strategies for lithium battery packs in remote monitoring devices. Real-time monitoring provides actionable insights into battery health, enabling you to detect anomalies, forecast failures, and optimize system dispatch.

Feature | Description |

|---|---|

Anomaly detection | Identifies battery cells that deviate from fleet averages using key performance indicators (KPIs) like voltage, temperature, and state of health (SOH). |

Forecasting | Projects failure points, remaining useful life (RUL), and degradation trends to inform timely maintenance. |

Actionable insights | Supports decision-making on maintenance schedules and system dispatch to enhance operational efficiency. |

You use these metrics to compare the performance of different lithium battery chemistries, such as LiFePO4, NMC, and LCO, across your remote monitoring devices. By leveraging real-time monitoring, you identify underperforming battery packs and schedule replacements before failures impact your operations.

Note: Real-time monitoring and health assessment metrics are essential for maintaining high reliability in medical, security, and industrial fleets. You improve safety, reduce costs, and extend the lifespan of your remote monitoring devices by acting on these insights.

Part4: Maintenance Schedules

4.1 Routine Intervals

You need to establish clear maintenance schedules for lithium battery packs in your organization. Routine intervals for battery maintenance help you prevent unexpected failures and keep your devices running smoothly. In medical, robotics, and industrial environments, you should follow industry best practices:

Track battery health regularly to catch early signs of wear.

Schedule preventive battery maintenance to avoid power outages and equipment downtime.

Plan battery replacements based on performance data, not just on failure.

A well-structured maintenance plan reduces device downtime and extends the lifespan of your lithium battery packs. Hospitals and security organizations that increase maintenance frequency see fewer battery failures and less disruption to operations. You can choose between replacing batteries only when they fail or adopting a comprehensive maintenance program to maximize battery life and predict optimal replacement times.

Standard | Description |

|---|---|

IEEE 1188-2005 | Maintenance and testing for VRLA batteries in stationary applications. |

IEEE 450-2010 | Maintenance and testing for VLA batteries in stationary applications. |

IEEE 1106-2015 | Installation and maintenance for NiCad batteries in stationary applications. |

Tip: Preventive battery maintenance ensures your equipment is always backed up and ready for critical tasks.

4.2 Centralized Tracking

Centralized tracking systems give you real-time visibility into your battery fleet. You can monitor the location, health, and operational status of every lithium battery pack across your medical, security, or industrial devices. This approach supports predictive maintenance scheduling, helping you spot potential failures before they cause downtime.

Use a unified dashboard to track all assets and schedule battery maintenance.

Analyze usage data to optimize resource allocation and project timelines.

Automate compliance documentation to meet industry standards.

Centralized tracking improves operational efficiency and reduces costs. You can streamline your maintenance schedules, enhance safety protocols, and ensure regulatory compliance across your organization.

Staff training is essential. Make sure your team understands how to use tracking tools and follow maintenance schedules for every lithium battery pack.

You improve battery lifespan in medical, robotics, and industrial handhelds by integrating battery management systems and predictive maintenance. The table below highlights key benefits:

Benefit | Description |

|---|---|

Reduces downtime | Early warnings prevent unexpected failures |

Lowers costs | Optimized maintenance cuts expenses |

Extends battery life | Data-driven routines maximize cycles |

Store lithium battery packs in cool, dry places.

Monitor performance metrics and educate staff on responsible usage.

Apply regular updates and proactive maintenance for continuous improvement.

FAQ

What is the best maintenance schedule for lithium battery packs in industrial and medical devices?

You should inspect battery health monthly and perform preventive maintenance quarterly. This schedule reduces downtime and extends battery lifespan in critical applications.

How do different lithium battery chemistries compare for robotics and security devices?

Chemistry Type | Cycle Life | Safety | Energy Density |

|---|---|---|---|

LiFePO4 | High | Excellent | Moderate |

NMC | Moderate | Good | High |

LCO | Low | Moderate | Moderate |

How can Large Power help you customize lithium battery solutions for infrastructure projects?

You can request a custom battery consultation with Large Power. Our experts design lithium battery packs tailored for your infrastructure, robotics, or security needs.