If you manufacture or manage battery pack production, you know that ultrasonic welding of battery housing offers a fast, safe, and precise solution—especially for lithium battery packs. You gain robust dust and water resistance, reduced material costs, and strong joint reliability. However, you must consider limits on material compatibility, joint design, and initial tooling investment.

Advantages:

Fast cycle times and seamless joints.

Consistent, automated welds with minimal defects.

No adhesives or screws needed, reducing costs.

Disadvantages:

Not suitable for all plastics or extra-thick housings.

High setup and equipment costs.

Custom tooling and design complexity.

Key Takeaways

Ultrasonic welding creates strong, fast, and seamless joints for battery housings, improving dust and water resistance without needing adhesives or screws.

This welding method suits high-volume production by reducing costs and supporting automation, but it requires careful material choice and joint design.

Ultrasonic welding has limits like high initial equipment costs, material compatibility issues, and permanent joints that make repairs and recycling harder.

Part 1:Ultrasonic Welding of Battery Housing

1.1 Principle

You use the ultrasonic welding process to join battery housing components without melting the materials. This method relies on high-frequency ultrasonic vibrations and pressure. The sonotrode presses the parts together and vibrates at ultrasonic frequencies, generating frictional heat at the interface. This heat causes the molecules at the surface to bond, creating a solid-state joint. Unlike other welding techniques, ultrasonic welding of battery housing produces a minimal heat-affected zone, which helps preserve the integrity of sensitive battery pack components.

Ultrasonic welding does not require adhesives or screws, making it ideal for plastic welding in battery packs.

The process forms strong, reliable joints, especially important for electrical connections and dust- or water-resistant enclosures.

Robotic ultrasonic welding systems enable high-volume, automated production for battery pack assembly lines.

Recent advancements in ultrasonic welding applications include real-time process monitoring, AI-driven parameter optimization, and integration with automated manufacturing cells. These improvements increase weld consistency and reduce defects, supporting the strict quality requirements of lithium battery pack production.

1.2 Materials

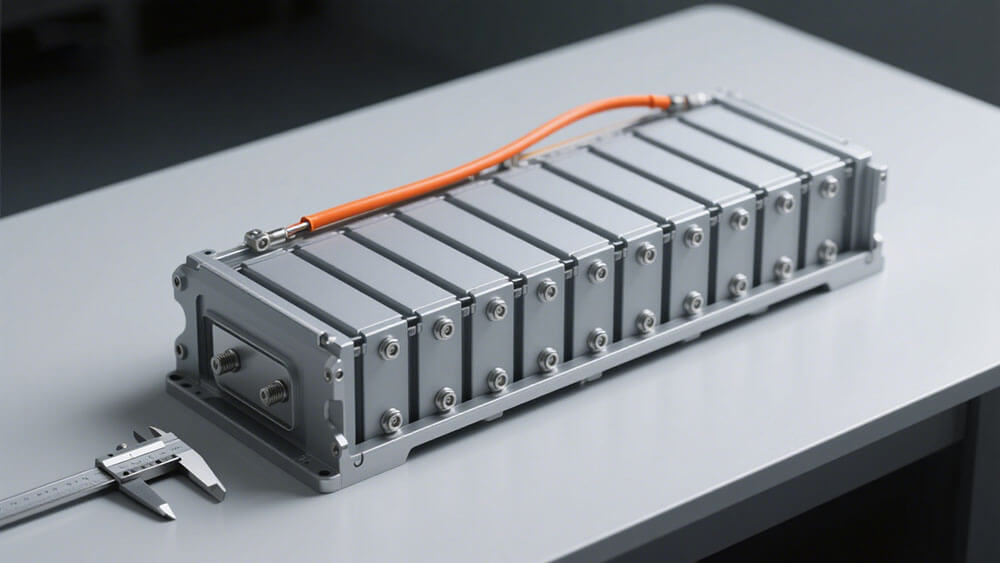

Selecting the right materials is critical for successful ultrasonic welding of battery housing. Most battery packs use thermoplastics such as PC, ABS, and Nylon, which offer excellent weldability and mechanical strength. For metal battery housings, ultrasonic welding works best with highly conductive metals, supporting robust electrical connections without melting or forming brittle intermetallic layers.

Joint Type | Strength Characteristics | Suitability for Battery Housings |

|---|---|---|

Shear Joint | Excellent mechanical strength (90-95%) | Structural components needing high strength |

Energy Director | Good strength (75-85%), ideal for thin walls | Thin-walled battery housings, electronic enclosures |

Tongue & Groove | Very good strength, hermetic sealing | Applications requiring sealing and strength |

Step Joint | Good to very good strength and sealing | EV battery enclosures, high insulation needs |

You should pay attention to joint design parameters, such as wall thickness and joint angles, to optimize the ultrasonic welding process. Robotic ultrasonic welding allows you to join dissimilar materials, such as copper and aluminum, which is essential for advanced battery pack designs. For more on sustainable battery solutions, visit our approach to sustainability.

Tip: For custom battery pack solutions or to discuss your specific ultrasonic welding applications, contact our experts.

Part 2:Advantages of Ultrasonic Welding

2.1 Dust and Water Resistance

You need battery housings that can withstand harsh environments, especially for lithium battery packs used in robotics, medical, and industrial applications. Ultrasonic welding creates a seamless bond between plastic components by using high-frequency vibrations to melt and fuse the material at the joint. This process eliminates gaps and potential leak paths, which is critical for achieving high levels of dust and water resistance.

Ultrasonic welding enables battery housings to reach IP66 or even IP67 ratings, providing robust protection against dust and water ingress. This level of sealing surpasses what you can achieve with adhesives or screws, which often leave micro-gaps or require additional sealing materials.

The process does not require adhesives or gaskets, so you avoid issues with aging, chemical degradation, or sealant detachment over time.

You can further enhance sealing performance by optimizing joint design, such as using energy directors or double-seal structures, and by selecting non-hygroscopic plastics like PP or ABS.

Note: Laboratory and field tests confirm that ultrasonic welding, when combined with precise design and process control, consistently delivers dust and water resistance up to IP67. This makes it ideal for battery packs in outdoor sensors, robotics, and medical devices where environmental protection is non-negotiable.

2.2 Strength and Reliability

You expect your battery pack to perform reliably under mechanical stress, vibration, and temperature fluctuations. Ultrasonic welding delivers strong, consistent joints that maintain integrity throughout the product lifecycle.

Joining Method | Strength Reduction Ratio | Material Compatibility | Suitability for Battery Packs |

|---|---|---|---|

Ultrasonic Metal Welding | ≥ 0.8 | Excellent for similar/dissimilar materials | Superior joint strength, ideal for thin sheets, tabs |

Resistance Spot Welding | < 0.8 | Limited for highly conductive/dissimilar | Weaker joints, less reliable for advanced packs |

Pulsed TIG Spot Welding | ≥ 0.8 | Good for similar/dissimilar conductors | Comparable to ultrasonic, less flexible |

Ultrasonic welding applications in battery packs show that you can achieve high mechanical strength and electrical reliability, even with thin or multi-layer materials. The process minimizes the formation of brittle intermetallic compounds, especially in Al/Cu joints, which helps maintain low electrical resistance and high fatigue life under dynamic loading.

Battery modules assembled with ultrasonic welding withstand over 500 cycles of vibration testing and maintain more than 90% of their original strength after temperature cycling, as required by standards like UL 2580.

The hermetic seal eliminates electrolyte leakage paths, which is essential for long-term moisture resistance and safety.

Real-time resistance monitoring during robotic ultrasonic welding ensures consistent joint quality, with less than 2mΩ variance under environmental changes.

Tip: For battery packs exposed to vibration, temperature swings, or humidity—such as those in robotics, infrastructure, or medical devices—ultrasonic welding offers proven long-term durability and reliability.

2.3 Cost Efficiency

You want to optimize your production costs without sacrificing quality. One of the main advantages of ultrasonic welding is its high welding efficiency and suitability for mass production.

Joining Method | Welding Time (s) | Cooling Time (s) | Total Cycle Time (s) | Mass Production Suitability |

|---|---|---|---|---|

Ultrasonic Welding | 0.1–1 | 0.5–2 | 1–5 | Excellent |

Heat Staking | 3–30 | N/A | 3–30 | Moderate |

Adhesive Bonding | 10–60+ | 60–600+ | 70–660+ | Poor |

Screw Fastening | 5–20 | N/A | 5–20 | Moderate |

Ultrasonic welding reduces per-unit costs by eliminating the need for screws, adhesives, or additional sealing materials.

The process supports full automation, especially with robotic ultrasonic welding systems, allowing you to achieve cycle times as low as 1–5 seconds per housing. This is ideal for high-volume battery pack manufacturing.

You benefit from lower labor costs, minimal material waste, and reduced energy consumption, supporting your sustainability goals. For more on sustainable manufacturing, see our approach to sustainability.

Note: While initial equipment and tooling investment may be higher, the long-term savings in material, labor, and cycle time make ultrasonic welding the preferred choice for large-scale battery pack production.

If you are considering custom battery pack solutions or want to explore how ultrasonic welding can improve your production line, contact our OEM/ODM experts for tailored advice.

Part 3:Disadvantages of Ultrasonic Welding

3.1 Material and Design Limits

You will encounter several limitations when you use ultrasonic welding for battery housings. The process works best with specific thermoplastics and certain metals, but not all materials are compatible. Material limitations can restrict your design flexibility, especially if you need to join dissimilar plastics or metals with different melting points. For example, welding multi-layer structures such as aluminum and copper in lithium battery packs often leads to uneven energy distribution. Aluminum layers may deform significantly, while copper remains mostly unchanged. This difference creates challenges in achieving a uniform and reliable weld. The physical nature of the bond, rather than true metallurgical fusion, means you may not get the strength you expect in complex, multi-material battery housings.

Complex housing shapes also present significant limitations. Finite element simulations show that the geometry of your battery housing directly affects how vibration energy travels through the parts. If your design includes sharp corners, thick sections, or intricate features, you risk uneven vibration transmission. This can increase the failure rate of your welds. You can reduce these risks by optimizing your design, selecting the right materials, and fine-tuning your process conditions. However, you must invest time and resources in this optimization phase.

Note: If you plan to use ultrasonic welding for advanced lithium battery pack designs, you need to consider these design and material constraints early in your development process.

3.2 Equipment and Setup Cost

You should prepare for a higher initial investment when you choose ultrasonic welding. The equipment itself, especially for automated or high-volume production, can be expensive. You will need to purchase specialized ultrasonic welding machines, which range from compact benchtop units to large, fully automated systems. Custom tooling, such as sonotrodes and fixtures, must be designed and manufactured for each battery housing model. This adds to your upfront costs.

The setup process also requires careful calibration. You must optimize parameters like welding energy, pressure, and vibration amplitude for each material and joint design. This process can take several weeks, especially if you work with new materials or complex shapes. You may need to conduct multiple rounds of testing, including leak tests and mechanical strength evaluations, to ensure your battery housings meet industry standards.

Cost Factor | Description | Typical Range |

|---|---|---|

Equipment | Ultrasonic welding machine (manual/automated) | $1,500 – $50,000+ |

Tooling | Custom sonotrode and fixture | $700 – $4,000 per set |

Process Development | Parameter optimization, testing, validation | 2–4 weeks per project |

Maintenance | Regular calibration, part replacement | Ongoing |

Tip: While the per-unit cost drops significantly at high production volumes, you should factor in these initial expenses when evaluating the total cost of ownership for ultrasonic welding.

3.3 Repair and Recycling Issues

Once you weld a battery housing using ultrasonic welding, you create a permanent, non-detachable joint. This feature improves dust and water resistance but introduces new limitations for repair and recycling. If you discover a defect or need to replace an internal component, you cannot simply open the housing without damaging it. This limitation can increase your scrap rate and reduce your ability to perform field repairs.

You also need to consider the impact on recycling. Non-detachable joints make it more difficult to separate different materials at the end of the product’s life. This can complicate your sustainability efforts, especially if your battery pack uses a mix of plastics and metals. For more on sustainable battery solutions, you can review our approach to sustainability.

Common Defects and Process Sensitivity

You must pay close attention to process sensitivity, as ultrasonic welding is prone to several types of defects. These defects often result from narrow process windows, material inconsistencies, or improper setup. Here are some of the most common issues you may encounter:

Overweld: Too much energy or weld time causes functional and cosmetic problems.

Underweld: Insufficient energy or poor setup leads to weak or incomplete welds.

Misalignment: Poor fixture support or part warping results in faulty joints.

Internal Component Damage: Excessive energy or improper mounting can damage sensitive parts.

Melting or Fracture: Sharp corners or molding defects can cause unusable parts.

Defect Type | Description | Typical Causes |

|---|---|---|

Missing or Incomplete Welds | Welds between tab and electrode are missing | Insufficient energy application |

Splatter | Metal ejected from welding surfaces | Contamination, damaged components |

Cracks | Cracks within the weld | Stress, improper welding parameters |

Misalignment | Joints are not properly aligned | Poor fixture support, part warping |

Tab Tears | Cracks or tears in the tabs themselves | Mechanical stress, poor weld quality |

You will also face process sensitivity factors such as material quality, chemical compatibility, fillers, internal lubricants, and moisture content. For example, using regrind material or plastics with high moisture content can lead to weak, foamy, or brittle welds. Fillers like glass or carbon fibers may weaken the joint and create weak lines prone to breakage. Surface contamination from mold release agents or lubricants can prevent proper bonding. You must monitor and control welding energy, pressure, and vibration amplitude to maintain weld integrity.

Note: The narrow process window of ultrasonic welding means that even small variations in material or process parameters can lead to defects. You should implement strict quality control and process monitoring to minimize these risks.

Ultrasonic welding suits high-volume battery pack production when you require permanent, reliable seals and cost efficiency. You achieve optimal results by prioritizing joint design, material compatibility, and strict process control. For complex projects, consult experts to evaluate ultrasonic welding’s fit for your application or request custom battery solutions here.

FAQ

1. What battery housing materials work best for high-sealing lithium battery packs?

You achieve the best sealing with non-hygroscopic plastics like PP or ABS. These materials resist moisture and support robust, seamless joints for lithium battery pack housings.

2. How do you ensure consistent weld quality in mass production?

You maintain high weld quality by using stable equipment, strict process control, and regular material checks. Automated monitoring helps you reduce defects in lithium battery pack assembly.

3. Can you repair or recycle a welded lithium battery housing?

You cannot open a welded housing without damage. For recycling, you must separate materials mechanically. For custom solutions, contact Large Power.